Manual - Peterson Electro

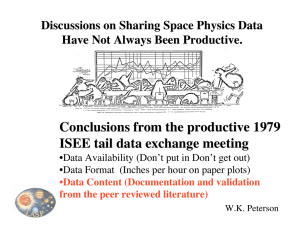

advertisement