GE 745 2

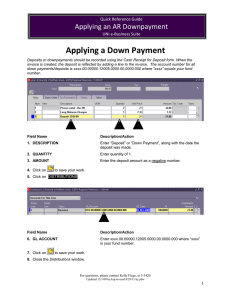

advertisement