INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL

Volume 1, No 4, 2011

© Copyright 2010 All rights reserved Integrated Publishing Association

RESEARCH ARTICLE

ISSN - 0976-4259

Size optimization of stand-alone photovoltaic system under local weather

conditions in India

Mahendra Lalwani1, D.P. Kothari2, Mool Singh1

1- Department of Electrical Engineering, Malaviya National Institute of Technology, Jaipur

2- Former Director i/c, Indian Institute of Technology, Delhi, India

mlalwani.ee@gmail.com

ABSTRACT

In this paper we scrutinized optimal sizing of solar array and battery in a stand-alone

photovoltaic (SPV) system, under the conditions of a fixed tilt angle and continuous size

variations of solar array and battery. Calculations and results for distinctive size combinations

of solar array and battery are based on the loss of power supply probability (LPSP) of the

SPV system. At a particular load demand and the desired LPSP, the optimal size combination

is achieved at the minimum system cost. Our case study shows the procedure of the size

optimization of the SPV system in Indian weather conditions.

Keywords: Stand-alone photovoltaic system, Loss of power supply probability, Tilt angle,

Maximum power point tracker, Borowy’s method, Size optimization.

1. Introduction

India has approximately 300 sunny days per year and receives an average hourly radiation of

200 MW/km2, so the solar is an important, although currently underutilized, energy resource

in India. For providing Electricity to remote areas where higher solar radiation is received,

SPV systems are becoming increasingly viable and cost-effective. The State of Rajasthan

receives maximum solar radiation intensity in India with very low average rainfall (Arora et

al. 2010). In stand-alone systems the solar energy yield is matched to the energy demand.

Since the solar energy yield often does not coincide in time with the energy demand from the

connected loads, additional storage systems (batteries) are generally used. This SPV system

typically consists of a solar array, a controller with maximum power point tracker (MPPT), a

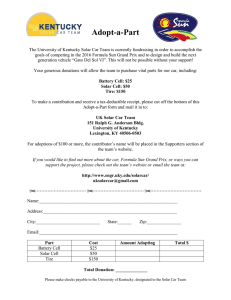

battery, an inverter and loads. The structure of an SPV system is shown in figure 1.

In SPV system, the solar array transforms solar radiation falling on its surface into DC

electricity. The controller with the MPPT helps to extract utmost power from the solar array.

It is unconcerned with the variation of solar radiation and temperature and conserves the

battery from overcharging and under-discharging. The energy is stored in the battery when

solar array produces more power than load demand or supplies power to load when the solar

array produces less power than the load demand during cloudy or rainy days or at nights. The

inverter converts DC into AC at a similar voltage level and frequency of the power grid for

the convenient usage of normal AC loads.

As output power of a solar array deviates with weather conditions, the rewarding activity of

the SPV system is to find out the optimal size of a solar array and battery to meet load

demand. Therefore we have done studies on sizing of the SPV system (Shrestha and Goel

1998, Sidrach-de-Cardona and Mora Lopez 1998). The optimum size of solar array and

battery is chosen based on the proper balance between the LPSP and the system cost in

951

INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL

Volume 1, No 4, 2011

© Copyright 2010 All rights reserved Integrated Publishing Association

RESEARCH ARTICLE

ISSN - 0976-4259

different configurations. The different configurations of battery and solar array with system

cost are shown in figure 2.

Battery

Sun

Radiations

DC

Controller,

MPPT

DC

DC Loads

DC

DC

SPV

Array

Inverter

DC to AC

AC Loads

500

15

400

12.5

10

300

7.5

200

5

100

2.5

0

Cost ( ` ) x 10000

Panel (Wp) &

Battery (Ah)

Figure 1: Stand-alone Photovoltaic System

0

1

2

3

4

5

6

7 8 9 10 11 12 13 14 15 16 17 18

Different Configration

Panel Size (Wp)

Battery Size (Ah)

Total Cost (`)

Figure 2: Different configurations of battery and solar array with system cost

The impact of tilt angle on sizes of the SPV system was scrutinized for the given load

demand (Bhuiyan and Ali 2003), the optimal size of solar array and battery was obtained

when the tilt angle was adjusted in accordance with seasons. Based on the spirit of Borowy’s

method (Salameh and Borowy 1996), this paper scrutinizes optimum sizes of solar array and

952

INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL

Volume 1, No 4, 2011

© Copyright 2010 All rights reserved Integrated Publishing Association

RESEARCH ARTICLE

ISSN - 0976-4259

battery in the SPV system under the conditions of a fixed tilt angle and continuous size

variations of solar array and battery. For the chosen LPSP at the given load demand, the

optimal size unification is acquired at the minimum system cost. Our case study shows the

procedure of the size optimization of the SPV system in Indian weather conditions.

2. Methodology

2.1. Everyday energy generation of a solar array

As the solar radiations incident on solar array of SPV system the energy is generated. This

output of a solar array rests on solar irradiation, temperature of solar cell and the operating

point of the SPV system. The solar irradiation is the integration of solar radiation of a day.

Solar arrays are rated at a solar radiation level of 1000 W/m2 and temperature of a solar cell is

25°C, the peak sun hours (PSHs) are often used to represent solar irradiation so that the daily

output of the solar array is easily calculated by using the peak watt (W p ) of solar array times

the PSHs, where the PSHs is equivalent to the length of time in hours at a solar radiation

level of 1000 W/m2 (Markvart 2000).

The temperature of solar cell significantly affects the output power of a solar array. The

temperature of solar cell (Tc ) can be estimated by using ambient temperature (Ta ) and solar

radiation (Messenger 2004, Shen et al. 2005).

Tc = Ta . (1+1.25 ξ )

(1)

Here, ξ is the average solar radiation over a day, in kW/m2.

The MPPT is included in this SPV system for the operating point of a solar array, thus the

solar array always operates at the maximum power point. The daily energy output of a solar

array can be calculated by,

Espv = Pspv maxima .{1+ ρ .(Tc - 25)} .PSHs. ηconnection . ηother

(2)

Here, ρ is the negative temperature coefficient of power with respect to solar cell

temperature; Pspv max ima is the maximum power output of the solar array under a solar radiation

of 1000 W/m2. ηother and ηconnection are the factors representing other losses (caused by

accumulative dust, etc.) and connection losses respectively.

2.2. Everyday battery caliber

In SPV system the operating conditions of the battery are very different from those which we

using in conventional systems because SPV system is neither a constant source of current nor

a voltage. As the solar radiation and temperature deviates the output power of a solar array,

which is used to charge the battery, deviates (Shen W.X 2009). Under such uncontrolled

953

INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL

Volume 1, No 4, 2011

© Copyright 2010 All rights reserved Integrated Publishing Association

RESEARCH ARTICLE

ISSN - 0976-4259

charge/discharge cycles, the estimation of the battery state of charge (SOC) is complicated

(Piller et al.2001). In this study, battery charge/discharge efficiency is adopted to estimate

daily battery SOC. Since the battery discharge efficiency is normally assumed to be 100%,

the battery charge efficiency is considered to be the round-trip efficiency which can normally

be found in the battery specifications.

The energy stored in the battery on the ‘ x ’ day during the charging period is calculated by,

E ( x)

EBatt ( x) = EBatt ( x -1).(1- µs ) + Espv ( x) - load . ηbattery

ηinverter

(3)

and the energy stored in the battery on ‘x’ day during the discharging period is calculated by,

E ( x)

EBatt ( x ) = EBatt ( x -1).(1- µs ) + Espv ( x ) - load

ηinverter

(4)

Here, the energy stored in the battery on the ‘x’ and ‘x-1’ day are EBatt ( x) and EBatt ( x − 1)

respectively; µs is the daily battery self-discharge rate; Espy ( x) is the energy generated by

the solar array on ‘x’ day; Eload ( x) is the load demand on ‘x’ day; ηinverter is the efficiency of

the inverter and ηbattery is the charge efficiency of the battery. The energy stored in the

battery on any ‘x’ day is within the following limits,

EBatt maxima ≥ EBatt ( x ) ≥ EBatt minima

(5)

Here EBatt max ima is the maximum allowable energy level which is equal to the rated capacity

of the battery AH battery times the rated voltage Vr and EBatt min ima is the minimum allowable

energy level which must be remain in the battery for each cycle to have the battery life as

stated in the battery specifications.

EBatt min ima is determined by the maximum depth of discharge (DOD) or minimum

SOC,

EBatt minima = (1- DODmaxima ) . AH battery = SOCminima . AH battery

(6)

Here, SOC = 1 - DOD

In general, the lower the battery DOD needs to be maintained, the lower the cost of the

systems, the shorter the battery life, and vice versa. The selection of the maximum allowable

DOD is actually a compromise between system life and cost. The battery SOC on the ‘x’ day

is,

954

INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL

Volume 1, No 4, 2011

© Copyright 2010 All rights reserved Integrated Publishing Association

RESEARCH ARTICLE

SOC ( x) =

ISSN - 0976-4259

EBatt ( x)

AH battery .Vr

(7)

2.3. The Base of size optimization

In SPV system when the generated power is higher than load demand, excess power is used

to charge the battery and when the generated power is lower than the load demand during

cloudy or rainy days or at nights, the battery provides the deficient part of power or fed full

power to the load.

The reliability of power supply to the load is described by the loss of power supply

probability (LPSP). LPSP is the ratio of the number of hours that the system fails to supply a

load to the total number of hours required by the load. An LPSP of 0 means that the power

can fully meet load demand; whereas an LPSP of 1 means that the power can never meet load

demand. An LPSP from 0 to 1 means the power cannot fully supply to the load when the

solar power is not enough while the battery has been in the allowable maximum DOD or the

allowable minimum SOC.

The purpose of the size optimization of solar array and battery is to match the load demand at

the desired LPSP with the preset allowable minimum battery SOC at the minimum cost of the

system. The SOC of battery on any ‘x’ day depends on the SOC on the previous (x-1) day, the

solar power for a charging battery and the load demand for discharging a battery on ‘x’ day.

When the SOC of battery is 0 i.e. fully discharged or the preset allowable minimum value is

reached, the system controller will stop discharging the battery and protect the battery from

over-discharging. When the SOC of battery is 1 i.e. fully charged, the system controller will

stop charging and prevent the battery from overcharging.

For the allowable minimum battery SOC the LPSP is,

LPSP = P { EBatt ( x) ≤ EBatt minima ; x ≤ X }

(8)

It means LPSP is the probability of the SOC at any ‘x’ day, within a period of X days, to be

less than or equal to the minimum allowable energy level EBatt min ima . Hence, the LPSP can be

calculated by

∑

LPSP =

∑

X

x =1

X

LES ( x)

E ( x)

x =1 load

(9)

where, LES ( x) is the loss of energy supply on ‘x’ day,

LES ( x ) = Eload ( x) − { Espv ( x) + EBatt ( x − 1) − EBatt minima } . ηinverter

(10)

955

INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL

Volume 1, No 4, 2011

© Copyright 2010 All rights reserved Integrated Publishing Association

RESEARCH ARTICLE

ISSN - 0976-4259

The LPSP of the solar photovoltaic system is calculated by Eq. (9). By using different size

combinations of solar array and battery can meet the given load demand for the desired LPSP.

To determine the optimal size combination, the cost function of the SPV system is defined as,

ϒsys = Wspv .λ + AH battery . ψ + ϒ oth

(11)

where ϒsys is the total costs of the systems; Wspv is the capacity of the solar array; AH battery is

the capacity of the battery; ϒ oth is the other total costs except the solar array and the battery,

which is considered to be constant, including the costs of the controller with MPPT, inverter,

etc. is the unit cost of the battery (`/Ah), λ is the unit cost of the solar array (`/Wp). From (11),

the condition to minimize ϒsys is:

∂AH battery

∂Wspv

=−

ψ

λ

(12)

400

Size of battery (Ah)

350

300

250

200

340

360

380

400

420

440

460

Size of solar array (Wp)

Figure 3: Size of solar array versus size battery at an LPSP of 0.01

956

INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL

Volume 1, No 4, 2011

© Copyright 2010 All rights reserved Integrated Publishing Association

RESEARCH ARTICLE

ISSN - 0976-4259

By using graphical methods we solve the Eq. (12), in the way that the two curves will be

drawn in the AH battery versus Wspv coordinate system, Figure 3. One curve represents different

size combinations of the solar array and battery for the desired LPSP. The other curve is the

line with a slope of (– ψ / λ). The tangent point of the two curves corresponds to the optimum

sizes of solar array and battery.

3. Case study for local weather conditions

By the above introduced method we solve a case study for the size optimization of solar

photovoltaic system based on Indian (Jodhpur-Rajasthan) weather conditions. The solar

radiation data is used in the optimization process which is taken from India Meteorological

Department, Ministry of Earth Sciences, New Delhi.

The load profile (Chronological load curve) of a typical house in remote areas in India

(Jodhpur-Rajasthan) is shown in figure 4. The details of the corresponding load profile are

shown in table 1(a) & (b).

Table 1(a)

Load

Symbol

CFL-1

CFL-2

Ceiling Fan

Table Fan

TV

C1

C2

CF

TF

TV

Rating in

Watt

25

11

60

25

70

Table 1(b)

Time Schedule

Loads Used

Power(Watts)

Energy (Wh)

12 midnight to 6 am

6 am to 7 am

6 am to 8 am

8 am to 9am

9 am to 5 pm

5 pm to 6 pm

6 pm to 7 pm

7 pm to 8 pm

8 pm to 11 pm

10 pm to 11 pm

11 pm to 12 pm

Total Energy

TF

TF+C2

TF+CF

TF+TV

CF

CF+TF

CF+TF+C2

CF+C1+C2+TF

CF+C1+C2+TV

TF+C2

TF

25

36

85

95

60

85

96

121

166

36

25

150

36

170

95

480

85

96

121

498

36

25

1792

957

INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL

Volume 1, No 4, 2011

© Copyright 2010 All rights reserved Integrated Publishing Association

RESEARCH ARTICLE

ISSN - 0976-4259

It is assumed that the battery DOD cannot be higher than 0.8 or the SOC cannot be lower

than 0.2; the desired LPSP of the system is set to 0.01 which means there is 14.4 min poweroff within one day or 3.65 days power-off within one year. With the help of the program

developed by using the MATLAB, the LPSPs for different size combinations of solar array

and battery are calculated. Figure 5 shows the calculated results in 3D plot.

180

160

L o a d d e m a n d (W a tt)

140

120

100

80

60

40

20

0

0

5

10

15

Time(Hours)

20

25

Figure 4: Chronological load curve of our Case study

Figure 3 shows the different size combinations of solar array and battery at an LPSP of 0.01

by adding the line with a slope of (–ψ/λ), where ψ = 78 (`/Ah) and λ=112 (`/Wp). The

tangent point of the two curves corresponds to the optimal size combination of solar array

and battery which are approximately equal to 300 Ah and 375 Wp, respectively.

If the commercial availability of solar array and battery is taken into account, 3 battery units

with 100 Ah and 5 solar modules with 75 Wp are selected. With this optimum configuration,

daily energy generation and battery SOC over the year are evaluated and the corresponding

results are shown in figures 6 & 7, respectively (Ajit 2009).

For the LPSP of 0.01, the size ratio of battery to solar array in this case study is about 0.69

Ah/Wp (300 Ah/375Wp) while the size ratio of battery to solar array in is about 0.84 Ah/Wp.

958

INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL

Volume 1, No 4, 2011

© Copyright 2010 All rights reserved Integrated Publishing Association

RESEARCH ARTICLE

ISSN - 0976-4259

0.25

LPSP

0.2

0.15

0.1

0.05

100

250

200

300

350

300

400

Size of battery (Ah)

400

450

Size of solar array (Wp)

D a ily sum o f g loba l sola r ra dia nt e xposure (M Jm-2 )

Figure 5: 3D plots of different size combinations of solar array and battery at different LPSP

values.

30

25

20

15

10

5

0

0

50

100

150

200

250

300

350

Day

Figure 6: Daily sum of solar radiant exposure in India (1 kWh = 3.0 MJ)

959

INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL

Volume 1, No 4, 2011

© Copyright 2010 All rights reserved Integrated Publishing Association

RESEARCH ARTICLE

ISSN - 0976-4259

1

0.9

0.8

B attery SO C

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

0

50

100

150

200

250

300

350

Day

Figure 7: Battery State of Charge

The conditions in this study are based on the Indian context, while the conditions in

(Ai et al. 2003) are based on the Hong Kong context. For both the places, weather conditions,

load profiles and unit costs of the system components are very different.

4. Conclusion

In this study, we presented the size optimization technique for solar array and battery in the

SPV system for Indian weather conditions. The criterion of optimal sizes of solar array and

battery was to find it at the minimum cost of the system, under the specific load demand and

the coveted LPSP. The solar radiation data used was of the state Rajasthan, receiving the

highest global radiation.

This work exhibits the significant impact of the places of the system used as well as the types

of the adopted systems on the optimization results. Although the case we have considered

takes Rajasthan for study i.e. solar radiation data, the same method is applicable to other

areas as well.

5. References

1.

Ai B, Yang H, Shen H, Liao X., (2003), “Computer-aided design of PV/wind hybrid

system. Renewable Energy”, 28, pp 1491–512.

2.

Arora D.S. , Busche Sarah, Cowlin Shannon, Engelmeier Tobias, Jaritz Hanna,

Milbrandt Anelia, Wang. Shannon, (2010), “Indian Renewable Energy Status Report”,

Background Report for DIREC 2010, NREL, October, 55-75.

960

INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL

Volume 1, No 4, 2011

© Copyright 2010 All rights reserved Integrated Publishing Association

RESEARCH ARTICLE

ISSN - 0976-4259

3.

Bhuiyan MMH, Ali Asgar M. (2003), “Sizing of a standalone photovoltaic power system

at Dhaka” Renewable Energy; 28, pp 929–938.

4.

Dr. Ajit P. Tyagi, “Solar Radiant Energy over India (2009), “Ministry of New and

Renewable Energy, India Meteorological Department; pp 3808-3819.

5.

Markvart Tomas, (2000), “Solar electricity”, 2nd ed. John Wiley & Sons Inc, pp 95–98.

6.

Messenger Roger A, Ventre Jerry, (2004), “Photovoltaic systems engineering” 2nd ed.

CRC Press LLC, pp 76–79.

7.

Piller Sabine, Perrin Marion, Jossen Andreas., (2001), “Methods for state of charge

determination and their applications” Journal of Power Sources; 96, pp 113–120.

8.

Salameh Ziyad M, Borowy Bogdan S. (1996), “Methodology for optimally sizing of the

combination of a battery bank and PV array in a wind/PV hybrid system” IEEE

Transactions on Energy Conversion; 11(2), pp 367–375.

9.

Shen Weixiang, Tan Wei Kuang, Kok Bin Alex See, Kok Seng Ong., (2005), “Sizing of

standalone photovoltaic system using Matlab/Simulink”, Proceedings of the international

conference on robotics, vision, information and signal processing, Penang, Malaysia, pp

288–293.

10. Shen W.X., (2009), “Optimally sizing of solar array and battery in a standalone

photovoltaic system in Malaysia”, Renewable Energy; 34, pp 348–352

11. Shrestha GB, Goel L., (1998), “A study of optimal sizing of standalone photovoltaic

stations”, IEEE Transactions on Energy Conversion; 13(4), pp 373–378.

12. Sidrach-de-Cardona M, Mora Lopez Li., (1998), “A simple model for sizing stand-alone

photovoltaic systems” Sol Energy Mater Sol Cells, 55, pp 119–214.

961