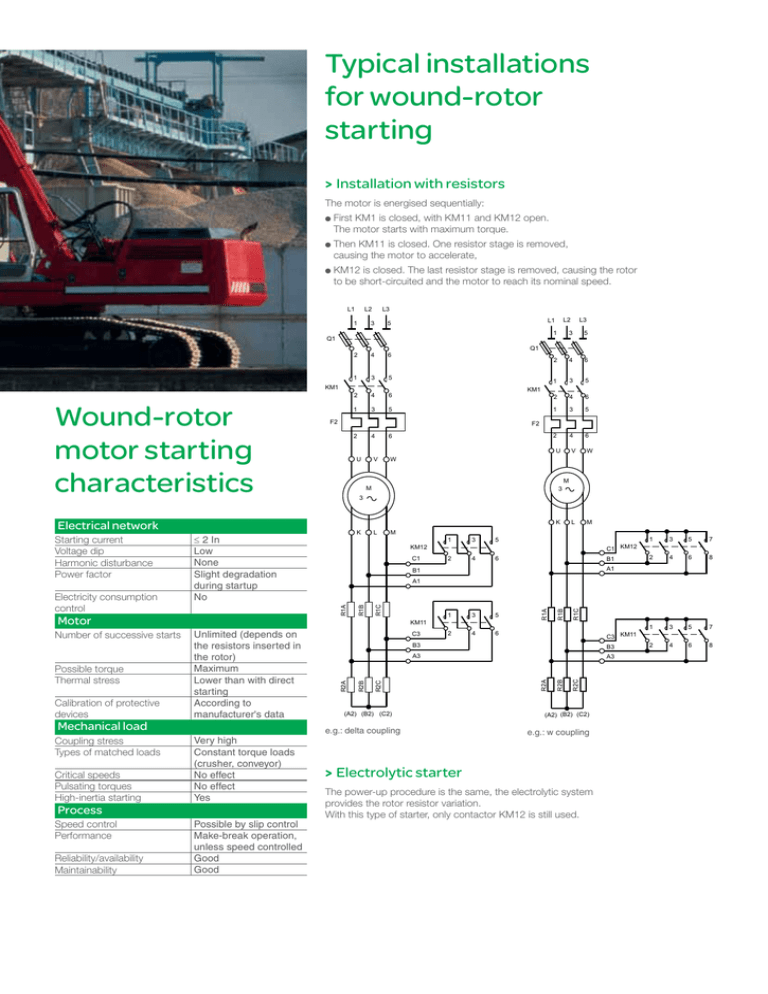

Typical installations

for wound-rotor

starting

> Installation with resistors

The motor is energised sequentially:

irst KM1 is closed, with KM11 and KM12 open.

F

The motor starts with maximum torque.

hen KM11 is closed. One resistor stage is removed,

T

causing the motor to accelerate,

M12 is closed. The last resistor stage is removed, causing the rotor

K

to be short-circuited and the motor to reach its nominal speed.

L2

L1

L3

3

1

Q1

2

4

6

1

3

5

2

4

6

1

3

5

2

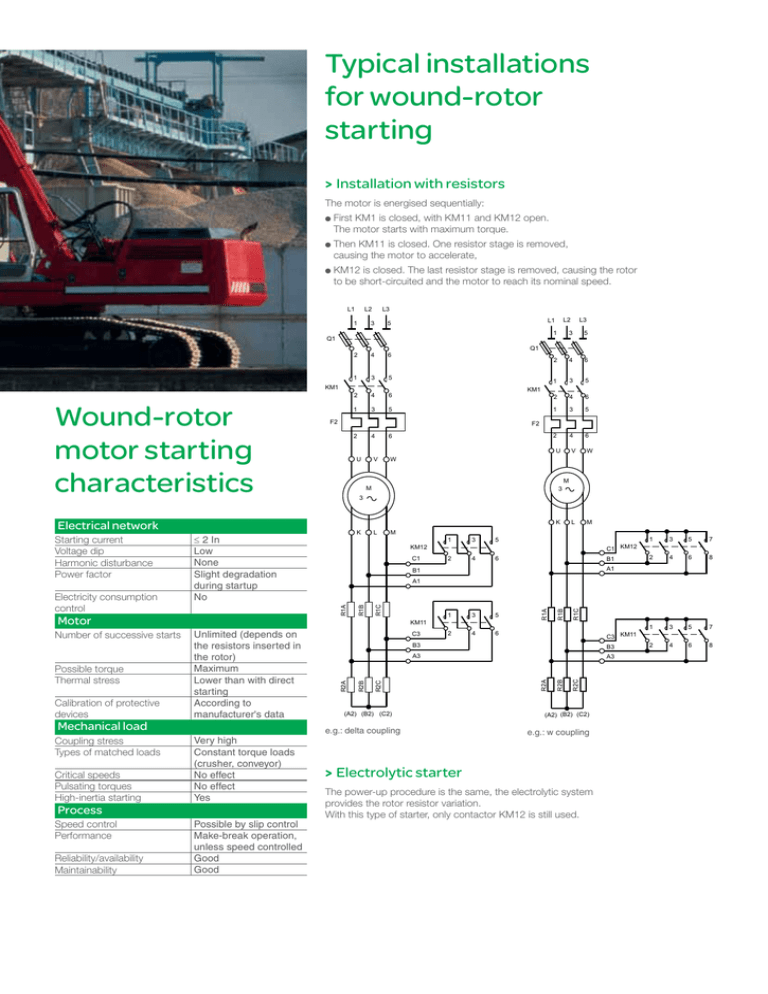

Calibration of protective

devices

Mechanical load

Coupling stress

Types of matched loads

Critical speeds

Pulsating torques

High-inertia starting

Process

Speed control

Performance

Reliability/availability

Maintainability

4

2

4

6

1

3

5

2

4

6

1

3

5

6

2

4

6

V

W

L

M

U

U

V

W

M

3

M

3

K

≤2 In

Low

None

Slight degradation

during startup

No

L

M

KM12

C1

Possible by slip control

Make-break operation,

unless speed controlled

Good

Good

5

2

4

6

C1 KM12

B1

1

3

5

7

2

4

6

8

1

3

5

7

2

4

6

8

A1

C3

5

2

4

6

R1C

3

R1B

1

R1A

R1C

C3 KM11

(A2) (B2) (C2)

e.g.: delta coupling

R2C

A3

R2B

B3

A3

R2C

B3

R2A

R1B

R1A

Very high

Constant torque loads

(crusher, conveyor)

No effect

No effect

Yes

3

A1

KM11

Unlimited (depends on

the resistors inserted in

the rotor)

Maximum

Lower than with direct

starting

According to

manufacturer's data

1

B1

R2B

Possible torque

Thermal stress

5

K

Motor

Number of successive starts

3

F2

R2A

Electricity consumption

control

KM1

F2

Electrical network

Starting current

Voltage dip

Harmonic disturbance

Power factor

L3

1

Q1

KM1

Wound-rotor

motor starting

characteristics

L2

L1

5

(A2) (B2) (C2)

e.g.: w coupling

> Electrolytic starter

The power-up procedure is the same, the electrolytic system

provides the rotor resistor variation.

With this type of starter, only contactor KM12 is still used.

To find out more about

TeSys B contactors

General documentation:

> Refer to the variable-composition contactor catalogue and the other

data sheets on TeSys B contactors.

> Download the "Soft-CustomerB" software.

Schneider Electric Industries SAS

35, rue Joseph Monier

CS 30323

F- 92506 Rueil Malmaison Cedex

RCS Nanterre 954 503 439

Capital social 896 313 776

www.schneider-electric.com

EDCED110014EN

As standards, specifications and designs change from time to time, please ask for confirmation of

the information given in this publication.

Printed on ecological paper

Publication: Schneider Electric

Design-Layout: SEDOC

Printing: Altavia connexion

04-2012

© 2012- Schneider Electric - All rights reserved.

www.schneider-electric.com

TeSys B bar-mounted contactors

Starting high-power

wound-rotor AC motors

Soft-start your AC motors

(> 400 kW) gradually without

reducing the torque

Soft-starting wound-rotor AC motors involves removing rotor resistors until the rotor

is short-circuited.

This makes it possible to start the motor with the maximum torque (fig. 1a-2a),

whilst reducing the inrush current (fig. 1b-2b).

This type of motor is found in lifting applications, as well as in crushers, mixers, centrifuges or

even conveyors and any Medium-Voltage motor application where it is necessary to limit the

starting current.

It is used in industrial facilities, for example iron and steel, naval, water and water treatment

installations, as well as harbour infrastructures, mines, quarries and paper mills.

3-stroke starting

4-stroke starting

Torque

Torque

Current

Current

2.5

Secon

d-

Sec

o

nd-

3

ew

it h

ou

tr

stro

ke

t

2

es

is

1.5

to

r

orq

ue

6

ithout resistor

ue w

Torq

rque

e to

ro k

ue

orq

et

rok

-st

5

4

oke

tor

qu

e

Torq

u

Third

-

st

1

6

Se

co

nd

Firs

t-st

r

s to r

t resi

1.5

u

tho

wi

ue

orq

et

ok

str

2

7

2.5

7

rque

To

First-str

o

ke to

rqu

e

1

1

Speed

0

fig.1a

0.25

0.50

0.75

1

4

First-strok

e

0

torqu

0.5

e

1

Speed

0.25

0.50

0.75

fig.1b

1

Speed

0

fig.2a

0.25

0.50

0.75

1

Tor

que

wit

ho

ut

res

ist

Thir

d-st

roke

3

2

2

0.5

5

torq

Seco

nd-st

roke

First-stroke t

or

0

or

ue

torq

ue

que

Speed

0.25

0.50

0.75

fig.2b

Note: this starting method allows the motor torque and the starting current required at each stage to be defined according

to the values of the rotor resistors.

> Provides a very good torque/current ratio at startup (lifting) to optimise the dimensioning of the electrical

installation and avoid in-line voltage drops.

> Makes it possible to adjust the starting torque and current.

> Avoids power failures during the startup period.

> In accordance with IEC 60947-4-1, the contactor utilisation categories for this type of starting are AC1

for the rotor and AC3 for the stator.

1

Our TeSys B range of bar-mounted

Designed to control AC motors from 400 kW to 900 kW, for all v

TeSys B range of bar-mounted contactors

Line contactor KM1

(stator)

Rotor resistor short-circuiting contactors*

KM11, KM12

AC3 utilisation category.

From the motor torque and starting current required for each stage

according to the application and depending on the type of contact

coupling:

Coupling : 4 contacts

Coupling: 2 contacts

Star coupling: 3 contacts

Delta coupling: 3 contacts

Depending on the characteristics of the motor

to be supplied, choose the range:

Line contactor KM1 (stator)

Motor

Power

Power factor

Rated voltage

Current frequency

Calculation to be

carried out

Rated current of

the contactor in

AC3*

Choose the range according to the rotor voltage:

* See table opposite

Rotor resistor short-circuiting contactors KM11, KM12

Rotor

Rotor voltage

Rotor steady state and

starting current

Calculation to be carried out

Resistance to be defined by the customer

* These contactors can be mounted on MV motors whose rotor voltage is less than 3000 V.

Selection table

Contactor

Line contactor KM1 (stator)

Motor (stator) supply voltage

690 V

1000 V

CV1B

CV3B, LC1B

Note : for motors less than 400 kW, choose TeSys F range.

Contactor

Rotor resistor short-circuiting

contactors KM11, KM12

Rotor voltage

< 2000 V

> 2000 V

TeSys F range or CV1B, CV3B, LC1B

Special construction (reinforced

insulation) CV1B, CV3B

The devices are designed to operate at an ambient temperature of 40°C. Current derating is required for higher temperatures.

contactors

voltages ≤ 1500 V for stators and 3000 V for rotors.

How to size the contactors?

Three-phase 4-pole motor (current values for power in kW)

Rated operating power (1)

Guideline values for rated operating currents at:

400 V

kW

500 V

690 V

A

A

A

400

690

552

400

500

850

680

493

560

950

760

551

630

1060

848

615

710

1190

952

690

800

1346

1076

780

900

1518

1214

880

1000

1673

1339

970

(1) Values in accordance with the IEC 60072-1 standard (at 50 Hz).

Note: The values given in this table are for information only, as they vary according to the type of motor, its polarity and the manufacturer.