C.I. Hayes: Vacuum Temper Furnaces

advertisement

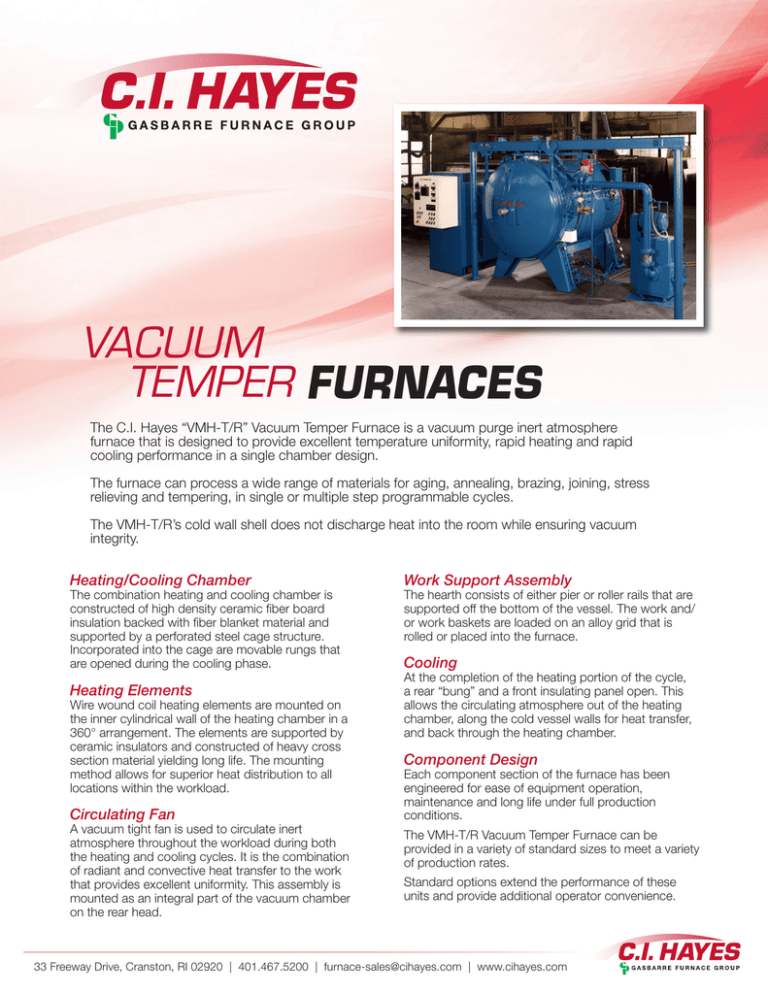

VACUUM TEMPER FURNACES The C.I. Hayes “VMH-T/R” Vacuum Temper Furnace is a vacuum purge inert atmosphere furnace that is designed to provide excellent temperature uniformity, rapid heating and rapid cooling performance in a single chamber design. The furnace can process a wide range of materials for aging, annealing, brazing, joining, stress relieving and tempering, in single or multiple step programmable cycles. The VMH-T/R’s cold wall shell does not discharge heat into the room while ensuring vacuum integrity. Heating/Cooling Chamber The combination heating and cooling chamber is constructed of high density ceramic fiber board insulation backed with fiber blanket material and supported by a perforated steel cage structure. Incorporated into the cage are movable rungs that are opened during the cooling phase. Heating Elements Wire wound coil heating elements are mounted on the inner cylindrical wall of the heating chamber in a 360° arrangement. The elements are supported by ceramic insulators and constructed of heavy cross section material yielding long life. The mounting method allows for superior heat distribution to all locations within the workload. Circulating Fan A vacuum tight fan is used to circulate inert atmosphere throughout the workload during both the heating and cooling cycles. It is the combination of radiant and convective heat transfer to the work that provides excellent uniformity. This assembly is mounted as an integral part of the vacuum chamber on the rear head. Work Support Assembly The hearth consists of either pier or roller rails that are supported off the bottom of the vessel. The work and/ or work baskets are loaded on an alloy grid that is rolled or placed into the furnace. Cooling At the completion of the heating portion of the cycle, a rear “bung” and a front insulating panel open. This allows the circulating atmosphere out of the heating chamber, along the cold vessel walls for heat transfer, and back through the heating chamber. Component Design Each component section of the furnace has been engineered for ease of equipment operation, maintenance and long life under full production conditions. F U R N A C E The VMH-T/R Vacuum Temper Furnace can be provided in a variety of standard sizes to meet a variety of production rates. Standard options extend the performance of these units and provide additional operator convenience. 33 Freeway Drive, Cranston, RI 02920 | 401.467.5200 | furnace-sales@cihayes.com | www.cihayes.com G R O U SPECIFICATIONS Models: VMH-T/R-242436 VMH-T/R-363648 Working Dimensions: 24”H x 24” W x 36”L (609mm x 609mm x 914mm) 36”H x 36” W x 48”L (914mm x 914mm x 1219mm) Hearth Level: 40” (1016mm) 40” (1016mm) Maximum Operating Temperature: 1450°F (787°C) 1450°F (787°C) Uniformity: 20°F Spread (10°C) 30°F Spread (17°C) Heating Elements: Nickel-Chromium Nickel-Chromium Load Capacity (Nominal): 800# (362kg) 1500-3000# (680-1360kg) Connected Load: 60KW 120KW Heat-Up Rate: 800# Load of 1” (25mm) Diameter Steel Bars to: 1000°F in 75 mins or 350°F in 20 mins (537°C in 75 mins or 176°C in 20 mins) 1600# Load of 1” (25mm) Diameter Steel Bars to: 1000°F in 75 mins or 350°F in 20 mins (537°C in 75 mins or 176°C in 20 mins) Operating Pressure: 0.5 PSIG Positive Pressure to Below 100 microns 0.5 PSIG Positive Pressure to Below 100 microns Vacuum Components: 6” (152mm) Pneumatically Operated Vacuum Valve Mechanical Pump 150 CFM (7.5HP Motor) Roots Type Blower 850 CFM (3HP Motor) 6” (152mm) Pneumatically Operated Vacuum Valve Mechanical Pump 150 CFM (7.5HP Motor) Roots Type Blower 1285 CFM (10HP Motor) Fan Assembly: Vacuum Tight with 15HP Motor Vacuum Tight with 10HP Motor Cooling Water: Steady State -10 GPM (37 LPM) Quench Cycle - 30 GPM (113 LPM) Steady State -10 GPM (37 LPM) Quench Cycle - 30 GPM (113 LPM) Cool Down Rate: 800# Load of 1” (25mm) Diameter Steel Bars from: 1000°F to 150°F in 45 mins (537°C to 65°C in 45 mins) 1500# Load of 1” (25mm) Diameter Steel Bars from: 1000°F to 150°F in 60 mins F U R N A C E (537°C to 65°C in 45 mins) Nitrogren Backfill: 144 ft (43 m ) 330 ft (100 m ) Compressed Air Requirements: Small Demand at 90 PSIG (0.62 MPa) Small Demand at 90 PSIG (0.62 MPa) Floor Space: 102”H x 210”W x 204”L (2590mm x 5334mm x 5181mm) 115”H x 276”W x 203”L (2921mm x 7010mm x 5156mm) 3 3 3 3 33 Freeway Drive, Cranston, RI 02920 | 401.467.5200 | furnace-sales@cihayes.com | www.cihayes.com G R O U F U R N A C E G R O U P Product Listing Continuous Belt Furnaces Sintering Furnaces Brazing Furnaces Steam Treat Furnaces Annealing Furnaces Austempering Furnaces Normalizing Stress Relief Furnaces Tempering Furnaces Mesh Belt Furnaces Solid Belt Furnaces Cast Link Furnaces Humpback Conveyor Furnaces Other Continuous Furnaces Pusher Furnaces (2000°-3000° F) Pusher Furnaces (below 2000° F) Roller Hearth Walking Beam Vacuum Furnaces Continuous & Modular Batch Integral, Gas, Pressure & Oil Quench Batch Furnaces Sintering Furnaces Carburizing Furnaces Carbonitriding Furnaces Normalizing Furnaces Spheroidize Annealing Furnaces Stress Relieving Furnaces Brazing Furnaces Annealing Furnaces Tempering Furnaces Box & Slot Furnaces (above 2000° F) Steam Treat Furnaces Bell (Carbon) Furnaces Quenching Furnaces Tip-Up Furnaces Atmosphere Tip-Up Furnaces Tempering Pit Furnaces Carburizing Pit Furnaces Nitriding Pit Furnaces Car Bottom Furnaces Tool Room Furnaces Atmosphere Generators Exothermic Gas up to 3000 CFH Exothermic Gas up to 20000 CFH Endothermic Gas up to 12000 CFH Ammonia Dissociators up to 10000 CFH Atmosphere Dryers Quench Systems Parts Washers Charge Cars Fabrications Automation Vacuum Impregnators Accelerated Delubrication Units Sinter Hardening/Accelerated Cooling Units Powder Handling Equipment Powder Blenders 500# Barrel Dumpers Bulk Pack Inverters Powder Bag Hangers Furnace Load/Unloaders Rebuild Services Spare Parts Training Field Service KEY A: Atmosphere V: Vaccuum www.gasbarrefurnacegroup.com Sinterite C.I. Hayes J.L. Becker A A A A A A A A A A A A A A A A A A A A A A A A A A A A V V V A V V A A A V V V A A A A A A A A A A A A A A A A A A A V A A A A A A A • • • • A A V F U R N A C E • • • • • • • • • • F U R N A C E • • • • • • U P G R O F U R N A C E G R O U P • • • • • • • • • • G R O U