Adventures in Wind System Grounding—Tales From Afield

advertisement

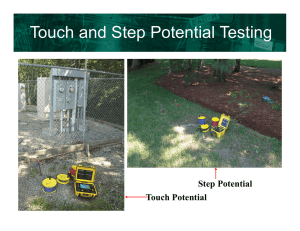

Adventures in Wind System Grounding Tales From A-field (literally) SWT Grounding System Evaluation Project • Commissioned by *NYSERDA to evaluate the effectiveness of grounding systems designed or recommended by turbine manufacturers • Owners of NYSERDA funded wind turbines were asked if they had experienced lightning damage • 15% of the respondents indicated that their systems may have been damaged by lightning • Perhaps a “one size fits all” approach to small wind turbine tower grounding is not sufficient? * New York State Energy Research & Development Authority SWT Grounding System Evaluation Project • 18 sites were selected for testing – wide variation in terrain and soil types – testing region covered 9 counties and an area of 80 x 260 miles • Turbines from 5 different manufacturers – Bergey, Endurance, Gaia, WTI (Jacobs) and Xzeres – 8.9 kW to 55 kW in rated capacity • Four different tower types – 9 guyed lattice, 7 free standing lattice, 1 fixed monopole and one guyed tilting pipe – Installation ages spanned 7 years, from April 2006 to May 2013 • This diverse group was chosen to help identify commonalities between the various grounding methods and tower types Project Goals • Measure & record grounding electrode resistance values • Observe the effect that turnbuckles and other hardware have on electrical conductivity between guy wires and the grounding electrode • Measure and record the resistance between the tower structure and the grounding system • Evaluate the overall integrity of the grounding system • Observe the effect that workmanship and variations in installation techniques have on grounding system integrity Tower Grounding • For small wind turbines there are two types of grounding – Safety grounding to prevent electrical shock hazard – Grounding metal structures for lightning protection • The primary focus of this project was on tower grounding • So the question is- what constitutes a good ground? • Let’s start with a grounding electrode resistance value • And where do we find this elusive value? Grounding Electrode Resistance? • Wind turbine installation manual grounding recommendations vary widely between manufacturers • Most give fairly specific guidelines for installing the grounding system but few give grounding electrode resistance recommendations • One of the exceptions found during the field testing was Endurance Wind Power. Their specifications call for a grounding electrode system having a resistance to ground of 10 ohms or less Grounding Electrode Resistance? • 2011 NEC Article 250.53 (2), the Exception mentions a resistance of 25 ohms or less for grounding electrodes, but this isn’t for towers • Article 694.40 covers small wind tower grounding in some detail but never mentions a minimum grounding electrode resistance value • NFPA 780-2011- Standard for the Installation of Lightning Protection Systems- chapter 9 covers Protection for Wind Turbines, but is this primarily for utility scale turbines – But nowhere in the document does it provide any electrode resistance values! • How about best practices from other industries? – Lightning protection industry recommends 10 ohms or less – The Telecomm industry is now recommending 5 ohms or less but this is more for protection against RF than for lightning The Testing Process • A 3 lead Extech Earth Resistance Tester was used • One lead attaches to the grounding electrode or other test point • The other two leads attach to two spikes driven into the ground, one at 33 feet, the other at 66 feet • The ground tester injects voltage into the ground and measures the voltage drop between the three test points • This allows it to calculate the resistance between these points The Testing Process • The guyed lattice towers all had 4 ground rods (electrodes), one at the tower base and one at each of the 3 guy anchor points • Free standing lattice towers had each leg grounded. – Some installations connected each leg to its own grounding electrode. – Others connected each leg to a grounding system consisting of multiple electrodes bonded together to make a grounding ring • The free standing monopole tower was connected to a grounding electrode system consisting of multiple electrodes bonded together to make a grounding ring • The guyed tilting tower had an electrode at all 4 guy anchor points, and one at the tower base. The Testing Process • All electrodes were measured first • Then a comparative reading was made between the electrodes and each guy wire, tower leg, turbine disconnect ground buss bar and a spot 7 feet up on the tower • When accessible, the tower ground to premises ground bonding conductor was tested • A visual inspection of the installation was also conducted to assess code compliance and quality of workmanship Findings- Guyed Lattice Towers • Grounding electrode readings ranged from 2.9 to 15.3 ohms – some sites had almost a 10 ohm variance between electrodes • Guy wire to ground readings ranged from 3.1 to 8.2 ohms – Most guy wire to ground resistance values were less than the grounding electrode resistance at that anchor point, due to the multiple paths to ground via the tower and other guy wires – Conductivity through the guy hardware and foundation anchor rod was much better than anticipated. Guy wire tension and vibration appear to be maintaining healthy electrical connections • Variance between guys and electrodes ranged from 0 to 9.8 ohms – The only tower with no variance had all the guy wires at each anchor bonded together with a continuous conductor and connected directly to the grounding electrode Findings- Free Standing Lattice Towers • The Endurance installations had the lowest resistance values of all the towers tested, with 1.5 ohms at one site and 1.7 at the other – This value was consistent for the entire structure to ground – no variance between any of the test points at either site • With only one exception, the electrodes at other lattice tower sites varied from 1.5 to 6.5 ohms – The exception was an installation on bedrock. An engineered grounding system was installed consisting of 8 electrodes, bonded to each other and to the tower with exothermic welds. Additional top soil was placed over the system – Tower to soil resistance values ranged from 9.6 to 10.3 ohms Findings- Guyed Tilting Tower • Grounding electrode readings ranged from 7.7 to 9.1 ohms • Variance between guys and their corresponding electrode ranged from 0 to 0.2 ohms – The guy wires at every anchor were bonded together with a continuous conductor and connected directly to the grounding electrode • As with the guyed lattice towers, the conductivity through the guy wire thimbles, turnbuckles and ground anchor rod was much better than anticipated • Guy wire tension and vibration appear to be helpful in maintaining healthy electrical connections Findings- Monopole Tower • Although the grounding electrodes were below ground level and inaccessible for testing, the grounding electrode conductor and one point on the tower both measured 6.1 ohms Findings- Mechanical • The most common issue found was improper installation of the grounding electrode conductors – Conductors installed with no slack, broken due to turbine vibration and/ or thermal cycling – Poor conductor routing methods, leading to damage by abrasion, foot traffic and livestock – Poor or lost electrical connections due to inadequate fasteners – Fastening techniques that allowed contact between dissimilar metals which caused corrosion due to electrolysis • Missing and/ or improperly installed tower ground to premises ground bonding conductor Conclusions • The manufacturers of all the wind turbines that were tested did a reasonably good job specifying grounding systems for their turbines and no significant deficiencies were observed with their designs • Most of the issues that were found were caused by the effects of vibration on grounding connectors and conductors • The majority of these were workmanship related, all of which could be easily rectified by the installers more closely following industry best practices • No matter how robust a wind turbine is or how well it is installed, annual inspections are absolutely critical to maintaining electrical, structural and aesthetic integrity • And that it’s damned difficult to fit all this into 15 minutes or less!