Op Amp Design in Nanoscale Processes Using Fixed

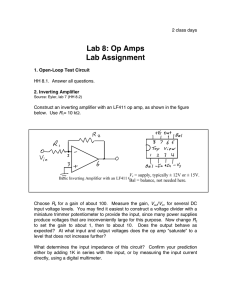

advertisement