e-News

Issue 71 April 2010

Evaporative Cooling: Saving

Energy in More Ways Than Ever

Introduction

Types of Evaporative Cooling

Benefits

Applications

Water Use and Treatment

Training Highlights

About e-News

Innovations in Evaporative Cooling and Water

Treatment

Introduction

vaporative coolers provide cool air by forcing hot dry air over a wetted

pad. The water in the pad evaporates, removing heat from the air while

adding moisture. Although the concept has been used in residential

“swamp” coolers in the Southwest for decades, technology advances have

made evaporative cooling a viable alternative to conventional cooling in

commercial buildings and in other areas of the country. Manufacturers

have begun to offer two-stage (“indirect-direct”) evaporative coolers that

offer greater cooling effectiveness, extending the geographic range where

evaporative cooling can be used.

E

Evaporative Cooling

Case Study

The Race Health Sciences Building at

Santa Rosa Junior College in Santa Rosa,

CA uses three indirect-direct evaporative

cooling (IDEC) units to provide cooling

to the 38,500 ft² building. On a

record setting day with 101°F drybulb temperatures, the IDEC systems

were able to maintain indoor space

temperatures within comfort levels and

maintain indoor humidity levels between

50% and 60% without the need for the

chiller. Santa Rosa Junior College is

reusing the design for other buildings on

campus.

Types of Evaporative Cooling

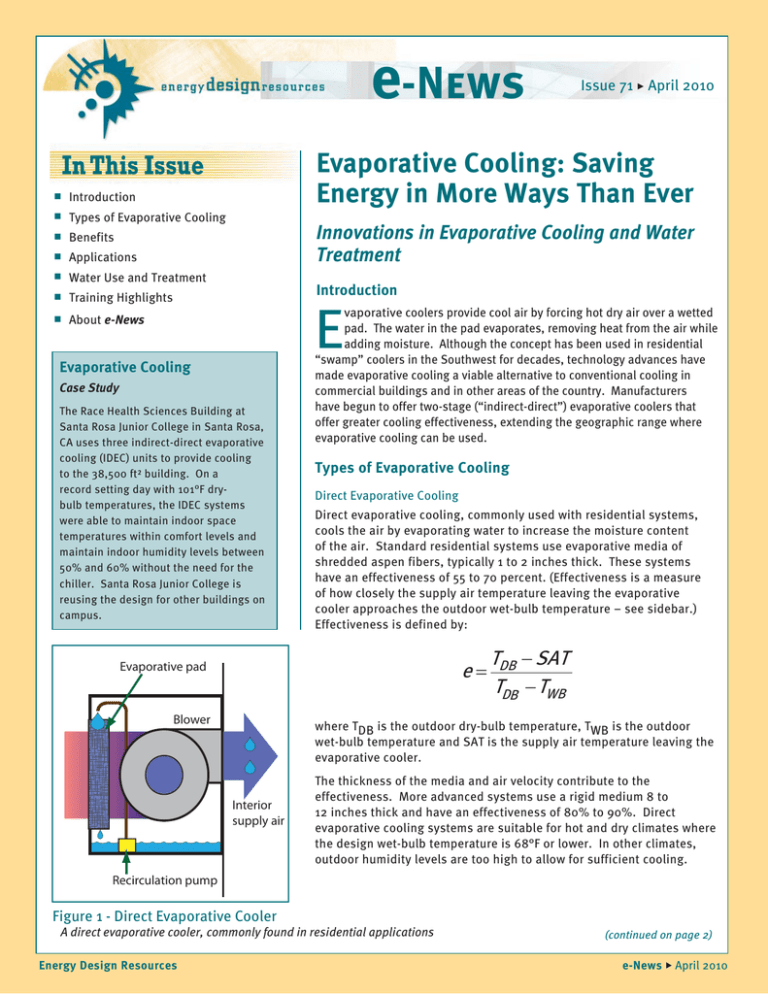

Direct Evaporative Cooling

Direct evaporative cooling, commonly used with residential systems,

cools the air by evaporating water to increase the moisture content

of the air. Standard residential systems use evaporative media of

shredded aspen fibers, typically 1 to 2 inches thick. These systems

have an effectiveness of 55 to 70 percent. (Effectiveness is a measure

of how closely the supply air temperature leaving the evaporative

cooler approaches the outdoor wet-bulb temperature – see sidebar.)

Effectiveness is defined by:

Evaporative pad

e

Blower

TDB SAT

TDB TWB

where TDB is the outdoor dry-bulb temperature, TWB is the outdoor

wet-bulb temperature and SAT is the supply air temperature leaving the

evaporative cooler.

Interior

supply air

The thickness of the media and air velocity contribute to the

effectiveness. More advanced systems use a rigid medium 8 to

12 inches thick and have an effectiveness of 80% to 90%. Direct

evaporative cooling systems are suitable for hot and dry climates where

the design wet-bulb temperature is 68°F or lower. In other climates,

outdoor humidity levels are too high to allow for sufficient cooling.

Recirculation pump

Figure 1 - Direct Evaporative Cooler

A direct evaporative cooler, commonly found in residential applications

Energy Design Resources

(continued on page 2)

e-News April 2010

moisture. The air is then passed through a direct stage,

which cools the air further while adding moisture. IDEC

systems typically have an effectiveness of 100% to

115%, cooling the air to a temperature slightly below the

outdoor air wet-bulb temperature (see sidebar).

Indirect Evaporative Cooling

Indirect evaporative cooling uses an air to air heat

exchanger to remove heat from the primary air stream

without adding moisture. In one configuration, hot

dry outside air is passed through a series of horizontal

tubes that are wetted on the outside. A secondary air

stream blows over the outside of the coils and exhausts

the warm, moist air to the outdoors. The outside air is

cooled without adding moisture as it passes through

the tubes. Indirect evaporative cooling typically has an

effectiveness of 75%.

For commercial systems, indirect-direct systems are

often coupled with a conventional DX cooling stage to

meet cooling demand during hot and humid outdoor

conditions (when outdoor air dry-bulb temperatures

exceed 70°F). Since the systems use 100% outside air

for cooling, they can also be paired with heat recovery to

capture some of the energy that is lost in the exhaust air

stream and reduce the ventilation cooling load.

Another system type that is used in residential and light

commercial applications uses the Maisotsenko cycle,

which uses a cross-channel heat exchanger that cools

the air incrementally over a large number of stages.

Systems using the Maisotsenko cycle can have wet-bulb

effectiveness values of 85% to over 100% (cooling the

supply air to below the wet-bulb temperature). While

the greater number of air passes increases the pressure

drop and the required fan power, the high effectiveness

extends the geographic range where the indirect

evaporative cooler can fully meet the cooling demand.

IDEC systems used in arid climates (with a design wetbulb temperature of 66°F or lower) can have power

consumption as low as 0.22 kW/ton, much lower than

compressor-based cooling which can have power

consumption on the order of 1 kW/ton. However, in more

humid climates indirect-direct systems have less power

reduction and energy savings.

Evaporative Pre-Cooling

Evaporative pre-coolers reduce air conditioner load

by cooling the air that surrounds air conditioner

condensers. Since the cooler, moister air is passed

over the condenser, the moisture is not added to the

space. The cooler air passed across the condenser coil

improves heat transfer efficiency, allowing the system to

run efficiently during hot outdoor conditions. Also, since

peak cooling capacity is increased it may be possible

to downsize equipment. Pre-coolers are generally only

used in hot and dry climates on large units of 40 tons or

greater.

Two Stage Systems

Indirect cooling is often paired with a second direct

evaporative cooling stage, to cool the supply air further

while adding some moisture to the supply air. Such

two-stage systems (referred to as indirect-direct or IDEC

systems) can meet the entire cooling load for many

buildings in arid to semi-arid climates. IDEC systems

provide cooler supply air at a lower relative humidity

than direct evaporative coolers. The first indirect stage

cools the supply air without increasing humidity. Since

the air is cooled it has a reduced capacity to hold

Evaporative Cooling Effectiveness

The cooling capacity of an evaporative cooler is limited by the outdoor wet-bulb temperature. The following table

shows supply air temperatures typically achievable with direct and indirect-direct (IDEC) evaporative coolers.

City

Sacramento

Palm Springs

Los Angeles

San Diego

San Jose

San Francisco

Design DB

100.4

111.2

83.7

84.1

92.3

83

Design WB

Direct Supply Air

Temperature

70.7

72.5

64.3

67.7

66.9

63

75.2

78.3

67.2

70.2

70.7

66.0

Indirect-Direct Supply Air

Temperature

67.7

68.6

62.4

66.1

64.4

61.0

Assumptions: weather data is ASHRAE 0.4% design dry-bulb and mean coincident wet-bulb; assumed effectiveness of

85% for direct and 110% for indirect-direct evaporative coolers.

(continued on page 3)

Energy Design Resources

2

e-News April 2010

Evaporatively Cooled Condensers

Evaporative pad

Vented

moist air

Exterior air

Exterior air

Blower

Evaporative

heat exchanger

Interior

supply air

Recirculation pump

Figure 2 - Indirect-Direct Evaporative Cooler (IDEC)

Typical air-cooled condensers used

with direct-expansion (DX) systems

lose efficiency significantly during hot

outdoor conditions. Evaporatively-cooled

condensers allow heat to be rejected

at a much cooler temperature, which

allows the system to operate at a much

higher efficiency during peak conditions.

Peak demand can be reduced by 40% in

comparison to air-cooled DX systems.

These systems provide the greatest benefit

in climates that have significant hours of

cooling during outdoor temperatures of

95°F or greater. Although these systems are

relatively common in larger cooling plants,

products are now available for residential

and light commercial applications.

Controls

Advanced features on evaporative coolers recently introduced to the market include variable air volume control.

Some units use variable-speed drives, or two-speed or electrically commutated motors for smaller units, to control the

space temperature to the desired setpoint. Lower air velocity increases heat transfer effectiveness and significantly

reduces system fan power.

An advanced feature not commonly available on evaporative coolers would include the use of sensors to monitor

system performance. Temperature and humidity measurements would allow for an estimate of system effectiveness.

Static pressure gauges that measure pressure drop across the media can also be used to determine when

maintenance of the media is required.

Due to the higher air temperatures than traditional air conditioning systems, much more air must be used to provide

the necessary cooling. As it is generally 100% outside air, provisions must

be made for venting the air to the outside without requiring the opening

Related Resources

of windows. With residential applications, vents installed in the ceiling

Assessment of Market-Ready Evaporative

(known as an “up duct”) are designed to open when the home is positively

Technologies for HVAC Applications, New

pressurized. Sufficient attic ventilation must be provided to then exhaust

Buildings Institute Report, 2006

the ventilation air to the outside.

http://www.newbuildings.org/documentlibrary

Benefits

Evaporative cooling systems have a number of benefits. First and

foremost, they use only a fraction of the energy of typical compressorbased cooling systems. Highly efficient evaporative cooling systems can

reduce energy use by 70%. (The actual savings will vary with the type of

evaporative system and the climate.) For dry climates where evaporative

cooling can meet the entire load, they dramatically reduce peak demand.

When evaporative cooling is used with supplemental DX cooling it can

reduce the DX cooling required. Moreover, since they use 100% outside

air for cooling, the right evaporative cooling system can provide good

indoor air quality.

Residential direct evaporative cooling systems cost much less than

DX cooling systems. However, two-stage units used for commercial

applications can cost as much as or more than conventional cooling

systems, since they are often custom-built. With the water pump and fan

as the primary serviceable components, evaporative cooling systems can

have low maintenance costs. Southern California Edison offers rebates of

$300 to $600 for qualifying evaporative coolers.

Southwest Energy Efficiency Project,

SWEEP / WCEC Workshop Summary,

Workshop on Modern Evaporative Cooling

Technologies, 2007

http://www.swenergy.org/events/

evaporative/Summary.pdf

Advanced Evaporative Cooling White

Paper, Davis Energy Group, 2004

http://www.energy.ca.gov/

reports/2004-04-07_500-04-016_AT1.PDF

ASHRAE Handbook, HVAC Systems and

Equipment, 2008.

http://www.ashrae.org/publications/

(continued on page 4)

Energy Design Resources

3

e-News April 2010

Applications

About e-News

D

on’t miss future issues—to sign up

for a free email subscription, please

visit www.energydesignresources.com.

Send letters to the editor, suggestions on

topics for future issues, or other comments to

enews@energydesignresources.com.

e-News is published by Energy Design

Resources (www.energydesignresources.

com), an online resource center for

information on energy efficiency design

practices in California.

Savings By Design

(www.savingsbydesign.com) offers design

assistance and incentives to design teams

and building owners in California to

encourage high-performance nonresidential

building design and construction.

Energy Design Resources and Savings

By Design are funded by California utility

customers and administered by Pacific Gas

and Electric Company, Sacramento Municipal

Utility District, San Diego Gas and Electric,

Southern California Edison and Southern

California Gas Company, under the auspices

of the California Public Utilities Commission.

Evaporative cooling has a number of applications in the residential

and light commercial markets. Direct evaporative cooling is primarily

used in very hot and dry regions and residential markets. Indirectdirect evaporative cooling can be used throughout most of California.

Since 100% outdoor air is used, it has significant secondary benefits in

applications with high outdoor air requirements such as classrooms.

Recently, the more advanced indirect and indirect-evaporative coolers

have been developed for the residential and light commercial market.

Indirect evaporative cooling can be coupled with conventional DX cooling

to lower refrigeration loads. A system using indirect evaporative cooling

with DX cooling can have a lower total cooling load than a recirculation

system using only DX cooling. Sutter Warrick Hospital in Santa Rosa,

California used this configuration to provide improved indoor air quality

in conjunction with reduced cooling load.

Water Use and Water Treatment

Water is used with evaporative systems to both replace the evaporated

water and to purge dissolved minerals that accumulate as water

evaporates. Residential systems typically use 5 to 10 gallons of water

per hour of operation. Most high efficiency units meet water use levels

recommended by the California Energy Commission (0.15 gpm/ton or

lower). This water consumption is partially offset by the reduced power

consumption of evaporative cooling units, since the reduced load reduces

water consumption at the power plant.

Water treatment is a concern, especially for areas of the desert southwest

that have hard water. Mineral deposits will accumulate in the sump and

eventually cause scale on the pads. One option is a bleed-off system, which diverts a small amount of water out of

the distribution basin to dilute mineral concentrations. The bleed rate depends upon water hardness and airborne

contaminant levels and can range from 5% to 100% of the evaporation rate. A blow-down system will periodically

dump water from the sump while the cooler is in operation. The discharged water can be used to water gardens.

Blow-down systems have an advantage over bleed-down systems in that they discharge accumulated dirt and debris

that collects at the bottom of the sump, and they often use less water than continuous bleed systems. A third option

is water treatment. Water treatment is often recommended for systems with rigid media due to high replacement

costs. Other treatment mechanisms include electromagnetic, electrostatic, catalytic and mechanical.

Training Highlights

California utilities offer outstanding educational opportunities

that focus on the design, construction and operation of energyefficient buildings. Listed here are a few of the many upcoming

classes and events; for complete schedules, visit each utility’s

website.

Green Buildings - Proven Emerging Technologies

Emerging efficient HVAC systems for various types of buildings

will be presented in terms of advantages and disadvantages.

HVAC systems to be discussed include chilled beam, positive

displacement, variable refrigerant flow, underground air

distribution, and VAV systems. San Diego Energy Resource

Center. May 19, 8:00am to 12:00pm, San Diego. https://

seminars.sdge.com

Compressorless Cooling

Learn about the design and installation of compressorless cooling

technologies. Topics to be covered include whole house cooling

fans, single-stage direct evaporative cooling, indirect/direct twostage evaporative cooling, residential economizers, and utility

rebates for whole house cooling fans and evaporative coolers.

Pacific Energy Center. April 15, 9:00am to 4:30pm, Stockton

ETC. http://www.pge.com/mybusiness/edusafety/training/pec/

classes/

Evaporative Cooling for Commercial and Industrial Facilities

Evaporative cooling will be explored as an energy efficient

and cost effectie means of cooling commercial and industrial

buildings. Participants will learn about the technology, climate

zone, economic considerations, maintenance, and water treatment

related to evaporative cooling. http://www.sce.com/ECR/

© 2004–2010 Energy Design Resources. All Rights Reserved.

Energy Design Resources

4

e-News April 2010