Parapro Roof Membrane System

advertisement

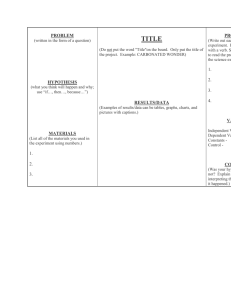

Parapro Roof Membrane System Installer’s Guide Table of Contents I. System Overview 1 II. Personal Protection 2 III. Storage 3 IV. Installation Materials, Tools, and Equipment 3 V. Substrate Requirements, Preparation, and Repair 4 VI. Measuring and Mixing Parapro Resins 11 VII. Pro Primer W, Pro Primer T, and Pro Primer R Resins 14 VIII. Pro Paste Resin and Pro Repair Mortar 15 IX. Pro Fleece 16 X. Parapro 123 Flashing Resin 16 XI. Parapro Roof Membrane Resin 17 XII. Pro Natural Quartz, Siplast No. 11 Granules, and Pro Color Finish 18 XIII. Coverage and Consumption Rates 19 XIV. Parapro Roof Membrane System Application over Paradiene 20 P Series Products 20 I. System Overview and Products System Overview The Parapro Roof Membrane System is a liquid-applied, PMMA resin-based system designed to provide watertight protection on low slope and sloped applications. Parapro Roof Membrane is used in conjunction with Parapro 123 Flashing. The Parapro Roof Membrane System is a layered application consisting of one coat of primer (where required depending on substrate conditions), and waterproofing layers reinforced with polyester fleece fabric. Parapro Roof Membrane Waterproofing Layer (Two waterproofing coats and reinforcing fleece) Substrate 1 Products The following products are used in the Parapro Roof Membrane System: Primers Other • Pro Primer R Resin • Pro Catalyst • Pro Primer T Resin • Pro Prep • Pro Primer W Resin Flashing Membrane • Parapro Flashing Resin Roofing Layers • Paradiene 20 P Series Sheets • Parapro Roof Membrane Resin Reinforcement • Pro Fleece Finish Resin • Pro Color Finish Surfacing Aggregates • Siplast No. 11 Roofing Granules • Pro Natural Quartz • Pro Paste • Pro Repair Mortar Weather Restrictions Do not apply Parapro or Pro products if there is a threat of precipitation, condensation is present on the sub- strate or the ambient temperature is within 5ºF of the dew point. Ambient and substrate temperatures affect the application of Siplast Parapro and Pro materials. Ambient and substrate temperature guidelines and re- strictions vary by product, and are noted in the product sections of this guide. Protection Upon completion of new work (including all associated work), use appropriate procedures for protection of fin- ished work during the remainder of the construction period. Protect all areas where membrane has been installed. II. Personal Protection Safety and Protection and Pro Catalyst dust. Use the products with adequate each Parapro and Pro product for specific PPE informa- exposure below TLV values. Do not ingest the prod- Refer to the Material Safety Data Sheet (MSDS) for tion. Parapro and Pro Resins are flammable, and are harmful if inhaled, swallowed, or absorbed through the skin. They can cause skin, eye, and respiratory irrita- tion, and may cause skin and respiratory sensitization. Do not smoke around Parapro or Pro Resins. Keep the products away from open flame, fire, or any ignition source. Avoid breathing Parapro or Pro Resin vapor ventilation or respiratory protection as needed to keep ucts, and avoid contact with eyes, skin, and clothing. Wear suitable gloves and eye/face protection. Wash thoroughly after handling the products. Keep the products out of reach of children. First aid information is available on Parapro and Pro product MSDS documents and product containers. 2 III. Storage Storage Exposure to a temperature of 122°F (50°C) or higher can result a well-ventilated, cool, dry area away from direct sunlight, heat, erating decomposition is signaled by the presence of bright Store Parapro and Pro products indoors in closed containers in open fire, any ignition source, oxidizing agents, strong acids, and strong alkalis. Resin products may auto-polymerize at temperatures greater than 140°F (60°C). Resin product shelf life is 6 months from ship date. The shelf life of resin products will be reduced if the products are stored at temperatures above 77°F (25°C). Pro Catalyst is extremely heat sensitive. Proper storage is important to help ensure handling safety and that product in self-accelerating decomposition of Pro Catalyst. Self-accel- white smoke, and can create temperatures in excess of 500°F (260°C), depending on the environmental conditions and quantity of catalyst present. Such temperatures can be haz- ardous in the presence of flammable materials. Therefore, Pro Catalyst should never be subjected to conditions that can result in self-accelerating decomposition. quality is not compromised. To maintain product quality, the Materials stored on the job site during application should be (25°C). The reactivity/effectiveness of Pro Catalyst will decrease areas, materials should be covered with a white, reflective tarp storage temperature of Pro Catalyst should not exceed 77°F progressively when stored under high temperature conditions. kept on a pallet in a shaded, well-ventilated area. In unshaded in a manner that allows air circulation beneath the tarp. IV. Installation Materials, Tools, and Equipment Substrate Preparation Application • Drum scarifier • Application brushes • Blower, vacuum, & broom • Shot blaster with dust collector/air-pulse compressor • Hand grinders with carbide disk or diamond cup wheel • Pro Prep • Pro Paste • Application rollers • Pro Prep • Heavy duty sissors • Disposable heavy duty butyl rubber or nitrile gloves • Pro Repair Mortar Miscellaneous Mixing • Clean cotton rags • Plastic tarps or sheeting • Variable speed drill with 1/2-inch chuck • Mixing agitator • Mixing stir sticks • 1-tablespoon measure • Plastic mixing buckets (1 and 5-gallon) • Battery operated scale with 40-lb (20-kg) capacity 3 • Masking Tape • Extension cords • Plastic garbage bags • Box or razor knife • Infrared thermometer • Tape measure • Chalk line V. Substrate Requirements, Preparation, and Repair Roof Deck Requirements following section titled Moisture Content Guidelines. Structural roof decks should be properly designed to provide Polymer-modified concrete products are acceptable provided and normal construction traffic without excessive deflection or Contact Siplast Technical Support for a list of products that General sufficient strength to support anticipated dead and live loads movement. Provisions for structural expansion and contraction should be incorporated into the design. All openings, walls, or that they have been tested/approved in advance by Siplast. have been tested and approved. projections through the roof deck should be completed before Concrete substrates that do not meet Siplast standard guide- be constructed according to the deck manufacturer’s specifi- Siplast Technical Support for qualification options. application of the roof membrane is begun. The deck should cations and best-established practices. Any Siplast accept- lines to receive a Siplast primer are listed below. Contact ance of a deck as satisfactory to receive roofing is based ● Split-slabs with a between-slab vapor impermeable sign of the roof deck is the responsibility of the architect, engi- ● Slab-on-grade construction. strictly on the condition of the surface to be roofed. The deneer, or owner. Roofing over Lightweight Insulating membrane. ● Concrete placed over a metal pan (including vented metal). ● Concrete utilizing porous aggregate (LWSC) or aggregate containing hydrocarbons (trap rock). Concrete Surfaces ● Concrete with a moisture content exceeding published Parabase FS be laid dry over all lightweight insulating concrete ● Concrete that has been treated with curing/waterproofing Parapro Roof Membrane System. All fastening should be done ● Concrete contaminated/affected by hydrocarbons, organic Siplast requires that one ply of Parabase Plus, Parabase or substrates prior to application of the Paradiene 20 P layer and with Zono-tite fasteners for ZIC, Insulcel, and Zonocel Lightweight Insulating Concrete substrates having a minimum 2- inch thickness, and with NVS Fasteners for substrates having a minimum 1-inch thickness. Paradiene 20 P is applied over the nailed Parabase base sheet using PA-100 Asphalt, or Paradiene 20 P TG is torch-applied over the nailed Parabase base sheet. Paradiene 20 TS P and Paradiene 20 TS SA P Applications over Poured Reinforced Concrete The concrete deck should be fully cured, dry, frost-free, smooth, and free from release or curing agents. When a Para- diene 20 P series sheet is used, the deck should be primed with PA-1125 or PA-917 LS at the rate of 1 gallon per 100- 400 sf and allowed to dry thoroughly. Paradiene 20 TS P may be torch applied or Paradiene 20 TS SA P may be adhered di- rectly to the prepared substrate prior to application of the Parapro Roof Membrane System. Parapro Roof Membrane System Applied Directly to Poured Reinforced Concrete The concrete substrate must have a minimum compressive strength of 3500 psi (25 N/mm²), provide for bottom-side venting, and have a maximum moisture content as indicated in the maximums. agents. compounds such as bitumen (asphalt) or coal tar, alkaline silica reaction (ASR), or unreacted silicates. ● Concrete “T”-type constructions without an overlay of reinforced concrete topping due to concerns about differential movement between sections. ● Pre-cast concrete panels. New Concrete Pours The mix design for new concrete pours should be submitted to Siplast for review prior to placement. New concrete must be allowed to hydrate for a minimum of 28 days in accordance with American Concrete Institute (ACI) Bulletin 308 – Guide to Curing Concrete, in addition to being below the maximum moisture content. Concrete should not utilize curing agents, penetrating release agents, or be treated with waterproofing materials as these materials can affect primer penetration and/or adhesion. New concrete pours may require an extended exposure time before an acceptable moisture content is reached. To prevent delays in system installation, the use of an epoxy-based moisture mitigation system should be considered when the mois- ture content is expected to be above the published maximum at the time of waterproofing application. 4 Existing Concrete Substrates Chloride" is a non-destructive method and measures moisture depth of 2 inches) and evaluated by an accredited lab. The days. Prior to performing the test, the concrete surface is Existing concrete should be cored (3 inches in diameter with a number of cores should be sufficient to provide a representation of all areas to be waterproofed. Testing procedures should include ion chromatography, infrared spectroscopy, xray diffraction, and thin-section petrographic analysis. The depth of carbonation should also be determined. The pres- ence of contaminants or carbonated concrete may affect the adhesion of the primer layer. Contaminants include hydrocar- bons or other organic compounds, concrete affected by alka- line silica reaction (ASR) or unreacted silicates. The lab should recommend the remedial work required to bring the concrete cleaned (ground) to remove any coatings or contaminants that may be present and to open the surface. A dish of anhydrous calcium chloride is then placed over the prepared surface for the specified period of time. The dish is then weighed before and after placement to measure moisture release from the concrete. This test method is primarily an indicator of surface moisture levels and is commonly used by the flooring/water- proofing industry. Calcium chloride testing must be performed under specific ambient conditions to yield proper results. substrate into a condition suitable to receive the waterproofing ASTM F 2170 "Standard Test Method for Determining Relative roofing or waterproofing system is also recommended when that holes be drilled through the concrete slab. Plastic sleeves system. Reviewing the performance of an existing coating, evaluating a concrete substrate. If blistering or loss of adhesion of the existing coating/waterproofing is evident, the source of the problem should be investigated and addressed with a plan of action before the existing system is removed. Moisture Content Guidelines – Concrete Substrates High moisture levels in both new and existing concrete sub- strates can adversely affect the adhesion of a Parapro System. The presence of moisture can prevent the primer from pene- trating the concrete and affect the bond of the Siplast system. Excessive moisture present beneath a Parapro System can Humidity in Concrete Floor Slabs Using in situ Probes" requires are then inserted into the holes. Relative humidity levels within the sleeved cavity are then measured over a 72-hour equilibrium period. The depth of penetration allows for an under- standing of the moisture percent throughout the core of the substrate, rather than the near-surface readings calculated using the ASTM F 1869 test. New test methods have also been developed for measuring relative humidity over a period of time shorter than the 72 hours as required by ASTM F 2170. Relative humidity testing must be performed under specific ambient conditions to yield proper results. also transport soluble salts into the condensation zone be- Following are Siplast guidelines for maximum moisture content the primer from the concrete surface after the system has col. neath the membrane, resulting in osmosis, which can disbond been in service for a period of time. Relative humidity and calcium chloride testing require specific ambient conditions for the testing period. This may preclude performing moisture testing under hot, cold or wet weather conditions. Moisture levels can be measured using several standard meth- ods: ASTM D 2216 "Test Method for Laboratory Determination of Water (Moisture) Content of Soil and Rock" is a physical measurement of the moisture before and after drying and is the most accurate of the tests available. This test requires cores to be removed from the concrete and the cores are then evalu- ated by a qualified laboratory. The obvious downside of this 5 movement through a concrete slab over the course of three (3) based upon testing in accordance with the above-listed protoASTM Method ASTM D 2216 ASTM F 1869 ASTM F 2170 Maximum Limit 6% moisture content by weight 3 lb of moisture release per 1000 ft2 of surface area per 24-hour period 75% relative humidity Siplast does not perform moisture content evaluations. The above tests are offered by most independent labs that provide services to design firms that utilize concrete in construction. The choice of test method and final acceptance of the concrete substrate is the responsibility of the design authority and/or waterproofing contractor. test is its destructive nature. Adhesion Testing for Concrete Substrates ASTM F 1869 "Test Method for Measuring Moisture Vapor unforeseen contaminants such as sealers, oils and surface Emission Rate of Concrete Subfloor Using Anhydrous Calcium Adhesion testing is an excellent indicator of the presence of moisture that can affect adhesion of the primer layer although it should not be relied upon as the sole means of evaluation. tem. Differential movement at cracks and between divided considered as a substrate. formance. Dynamic (moving) cracks should be investigated Adhesion testing is required for all concrete surfaces to be Adhesion to concrete is evaluated using a device conforming to ASTM D 4541 that utilizes a 50 mm stainless steel dolly. The concrete surface should be prepared using the same areas can potentially compromise long-term roof system perand the causes addressed before system application. Me- chanical expansion joint systems should be considered for waterproofing structural expansion joints. techniques of surface preparation that will be required, or at a Gypsum hered to the concrete deck surface using the applicable primer inch thickness over form boards, allowing drying from the un- minimum, ground to a CSP 2 profile. The dolly is then ad- for the project. The adhesion value must exceed 220 psi to be considered acceptable. The results of adhesion testing performed by Siplast personnel Gypsum decks should be poured in place to a minimum 2derside. They should be reinforced with wire mesh and present a smooth, dry, frost-free surface, free of depressions or projections. are strictly for informational purposes and should be evaluated Siplast requires that one ply of Parabase Plus, Parabase or the accuracy, adequacy, and appropriateness of the results. sheet fasteners prior to the application of the Paradiene 20 P Preparation of Concrete Substrates mends that fastener pullout tests be performed by the con- by the design authority and waterproofing contractor to verify Concrete preparation methods should be chosen based upon how much of the surface requires removal and the desired concrete surface profile (CSP). For existing concrete sub- strates, core testing will provide the information needed to determine the amount (depth) of concrete to be removed from the surface. Concrete affected by carbonation and/or con- Parabase FS be laid dry and fastened using approved base layer and Parapro Roof Membrane System. Siplast recom- tractor on site to verify the appropriateness of the fastener to meet all applicable roof design criteria. Paradiene 20 P is applied over the nailed Parabase base sheet using PA-100 Asphalt or SFT Adhesive. Paradiene 20 P TG can be torch-applied to the Parabase base sheet. tamination must be removed in its entirety. Concrete surfaces Structural Wood/Cement-Fiber Concrete Repair Institute (ICRI) as CSP 2 through CSP 4. weather during storage and installation. Any wet or damaged should be prepared to a profile designated by the International Preparation methods for concrete substrates include shotblasting or scarification followed by shotblasting. Multiple passes with scarification and shotblasting equipment may be required to remove materials from the concrete surface and achieve the desired concrete preparation depth and surface profile. Grinding can be considered for preparation of con- crete flashing substrates but it is important to note that generation of the desired surface profile can prove difficult. Concrete preparation should be immediately followed by appli- cation of the appropriate primer. Exposure of the prepared concrete surface to the elements may result in contamination, which can adversely affect Pro Primer adhesion. Concrete Crack and Joint Treatment Before application of the Parapro System, cracks and joints Structural cement-fiber decks must be protected from the panels should be replaced. Structural cement-fiber decks should be adequately secured against wind uplift and lateral movement, and should comply strictly with the specifications of the deck manufacturer. Decks must be roofed promptly after installation. Siplast requires that one ply of Parabase Plus, Parabase, or Parabase FS be laid dry and fastened using approved base sheet fasteners prior to the application of the membrane. Siplast recommends that fastener pullout tests be performed by the contractor on site to verify the appropriateness of the fastener to meet all applicable roof design criteria. Paradiene 20 P is applied over the nailed Parabase base sheet using PA100 Asphalt or SFT Adhesive. Paradiene 20 TG P can be torch-applied to the Parabase base sheet. should be prepared and treated in accordance with Siplast de- Wood preparation/treatment are intended to provide methods on a lumber of a minimum 1-inch thickness, tongue and groove, tails. Siplast recommendations for crack and joint best effort basis to construct a watertight waterproofing sys- Wood decks should be constructed of dry, well-seasoned and shiplap or splined together at side joints, and matched at 6 end joints. Boards should have a bearing on rafters at each with the “A” side to receive the primer. “A” surfaced plywood knotholes larger than one inch in diameter should be covered of which can contaminate primers. end and be securely nailed. Cracks wider than 1/4-inch and with sheet metal. Siplast requires that one ply of Parabase Plus, Parabase or Parabase FS be laid dry and fastened prior to application of the Paradiene 20 P layer and Parapro Roof Membrane Sys- tem. All nailing should be done with annular-threaded or spiralthreaded type nails having attached caps of minimum 1-inch diameter. Siplast recommends that a fastener pullout test be performed by the contractor on site to verify the appropriate- Pressure treated and fire-retardant plywood is typically not produced in a A-grade finish although if available, the panel type must be tested by Siplast R&D before use to ensure that the chemicals will not affect primer adhesion. Marine plywood can be used for exterior applications since it is manufactured to resist deterioration when exposed to high moisture environments and is free of knots and glues. ness of the fastener to meet all applicable roof design criteria. When used in a single-layer orientation, the panels should using PA-100 Asphalt or SFT Adhesive. two-layer configuration, minimum 1/2-inch panels can be Paradiene 20 P is applied over the nailed Parabase base sheet Plywood Plywood decks should be designed and fabricated in accordance with the recommendations of the APA – The Engi- neered Wood Association. Each panel should be identified with the appropriate APA trademark, and must meet the re- quirements of the latest edition of the U.S. Product Standard PS-1 for Construction and Industrial Plywood. Plywood panels must meet or exceed a span rating of 32/16 and be a minimum of 15/32-inch thick. They should be fabricated to meet or exceed the requirements of Exposure 1 Durability Classification. Plywood panels should be applied at right angles to rafters, continuous over two or more spans with either solid backing or panel clips stiffening all joints between rafters. Rafter spacing should be a maximum of 24 inches. Siplast requires that one ply of Parabase Plus, Parabase, or Parabase FS be laid dry and fastened prior to application of the Paradiene 20 P layer and Parapro Roof Membrane Sys- tem. All nailing should be done with annular-threaded or spiralthreaded type nails having attached round caps of a minimum 1-inch diameter. Siplast recommends that fastener pullout tests be performed by the contractor on site to verify the ap- propriateness of the fastener to meet all applicable roof design criteria. Paradiene 20 P is applied over the nailed Parabase base sheet using PA-100 Asphalt or SFT Adhesive. Plywood Substrates to Receive a Direct Parapro 7 is used to eliminate the presence of knots and/or glues, both Application Plywood should be exterior grade, AC or better. Install panels have a minimum thickness of 3/4-inch. When installed in a used. Ensure that all plywood edges are supported by blocking or primary framing and gap panels in accordance with the plywood manufacturer’s specifications to minimize the potential for rupture at joints. Plywood panels should be fastened with corrosion resistant screws using a spacing of not greater than 6-inches o.c. along panel edges and 12-inches o.c. over intermediate supports. Plywood Joint Treatment Following panel securement, prime panels using Pro Primer W, including the vertical surfaces at gaps between panels, and allow to cure. Ensure that the Pro Primer W does not pool in the joints. Fill joints with Pro Paste and allow to cure. Reinforce the joints using a 6-inch (150 mm) wide strip of Pro Fleece and Parapro Flashing Resin. Pre-cast Hollow Core Slabs or Pre-cast Concrete Pre-cast hollow core slabs or pre-cast concrete should be dry, fully cured, clean, and free of imperfections. Slabs should be securely fastened to the sub frame to prevent movement or sagging, and should be set level with all joints aligned and closely butted to provide a smooth, even surface. Using ZonoPatch Patching Compound, grout all joints between uneven slabs to a slope not to exceed 18-inch per foot on the low member. For asphalt applications, prime the deck surface with PA-1125 Primer or PA-917 LS Primer at the rate of 1 gallon per 100 square feet; keep the primer back 4 inches from joints. Cover all of the joints with an 8-inch wide strip of Parabase Plus or Parabase, adhered on one side only with PA-1021 Plastic Cement. Pre-cast hollow core slabs or pre- cast concrete decks must be covered by a lightweight insulating concrete fill or an acceptable rigid roof insulation. Prestressed T or Double T Sections Prestressed T or Double T sections shall be dry, fully cured, clean, and free from excessive camber or “set.” Prestressed sections should be securely anchored against uplift and lateral movement. Welding plates should be positioned next to the edge and on the top surface of the member for mid-span securement. Camber differential resulting in offset edges in excess of 14-inch should be corrected with Zono-Patch Patching Compound prior to the application of insulation and roofing. Using Zono-Patch, grout all joints between uneven units to a slope not to exceed 18-inch per foot on the low member. For asphalt applications, prime the deck surface with PA-1125 Primer or PA-917 LS Primer at the rate of 1 gallon per 100 square feet; keep the primer back 4 inches from the joints. Cover all of the joints with an 8-inch wide strip of Parabase Plus or Parabase, adhered on one side only with PA-1021 Plastic Cement. Prestressed T or Double T decks must be covered by a lightweight insulating concrete fill or an acceptable rigid roof insulation. Steel Steel roof decks should be constructed in accordance with the FM Approvals structural requirements listed in the current Fac- tory Mutual Loss Prevention Data Sheet 1-29. Steel roof decks should be 22-gauge minimum, and factory galvanized or factory coated with aluminum zinc alloy for corrosion protection. When specifying galvanized protection, the designer should decks. Rigid Roof Insulation Rigid roof insulation should be kept dry at all times. Edges of the insulation panels should be butted without forcing, and cut to fit neatly against adjoining surfaces. The insulation layer should present a smooth surface to accept the roof mem- brane. No more insulation should be installed than can be covered in the same day. Insulation panels should be installed strictly according to the insulation manufacturer’s recommendations and FM Approvals requirements (if applicable). Im- properly attached insulation can result in roof blow-offs. Siplast will not be responsible for (and the standard Siplast guarantee does not include) roof blow-offs due to loss of adhesion of the insulation layer or performance failure of the insulation itself. Polyisocyanurates and other materials used as a roofing substrate must be specifically approved by Siplast prior to use, and a coverboard is required over all polyisocyanurate panels prior to installation of the Parapro Roof Membrane System. When insulation panels are applied with hot asphalt over sloped roof decks, insulation stops may be required. Consult with the insulation manufacturer regarding requirements for, and the construction and spacing of, insulation stops. Paratherm and other Siplast-supplied rigid insulation products, when incorporated into a full Siplast Roof System construction and attached with Parafast Fasteners or Para-Stik Adhesive, and overlayed with an approved coverboard are covered by the Siplast Membrane/System Guarantee. specify a coating that complies with ASTM A 525, Class G-60 Coverboard tion, the designer should specify a deck complying with ASTM strates for direct application of Parapro Roof Membrane Sys- or Class G-90. When specifying aluminum zinc alloy protec- A 792. Deck manufacturers should be contacted when specifying decks where highly corrosive atmospheric conditions exist. Steel decks should be clean and dry, and the ribs of the deck should be free of snow, ice, and water. The top flanges of installed steel decks should be flat. Mechanical fastening should be provided at all of the side laps; spacing between the side lap fasteners and bar joists or beams should not exceed DensDeck™ and DensDeck Prime™ are acceptable subtems. All substrate panels must be applied in Para-Stik Insulation Adhesive. All joints between panels and panel edges at walls, penetrations and nailers must be taped using an approved tape or membrane. Prime DensDeck and DensDeck Prime with Pro Primer W prior to application of the Parapro Roof Membrane. 3 feet. Siplast recommends that insulation fastener pullout In most instances, it will be preferable to replace the applica- propriateness of the fastener to meet all applicable roof design 20 P layer. In such cases, Paradiene 20 TS P may be torch- tests be performed by the contractor on site to verify the ap- criteria. Steel decks must be covered by an acceptable FM Approvals Class I rigid roof insulation or lightweight insulating concrete pour. New or Unusual Roof Decks Approval must be secured from the Siplast Technical Depart- ment prior to the installation of roofing over new or unusual tion of Pro Primer W over DensDeck panels with a Paradiene applied or Paradiene 20 TS SA P adhered directly to a DensDeck Prime surface. Standard DensDeck surfaces are not suitable for self-adhesive applications unless first primed using the appropriate Siplast primer. Insulation Adhesives Insulation adhesives should be properly stored, and applied 8 according to the specifications and job-specific recommenda- compatible materials. (2) Remove any areas of the assembly adhesive manufacturer should be contacted regarding any re- materials, bringing the area back to level with the surrounding tions of the insulation adhesive manufacturer. The insulation quired guarantee that covers the performance of the insula- tion adhesive itself. Siplast will not be responsible for (and the standard Siplast guarantee does not include) roof blow-offs due to failure of insulation adhesives. Para-Stik Adhesive, when incorporated into a full Siplast Roof System construc- tion, is covered by the Siplast Membrane/System Guarantee. Re-cover Because Siplast materials are light in weight, they are espe- cially suitable and widely used for re-cover applications. Each re-cover application is unique and should be considered individually. However, certain requirements and procedures are necessary in the general consideration of any project. It should be noted that certain design considerations (such as the use or construction of vapor retarders and the addition and positioning of expansion joints as necessary, etc.) are the responsibility of the architect, engineer, or owner and, as such, are not part of this section. Although the following criteria are not all inclusive, they do, if met and used in conjunction with the applicable Siplast specification and details, indicate an appropriate situation for the consideration of re-cover with Siplast materials. Siplast recommends the use of analytical tools such as non- destructive moisture survey methods as well as test cuts and any other evaluation methods available to ascertain existing surfaces. (3) Remove and discard all of the base flashings, and any metal incorporated into the roof system (i.e. gravel stops, vent stack jacks, drain leads, etc). Bring these areas back to level using compatible materials. (4) Existing perimeter nailers should be carefully inspected for proper securement, and be anchored to the structural deck or supporting mem- bers as required to meet building code regulations and appropriate uplift approvals. Install new wood nailers where necessary due to deterioration or inadequate securement, or when required to bring the nailer to the proper height. (5) Remove all of the existing counterflashing and determine whether it is in a reusable condition. Lifting of the existing counterflashing in good condition is acceptable only if it can be returned to its original position without deformation that would affect its performance. (6) Except in those cases where the new assembly will be mechanically attached to the deck, the existing assembly should be resecured as necessary to meet all local code and insurance wind uplift requirements. In most cases, the old roof assembly should be separated from the new Siplast materials with a product and installation procedure appropriate for the existing deck, roof system, and surfacing. Where possible, it is preferable that the separating materials be mechanically attached using fasteners designed for that purpose. Please contact your Siplast representative for recommendations tailored to meet your particular re-cover conditions. roof conditions. General Substrate Preparation This thorough inspection of the existing roof conditions must terial, unsound material, foreign material (such as dirt, ice, be made to determine that: (1) the deck is structurally sound, (2) the deck is able to take the added weight of the new as- sembly, (3) areas where moisture may be present have been located, (4) the method and degree of attachment of the ex- isting assembly has been specifically ascertained, (5) mini- mum 8-inch flashing heights will exist at curbs, walls, etc, and (6) the new assembly will provide proper drainage. Preparation of the existing assembly is extremely important to the ultimate performance of the new membrane. The following preparatory procedures should be followed: (1) Power-broom and vacuum all surfaces, removing all loose aggregate and 9 where moisture is present and replace them with compatible foreign substances. Splits, blisters, buckles, and surface irregularities should be cut out and patched using appropriate All substrates must be free from gross irregularities, loose masnow, water, grease, oil, release agents, lacquers, paint coverings), or any other condition that would be detrimental to the adhesion of the catalyzed primer and/or resin to the sub- strate. Some surfaces may require shotblasting, scarification followed by shotblasting, or grinding to achieve a suitable substrate. Substrate preparation guidelines appear in the chart on the following page. However, requirements can vary for a particu- lar situation. In applications where adhesion to a substrate not listed in the chart is required, please contact the Siplast Technical Department at 1-800-922-8800 for information on testing such substrates for adhesion by performing a field bond test. Substrate Aluminum, Copper, Lead, Steel Stainless Steel Paint/Coating Oxidized Mopping Asphalt/ Smooth-Surfaced SBS-modified bitumen, Hot Rubberized Asphalt Concrete (horizontal) Preparatory Guidelines 1, 2, 3, 4 Pro Primer W Required Pro Primer T Required Pro Primer R Required 1, 2, 3, 4, 13 7 1, 10 11 Concrete (vertical) Polymer Concrete Clay, Ceramic Tiles, Brick Wood Plywood (ACX) Mortar DensDeck, DensDeck Prime and Durock Paradiene 20 • 1, 5 1, 5 • 1, 6 • 1, 8 • 1 • 1 • 1, 5 • 1, 9 Paradiene 30 Paradiene 20 P Galvalume Metal (not approved) • • 1 1 11 1 Key to Preparation Guideline 1. Substrate must be clean and dry and free from gross irregularities, loose material, unsound material, or any foreign material (such as dirt, ice, snow, water, grease, 12 11 priming. 10. Mopping asphalt residue should be removed from the primary substrate that will receive the Parapro or Parapro Flashing materials. bitumen/coaltar, oil, release agents, lacquers, paint 11. Priming is recommended only at exposed bitumen over- tal to the adhesion of the catalyzed primer and/or resin to 12. While priming of the Paradiene 20 is not required, Pro coverings), or any other condition that would be detrimenthe substrate. 2. Remove rust or other oxidation layers. 3. Abrade surface to bright finish prior to cleaning with Pro Prep. 4. Wipe down thoroughly with Pro Prep prior to coating. Allow Pro Prep a minimum of 20 minutes drying time after application before continuing. The next application rocess should be completed within 60 minutes of cleaning with Pro Prep. 5. See substrate preparation and repair guidelines on page 5. 6. Grind surface to remove glaze. Tiles must be fully bonded to a sound foundation. No moisture should be present beneath tiles. 7. All paint coverings and coatings must be removed. 8. Refer to polymer concrete manufacturer’s requirements for suitability as a substrate for waterproofing materials. Prepare by shotblasting or grinding. Contact Siplast for uns at side laps. Primer R can be applied to maintain a consistent aesthetic appearance. Pro Primer R cannot be used over concrete or masonry and is not intended for use over asphalt contaminated roofing or flashing substrates. 13. A peel test is recommended to ensure that adhesion is adequate. Substrate Preparation and Repair Masonry Walls Masonry walls should be prepared in the same manner as concrete substrates (see page 5). Parapro materials must not be applied over soft or scaling brick or masonry, faulty mortar joints, or walls with broken, damaged or leaking coping. Laitance must be completely removed by grinding. The Siplast Parapro Roof Membrane Guarantee excludes from coverage moisture entry through walls above the Parapro Flashing termination. a list of approved polymer concrete products. Metal & Rigid Plastic walls, perimeters, and penetrations using gaffer’s tape Extend the preparation area a minimum of 1⁄4-inch (7 mm) 9. Tape all joints between panels and panel edges at all before priming or apply Eternabond Webseal after Lightly abrade and clean metal and rigid plastic substrates. beyond the termination of the Parapro materials. 10 Cracks, Joints, and Small Indentations Before application of the Parapro Flashing Membrane and Parapro Roof Membrane (and after priming if required), all immediately after the Pro Paste sets and/or reinforcing strip(s) cure(s). joints, cracks, voids, fractures, depressions, and small inden- Substrate Leveling & Patching use of Pro Paste for all such substrate repairs. The use of ad- be leveled using Pro Paste. Pro Repair Mortar can be used for tations in the substrate must be filled. Siplast recommends the ditional reinforcement in the form of strips of Parapro Flashing Resin/Pro Fleece/Parapro Fashing Resin is recommended over joints or cracks subject to movement. The Parapro Flash- Following preparation and priming (if required), low areas may areas requiring a greater thickness. See page 15 for additional information. ing Membrane and Parapro Roof Membrane may be applied VI. Measuring and Mixing Parapro Resin General Guidelines Batch Weighing ting and should only be catalyzed as needed. Depending on Catalyst is with a portable, battery-operated scale. Resins used in Parapro Roof Membrane Systems are fast setthe resin type and ambient/temperature, the amount of catalyst needed will vary. The Tablespoon Method Mixing All Parapro Resins tablespoon measure using a standard culinary-type measur- If a portable, battery-operated scale is not available, a level 1- Thoroughly mix the entire drum of uncatalyzed Parapro or Pro Resin for 2-3 minutes prior to pouring off into a second container when batch mixing. This will redistribute liquids/solids that may have separated during storage. Catalyze only the amount of resin that can be used within the anticipated pot life. Add premeasured Pro Catalyst Powder to the resin component, and stir for a full 2 minutes using a slow-speed mechanical agitator or mixing stick before applying to the substrate. Liquid Measure of Resins ing spoon equals approximately 10 grams or 0.01 kilograms of catalyst powder. The following table can be used for calculating catalyst quantities per kg of resin. Catalyst Tablespoon Measurements (per kg resin) % Catalyst 2% 4% 6% Tablespoons per kg of resin 2 4 6 The amount of Pro Catalyst that should be used is based on Pro Catalyst Mixing products have different volumes for the same measure of The amount of Pro Catalyst added to Parapro and Pro Resins the weight of the uncatalyzed Parapro or Pro Resin. Resin weight. When a scale is not available, the approximate liquid measure on the following chart may be used for Parapro and Pro Resins. Parapro and Pro Resins may be field measured using the following conversions: Resin Type 11 The most accurate means for field measuring resin and Pro Pro Primer R Resin Pro Primer T Resin Pro Primer W Resin Pro Paste Resin Parapro Roof Membrane and Flashing Resin Pro Color Finish Density Liquid 1.0 kg/liter 1.0 kg/liter 1.0 kg/liter 1.4 kg/liter 1.0 liter/kg 1.0 liter/kg 1.0 liter/kg 0.72 liter/kg 1.0 kg/liter 1.0 liter/kg 1.4 kg/liter 0.72 liter/kg Ratios & Measurements is based on the weight (or associated volume) of the resin used, and varies with the ambient temperature and type of resin (primer, paste, base, flashing, or color finish). Pro Catalyst is available in 0.1-kg (100 gram) pre-measured bags to simplify the catalyzing and mixing of Pro Resins. Whenever possible, pre-measured bags of Pro Catalyst should be used for mixing. See pages 12-13 for mixing ratios. The amount of Pro Catalyst added to Parapro and Pro Resins must not be less than 2%. If resin mixed with the minimum required cata- lyst of 2% does not offer sufficient pot life, the resin temperature may be too high. Pro Catalyst Mixing Charts Pro Paste Resin The amount of Pro Catalyst used with Pro Paste Resin varies from a minimum of 2% to 6% maximum by weight, depending upon the ambient temperature as indicated in the following table: Resin Quantity 1.0 kg (0.72 liter) 5.0 kg (3.6 liter) 2% Catalyst Ambient Temperature 77°F to 95°F (25°C to 35°C) g 20 100 kg Tblsp. 0.1-kg Bags 0.1 10 1 .02 2 n/a 4% Catalyst Ambient Temperature 41°F to 77°F (5°C to 25°C) 6% Catalyst Ambient Temperature 32°F to 41°F (0°C to 5°C) 40 60 g 200 kg Tblsp. 0.1-kg Bags 0.2 20 2 .04 4 n/a g 300 kg .06 0.3 Tblsp. 0.1-kg Bags 6 n/a 30 3 Pro Primer W Resin, Pro Primer T Resin, and Pro Primer R Resom The amount of Pro Catalyst used with Pro Primer W Resin, Pro Primer T Resin, and Pro Primer R Resin varies from a minimum of 2% to 6% maximum by weight, depending upon the ambient temperature as indicated in the following table: Resin Quantity 1.0 kg (1.0 liter) 5.0 kg (5.0 liter) 10.0 kg (10.0 liter) 2% Catalyst Ambient Temperature 77°F to 95° (25°C to 35°C) g kg Tblsp. 0.1-kg Bags 0.1 10 1 20 .02 200 0.2 100 2 20 n/a 2 4% Catalyst Ambient Temperature 41°F to 77°F (5°C to 25°C) g kg Tblsp. 0.1-kg Bags 0.2 20 2 40 .04 400 0.4 200 4 40 n/a 6% Catalyst Ambient Temperature 32°F to 41°F (0°C to 5°C) g .06 600 0.6 300 4 kg 60 0.3 Tblsp. 0.1-kg Bags 6 n/a 60 6 30 3 Summer Grade Parapro Flashing Resin The amount of Pro Catalyst used with Summer Grade Parapro Flashing Resin varies from a minimum of 2% to 4% maximum by weight, depending upon the ambient temperature as indicated in the following table: Resin Quantity 1.0 kg (0.72 liter) 5.0 kg (3.6 liter) 10.0 kg (7.2 liter) Summer Grade 2% Catalyst Ambient Temperature 68°F to 104°F (20°C to 40°C) g kg Tblsp. 0.1-kg Bags 20 .02 200 0.2 100 0.1 2 n/a 20 2 10 1 Summer Grade 4% Catalyst Ambient Temperature 59°F to 68°F (15°C to 20°C) g kg Tblsp. 0.1-kg Bags 40 .04 400 0.4 200 0.2 4 n/a 40 4 20 2 12 Winter Grade Parapro Flashing Resin The amount of Pro Catalyst used with Winter Grade Parapro Flashing Resin varies from a minimum of 2% to 4% maximum by weight, depending upon the ambient temperature as indicated in the following table: Winter Grade 2% Catalyst Ambient Temperature 59°F to 68°F (15°C to 20°C) Resin Quantity 1.0 kg (0.72 liter) 5.0 kg (3.6 liter) 10.0 kg (7.2 liter) g kg Tblsp. 0.1-kg Bags 0.1 10 1 20 .02 200 0.2 100 2 n/a 20 g Winter Grade 4% Catalyst Ambient Temperature 23°F to 59°F (-5°C to 15°C) Tblsp. 0.1-kg Bags 0.2 20 2 .04 400 0.4 200 2 kg 40 4 n/a 40 4 Summer Grade Parapro Roof Membrane Resin The amount of Pro Catalyst used with Summer Grade Parapro Roof Membrane Resin varies from a minimum of 2% to 4% maximum by weight, depending upon the ambient temperature as indicated in the following table: Summer Grade 2% Catalyst Ambient Temperature 68°F to 104°F (20°C to 40°C) Resin Quantity g 1.0 kg (0.72 liter) Tblsp. 0.1-kg Bags 0.1 10 1 200 0.4 40 4 800 .02 200 0.2 100 20.0 kg (14.3 liter) 400 10.0 kg (7.2 liter) kg 20 5.0 kg (3.6 liter) 2 n/a 20 2 g Summer Grade 4% Catalyst Ambient Temperature 59°F to 68°F (15°C to 20°C) kg Tblsp. 0.1-kg Bags 0.2 20 2 0.8 80 40 .04 400 0.4 4 n/a 40 4 8 Winter Grade Parapro Roof Membrane Resin The amount of Pro Catalyst used with Winter Grade Parapro Roof Membrane Resin varies from a minimum of 2% to 4% maximum by weight, depending upon the ambient temperature as indicated in the following table: Winter Grade 2% Catalyst Ambient Temperature 59°F to 68°F (15°C to 20°C) Resin Quantity g 1.0 kg (0.72 liter) Tblsp. 0.1-kg Bags 0.1 10 1 200 0.4 40 4 800 .02 200 0.2 100 20.0 kg (14.3 liter) 400 10.0 kg (7.2 liter) kg 20 5.0 kg (3.6 liter) 2 n/a 20 2 g Winter Grade 4% Catalyst Ambient Temperature 23°F to 59°F (-5°C to 15°C) kg Tblsp. 0.1-kg Bags 0.2 20 2 0.8 80 40 .04 400 0.4 4 n/a 40 4 8 Pro Color Finish Resin The amount of Pro Catalyst used with Pro Color Finish Resin varies from a minimum of 2% to 6% maximum by weight, depending upon the ambient temperature as indicated in the following table: Resin Quantity 1.0 kg (1.0 liter) 5.0 kg (5.0 liter) 10.0 kg (10.0 liter) 13 2% Catalyst Ambient Temperature 59°F to 95°F (15°C to 35°C) g kg Tblsp. 0.1-kg Bags 0.1 10 1 20 .02 200 0.2 100 2 20 n/a 2 4% Catalyst Ambient Temperature 41°F to 59°F (5°C to 15°C) 6% Catalyst Ambient Temperature 32°F to 41°F (0°C to 5°C) 40 .04 60 .06 400 0.4 600 0.6 g 200 kg Tblsp. 0.1-kg Bags 0.2 20 2 4 40 n/a 4 g 300 kg 0.3 Tblsp. 0.1-kg Bags 6 n/a 60 6 30 3 VII. Pro Primer W Resin, Pro Primer T Resin, and Pro Primer R Resin General Application Guidelines The temperature of the resin itself should be within storage application of Parapro Roof Systems where horizontal areas of that the product maintains a workable pot life. In warm tem- Priming with catalyzed Pro Primer T Resin is required prior to concrete are to be treated. Pro Primer W is required for concrete in a vertical orientation, plywood, wood, DensDeck, or DensDeck Prime. For specific priming requirements, refer to the substrate preparation chart on page 10 of this guide. Priming with catalyzed Pro Primer R Resin is recommended prior to application of Parapro Roof Membrane Systems over asphaltic substrates. For specific priming requirements, refer to the substrate preparation chart on page 10 of this guide. Pro Primer T, Pro Primer W, and Pro Primer R may be applied when the ambient and substrate temperatures are between 32°F (0°C) and 95°F (35°C). The resin itself should be within storage temperature guidelines at the time of catalyzation to ensure that the product maintains a workable pot life. Discontinue membrane application when the ambient and/or substrate temperature exceeds 95°F (35°C). In warm temperatures, the substrate should be shaded for a sufficient period of time both prior to and during application, as necessary, to maintain substrate temperatures below 95ºF (35ºC). temperature guidelines at the time of catalyzation to ensure peratures, the substrate should be shaded for a sufficient pe- riod of time both prior to and during application, as necessary, to maintain substrate temperatures below 122ºF (50ºC). Pro Primer W, Pro Primer T, and Pro Primer R Coverage Rate Pro Primer W Coverage Rate for Wood, Plywood, Vertical Concrete, and Other Substrates Listed on Page 10. Minimum Consumption: 0.037 kg/sf - 3.7 kg/sq (0.4 kg/m2). Pro Primer T Coverage Rate — Concrete Substrates (horizontal). Minimum Consumption: 0.037 kg/sf - 3.7 kg/sq (0.4 kg/m2). Pro Primer R Coverage Rate — Siplast SBS Smooth Surfaced Sheet Minimum Consumption: 0.037 kg/sf - 3.7 kg/sq (0.4 kg/m2). Pro Primer W, Pro Primer T, and Pro Primer R are applied with NOTE: Application rates vary with substrate type. Primer con- Flashing Resin after the primer is cured (generally a minimum such as DensDeck and DensDeck Prime and cement boards. a roller and can be covered with Parapro Roof Membrane or of 45 minutes following application). Pro Primer W, Pro Primer T, and Pro Primer R can be exposed for up to 6 months. If work is interrupted for more than 12 hours, or the surface of the primer becomes dirty or contaminated from exposure to the elements, thoroughly clean the in-place and cured primer with Pro Prep. Pro Prep should be allowed a minimum of 20 minutes drying time after application before continuing. Following the Pro Prep drying time, the next application process should be completed within 60 minutes. Pro Primer W, Pro Primer T, and Pro Primer R Pot Life The pot life of Pro Primer W, Pro Primer T and Pro Primer R is approximately 15 minutes when the catalyzed liquid is at 68ºF (20ºC). Pot life will be reduced if the resin is at higher temper- atures. Pot life can be maximized by storing product under controlled conditions and ensuring that the liquid resin is at the low range of minimum storage temperature during/following catalyzation and prior to application. sumption rate is increased over more absorptive substrates For DensDeck and DensDeck Prime the minimum consumption rate is as follows: Pro Primer W Coverage Rate — DensDeck and DensDeck Prime Minimum Consumption: 0.074 kg/sf - 7.4 kg/sq (0.8 kg/m2). Pro Primer W, Pro Primer T, and Pro Primer R Set Times Minimum set times noted below are approximate, and may vary. The information provided is based on laboratory conditions, and is intended for use as a guideline only. Actual set (cure) times should be established in the field, based on actual field conditions. Rain Proof at 68°F (20°C): 25 minutes Ready for Next Coat at 68°F (20°C): 45 minutes 14 VII. Pro Paste Resin and Pro Repair Motar Pro Paste and Pro Repair Mortar Resin Pro Paste and Pro Repair Mortar are applied with a trowel and strate surfaces or other irregularities prior to application of the or the Parapro Roof Membrane System after the Pro Paste or Pro Paste Resin is used for remediation of depressions in subParapro System. Pro Repair Mortar consists of separate resin and aggregate components that are mixed to create a concrete patching product. Pro Repair Mortar can be used for patching concrete. Pro Repair Mortar has a compressive strength similar to that of structural concrete. Pro Paste and Pro Repair Mortar Application Guidelines Pro Repair Mortar is set. Pro Paste and Pro Repair Mortar Coverage Rates Pro Paste Thickness and Coverage Rates Typical Coverage: 0.13 kg/sf per 1 mm of thickness (1.4 kg/m² per 1 mm layer of thickness) Maximum Thickness (per lift): 3/16 inch (5 mm) Pro Paste Resin and Pro Repair Mortar may be applied when Pro Repair Mortar Thickness (35ºC). The resin or aggregate/resin mixture itself should be Maximum Thickness (per lift): 2 inches (50 mm) the ambient temperature is between 32ºF (0ºC) and 95ºF within storage temperature guidelines at the time of catalyzation to ensure that the product maintains a workable pot life. At the point of application, the substrate temperature should be between 32ºF (0ºC) and 122ºF (50ºC). Discontinue product Minimum Thickness: 3/16 inch (5 mm) A total thickness greater than 2 inches (50 mm) can be achieved by applying Pro Repair Mortar in layers (lifts) after the previous layer has cured. application when the ambient temperature exceeds 95ºF Pro Paste and Pro Repair Mortar Pot Life (50ºC) maximum. Provide adequate shade over the substrate mately 15 minutes when the catalyzed liquid or liquid/aggre- (35ºC) and/or the substrate temperature exceeds the 122ºF area both prior to and during application as necessary to maintain surface temperatures below the maximum. Pro Paste Resin and Pro Repair Mortar, as with all Parapro and Pro resin products, may require the application of a Pro Primer product before application. See the table on page 10 for specific substrate preparation guidelines. When Pro Paste or Pro Repair Mortar are to be applied over a Pro or Parapro product, thoroughly clean the surface of the in- place resin product with Pro Prep. This step is required even if the Pro or Parapro product has been recently applied. Pro Prep should be allowed a minimum of 20 minutes of drying time after application before continuing. Following the Pro Prep drying time, the Pro Paste or Pro Repair Mortar applica- The pot life of Pro Paste and Pro Repair Mortar is approxi- gate mixture is at 68ºF (20ºC). Pot life will be reduced if the resin or liquid/aggregate mixture is at higher temperatures. Pot life can be maximized by storing product under controlled conditions and ensuring that the liquid resin and aggregate are at the low range of minimum storage temperature during/following catalyzation and prior to application. Pro Paste and Pro Repair Mortar Set Times Minimum set times noted below are approximate and may vary. The information provided is based on laboratory conditions and is intended for use as a guideline only. Actual set/cure times should be established in the field, based upon actual field conditions. tion process should be completed within 1 hour. Pro Paste Resin Due to its porosity, catalyzed Pro Repair Mortar should not be Ready for Next Coat at 68ºF (20ºC): 1 hour exposed to precipitation or allowed to be exposed overnight. If Rain Proof at 68ºF (20ºC): 30 minutes Pro Repair Mortar will not be overlaid with Parapro Flashing or Pro Repair Mortar using Pro Primer W or Pro Primer T at a minimum rate of Ready for Next Coat at 68ºF (20ºC): 45 minutes Base Resin immediately following application, seal the surface 15 can be covered with Pro Primer, the Parapro Flashing System, 0.037 kg/sf - 3.7 kg/sq (0.4 kg/m ). 2 Rain Proof at 68ºF (20ºC): 30 minutes Stress Resistant at 68ºF (20ºC): 1 hour IX. Pro Fleece Pro Fleece Pro Fleece Sizes Membrane Systems and Parapro Flashing applications. 25-inch (630 mm) for use in the Parapro Flashing System and Pro Fleece is the reinforcement layer used in Parapro Roof Pro Fleece is available in three widths: 12-inch (315 mm) and 41-inch (1050 mm) for use in Parapro Roof Membrane applications X. Parapro Flashing Resin Parapro 123 Flashing Resin - An even, generous base coat of catalyzed Parapro Flashing Parapro Flashing Resin, when catalyzed, is combined with brush. Pro Fleece reinforcement is worked into the wet, cat- General Application Guidelines fleece fabric to form a monolithic, reinforced flashing mem- brane used for flashing details. Parapro Flashing Resin is available in two formulations: Summer Grade and Winter Grade. Care should be taken to ensure that the correct formulation of Parapro Flashing Resin (Summer Grade or Winter Grade) is chosen for the application based upon the ambient temperature. Summer Grade Parapro Flashing Resin may be applied when the ambient temperature is between 59°F (15°C) and 104°F Resin is applied to the substrate with an application roller or alyzed Parapro Flashing Resin base coat using an application roller or brush to fully embed the fleece in the resin and re- move trapped air. Pro Fleece must be overlapped a minimum of two inches (51 mm). An additional coat of catalyzed Para- pro Flashing Resin must be placed between all layers of over- lapping fleece. Catalyzed Parapro Flashing Resin must extend a maximum 1⁄4-inch beyond the Pro Fleece reinforcement. An even, generous top coat of catalyzed Parapro Flashing Resin is applied immediately following embedment of the fleece to ensure full saturation of the fleece reinforcement. (40°C). The resin itself should be within storage temperature If work is interrupted for more than 12 hours, or the surface of uct maintains a workable pot life. The substrate temperature taminated from exposure to the elements, thoroughly clean the guidelines at the time of catalyzation to ensure that the prodshould be between 59°F (15°C) and 122°F (50°C). Discontinue membrane application when the ambient temperature ex- ceeds 104°F (40°C) and/or the substrate temperature exceeds the 122°F (50°C) maximum. In warm temperatures, the substrate should be shaded for a sufficient period of time both prior to and during application, as necessary, to maintain substrate temperatures below 122ºF (50ºC). Winter Grade Parapro Flashing Resin may be applied when the ambient temperature is between 23°F (-5°C) and 68°F (20°C). The resin itself should be within storage temperature guidelines at the time of catalyzation to ensure that the product maintains a workable pot life. The substrate temperature should be between 23°F (-5°C) and 77°F (25°C). the catalyzed Parapro Flashing Resin becomes dirty or contransition area with Pro Prep. Pro Prep should be allowed a minimum of 20 minutes evaporation time after application be- fore continuing work. Following the drying time, the next application process should be completed within 1 hour. Parapro Flashing Resin Pot Life Parapro Flashing Resin pot life is approximately 15 minutes when the catalyzed liquid is at 68°F (20°C). Pot life will be reduced if the resin is at higher temperatures. Pot life can be maximized by storing product under controlled conditions and ensuring that the liquid resin is at the low range of minimum storage temperature during/following catalyzation and prior to application. All flashing/penetration applications installed in conjunction with the Parapro Roof System should be completed prior to the liquid field membrane application. 16 Parapro Flashing Resin Parapro Flashing Resin Set Times Minimum Total Consumption: may vary. The information provided is based on laboratory Coverage Rate (smooth surfaces) 0.31 kg/sf (0.22 liter/sf) (3.3 kg/m²) Base Coat Minimum Consumption: 0.19 kg/sf (0.13 liter/sf) (2 kg/m²) Top Coat Minimum Consumption: 0.12 kg/sf (0.09 liter/sf) (1.3 kg/m²) Coverage Rate (granule surfaces) Minimum Total Consumption: Minimum set (cure) times noted below are approximate, and conditions, and is intended for use as a guideline only. Actual (cure) times should be established in the field, based on actual field conditions. Rain Proof at 68°F (20°C): 30 minutes Ready for Next Coat at 68°F (20°C): 45 minutes Ready for Foot Traffic at 68°F (20°C): approximately 2 hours 0.4 kg/sf (0.29 liter/sf) (4.3 kg/m²) Base Coat Minimum Consumption: 0.28 kg/sf (0.20 liter/sf) (3 kg/m²) Top Coat Minimum Consumption: 0.12 kg/sf (0.09 liter/sf) (1.3 kg/m²) XI. Parapro Roof Membrane Resin General Application Guidelines Parapro Roof Membrane Resin, when catalyzed, forms the waterproofing layer in the system. Parapro Roof Membrane Resin is available in two formulations: Summer Grade and Winter Grade. Care should be taken to ensure the correct formulation of Parapro Roof Membrane Resin (Summer Grade or Winter Grade) is chosen for the ap- even waterproofing layer of catalyzed Parapro Roof Membrane Resin is applied to the substrate with a roller. Pro Fleece reinforcement is worked into the wet, catalyzed Parapro Roof Membrane Resin waterproofing layer using a roller to fully embed the fleece in the resin and remove trapped air. At side and end laps, Pro Fleece must be overlapped a minimum of plication based upon the temperature. 2 inches (51 mm). An additional coat of catalyzed Parapro Summer Grade Parapro Roof Membrane Resin may be ap- overlapping fleece. An even top coat of catalyzed Parapro plied when the ambient temperature is between 59°F (15°C) and 104°F (40°C). The resin itself should be within storage temperature guidelines at the time of catalyzation to ensure that the product maintains a workable pot life. The substrate Roof Membrane Resin must be placed between all layers of Roof Membrane Resin is then applied immediately following embedment of the fleece to ensure full saturation of the fleece reinforcement. Allow the waterproofing layer of Parapro Roof Membrane Resin to cure for a minimum of 45 minutes before temperature should be between 59°F (15°C) and 122°F application of the optional wearing layer and surfacing. temperature exceeds 104°F (40°C) and/or the substrate tem- If work is interrupted for more than 12 hours, or the surface of peratures, the substrate should be shaded for a sufficient contaminated from exposure to the elements, thoroughly clean (50°C). Discontinue membrane application when the ambient perature exceeds the 122°F (50°C) maximum. In warm tem- period of time both prior to and during application, as necessary, to maintain substrate temperatures below 122ºF (50ºC). the Parapro Roof Membrane Resin layer becomes dirty or the area with Pro Prep. Pro Prep should be allowed a mini- mum of 20 minutes evaporation time after application before continuing work. Following the drying time, the next applica- Winter Grade Parapro Roof Membrane Resin may be applied tion process should be completed within 1 hour. 68°F (20°C). The resin itself should be within storage tempera- Parapro Roof Resin Pot Life when the ambient temperature is between 23°F (-5°C) and ture guidelines at the time of catalyzation to ensure that the 17 After priming with the appropriate Pro Primer (if applicable), an product maintains a workable pot life. The substrate temperature should be between 23°F (-5°C) and 77°F (25°C). Parapro Roof Resin pot life is approximately 15 minutes when the catalyzed liquid is at 68°F (20°C). Pot life will be reduced if the resin is at higher temperatures. Pot life can be maximized by storing product under controlled conditions and ensuring that the liquid resin is at the low range of minimum storage temperature during/following catalyzation and prior to application. Parapro Roof Membrane Summer Grade Resin Set Times Minimum set (cure) times noted below are approximate, and may vary. The information provided is based on laboratory conditions, and is intended for use as a guideline only. Actual Parapro Roof Membrane Resin Coverage Rates: Smooth Surfaces Minimum Total Consumption: 0.31 kg/sf - 30.7 kg/square (3.3 kg/m2). Base Coat Minimum Consumption: 0.19 kg/sf - 18.6 kg/square (2.0 kg/m ) 2 Top Coat Minimum Consumption: set (cure) times should be established in the field, based on actual field conditions. Rain Proof at 68°F (20°C): 30 minutes Ready for Next Coat at 68°F (20°C): 45 minutes Ready for Foot Traffic at 68°F (20°C): 2 hours 0.12 kg/sf - 12.1 kg/square (1.3 kg/m2) Night Seals Resin Coverage Rates: Granule Surfaces grate beneath the new membrane during breaks in applica- Minimum Total Consumption: 0.40 kg/sf -39.9 kg/square (4.3 kg/m ). Base Coat Minimum Consumption: 2 0.28 kg/sf - 27.9 kg/square (3 kg/m ) 2 Top Coat Minimum Consumption: 0.12 kg/sf -12.1 kg/square (1.3 kg/m2) Night seals are necessary to ensure that water does not mition. At the end of the day’s work, or when precipitation is imminent, a night seal must be installed at all open edges. Such tie-ins can be built using Parapro materials constructed to withstand protracted periods of service. Refer to the sub- strate preparation table or contact the Siplast Technical De- partment for information on compatibility with special materials not shown. Night seals must be completely removed prior to the resumption of work. XII. Pro Natural Quartz, Siplast No. 11 Granules and Pro Color Finish Optional Surfacings layer. Pro Color Finish layers must not be applied until the for Parapro Roof Membrane Systems: Pro Natural Quartz and is set (cured). Two protective walkway/skid resistant surfacings are available Siplast No. 11 Granules. Pro Natural Quartz and Siplast No. 11 Granules Pro Natural Quartz or Siplast No.11 Granules are broadcast into a wearing coat of Parapro Roof Membrane Resin before resin sets (cures). A finish coat of Pro Color Finish is applied over Pro Natural Quartz Base Resin Wearing Layer (for embedment of aggregate to rejection): wearing layer has been in place for approximately 2 hours, and Pro Color Finish Resin Pot Life Pro Color Finish Resin pot life is approximately 15 minutes when the catalyzed liquid is at 68°F (20°C). Pot life will be reduced if the resin is at higher temperatures. Pot life can be maximized by storing product under controlled conditions and ensuring that the liquid resin is at the low range of minimum storage temperature during/following catalyzation and prior to application. Minimum Consumption: 0.09 kg/sf -9 kg/square (1.0 kg/m2) Pro Color Finish over Finished Aggregate Surfacing Application Rate Minimum Consumption: 0.046 kg/sf - Pro Natural Quartz or No. 11 Roofing Granules – 1 lb per square foot - 100 lb/square Pro Color Finish - General Application Guidelines Catalyzed Pro Color Finish Resins are applied using a roller over the completed Parapro Roof Membrane to form a color Parapro Roof System Coverage Rate 4.6 kg/square (0.5 kg/m2). Pro Color Finish Resin Coverage Rate over Pro Natural Quartz Minimum Consumption: 0.06 kg/sf - 6 kg/square (0.65 kg/m2). 18 Pro Color Finish Resin Set Times Minimum set (cure) times noted below are approximate, and may Rain Proof at 68°F (20°C): 30 minutes and is intended for use as a guideline only. Actual set (cure) times Ready for Foot Traffic at 68°F (20°C): 2 hours vary. The information provided is based on laboratory conditions, should be established in the field, based on actual field conditions. Ready for Next Coat at 68°F (20°C): 45 minutes XIII. Coverage and Consumption Rates LAYER Pro Primer T (concrete) Pro Primer R (smooth substrates) Pro Primer W (plywood) Pro Primer W (DensDeck and DensDeck Prime) Parapro Base Layer (smooth surfaces) Reinforcing Fleece - Pro Fleece Parapro Top Layer Parapro Base Layer (granule surfaces) sf/unit* 270 sf (10-kg pail) 135 sf (5-kg pail) 270 sf (10-kg pail) 135 sf (10-kg pail) 64 sf (20-kg pail) MINIMUM CONSUMPTION kg/sf kg/sq kg/m2 0.037 3.7 0.4 0.037 3.7 0.4 0.037 3.7 0.4 0.074 7.4 0.8 0.19 18.6 2 0.12 12.1 1.3 0.28 27.9 3 0.12 12.1 1.3 Reinforcing Fleece - Pro Fleece 50 sf (20-kg pail) Pro Color Finish (smooth surfaces) 215 sf (10-kg pail) 0.046 4.6 0.5 Parapro Roof Resin (wearing layer for embedment of quartz or granule surfacing) 220 sf (20-kg pail) 0.09 9 1 Pro Color Finish (quartz-surfaced substrates) 166 sf (10-kg pail) 0.06 6 0.65 Parapro Top Layer * Does not include waste, overage due to uneven/rough substrates, product needed to treat joints/cracks/overlaps and material required to saturate roller/covers. See the Parapro Estimating Guide for more information. 19 XIV. Parapro Roof Membrane System Applied over Paradiene 20 P Series Products NOTE: Flashing membrane application is typically accomplished prior to application of the Parapro field membrane. See the Parapro 123 Flashing System Installer’s Guide for information regarding detailed application of flashing materials. Preparation of Existing Parapro Surfaces Using Pro Prep, wipe down thoroughly all horizontal areas of the Parapro Flashing Membrane which will receive an overlap of the Parapro Roof Membrane. Allow Pro Prep a minimum 20 minutes drying time after application before continuing. Note: Certain substrates require priming with Pro Primer before application of Parapro Roof Membrane Resin. Refer to the Substrate Preparation Chart in the Parapro Roof Membrane Installer’s Guide for priming requirements. Apply a base coat of catalyzed Parapro Roof Membrane Resin at a minimum consumption rate of 0.19 kg/sf - 18.6 kg/square (2.0 kg/m2) using an approved roller. Due to the Install a layer of Pro Fleece into the wet Parapro Roof Membrane Resin. varying porosity of different substrates, additional Parapro Roof Membrane Resin may be required to ensure proper coverage and fleece embedment. Use a roller to embed the fleece in the resin and remove trapped air. Lap fleece layers a minimum of 2 inches, and apply an additional coat of catalyzed Parapro Roof Membrane Resin between layers of overlapping fleece. Apply a top coat of catalyzed Parapro Roof Membrane Resin at a minimum consumption rate of 0.12 kg/sf -12.1 kg/square (1.3 kg/m2) using an approved roller immediately following embedment of the Pro Fleece to ensure full saturation of the fleece. Allow to cure for 2 hours prior to application of any optional color finishes or anti-skid surfacings. The completed Parapro Roof Membrane can be exposed to foot traffic after a 2-hour cure time. 20 páéä~ëí= 1000 E. Rochelle Blvd., Irving, Texas 75062 469-995-2200 Facsimile: 469-995-2205 In Canada: 201 Bewicke Ave., Suite 210 Vancouver, BC, Canada V7M 3M7 604-929-7687 Customer Service in North America: Toll Free 1-800-922-8800 www.siplast.com www.siplastgreen.com www.siplast.com For information on Siplast Roofing and Waterproofing Systems, scan our QR codes. November 2014