hyderabad growth corridor limited

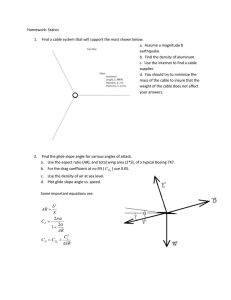

advertisement