POWDURA® NSF-61 Certified Powder Coating

advertisement

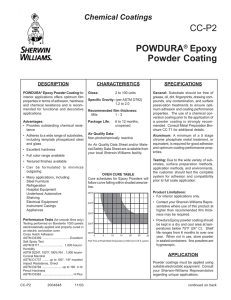

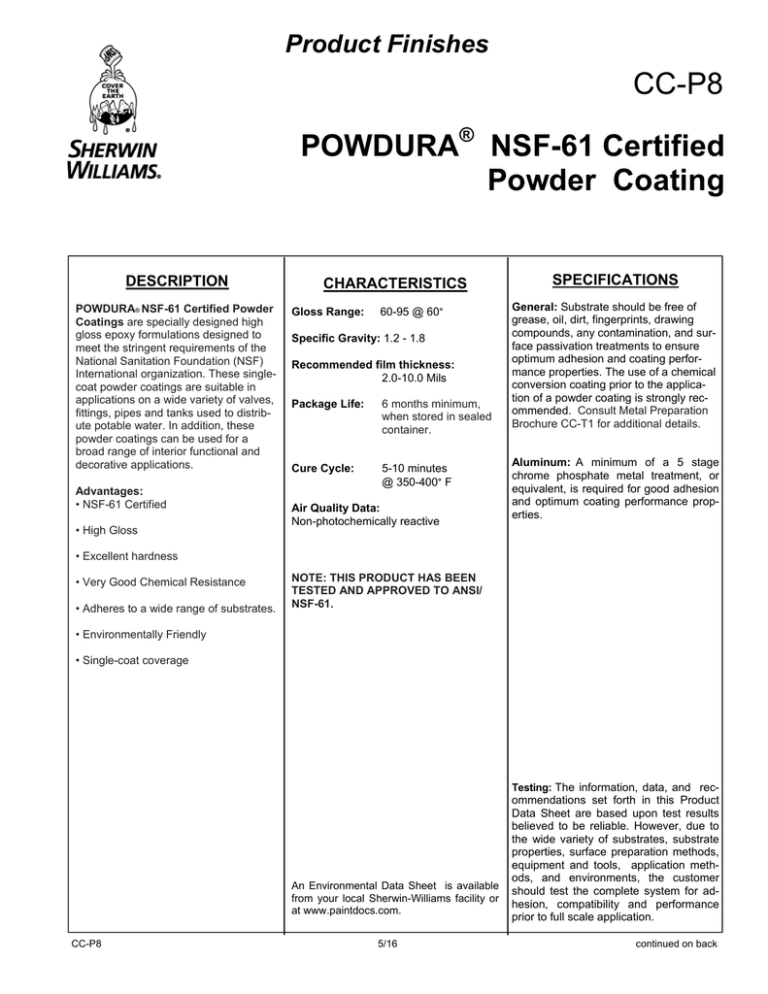

Product Finishes CC-P8 POWDURA® NSF-61 Certified Powder Coating DESCRIPTION POWDURA® NSF-61 Certified Powder Coatings are specially designed high gloss epoxy formulations designed to meet the stringent requirements of the National Sanitation Foundation (NSF) International organization. These singlecoat powder coatings are suitable in applications on a wide variety of valves, fittings, pipes and tanks used to distribute potable water. In addition, these powder coatings can be used for a broad range of interior functional and decorative applications. Advantages: • NSF-61 Certified • High Gloss CHARACTERISTICS Gloss Range: 60-95 @ 60° Specific Gravity: 1.2 - 1.8 Recommended film thickness: 2.0-10.0 Mils Package Life: 6 months minimum, when stored in sealed container. Cure Cycle: 5-10 minutes @ 350-400° F Air Quality Data: Non-photochemically reactive SPECIFICATIONS General: Substrate should be free of grease, oil, dirt, fingerprints, drawing compounds, any contamination, and surface passivation treatments to ensure optimum adhesion and coating performance properties. The use of a chemical conversion coating prior to the application of a powder coating is strongly recommended. Consult Metal Preparation Brochure CC-T1 for additional details. Aluminum: A minimum of a 5 stage chrome phosphate metal treatment, or equivalent, is required for good adhesion and optimum coating performance properties. • Excellent hardness • Very Good Chemical Resistance • Adheres to a wide range of substrates. NOTE: THIS PRODUCT HAS BEEN TESTED AND APPROVED TO ANSI/ NSF-61. • Environmentally Friendly • Single-coat coverage An Environmental Data Sheet is available from your local Sherwin-Williams facility or at www.paintdocs.com. CC-P8 5/16 Testing: The information, data, and recommendations set forth in this Product Data Sheet are based upon test results believed to be reliable. However, due to the wide variety of substrates, substrate properties, surface preparation methods, equipment and tools, application methods, and environments, the customer should test the complete system for adhesion, compatibility and performance prior to full scale application. continued on back APPLICATION ADDITIONAL INFORMATION CAUTIONS Typical Setups Powder coatings must be applied using suitable electrostatic equipment. Consult your Sherwin-Williams Representative regarding unique applications. Performance Tests (for smooth films only) : Testing performed on ACT B1000 panels electrostatically applied and properly cured in an electric convection oven. Cross Hatch Adhesion ASTM D3359.......................... Excellent Flexibility ASTM D522 .. Pass 1/8" Mandrel Bend • Due to the nature of epoxy coatings, these products are not recommended for use on items that will be directly exposed to sunlight, as chalking and color fading will occur. • Contact your Sherwin-Williams Representative where use of this product at higher than recommended film thickness may be required. • Powdura NSF-61 Certified powder coating should be kept in a dry and cool area. Shelf life is 6 months minimum. When not in use, store powder in sealed containers: fine powders are hygroscopic. FOR INDUSTRIAL SHOP APPLICATION ONLY Thoroughly review product label and Safety Data Sheet (SDS) for safety information and cautions prior to using this product. To obtain the most current version of the Environmental Data Sheet (EDS), Product Data Sheet (PDS), or Safety Data Sheet (SDS) please visit your local Sherwin-Williams facility or www.paintdocs.com. Please direct any questions or comments to your local Sherwin-Williams facility. Impact Resistance ASTM D2794............... Up to 160 in/lbs Pencil Hardness ASTM D3363.................................... 2H Salt Spray ASTM B117 ......................... 500 hours Humidity ASTM D2247........................ 500 hours Note: All purchases of products from Sherwin-Williams are exclusively subject to Sherwin-Williams' terms and conditions of sale which can be found at www.sherwin.com. Please review these terms and conditions prior to the purchase of the products. Conical Mandrel ASTM D1737 .......... up to 1/8" mandrel Sherwin-Williams warrants the product to be free of manufacturing defect in accordance with Sherwin-Williams’ quality control procedures. Except for the preceding sentence, due to factors that are outside of SherwinWilliams’ control, including substrate selection, and customer handling, preparation, and application, Sherwin-Williams cannot make any other warranties related to the product or the performance of the product. SHERWIN-WILLIAMS DISCLAIMS ALL WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTY OF MERCHANTABILITY, THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE. Liability for products proven to be defectively manufactured will be limited solely to replacement of the defective product or the refund of the purchase price paid for the defective product, as determined by Sherwin -Williams. Under no circumstances shall Sherwin-Williams be liable for indirect, special, incidental or consequential damages, lost profits or punitive damages arising from any cause whatsoever. CC-P8 POWDURA® NSF-61 Certified Powder Coating