Temposonics

®

Magnetostrictive, Absolute, Non-contact

Linear-Position Sensors

Load-Frame Monitoring for

Injection-Molding Machines

®

SENSORS

Document No.: 551068

Revision A

Case Study

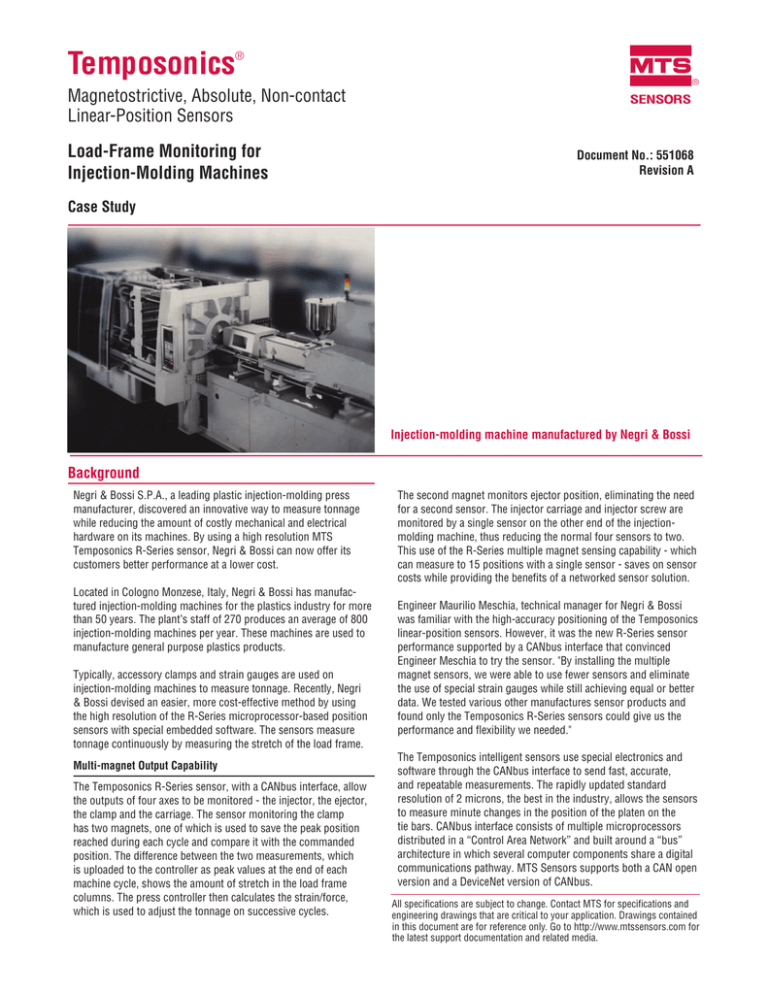

Injection-molding machine manufactured by Negri & Bossi

Background

Negri & Bossi S.P.A., a leading plastic injection-molding press

manufacturer, discovered an innovative way to measure tonnage

while reducing the amount of costly mechanical and electrical

hardware on its machines. By using a high resolution MTS

Temposonics R-Series sensor, Negri & Bossi can now offer its

customers better performance at a lower cost.

Located in Cologno Monzese, Italy, Negri & Bossi has manufactured injection-molding machines for the plastics industry for more

than 50 years. The plant’s staff of 270 produces an average of 800

injection-molding machines per year. These machines are used to

manufacture general purpose plastics products.

Typically, accessory clamps and strain gauges are used on

injection-molding machines to measure tonnage. Recently, Negri

& Bossi devised an easier, more cost-effective method by using

the high resolution of the R-Series microprocessor-based position

sensors with special embedded software. The sensors measure

tonnage continuously by measuring the stretch of the load frame.

Multi-magnet Output Capability

The Temposonics R-Series sensor, with a CANbus interface, allow

the outputs of four axes to be monitored - the injector, the ejector,

the clamp and the carriage. The sensor monitoring the clamp

has two magnets, one of which is used to save the peak position

reached during each cycle and compare it with the commanded

position. The difference between the two measurements, which

is uploaded to the controller as peak values at the end of each

machine cycle, shows the amount of stretch in the load frame

columns. The press controller then calculates the strain/force,

which is used to adjust the tonnage on successive cycles.

The second magnet monitors ejector position, eliminating the need

for a second sensor. The injector carriage and injector screw are

monitored by a single sensor on the other end of the injectionmolding machine, thus reducing the normal four sensors to two.

This use of the R-Series multiple magnet sensing capability - which

can measure to 15 positions with a single sensor - saves on sensor

costs while providing the benefits of a networked sensor solution.

Engineer Maurilio Meschia, technical manager for Negri & Bossi

was familiar with the high-accuracy positioning of the Temposonics

linear-position sensors. However, it was the new R-Series sensor

performance supported by a CANbus interface that convinced

Engineer Meschia to try the sensor. "By installing the multiple

magnet sensors, we were able to use fewer sensors and eliminate

the use of special strain gauges while still achieving equal or better

data. We tested various other manufactures sensor products and

found only the Temposonics R-Series sensors could give us the

performance and flexibility we needed."

The Temposonics intelligent sensors use special electronics and

software through the CANbus interface to send fast, accurate,

and repeatable measurements. The rapidly updated standard

resolution of 2 microns, the best in the industry, allows the sensors

to measure minute changes in the position of the platen on the

tie bars. CANbus interface consists of multiple microprocessors

distributed in a “Control Area Network” and built around a “bus”

architecture in which several computer components share a digital

communications pathway. MTS Sensors supports both a CAN open

version and a DeviceNet version of CANbus.

All specifications are subject to change. Contact MTS for specifications and

engineering drawings that are critical to your application. Drawings contained

in this document are for reference only. Go to http://www.mtssensors.com for

the latest support documentation and related media.

Non-Contacting Technology

Temposonics R-Series sensors feature a magnetostrictive design

which uses a non-contacting technology, which eliminates

maintenance and premature failure problems commonly associated

with other position sensing methods. The waveguide assembly and

electronics are each fully encapsulated, allowing for more durability

in rugged, industrial environments.

Negri & Bossi now specifies Temposonics R-Series sensors with a

CANbus interface on all their new injection-molding machines. The

high resolution and accuracy inherent in the Temposonics design

has allowed Negri & Bossi to offer its customers better quality and

performance at a lower cost.

Both V370 and V480 injection-molding machines, which were the

first Negri & Bossi machines to feature Temposonics sensors,

were first introduced at the Plast ‘97 Show in Milan. In addition to

eliminating the load cell, Negri & Bossi has also opted to replace the

linear potentiometers, used for positioning, with Temposonics position sensors. According to Engineer Maurilio Meschia, the improved

quality and performance of the machines is directly attributable

to the accuracy and resolution of the R-Series sensor. "We have

switched all of our series to the new Temposonics R-Series system

with CANbus interface."

Part Number: 551068 Revision A 12-05, 02-09

MTS and Temposonics are registered trademarks of MTS Systems Corporation.

All other trademarks are the property of their respective owners.

All Temposonics sensors are covered by US patent number 5,545,984. Additional patents are pending.

Printed in USA. Copyright © 2009 MTS Systems Corporation. All Rights Reserved in all media.

MTS Systems Corporation

Sensors Division

MTS Sensor Technologie

GmbH & Co. KG

MTS Sensors Technology

Corporation

3001 Sheldon Drive

Cary, North Carolina,

27513, USA

Tel.: +1-800-633-7609

Fax: +1-919-677-2343

+1-800-498-4442

e-mail: sensorsinfo@mts.com

http://www.mtssensors.com

Auf dem Schüffel 9

D - 58513 Lüdenscheid, Germany

Tel.: +49-2351-9587-0

Fax: +49-2351-56491

e-mail: info@mtssensor.de

http://www.mtssensor.de

737 Aihara-cho, Machida-shi

Tokyo 194-0211, Japan

Tel.: +81-42-775-3838

Fax: +81-42-775-5516

e-mail: info@mtssensor.co.jp

http://www.mtssensor.co.jp

®

SENSORS