DNV-RP-C206: Fatigue Methodology of

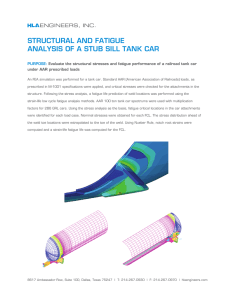

advertisement