XRD and TEM Characterization of Compound

advertisement

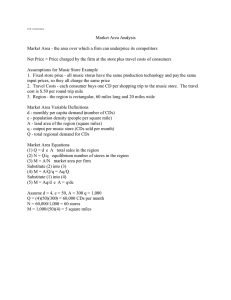

XRD and TEM Characterization of Compound Semiconductor Solid Solutions: Sn(S,Se) and (Pb,Cd)S B.R. Jarabek., D.G. Grier., D.L. Simonson, Center for Main Department North Dakota Fargo, ND D.J. Seidler, P. Boudjouk Group Chemistry of Chemistry State University 58 105-55 16 and G.J. McCarthy L.P. Keller MVA Inc. 5500 Oakbrook Pkwy., Suite 200 Norcross, GA 30093 Abstract X-ray powder diffraction (XRD) is an essential component of research into use of organometallic precursors as a route to low temperature (<500 “C) synthesis of bulk compound semiconductors. This paper illustrates the use of XRD to study solid solution behavior in the systems SnS-SnSe and PbS-CdS. XRD characterization demonstrated that phase pure intermediate members of the Sn(S,Se) solid solution prepared by this low temperature route showed the typical dependence of unit cell parameters on composition. PbS-CdS exhibits essentially no solid solution behavior at low temperatures according to established phase diagrams. Characterization of organometallic precursor thermolysis products with intermediate compositions initially suggested that a metastable solid solution with perhaps 30% of CdS in PbS could be prepared at 150°C. More detailed XRD and high resolution transmission electron microscopy (HRTEM) characterization indicated that the CdS was in fact present as a separate phase with such small crystallites (2-5 nm) that peak broadening made it essentially undetectable in concentrations below 30%. The actual amount of solid solution was 2% or less of CdS in PbS. Introduction Organometallic precursors have been found to provide a facile route to low temperature synthesis of bulk compound semiconductor metal chalcogenide solid solutions’. The primary advantage of producing solid solutions by organometallic precursor decomposition is intimate mixing of the inorganic constituents at the molecular level. This mixing occurs in the melt phase, during heating of mixtures of the organometallic precursor end-member molecules, prior to decomposition of these precursor molecules and subsequent crystallization of the inorganic end products, The organometallic compounds decompose at relatively low temperatures typically less than 300°C. Synthesis of solid solutions by conventional means, i.e. from the elements or binary end member compounds, would require temperatures of 500-lOOO”C, long heating times, intermediate grindings, and possibly explosive conditions. Copyright (C) JCPDS-International Centre for Diffraction Data 1997 Copyright 0 JCPDS-International Centre for Diffraction Data 1997 This document was presented at the Denver X-ray Conference (DXC) on Applications of X-ray Analysis. Sponsored by the International Centre for Diffraction Data (ICDD). This document is provided by ICDD in cooperation with the authors and presenters of the DXC for the express purpose of educating the scientific community. All copyrights for the document are retained by ICDD. Usage is restricted for the purposes of education and scientific research. DXC Website – www.dxcicdd.com ICDD Website - www.icdd.com XRD characterization, including the use of calculated X-ray powder diffraction patterns2, is an essential component of these studies. Here we describe results from studies of two binary chalcogenide systems, one in which XRD characterization was routine, and one in which the characterization was more challenging. The first binary system was that of the chalcogen anion-substituted solid solution, Sn(S,Se), in which complete solid solution between the isostructural (GeS structure) SnS and SnSe components is known3. Phase pure intermediate members of the Sn(S,Se) solid solution prepared at 450°C showed the typical dependence of unit cell parameters on composition. The equilibrium phase diagram for PbS-CdS4 indicates essentially no solid solution between the cubic (Fm3m) rocksalt structure PbS and the hexagonal (P63mc) wiirtzite structure CdS end members at temperatures below 500 “C. However, some solid solution of CdS in PbS is known to occur under equilibrium conditions at higher temperatures (maximum of ca. 40 mol% at the eutectic temperature of 1052°C)4. In addition, complete solid solution with metastable retention of the rocksalt structure at ambient conditions has been reported for high pressure syntheses’. The organometallic precursor route was explored as a possible low temperature (<5OO”C), ambient pressure synthesis of metastable (Pb,Cd)S. Examination of routine powder diffraction patterns of products of syntheses of intermediate compositions suggested at first that a metastable solid solution with perhaps 30% of CdS in PbS could be prepared at 150°C. However, the rocksalt unit cell parameter did not show the substantial decrease that substitution of the smaller Cd for Pb would produce. We describe here the additional characterization by XRD and TEM that led to the conclusion that up to about 30%, the CdS was actually present in thermolysis products as a crystalline phase, but with such small crystallite sizes (2-5 nm) that peak broadening made it essentially impossible to detect in the X-ray diffraction patterns. Experimental To study the low temperature synthesis of SnS-SnSe solid solutions, thermolysis of mixtures of (Bn$nS)s and (Bn$nSe)j (where Bn = benzyl, CHzCsHs) was carried out in a programmable tube furnace under nitrogen flow. The mixtures were heated to, and held for 2 h at, 450 “C before cooling to room temperature. With the PbS-CdS system, mixtures of Pb(SBn)z and Cd(SBn);l were heated for 12 h at 150 “C. The compositions studies were 2, 5, 10, 15, 20, 30, 35, 40, 45, 50, 60, 70, 75 and 90 mol% CdS. Three replicate runs were made for the 5%, 20%, 35% and 50% test compositions. X-ray powder diffraction (XRD) patterns were recorded from ethanol slurry-mounted samples on zero background quartz slides using a Philips automated vertical diffractometer with CuKa radiation. The diffractometer setup included a theta-compensating variable divergence slit, a graphite diffracted beam monochrometer, and a scintillation detector. Data reduction was performed on personal computers using MD1 Jade software. Unit cell parameters were determined by the least squares method, also using MD1 Jade software. NIST SRM 640b silicon was used as the internal standard for the SnS-SnSe system. For the PbS-CdS system, NIST SRM 660 LaB6 was used as the internal standard for cell parameter and crystallite size determinations. Copyright (C) JCPDS-International Centre for Diffraction Data 1997 f?nnvrinht 61 .ICPnS-lntcmntinnal Cantre for Diffraction Data 1997 Calculated powder patterns were used in characterizing all decomposition products, including the intermediate members of the SnS-SnSe and PbS-CdS systems, using the POWD code.6 Indexing and subsequent unit cell refinements of the orthorhombic patterns were aided by calculated pattern intensities, which allowed unique indexing of many peaks that would otherwise have been multiply indexed. Intermediate Sn(S,Se) patterns were calculated assuming random substitution in the chalcogenide site, using literature values’ for atomic parameters and interpolated unit cell dimensions. Intensity variations in a potential PbS-CdS rocksalt structure solid solution phase were also modeled with POWD, estimating all thermal parameters as Bi,,=l .O. Neutral atom scattering factors were used in all cases, with corrections for anomalous dispersion for all atoms heavier than Li. The Philips diffractometer was modeled using Cauchy peak profiles and a dit?i-acted beam monochromator setting. For the transmission electron microscope (TEM) analyses, an aliquot of each sample was ground in acetone, and a drop of the suspension was placed on a holey carbon thin film that was supported by a copper TEM grid. High-resolution TEM (HRTEM) images, selected-area electron diffraction (SAED) patterns, and chemical analyses of the materials were obtained using a JEOL 2010 (200 KeV) TEM equipped with a NORAN thin window energy-dispersive X-ray (EDX) spectrometer. The high resolution TEM images were recorded at magnifications of 400kX to 8OOkX. Results and Discussion SnS-SnSe System Sn(S,Se) formed in the expected continuous solid solution series, with random chalcogen substitution at the anion site. The products of the 450 “C thermolysis were crystalline phase pure, with no peak splitting to suggest phase separation, and no significant elevation in diffuse background scattering to suggest a significant amorphous contribution (Figure 1). In many cases, upon exposure to humid laboratory conditions during specimen preparation, minor oxidation of the platy crystallites (with large surface areas) occurred, producing trace to minor tin oxide. Unit cell volume varied linearly with sulfur content in the SnS-SnSe solid solution (Figure 2). The diffraction patterns also showed peak broadening of the 101 reflection of the intermediate member Sn(Seo.&s) with FWHM=0.267(40 nm). This peak broadening is greater than both the SnSe endmember with FWHM=0.210 (55 nm) and the SnS endmember with FWHM=O. 190 (80 m-n). PbS-CdS System Initial examination of diffraction patterns of thermolysis products of intermediate compositions in the PbS-CdS system seemed to suggest that extensive solid solubility of CdS in PbS had occurred, i.e., the diffraction patterns appeared to show crystalline phase pure FCC materials, with broad peaks but without peak splitting, which would suggest phase separation, and with no prominent elevations in background scattering, which would suggest amorphous phase(s) (Figure 3). These results seemed to hold true throughout the range of CdS addition until approximately 60% CdS, at which point minor broad hexagonal CdS peaks typical of the end member were observed (Figure 4). However, careml, re-examination of background regions containing these peaks in more PbS-rich mixtures revealed barely observable broad hexagonal CdS “peaks” to approximately 30% CdS, but not below. Copyright (C) JCPDS-International Centre for Diffraction Data 1997 26 28 30 32 34 36 3s 2-Theta Figure 1. Diffraction patterns of SnS, Sn(So.s Seo.s), and SnSe, showing typical solid solution behavior. 210 195 190 J 40 60 80 Composition, x, in Sn(S l-x, Se X) Figure 2. Unit cell variation in Sn(S1, Se,). For the linear regression, R* = 0.991. Copyright (C) JCPDS-International Centre for Diffraction Data 1997 r-,,.:d.+ h lrnnc In+nm--s+ir\ne3l Pdn4ra fnr niff~~dinn n3t3 1007 100 PbSKdS PbS CdS 35 Figure 3. 40 2-Theta Diffraction patterns from PbS, CdS, and an 80% PbS-20% CdS run. The cubic phase is the only apparent crystalline phase in the product, suggesting incorporation of CdS into the PbS structure. PbSlCdS PbS 2-Theta Diffraction patterns from PbS, CdS, and a 40% PbS-60% CdS run. With 60% CdS addition, increases in background from broad hexagonal peaks of the CdS end member were noted, indicating that at least some portion of the CdS was now crystallizing in a second, hexagonal phase. Figure 4. Copyright (C) JCPDS-International Centre for Diffraction Data 1997 Despite the initial implication that solid solutions had formed in samples containing up to 30% CdS, little variation in unit cell parameters was observed across the range of input stoichiometries compared to the end member PbS (Figure 5). The large peak shifts predicted by Vegard’s law for solid solution and observed in a previous high pressure study’ are absent in the experimental data of Figure 3. These results suggested that very little (<2%) solid solution had actually formed. Unfortunately, this interpretation leaves most of the CdS input to the system unaccounted for. The thermolysis apparatus included a liquid nitrogen trap to capture volatile byproducts. Bn$ was the only byproduct. No cadmium was detected by XRF in the byproducts, which indicated that all of the input cadmium had been retained in the thermolysis product. Two hypotheses were suggested by these observations: (1) Cd was present in the crystalline FCC phase observed (without causing a resultant change in unit cell parameters), or (2) Cd was present in a separate phase that was not observable by XRD. In order to test these hypotheses, more detailed investigations of the diffraction data were performed. Clearly, since the peak positions and unit cells remained constant throughout the range of compositions, the diffraction peak positional data were not helpful. Instead, the relative peak intensities were used to obtain another line of evidence in support of a separate cadmium sulfide phase. Site substitution of Cd (atomic no. 48) for Pb (atomic no. 82) in (Pb,Cd)S (hypothesis (l)), would lead to variation in average scattering factor on the metal site, which should affect diffraction peak intensities of certain reflections. The three peaks from the calculated diffraction patterns shown in Figure 6 predict, a significant decrease in relative intensity of the (111) peak relative to either the (200) or (220). These ratios, then, should decrease with addition of CdS, if major solid solution were occurring. Figure 7 is a plot of the ratios of the (111) to (220) reflections for all of the runs made. There is significant scatter of the data, but the peak height ratio of most run products remained between 0.8 and 0.9, supporting hypothesis (2), and did not decrease toward 0.6 as would occur if Cd were substituting for Pb in (Pb,Cd)S. Similar results were obtained for the (111) / (200) ratio. Based on all of these data, it was concluded that at most only 2% CdS had substituted in the rocksalt PbS structure. The remaining CdS was present as a separate phase that was below the detection limit of our instrument for compositions to 30% of CdS in the CdS-PbS binary. As the weight fraction was increased past 30% the hexagonal phase of CdS became apparent. A crystallite size estimate of 5-7 nm was obtained using the Scherrer equation on the diffraction pattern of pure CdS. TEM analysis was then performed to learn more about the CdS phase. HRTEM and SAED showed 20-100 nm crystallites of rocksalt phase intermixed with nanocrystalline (2-5 nm) CdS (Figures 8 and 9). These crystallite sizes of the rocksalt structure phase were consistent with the 20-40 nm crystallite size estimates obtained from XRD using the Scherrer equation. An important observation for analytical XRD in general was that although the CdS phase was nearly “X-ray amorphous” in the mixtures, the HRTEM results demonstrated that it is actually quite crystalline. The very small crystallite sizes led to extreme peak broadening in XRD making it impossible to distinguish the CdS phase under 30 mole% CdS and requiring great magnification of the background to see the nanocrystalline CdS phase in scans between 30 and 60 mole%. Copyright (C) JCPDS-International Centre for Diffraction Data 1997 5.95 -\ 4 f 3 E $ 8 f \\ 5.91 -- \\ ‘\ -\ 5.89 -- ‘\ n \ -. ‘\ \ , f\ 5.87 -- \ 150°C ------- Sood,etal - Regression *\ -. \ -\ -. 5.85 7 4 \ 0 20 40 60 mol% CdS in PbSlCdS Figure 5: Measured unit cell parameters of the FCC phases in all run products as a function of nominal composition, and the cell parameter variation in solid solutions quenched from high pressure syntheses.’ 3 2-Theta Figure 6: Calculated (Pb,Cd)S FCC phase solid solution intensities for the (11 l), (200) and (220) reflections. Only the (111) varies substantially with substitution of Cd for Pb. Copyright (C) JCPDS-International Centre for Diffraction Data 1997 fkmvrinht 6 .ICPiT.Clnt~rnntinnaI Cnntre fnr niffrxtion Data 1997 120 l l l l 0 l n 0 q 0 0 0 0 40 110 60 40 20 mol% CdS Figure 7: system. Observed and calculated ratio of the (111) to the (220) reflection in the PbS-CdS I ’ PbS 50nm Figure 8: TEM image from a run products at an intermediate composition. with much smaller 2-5 nm crystallites of hexagonal CdS. Copyright 0 JCPDS-International Centre for Diffraction Data 1997 Cubic PbS crystals Figure 9. HRTEM image showing a 20 nm PbS crystallite and randomly oriented 2-5 nm CdS crystallites. EDX analysis of the larger, rocksalt structure crystallites indicated that no more than 2 mol% Cd could be substituting for Pb in this phase. It is also possible that this small amount of Cd observed by EDS under TEM was present as a thin coating of CdS on larger, pure PbS crystallites. The presence of a small amount of Cd in solid substitution for Pb in the rocksalt structure phase, rather than as a coating, is consistent with the XRD result shown in Figure 5. Conclusions The low temperature organometallic precursor synthesis produced complete solid solution between SnS and SnSe, and the XRD characterization was routine. Characterization by XRD and TEM of possible solid solution between PbS and CdS indicated that, for the synthesis conditions used, at most only 2% of CdS was miscible in rocksalt structure PbS. TEM analysis indicated that the CdS in other intermediate compositions consisted of 3 to 5 nm crystallites. XRD could not detect the CdS phase(s) in the products of experiments with up to 30% CdS in PbS-CdS due to the resulting peak broadening. This study illustrates the need for XRD analysts to be alert to nanocrystalline phases which may go unnoticed in mixtures with much better crystallized phases. Acknowledgments Financial support for this research was provided by the National Science Foundation Grant No. OSR 9452892. Copyright 0 JCPDS-International Centre for Diffraction Data 1997 through References 1. Boudjouk, P., Seidler D. J., Grier, D., McCarthy G. (1996) “Benzyl-Substituted Tin Chalcogenides. Efficient Single-Source Precursors for Tin Sulfide, Tin Selenide, and Sn(S,Ser,),” J. Chem. Mater. 8, 1189-l 196. 2. McCarthy, G. J., Martin, K.J., Holzer, J.M., Grier, D.G., Syvinski, W.M., Nodland, D.W. (1992). “Calculated Patterns in X-Ray Powder DifTraction Analysis,” Adv. X-Ray Anal. 35, 17-23. 3. Albers, W.; Haas, C.; Ober, H.; Schodder, G. R.; Wasscher, J.D. (1962) “Preparation and Properties of Mixed Crystals Sn So-X)Se.,” J. Phys. Chem. Solids 23, 215-220. 4. Leute, V., Schmidt, R. 2. (1991). “The Quasiternary System (Cdx Pbr_x)(Sr_LTel-L),” Phys. Chem. 172, 81-103. 5. Sood, A. K., Wu, K., Zemel, J. N. (1978). “Metastable Pbi_,Cd, S Epitaxial Films 1. Growth and Physical Properties,” Thin Solid Films 48, 73-86. 6. Smith, K. L. and Smith, D.K. (1993). “Micro-POWD, Ver. 2.3,” Materials Data Inc., Liver-more, CA, U. S. A. 7. Wiedemeier, H., Georg, H., von Schnering, H.G. (1978). “Refinement of the structures of GeS, GeSe, SnS and SnSe,” Z. Krist. 148, 295-303. Copyright (C) JCPDS-International Centre for Diffraction Data 1997