Plastic Machine Controller

advertisement

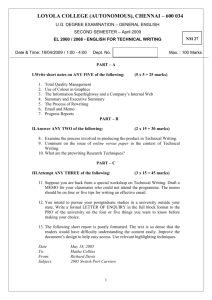

長新科技股份有限公司 ARICO Technology Co., Ltd. Plastic Machine Controller Easy To Link Good Extensibility Distributed Control System AT-AR-EN-1.1.0 Total Solutions for Plastic Machine .............................................................................................................. 3 Characteristic................................................................................................................................................... 4 Human Machine Interface ............................................................................................................................. 5 AR1260 System Block Diagram ................................................................................................................... 6 AR1860 System Block Diagram ................................................................................................................... 7 AR2000 System Block Diagram ................................................................................................................... 8 AR2100 System Block Diagram ................................................................................................................... 9 Industrial Controller Comparison Table........................................................................................................ 10 HMI Dimension .............................................................................................................................................. 11 SKY-Link Network Program Environment............................................................................................................. 12 Remote Connection Monitoring Screen ....................................................................................................... 13 External Expansion module ........................................................................................................................ 14 Other Accessories ........................................................................................................................................ 15 Switching Power Supply - NES-35-12 ............................................................................................................. 16 Switching Power Supply - S-350-24 .......................................................................................................... 17 Switching Power Supply - NES-100-48 ........................................................................................................... 18 The specification of Transformer MA-02 .......................................................................................................... 19 TC500 Multi-Cavity Hot Runner Temperature Controller ....................................................................... 20 Products Overview........................................................................................................................................ 22 2 Back to Contents Total Solutions for Plastic Machine Desktop Notebook Ethernet AR Series Plastic Machine Controllers Solid State Relays Temperature Controllers Heater Power Regulators Displacement Transducers Inverters Load Cells Displacement Transducers Indicators / Alarm units Pressure Transducers Pressure Controllers Hot Runner Temperature Controllers Melt Pressure Transducers MODBUS 3 MODBUS Back to Contents Characteristic Fast software interrupt timing is 0.25ms apply to control, enhance the accuracy of more than 2 times the displacement It is simple to update all of program via USB memory driver DCS control (HMI and Remote I/O module) for easy access of external device and/or controller Various HMI size options: 5.6", 8", 10.4" and 12.1" or touch panel(10.4" & 12.1") 3 of high speed 32 bits CPU (266MHz) High speed Ethernet communication between HMI and Remote I/O module RS485 and SKY-Link(Option) Interface State-of-the-art window system HMI Screen Editor design by ARICO PLC ladder editor for process program The Demolished architecture, CPU board can be upgraded to more powerful new one on base main control board It is non-industrial personal computer board, because the CPU of PC update very fast, face stop manufacture and version change, software maintain and cost will go high I/O function define self and shift function (1) Change the defect I/O to another by setting, to solve problem at once (2) For some multi function valve, use program control them, it can use one program to apply the timing of the different hydraulic valve in extent permitted (3) For some multi function valve, use program control them, and collect them to front I/O to save the I/O ports (D/O have to consider the 2A/port, 16 ports max. is 10A) (4) Define different D/I、D/O、A/I、A/O for different model machine, no need to modify the wiring, just setting to suitable hardware(example: it can be applied at old machine replace new controller, no need re-wire the all wires) Flip up icon of screen and alarm message PLC Real-Time control The 10 levels control for user The present screen picture can be saved via USB port to external memory device (USB memory device) 4 Back to Contents Human Machine Interface Monitor Page Module Memory Backup Injection Curve Operation Record Temperature Curve Alarm message record 5 Back to Contents AR1260 System Block Diagram HMI Remote I/O Module Standard Standard TFT LCD Size Digital Input port Digital Output port 8" 32 ports 32 ports Mechanical Keys FDA Output Port (0~10V) Temperature IN(TC) 5 channels 8 zones A/D Input Port 14 bit, range: 0~10V Heater Output(HT) 6 channels RPM Count Ethernet 64 keys USB Host port 1 port 8 zones Extended module 1 port Module Memory Digital Input port Option 100 sets RS-485, 2 line 1 port +8 ports D/A Output Port 12 bit, range: 0~10V / ±10V Digital Output port +2 channels +8 ports Extended Module Option TFT LCD Size 5.6"/10.4"/12.1" SKY-Link W207.3mm × H345mm RS-485 Temperature IN(TC) Cooling output(CL) 8 zones 8 zones 1 set Heater Output(HT) Touch Panel 8 zones RS-485 Temperature of 15 groups can be cascaded I/O 10.4" 以上 Extended Keys 64 keys RS-485, 4 line 1 port 6 Back to Contents AR1860 System Block Diagram Remote I/O Module HMI Standard Standard Digital Input port Digital Output port 32 ports 32 ports A/D Input Port 16 bit, range: 0~10V D/A Output Port 12 bit, range: 0~10V / ±10V USB Host port 8 channels 8 channels 1 port Module Memory FDA Output Port (0~10V) Temperature IN(TC) 100 sets 10 channels 13 zones RS-485, 2 line RPM Count Heater Output(HT) 1 port 4 ports 13 zones TFT LCD Size 8" Mechanical Keys 64 keys W209mm × H393.4mm Ethernet Servo control Extended Module Encoder Input port 8 channels MagBridge Option TFT LCD Size I/O Extended Module #5~#8 A/D Input Port / Encoder Extended Module A/D Input Port 16 bit, range: 0~10V (+16/+16)or(+32/+32)or(+48/+48)or(+64/+64) ports 8 channels I/O Extended Module #9~#12 Encoder 32 bit (+16/+16)or(+32/+32)or(+48/+48)or(+64/+64) ports 4 channels I/O Extended Module Array I/O Extended Module #1~#4 5.6"/10.4"/12.1" (+16/+16)or(+32/+32)or(+48/+48)or(+64/+64) ports SKY-Link 1 set Touch Panel 10.4" 以上 Extended Module Extended Keys 64 keys RS-485, 4 line 1 port RS-485 Temperature IN(TC) Cooling output(CL) 8 zones 8 zones Heater Output(HT) Temperature of 15 groups RS-485 can be cascaded I/O 8 zones 7 Back to Contents AR2000 System Block Diagram Remote I/O Module HMI W243mm × H356mm Standard Standard TFT LCD Size Digital Input port Digital Output port 8" 32/48 ports 32/48 ports A/D Input Port 16 bit, range: 0~10V FDA Output Port (0~10V) 6 channels 4 channels PWM Output RPM Count 1 port 1 port Option Temperature IN(TC) Heater Output(HT) 8 zones 8 zones D/A Output Port 12 bit, range: 0~10V or ±10V Mechanical Keys Ethernet 64 keys USB Host port 1 port Module Memory 100 sets RS-485, 2 line CAN 1 port 4 channels S/S Interface 1 set 4 sets MagBridge Option TFT LCD Size I/O Extended Module Array I/O Extended Module #1~#4 5.6"/10.4"/12.1" (+16/+16)or(+32/+32)or(+48/+48)or(+64/+64) ports SKY-Link I/O Extended Module #5~#8 (+16/+16)or(+32/+32)or(+48/+48)or(+64/+64) ports 1 set I/O Extended Module #9~#12 Touch Panel (+16/+16)or(+32/+32)or(+48/+48)or(+64/+64) ports 10.4" 以上 Extended Module Extended Keys 64 keys RS-485, 4 line 1 port RS-485 Temperature IN(TC) Cooling output(CL) 8 zones 8 zones Heater Output(HT) Temperature of 15 groups RS-485 can be cascaded I/O 8 zones 8 Back to Contents AR2100 System Block Diagram Remote I/O Module HMI W243mm × H386mm Standard Standard Digital Input port Digital Output port 32/48 ports 32/48 ports A/D Input Port 16 bit, range: 0~10V D/A Output Port 12 bit, range: 0~10V / ±10V 8 channels 8/12 channels RPM Count Temperature IN(TC) 100 sets 3 ports 8 zones Extended Module RS-485, 2 line CAN Heater Output(HT) Encoder Input port 1 port 1 set 8 zones 8 channels TFT LCD Size 8" Mechanical Keys 64 keys Ethernet USB Host port 1 port Module Memory MagBridge Option TFT LCD Size 5.6"/10.4"/12.1" SKY-Link 1 set Servo control I/O Extended Module Array A/D Input Port / I/O Extended Module #1~#4 Encoder Extended Module A/D Input Port 16 bit, range: 0~10V (+16/+16)or(+32/+32)or(+48/+48)or(+64/+64) ports I/O Extended Module #5~#8 (+16/+16)or(+32/+32)or(+48/+48)or(+64/+64) ports 8 channels I/O Extended Module #9~#12 Encoder 32 bit (+16/+16)or(+32/+32)or(+48/+48)or(+64/+64) ports 4 channels Touch Panel 10.4" 以上 Extended Module Extended Keys 64 keys RS-485, 4 line 1 port RS-485 Temperature IN(TC) Cooling output(CL) 8 zones 8 zones Temperature of 15 groups RS-485 can be cascaded Heater Output(HT) I/O 8 zones 9 Back to Contents Industrial Controller Comparison Table HMI Specifications Comparison Table Categories AR1260 & AR1860 & AR2000 & AR2100 NSV HMI 5.6" / 8" / 10.4" / 12.1" HMI CPU 266MHz Internet Connection (Optional) Yes Able to expand with an Ethernet card Yes Touch Panel (Optional) Able to expand with a Touch Panel Controller Specifications Comparison Table Controller AR1260 AR1860 PLC CPU AR2000 AR2100 266MHz 266MHz Time base = 0.25ms Control CPU 1. Higher control precision 2. Software can be updated through USB IO Connection NPN NPN NPN PNP Temperature PID Control 8 13 8 8 D/I Digital Input 32 32 32 / 48 32 / 48 D/O Digital Output 32 32 32 / 48 32 / 48 A/D Analog Input 14 bit * 6 16 bit * 8 16 bit * 6 16 bit * 8 Start/Stop Input X X 0/4/8 X FDA Analog Output 12 bit * 5(0~+10v) 12 bit * 10(0~+10v) 12 bit * 4(0~+10v) X D/A Analog Output 12 bit * 0/2(0~±10v) 12 bit * 8(0~±10v) 12 bit * 0/4(0~±10v) 12 bit * 8/12(0~±10v) PWM Output X X 1 X RPM Count 1 4 1 3 FPGA PLC CPU & Control CPU data transmitted through a parallel FPGA connection; allows more precise control accuracy 10 Back to Contents Hardware Expansion Specifications Comparison Table Controller AR1260 AR1860 AR2000 AR2100 Temperature Module Man-machine communication allows 15 sets of temperature module expansions; each module includes 8-stage temperature control IO Expansion Module DI / DO*8(Max) AD/Encoder Compound Module X AD 16 bit*8 Encoder 32 bit*4 X AD 16 bit*8 Encoder 32 bit*4 Encoder X 32 bit * 8 X 32 bit * 8 Able to expand 12 modules; each module DI / DO * 16 (Max=192) HMI Dimension 5.6" 8" 10.4" Vertical Panel 10.4" H370.6×W193 mm H417.8×W237.5 mm H469.1×W 285 mm H507.9×W237.5 mm Multi-Injection molding 10.4" 12.1" H505.3×W288.9 mm H517.8×W332 mm Extruder Panel 10.4" H244.8×W287.6 mm H196×W257 mm Note: 5.6" is VGA (640x480); other LCD modules are all SVGA (800x600) 11 Back to Contents SKY-Link Network Program Environment Server Hardware Environment Server NET Operating Environment 1. XP System: CPU: Intel Core i3 or above RAM:4G HARD DISK:1TB 2. WIN7 64 bit system: CPU: Intel Core i5 or above RAM: 8G or above HARD DISK:1TB 3. HUB: 10/100Mbs high speed Ethernet switch 4. Network cable specification CAT.6 or above 1. Operating System: XP Professional or Window 7 Professional 64 bit 2. IIS information services installation required (if external webpage browsing needs to be permitted, MIS needs to set the real IP and communication port) 3. Local area network properties must include Client Microsoft Networks and TCP/IP 4. Office 97 or above (Excel must be installed) 5. Framework 4.0 or above System Architecture Machine 01 Machine 02 Machine 09 Machine 10 …Machine xx …Machine xx HUB HUB Central Controller Server Tablet computer Manufacture Department PC Production Insurance Section PC 12 Manager Computer Mobile phone Back to Contents Remote Connection Monitoring Screen 13 Back to Contents External Expansion module AR1860 / AR2000 / AR2100 AR1260 / AR1860 / AR2000 / AR2100 Temperature Expansion Module 16*D/I & 16*D/O Expansion Board (connect HMI) 24V E DI O- 0 1 E DI O- 0 2 I N (extension) 24V OUT 1 9 1 9 CN 1 2 10 210 3 11 311 ETC-08 4 12 412 6 14 614 1 1 CN 1 Run 2 2 7 15 715 4 4 CN 2 1 2 3 4 1 1 2 2 3 3 4 4 Tx 5 5 HT 6 6 CL 7 7 8 8 5 5 Rx HT CN 2 1 2 8 3 9 HT 5 6 7 8 5 5 6 6 7 7 8 8 AR1860 / AR2100 S1 ~8 1 2 3 CL 4 5 6 7 8 G NC G 12V 4 5 6 7 8 1 2 3 CL 4 5 6 7 8 G G G 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 NC 12G FG 12G FG Expansion Board 3 1 2 3 4 5 6 7 8 12V (Max. 192 ports) Rx 1 2 HT 4 4 G Main Board Tx 24V 3 3 4 ON S1 ~8 1 2 3 4 5 6 7 8 G G ON G Run Debug1 Debug2 CN 2 1 1 2 2 24V 6 7 10 11 12 13 14 15 16 6 6 CL 7 7 8 8 TC TC 5 12V 24V CN 1 Debug1 Debug2 3 3 8 16 816 V ETC-08 12V 24V 5 13 513 The first piece After the second piece (Cable Standard= 5m or (Cable Standard= ___m) 0.45m) AR1260 8*D/I & 8*D/O Expansion Module 8 Channels Expansion Module ARENC-01-D A1 A3 A5 A7 A1 A3 A5 A7 B1 B3 B5 B7 A 1 B 1 B1 B3 B5 B7 2 2 Z1 Z3 Z5 Z7 3 3 Z1 Z3 Z5 Z7 4 4 A2 A4 A6 A8 5 5 A2 A4 A6 A8 6 6 B2 B4 B6 B8 7 7 B2 B4 B6 B8 8 8 Z2 Z4 Z6 Z8 Z2 Z4 Z6 Z8 VI 33 35 37 39 G I34 36 38 40 ED I-S08 Line Driver Open Collector FPGA Firmware: FE12 FPGA Firmware: FE12 AR1860 AR1260 PNP Output & Input Adapter Plate PNP Output & Input Adapter Plate Source,NPN → Sink, NPN → Source,NPN → Sink, NPN → Sink,PNP Source, PNP Sink,PNP Source, PNP 14 Back to Contents Other Accessories FPV-01 FPV-01N ARPV-01 ARPV-04 AC Auxiliary Power 15Vac/0Vac/15Vac 一 AC Input Power 50Vac(40Ω)/24Vac(10Ω) 一 DC Auxiliary Power 一 24Vdc DC Input Power Power Output(Max.) 一 25.6W(40Ω) / 6.4W(10Ω) Jumper Select Load Impedance 40/10 Ω 10 Ω Output Current(Max.) 0.8A 4A Control Signal Input 48Vdc 160W 0~10 Vdc Fuse 2A 5A Vibration Frequency 120 Hz Ascending Speed Coarse Adjustment (Three-quarters turn) Descent Speed Coarse Adjustment (Three-quarters turn) Output Value(Max.) Output Value(Min.) Fine Adjustment (25 rpm) Fine Adjustment (25 rpm) Coarse Fine Adjustment Adjustment (Three-quarters (25 rpm) turn) Control Input Control Output Relay-04 Fine Adjustment (25 rpm) Rated Carrying Current 12A Nominal Voltage 15mA Min. Applicable Load 10mA 5VDC Nominal Current 15mA Max. Allowable Voltage 250VAC/30VDC Pick Up Voltage >18VDC Rated Load 12A/120VAC 10A/24VDC 10A/240VAC Drop Out Voltage <2.4VDC Max. Applicable Voltage 26.4VDC Operate Time 10ms Release Time 5ms Power Consumption 0.36W 15 Back to Contents Switching Power Supply - NES-35-12 Features: ● Universal AC input/Full range ● Protections: Short circuit/Overload/ Over voltage ● Cooling by free air convection ● 100% full load burn-in test Specification DC Voltage Rated Current Current Range Rated Power OUTPUT Ripple & Noise(max.) note. 2 Voltage Adj. Range Voltage Tolerance note. 3 Line Regulation note. 4 Load Regulation note. 5 Setup, Rise Time Hold Up Time(Typ.) INPUT Voltage Range Frequency Range Efficiency(Typ.) AC Current(Typ.) Inrush Current(Typ.) SAFETY & EMC ENVIRONMENT PROTECTION Leakage Current note. 7 Over Load Over Voltage Work Temp. Working Humidity Storage Temp., Humidity Temp. Coefficient Vibration Safety Standards note. 6 12V 3A 0~3A 36W 12mVp-p 10.8~13.2V ±1.0% ±0.5% ±0.5% 500ms, 30ms/230VAC 1200ms, 30ms/115VAC(at full load) 50ms/230VAC 10ms/115VAC (at full load) 85~264VAC 或 120~370VDC 47~63Hz 81% 0.75A/115VAC 0.5A/230VAC Cold Start: 45A <2mA/240VAC 110%~150% rated output power Derating Curve Output Derating VS Input Voltage Protection type: Hiccup mode, recovers automatically after fault condition is removed 13.8~16.2V Protection type: Shut down o/p voltage, re-power on to recover -20~+60°C (Refer to "Deratin Curve") 20~90%RH non-condensing -40~+85°C, 10~95%RH ±0.03%/°C(0~45°C) 10~500Hz, 2G 10min/1 cycle, 60min. each along X, Y, Z axes UL60950-1, CB(IEC60950-1), CCC GB4943.1:2011 approved Withstand Voltage I/P-O/P:3KVAC I/P-FG:2KVAC O/P-FG:0.5KVAC Isolation Resistance I/P-O/P, I/P-FG, O/P-FG:100M Ohms/500VDC/25°C/70% RH EMC Emission Compliance to EN55022(CISPR22) Class B, EN61000-3-2, -3 EMC Immunity Compliance to EN61000-4-2, 3, 4, 5, 6, 8, 11, EN55024, EN61000-6-1, light industry level, criteria A 註:1. All parameters NOT specially mentioned are measured at 230VAC input, rated load and 25°C of ambient temperature. 2. Ripple & noise are measured at 20MHz of bandwidth by using a 12" twisted pair-wire terminated with a 0.1uf & 47uf parallel capacitor. 3. Tolerance: includes set up tolerance, line regulation and load regulation. 4. Line regulation is measured from low line to high line at rated load. 5. Load regulation is measured from 0% to 100% rated load. 6. For the request of GB4943.1, the power supply is only suitable for use in the altitude 2000m below and the non tropical climate condition. 7. The power supply is considered a component which will be installed into a final equipment. The final equipment must be re-confirmed that is still meets EMC directives. 16 Back to Contents Switching Power Supply - S-350-24 Features: ● AC input range selectable by switch ● Protections: Short circuit/Overload/Over voltage/Over temperature ● Forced air cooling by built-in DC fan ● Withstand 300VAC surge input for 5 second ● Built-in cooling Fan ON-OFF control ● Built-in constant current limiting circuit ● 100% full load burn-in test ● LED indicator for power on ● Fixed switching frequency at 90KHz ● Low cost, high reliability OUTPUT Specification DC Voltage Rated Current Current Range Rated Power Ripple & Noise(max.) note. 2 Voltage Adj. Range Voltage Tolerance note. 3 Line Regulation Load Regulation Setup, Rise Time Hold Up Time(Typ.) INPUT Voltage Range note. 4 Frequency Range Efficiency(Typ.) AC Current(Typ.) Inrush Current(Typ.) Leakage Current SAFETY ENVIRONMENT FUNCTION PROTECTION Over Load Over Voltage Over Temperature Fan on/off Control(Typ.) 24V 14.6A 0~14.6A 350.4W 150mVp-p 20~26.4V ±1.0% ±0.5% ±0.5% 1000ms, 50ms/230VAC 1000ms, 50ms/115VAC(at full load) 20ms/230VAC 16ms/115VAC(at full load) 90~132VAC/180~264VAC (selected by switch) or 254~370VDC 47~63Hz 87% 7A/115VAC 4A/230VAC 40A/115VAC 60A/230VAC <3.5mA / 240VAC 105~135% rated output power Static Characteristics Protection type : Constant current limiting, recovers automatically after fault condition is removed 27.6 ~ 32.4V Protection type :Shut down O/P voltage, re-power on to recover 90°C±5°C(3.3~7.5V);85°C±5°C(12~15V); 80°C±5°C(24V);75°C±5°C(27~48V)(TSW1) Detect on case Protection type: Shut down O/P voltage, recovers automatically after temperature goes down RTH2≧50°C FAN ON, ≦45°C FAN OFF(3.3~7.5V) RTH2≧55°C FAN ON, ≦50°C FAN OFF(12~48V) Work Temp. Working Humidity Storage Temp., Humidity Temp. Coefficient -20~+60°C (Refer to output load derating curve) Vibration 10~500Hz, 3G 10min./1cycle, 60min. each along X, Y, Z axes 20~90%RH non-condensing -40~+85°C, 10~95%RH ±0.03%/°C(0~50°C) Safety Standards UL60950-1 approved Withstand Voltage I/P-O/P:3KVAC I/P-FG:2KVAC O/P-FG:0.5KVAC Isolation Resistance Derating Curve I/P-O/P, I/P-FG, O/P-FG:100M Ohms/500VDC / 25 / 70% RH 註:1. All parameters NOT specially mentioned are measured at 230VAC input, rated load and 25°C of ambient temperature. 2. Ripple & noise are measured at 20MHz of bandwidth by using a 12" twisted pair-wire terminated with a 0.1uf & 47uf parallel capacitor. 3. Tolerance: includes set up tolerance, line regulation and load regulation. 4. Please connect positive pole of input voltage with mark "L" of terminal block, connect negative pole of input voltage with mark "N" of terminal block, using DC voltage for input voltage. 17 Back to Contents Switching Power Supply - NES-100-48 Features: ● Protections: Short circuit/Overload/Over voltage ● Cooling by free air convection ● LED indicator for power on ● 100% full load burn-in test OUTPUT Specification DC Voltage Rated Current Current Range Rated Power Ripple & Noise(max.) note. 2 Voltage Adj. Range Voltage Tolerance note. 3 Line Regulation note. 4 Load Regulation note. 5 Setup, Rise Time Hold Up Time(Typ.) INPUT Frequency Range Efficiency(Typ.) AC Current(Typ.) Inrush Current(Typ.) Leakage Current PROTECTION Voltage Range Over Load Over Voltage SAFETY & EMC ENVIRONMEN T Work Temp. Working Humidity Storage Temp., Humidity Temp. Coefficient Vibration note. 7 48V 2.3A 0~2.3A 110.4W 150mVp-p 45.6~52.8V ±1.0% ±0.5% ±0.5% 1000ms, 20ms/230VAC 1000ms, 20ms/115VAC(at full load) 30ms/230VAC 25ms/115VAC(at full load) 85~132VAC/176~264VAC (selected by switch) or 248~373VDC 47~63Hz 86% 2A/115VAC 1.2A/230VAC Cold Start: 45A <2mA/240VAC 110%~150% rated output power Deration Curve Static Characteristics Protection type: Hiccup mode, recovers automatically after fault condition is removed 55.2~64.8V Protection type: Hiccup mode, recovers automatically after fault condition is removed -20~+60°C (Refer to "Derating Curve") 20~90%RH non-condensing -40~+85°C, 10~95%RH ±0.03%/°C(0~50°C) 10~500Hz, 2G 10min/1 cycle, 60min. each along X, Y, Z axes Safety Standards note. 6 UL60950-1, CB(IEC60950-1), CCC GB4943.1:2011 approved Withstand Voltage I/P-O/P:3KVAC I/P-FG:2KVAC O/P-FG:0.5KVAC Isolation Resistance I/P-O/P, I/P-FG, O/P-FG:100M Ohms/500VDC/25°C/70% RH EMC Emission Compliance to EN55022 (CISPR22) Class B, EN61000-3-2,-3 EMC Immunity Compliance to EN61000-4-2,3,4,5,6,8,11, EN55024, EN61000-6-1, light industry level, criteria A 註:1. All parameters NOT specially mentioned are measured at 230VAC input, rated load and 25°C of ambient temperature. 2. Ripple & noise are measured at 20MHz of bandwidth by using a 12" twisted pair-wire terminated with a 0.1uf & 47uf parallel capacitor. 3. Tolerance: includes set up tolerance, line regulation and load regulation. 4. Line regulation is measured from low line to high line at rated load. 5. Load regulation is measured from 0% to 100% rated load. 6. For the request of GB4943.1, the power supply is only suitable for use in the altitude 2000m below and the non tropical climate condition. 7. The power supply is considered a component which will be installed into a final equipment. The final equipment must be re-confirmed that is still meets EMC directives. 8. Please connect positive pole of input voltage with mark "L" of terminal block, connect negative pole of input voltage with mark "N" of terminal block, using DC voltage for input voltage. 18 Back to Contents The specification of Transformer MA-02 1. The Primary side input: AC 0V, 220V, 380V, E. 2. The secondary side have 3 sets output: (1) AC 15V, 0V, 15V (1.5A) (2) AC 0V, 24V, 50V (1.5A) (3) AC 0V, 24V, 50V (1.5A) 3. The total Watt: 195W 4. The diagram as follow: 19 Back to Contents TC500 Multi-Cavity Hot Runner Temperature Controller 1. Wiring Friendly design 2. Easy swapping for individual module failures 3. Compact size, light weight, installed directly on the injection molding machine 4. Automatic ID recognition 5. Fast alternative for 230V / 380V power input 1. Built-in NFB switch 2. Auto/Manual function 3. PID auto temperature control 4. Current, output percentage display function 5. Setting for output percentage limit 6. Heat sink temperature detection 7. Selectable two thermocouple types (J/K) 8. Selectable two temperature scales (°C/°F) 9. Selectable six alarm modes 10. Selectable two output trigger modes (Phase angle/Zero cross) 11. Temperature range: K TYPE: 0~600°C(32~999°F) / J TYPE: 0~600°C(32~999°F) 12. RS485 communication function: ASCII and RTU mode 13. Thermocouple break and inverse detect 14. Detection for heater open and short circuits 15. Detection fuse breakage 16. Automatic shutdown for heater abnormality 17. Automatic switch to manual mode if thermocouple breaks 20 Back to Contents 6 Zones (3 Modules) Bracket (fixed by screw M4) Unit: mm 12 Zones (6 Modules) Bracket (fixed by screw M4) Unit: mm 21 Back to Contents Products Overview GEFRAN AGENT & OTHER PRODUCTS Melt pressure Transducers M3/W3/K3 Series ME/WE/KE Series MN/WN/KN Series MD/WD/KD Series MX/WX Series MX4 MF/WF Series M6/W6 Series IE1/IN1/I3 IX M50 M51 M52 IJ-N (Voltage output)/IJ-D (Digital output) Pressure KS TK TKDA MJ-N (Voltage output)/MJ-D (Digital output) TSA TPS TPSA TPSADA TPF Transducers TPFADA TPH LT Displacement PC TPHADA PK XPSA PA1 XSA TDP PZ Series PME12 PMI12 PMISL PMISLE PMA12 LT67 PC67 PZ67A PZ67S ONP1-A PY Series IC PCIR Transducers MK4 Series Encode IK4 Series Controller / Alarm unit / Programmer RK2 Series PS Series EG 400 401 600 1000 1001 1101 4T48 4T96 40B48 40T72 40B96 40TB 2300 2308 2400 2500 / Indicator Ceramic Band Heater Ceramic Band Heater Insulation plus ceramic band heater 22 Air cooled ceramic band heater Back to Contents Products Overview Temperature Controllers V Series Temperature Controllers C Series Temperature Controllers A Series Temperature Controllers TC Series V100 V200 V300 V400 V500 C100 C200 C300 C400 C500 A1AN A2DD A3AA A3DA A3DD A4DA A4DD TC2DA TC3AO TC3AA TC3DA TC3DD TC4AA TC4DD Hot Runner Temperature Controllers TC5H Series Multi-Cavity Hot Runner Temperature Controllers TC5E Series Valve gate Controller TC5200 TC5100 TC500 TC5V Series Plastic Machine Controllers AR1260 AR1860 AR2000 AR2100 AR Series Solid State Relay ARD24 Series ARD48 Series ARV24 Series Solid State Relay ARA24 Series Signal transmitter Heatsoft SY Series SV Series SW Series 23 ARA48 Series SB Series TR100 Back to Contents 授權經銷商 DISTRIBUTORS ARICO TECHNOLOGY CO., LTD. 長新科技股份有限公司 總公司【Headquarters】 23145 台灣新北市新店區寶橋路 235 巷 1 弄 1 號 8 樓 8F., No. 1, Alley 1, Lane 235, Baoqiao Rd., Xindian Dist., New Taipei City 23145, Taiwan TEL:+886-2-2910-1266 FAX:+886-2-2915-9434 info@arico.com.tw www.arico.com.tw 台北工廠【Taipei Factory】 TEL:+886-2-2910-1077 FAX:+886-2-2910-1056 台中分公司【Taichung Branch】 華南總經銷–東莞亞洛克【Dong Guan】 TEL:+886-4-2291-7011 TEL:+86-769-8390-2101~3 FAX:+886-4-2292-4021 FAX:+86-769-8398-8791 台南分公司【Tainan Branch】 TEL:+886-6-253-9940 FAX:+886-6-253-9945 華東總經銷–上海瑞昂【Shanghai】 TEL:+86-21-6111-5256~9 FAX:+86-21-6227-0065 長新科技股份有限公司 保有權利於任何時間未經通知而修改或變更本手冊內容及型式,未經本公司同意,不得作任何形式的使用。 24 Back to Contents ARICO Technology Co., Ltd. Reserves the right to make any kind of design or functional modification at any moment without prior notice.