83.214.xx06.3

83.210.xx81.3/ ...xx89.3

xx.xxx.xxxx.x

Wieland Electric GmbH

Brennerstraße 10-14

96052 Bamberg

Ph.: +49 (951) 9324-0

Fax: +49 (951) 9324-198

Internet: www.wieland-electric.com

E-mail: info@wieland-electric.com

podis MOT RA C 3I/RS485 SEW

ENGAssembly instructions

AS-i field distributor on energy bus

A. Important information - please read carefully

This addendum describes the assembly of the podis MOT RA C and its connection to

the energy bus. Please observe the warnings and notes at all times.

CAUTION

• All electrical installations and connections may be performed only by trained

electricians!

• The applicable safety and accident prevention regulations must be observed!

• The connectors may never be connected or disconnected under load!

• Before opening and removing the electronics cover, all cables must be de-energized.

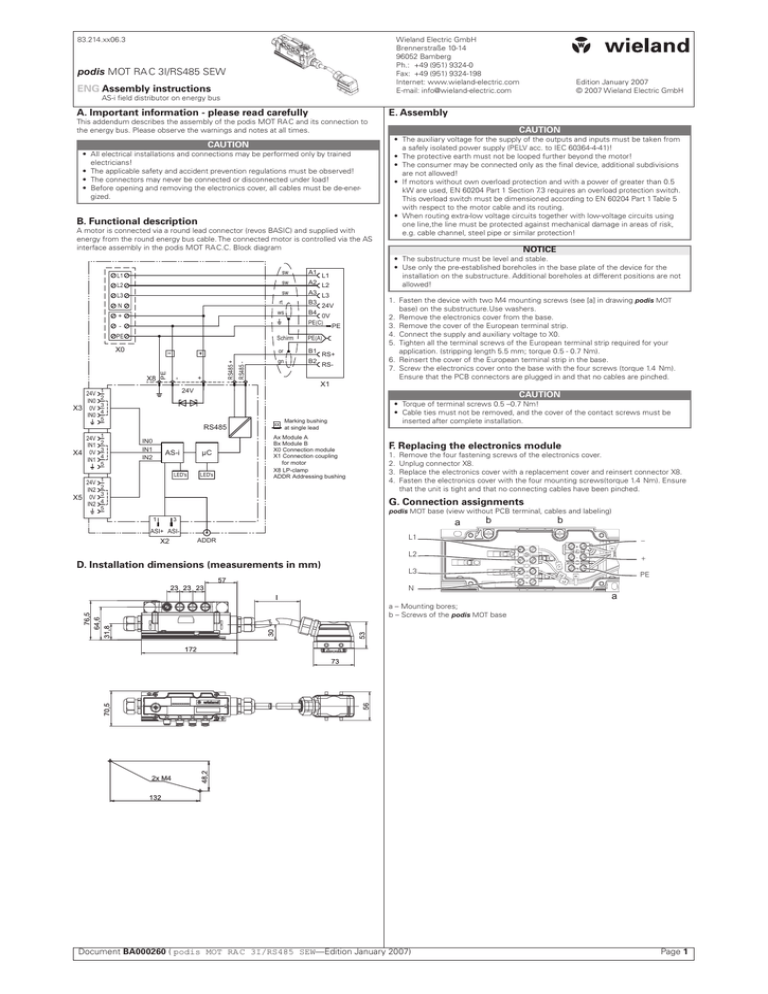

B. Functional description

A motor is connected via a round lead connector (revos BASIC) and supplied with

energy from the round energy bus cable. The connected motor is controlled via the AS

interface assembly in the podis MOT RA C.C. Block diagram

L1

L2

L3

N

+

sw

A1

sw

A2

sw

A3

rt

B3

ws

B4

PE

24V

IN0

X3 0V

IN0

1

2

3

4

5

24V

IN1

1

2

3

4

5

X4 0V

IN1

24V

IN2

X5 0V

IN2

RS485 -

RS485 +

+

-

X8

PE

X0

LED's

1

2

3

4

5

24V

or

B1

gn

B2

PE

RS+

RS-

X1

CAUTION

• The auxiliary voltage for the supply of the outputs and inputs must be taken from

a safely isolated power supply (PELV acc. to IEC 60364-4-41)!

• The protective earth must not be looped further beyond the motor!

• The consumer may be connected only as the final device, additional subdivisions

are not allowed!

• If motors without own overload protection and with a power of greater than 0.5

kW are used, EN 60204 Part 1 Section 7.3 requires an overload protection switch.

This overload switch must be dimensioned according to EN 60204 Part 1 Table 5

with respect to the motor cable and its routing.

• When routing extra-low voltage circuits together with low-voltage circuits using

one line,the line must be protected against mechanical damage in areas of risk,

e.g. cable channel, steel pipe or similar protection!

NOTICE

1. Fasten the device with two M4 mounting screws (see [a] in drawing podis MOT

base) on the substructure.Use washers.

2. Remove the electronics cover from the base.

3. Remove the cover of the European terminal strip.

4. Connect the supply and auxiliary voltage to X0.

5. Tighten all the terminal screws of the European terminal strip required for your

application. (stripping length 5.5 mm; torque 0.5 - 0.7 Nm).

6. Reinsert the cover of the European terminal strip in the base.

7. Screw the electronics cover onto the base with the four screws (torque 1.4 Nm).

Ensure that the PCB connectors are plugged in and that no cables are pinched.

CAUTION

RS485

AS-i

L3

PE(A)

24V

IN0

IN1

IN2

L2

Schirm

E. Assembly

• The substructure must be level and stable.

• Use only the pre-established boreholes in the base plate of the device for the

installation on the substructure. Additional boreholes at different positions are not

allowed!

L1

0V

PE(C)

Edition January 2007

© 2007 Wieland Electric GmbH

µC

LED's

xx

Marking bushing

at single lead

Ax Module A

Bx Module B

X0 Connection module

X1 Connection coupling

for motor

X8 LP-clamp

ADDR Addressing bushing

• Torque of terminal screws 0.5 –0.7 Nm!

• Cable ties must not be removed, and the cover of the contact screws must be

inserted after complete installation.

F. Replacing the electronics module

1.

2.

3.

4.

Remove the four fastening screws of the electronics cover.

Unplug connector X8.

Replace the electronics cover with a replacement cover and reinsert connector X8.

Fasten the electronics cover with the four mounting screws(torque 1.4 Nm). Ensure

that the unit is tight and that no connecting cables have been pinched.

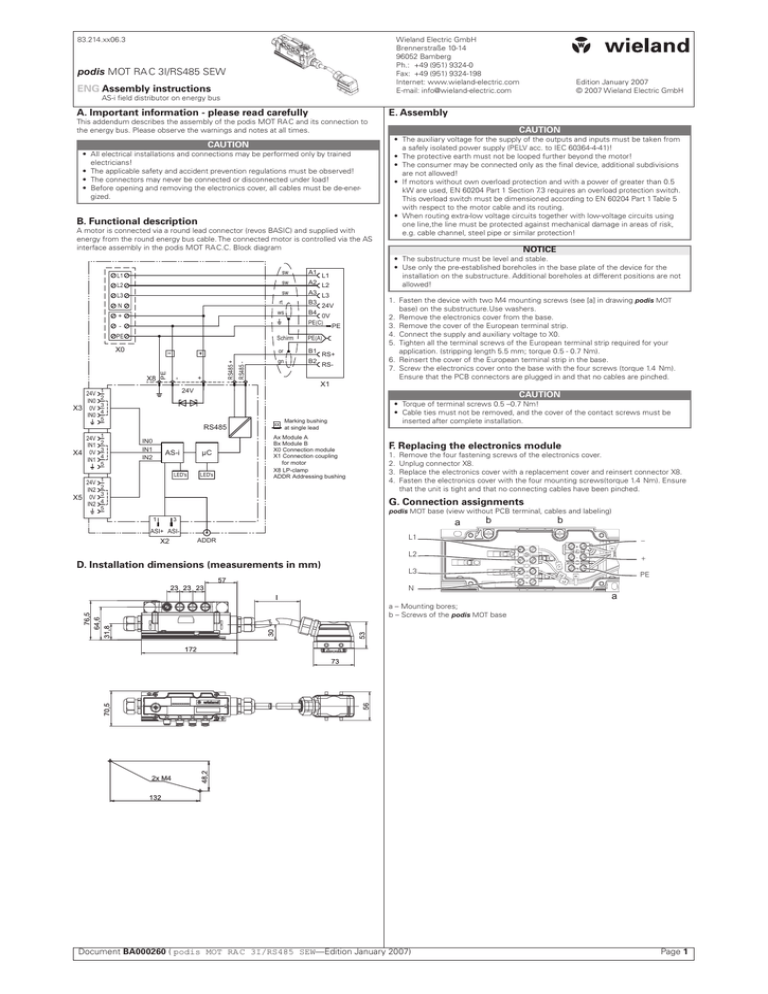

G. Connection assignments

1

podis MOT base (view without PCB terminal, cables and labeling)

3

�

ASI+ ASI-

X2

ADDR

D. Installation dimensions (measurements in mm)

�

�

L1

−

L2

+

L3

N

PE

�

a – Mounting bores;

b – Screws of the podis MOT base

Document BA000260 ( podis MOT RA C 3I/RS485 SEW—Edition January 2007)

Page H. Technical data

Motor connection coupling X1

orange

AC input

Input voltage Vsupply

Supply frequency input

AC output

Output voltage

Output current per phase

Output frequency

Connection (X1) to motor

black

green

black

red (+)

white (-)

negro

Border

Cable shielding

with wires

RS+, RS- and 0V,

24V on-hook

DC inputfor MOVIMOT electronics

supply, 24 V external

Input voltage

Power consumption for each MOVIMOT

AS interface

AS-i specification

green-yellow

Module C

Module A

Module B

Module

PIN

A

1

2

3

1

2

3

4

B

Designation

Meaning

L1

L2

L3

RS+

RS+

−

Motor lead voltage U

Motor lead voltage V

Motor lead voltage W

RS485 signal voltage +

RS485 signal voltage 24 VDC of external voltage (from 24-V power supply)

0 V of external voltage (from 24-V power supply)

AS interface connection X2 (M12)

(view from outside onto plug contacts)

Pin

Brief description

1

3

2, 4, 5

AS interface +

AS interface −

Comments

Contacts not fitted

Digital inputs X3, X4, X5 (M12)

(view from outside onto socket contacts)

�

�

�

Pin

Brief description

Comments

1

2/42

3

5

24 V

INx

0V

Ground

24-V sensor supply1

Digital inputs

0V Sensor-Versorgung1

Equipotential bonding

The digital inputs at X3, X4 and X5 are supplied from the

AS interface

2

Pin 2 and 4 are internally bridged

1

�

�

CAUTION

To be able to ensure enclosure IP 65, all unused inputs or outputs must be fitted

with protection covers!

Meaning of LEDs on the housing cover

����������

No.

Color

Designation

Meaning

1

Green

AS-i power

AS-i power ok.

2

Red

AS-i fault

Fault of AS-i

3

Yellow

IN 0

Input M12

IN0

���

4

Yellow

IN 1

Input M12

IN1

���

5

Yellow

IN 2

Input M12

IN2

����

6

Yellow

M ok

Motor is operational

IN3

�����

7

Yellow

M fwd

CW rotation of motor

�����

8

Yellow

M rev

CCW rotation of motor

9

Yellow

M RS485

RS485

10

Red

M fault

Fault of motor

�������

�������

AS-i voltage, min.

Current consumption from AS-i

Addressing option

Digital inputs

Digital inputs (via AS-i)

Input current

Input resistance

Supply current of initiators

Signal level VHIGH / VLOW

Scan time

General data

Environmental conditions (overall device)

Overvoltage category

Fire behavior of contact carriers

Temperature ranges

– Operating environment

– Storage/transport

Vibration

Air humidity

Enclosure

Protection class

Mounting position

Dimensions

Vsupply (input voltage)

max. 16 A (observe line fusing!)

50 Hz ±10% (45 Hz...55 Hz)

Hybrid cable max. 5 m (RS485 interface,

integrated bus termination;24 V supply voltage, damping diode; L1, L2, L3 and PE)

24 VDC ± 20 % (19.2 V…28.8 V)

approx. 0.2 W (without inputs and outputs)

V2.11, single slave, profile S7.4, identification 74F0

31

max. 30 cm tap line per module + 100 m

AS interface line

26.5 V

max. 280 mA

DC socket 1.3 mm

3 (IN0, IN1, IN2)

typ. 5 mA

typ. 5 kΩ

max. 50 mA for each initiator

+15 V…+31.5 V/ −3 V…+5 V

approx. 5 ms

Industrial atmosphere

3

min. UL94V2

0…50 °C

−25 °C…60 °C/ −25 °C…+70 °C

IEC 60721-3-3 Class 3M6

100 %, non-condensing

IP 65 acc. to EN 60529

Class 1 acc. to 60536

any (preferablyhorizontal wall mounting)

see under "D. Installation dimensions"

I. Ordering information

Accessories

• AS-i tap line 30 cm

• AS-i branching profile line M12

• AS-i hand-held PPG 1

• Programming cable AS-i 1.5 m

Spare parts

• Electronics module

• European terminal strip 6ETS 3 pins

• European terminal strip 6ETS 4 pins

• Motor cable, complete

83.209.2203.0

83.209.2201.0

83.209.2204.1

83.209.2205.0

83.209.2102.2

99.360.4379.9

99.361.4379.9

Upon request

I/O bit

���

����������

Number of addressable slaves

Line length

230/400 VAC

50 Hz ±10 % (45 Hz…55 Hz)

Operating indicators

Check the device for safe functioning. The operating state of the AS-i slave is indicated

as follows by LED 1 and 2:

No.

LED

Status

Meaning

1

2

Green

Red

constantly on

constantly on

2

Red

flashing

Voltage supply ok.

Communication error at AS interface, slave

does not participate in normal data traffic (e.g.

slave address 0)

Periphery error, e.g. short circuit of AS-i

voltage

© 2007 Wieland Electric GmbH. All rights reserved. Third-party products are used without reference to patent rights. For this reason, the existence of such rights should not

be excluded. Any type of changes to the hardware or software of WIELAND products

results in the exclusion of liability by WIELAND ELECTRIC GmbH.

Document BA000260 ( podis MOT RA C 3I/RS485 SEW—Edition January 2007)

Page