sizing of a standalone photovoltaic system for small scale

advertisement

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, Volume 8, Issue 20, August 2012)

SIZING OF A STANDALONE PHOTOVOLTAIC SYSTEM

FOR SMALL SCALE INDUSTRY

Akanksha Kumra1, Manoj Kumar Gaur2, Chandrashekhar Malvi3

1,2,3

Deptt of Mechanical Engg, MITS, Gwalior

government support , solar PV technology is seen as a

solution for energy supply.

The solar cell efficiency has increased over 24 %[2].The

world annual production is currently over 10000 MW and

solar PV technology are now increasingly seen as a major

energy provider for Indian scenario[3].

Solar photovoltaic has a wide range of applications, one

of them being developing a standalone PV system for small

scale industries. Various advantages for small scale

industries by using this technology are:

1. Reduction in conventional electricity cost.

2. Reduction in Carbon credits

3. Gives clean energy which will offset carbon

dioxide emission every year.

4. During power outages or load shedding electricity

can be provided through these systems especially

in administrative buildings in small scale

industries.

This paper includes a small scale industry’s

administrative building for sizing of PV system. This

industry is situated in Gwalior M.P.

Abstract - This paper presents a study pertaining to the

design of a standalone photovoltaic system to supply

electricity to a small scale industry’s administrative building.

The estimated load of the system is about 6.5 kWp.

Methodology is discussed and based on the load estimation,

batteries and arrays are sized and result presented in a

tabulated form. Layout, installation and life cycle cost of the

system have also been discussed with life cycle cost of the

system as 42 lakhs and payback period as .72 years.

Keywords - Photovoltaic system, standalone, small scale

industry building, sizing, life cycle cost, payback period.

I.

INTRODUCTION

Electricity from unconventional energy sources is

becoming popular these days due to governmental support

and investment from private enterprises. Among these

unconventional energy sources solar photovoltaic

technology is emerged out in gaining interest especially in

country like India, where solar energy is abundantly

available throughout the year[1].

Rising electricity cost ,concern for climate change and

need to find alternative energy solutions and with

65

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, Volume 8, Issue 20, August 2012)

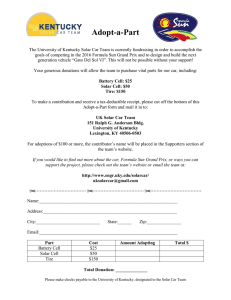

FIGURE 1

SOLAR RADIATION MAP OF INDIA [1]

66

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, Volume 8, Issue 20, August 2012)

II.

For a clear day, the intensity of solar radiation at a given

location is symmetrical around the solar noon time of the

location. Also the radiation intensity is maximum at noon.

Therefore the solar PV modules are oriented to maximize

solar radiation interception at noon time. It can be shown

that if the PV modules are to be fixed throughout the year,

at a fixed angle, the optimum tilt of solar PV modules

should be equivalent to the latitude angle of the location.

Also, if the modules installation is done in the Northern

hemisphere the orientation should be South facing and if

the PV modules are being installed in Southern hemisphere

then the PV modules should be installed North facing [3].

C. Battery sizing

Only PV bateries should be use for PV system. While

designing battery bank days of autonomy should be kept in

mind. The days of autonomy are the days of below average

insolation days. Generally two or three days are considered

in designing. Other factors like maximum depth of

discharge, temperature correction, rated battery capacity

and battery life are also considered [4].

For deep cycle battery maximum depth of discharge is

80%. In this design we will take depth of discharge to be

65%. Temperature correction is needed because at low

temperature battery efficiency decreases. Temperature

correction factor is taken to be 0.9.

Required battery capacity in Ampere hour (Ah) is given

by

Brc= Ec(Ah) × Ds/(DOD)max × t

(4)

where, Ds =battery autonomy or storage days;

(DOD)max = maximum battery depth of discharge;

t = temperature correction factor.

Batteries in parallel is given by

Bp =Brc/Bsc

(5)

where, Bsc = capacity of selected battery (Ah).

Batteries in series is given by

Bs =Vnsv/Vnbv

(6)

where, Vnbv = nominal battery voltage.

Vnsv= Nominal system voltage

Total battery

BT = Bp × Bs

(7)

D. Array sizing

For a DC bus voltage of 110 V,

No. of modules per string =

110 + 1 (allowance for blocking diode)/

Working voltage

(8)

METHODOLOGY

The system sizing involves various steps which are as

followed:

1. Load estimation of the system under consideration

2. Battery sizing

3. Array sizing

4. Array tilt

5. Layout of the proposed system

6. Life cycle cost of the system

7. Payback period

A. Load Estimation

System design is based on the size of the load. The

operating voltage selected for a PV standalone system is

usually the voltage required by the largest loads [4].

Energy demand is given by Watt –hour per day

by

Ed(Wh)= ∑

NiIiViHi

(1)

th

Where Ni =number of i load

Ii and Vi are the current and voltage drawn by the ith loads

Hi= Daily duty cycle of the ith load (hrs/day)

Load demand in ampere-hour is given by

Ed(AH)= Ed(WH)/ηpce Vnsv

(2)

Where ηpce = power conversion efficiency

As we are not using inverter hence we will not consider

the above efficiency factor.

However where inverter is used power conversion

efficiency factor should be taken into consideration.

Vnsv =Nominal system voltage

Corrected Ampere hour load is given by

EcAh = Ed(Ah)/ ηwηb

(3)

ηw =wire efficiency= 2%

ηb = Battery efficiency= 16.5%

B. Array Tilt

Optimum tilt of PV modules – permanently fixed

To maximize generation of solar radiation the

interception of solar radiation has to be maximized. For

maximum interception of solar radiation the solar PV

modules should be kept perpendicular to the sun rays. Sun

changes its position throughout the day, hence the position

of the PV modules should also be changed throughout the

day, i.e. sun tracking is required. Since precise tracking is

not possible also the cost of the system increases due to

costly tracking equipment moreover it requires

maintenance. Therefore fixed mounting of solar PV

modules is advised and preferred.

67

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, Volume 8, Issue 20, August 2012)

Now Total cell area required to meet a mean daily load

can be found out from the following [5]:

1. Calculate the mean daily solar radiation available

2. Calculate Mean daily output available from PV

module surface area of 1 m2 is given by

{(mean daily solar radiation available)* (module

efficiency) * (irradiance of cell available from

manufacturer’s specification) }/ Largest system

voltage

3. Array losses due to module mismatch, blocking

diodes, dirt, and degradation is considered and

multiplied with the above to get Gross mean daily

output available from module area of 1 m 2

4. The area of PV module required is given by

Mean daily load required/ Gross mean daily

output available from module area of 1 m 2.

5. Number of PV Modules is given by

(The area of PV module required)/(Area of

standard PV module available)

6. Minimum number of module strings is given by

Number of PV Modules/ No. of modules per string

III.

The total estimated load for the entire system is 6.5kW p

as shown in the Table 1 above.

FIGURE II

SHOWING BASIC LAYOUT OF THE SYSTEM

TABLE II

RESULT OBTAINED FROM THE SYSTEM SIZING

RESULTS AND DISCUSSION

A. Load Estimation for the system

TABLE I

SHOWS LOAD ESTIMATION OF THE SYSTEM AS GIVEN BY

BRITANNIA INDUSTRIES J B MANGARAM GROUP GWALIOR

Corrected Amp – hour load Ec =Ed/ηwηb

Here ηw =Wire efficiency= .975

ηb= Battery efficiency= .835

Ec= 726.23

The system consists of Solar PV Panels which are

connected to batteries through a control system and an

inverter.

Batteries are used due to intermittent nature of solar

energy so that excess energy can be stored during active

periods so that load can be carried during inactive periods.

68

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459, Volume 8, Issue 20, August 2012)

IV.

Payback Period

Yearly conventional electricity cost for the system

=3321500

Payback Period = .72 years

LIFE CYCLE COSTING OF THE SYSTEM

Economic parameters and cost of components [6] are

shown below in Table 4.

TABLE III

SHOWING ECONOMIC PARAMETERS AND COST

PV array cost

Rs 150/Wp

Battery cost

Rs 4000/kWh

Battery Charge controller

Rs 27000

V.

cost

Auxiliaries cost

Rs 11250

General Inflation rate

7.5%

Discount rate

10 %

Annual Maintenance and

2%

‐ Roof tops of buildings

‐ Roofs of parking area and path ways

‐ Any other open area

In this particular case installation design has been done

on the roof of the administrative building.

VI.

Operation cost

PV system installation cost

10 %

DC Motor Cost

Rs 10,000

Interest Rate

14.29 %

Number of Years

25

PV INSTALLATIONS IN ADMINISTRATIVE BUILDING

Since most of the buildings in a given industry are of

same height, building terraces offer excellent locations for

SPV installations.

The possible spaces for installation of PV modules

include:

CONCLUSION

Suitable layout of the system has been given and results

of battery and array sizing have been tabulated. Initial cost

of the system is high but since the payback period is .72

years , hence the system is economical. Future scope exists

in sizing of the standalone system using Fuzzy logic.

ACKNOWLEDGEMENT

We would like to express our sincere thanks to Mr. U .K

Chauhan Production Head, Britannia Industries JB

Mangaram Gwalior for all his support.

The life cycle of the system is taken as 25 years .

Batteries have a life time of 8 years.

The cost of first group of batteries = 12,80,000

Present worth of second group of batteries= A(1+i) N-1/

(1+d)N= 985535

Present Worth of third group of batteries= 822658

Total PV array cost= 975900

Cost of battery charge controller= 27000

Initial cost of the PV system= PV array cost + first group of

batteries cost +Cost of battery charge controller + Inverter

Cost + Auxiliary cost

Initial cost of the system= 2399740

Life cycle cost of the system= Initial cost of the PV system

+ Installation cost + cost of second and third group of

batteries + Maintenance and operation costs

Life cycle cost of the system= 4207932

Life cycle output energy= 474500 kWh

REFERENCES

[1] Ministry of non renewable energy http://www.mnre.gov.in/ .

[2] Martin A. Green, Keith Emery, Yoshihiro Hishikawa, Wilhelm

Warta and Ewan D. Dunlop- Solar cell efficiency tables (version 39)

progress in photovoltaics: research and applications Wiley

[3] Chetan S. Solanki -Solar PV Energy for Academic Campuses in

India -A White Paper Department of Energy Science and

Engineering IIT Bombay Oct 2010.

[4] M.M.H Bhuiyan , M. Ali Asgar -Sizing of a standalone photovoltaic

power system at Dhaka Renewable Energy 28 (2003) 929–938

Science Direct

[5] Vinod kumar Sharma Antonio Colangelo- Photovoltaic Technology:

Basic Concepts , Sizing of standalone PV system for Domestic

applications and Preliminary Economic Analysis Vol. 36, No. 3, pp.

161-174, 1995 Elsevier Science Ltd

[6] Mohanlal Kolhe, Sunita Kolhe, J.C Joshi-Economic viability of

standalone solar PV system in comparison to diesel power systems

in India

69