High Frequency dielectric Response of Paper/Oil Insulation

advertisement

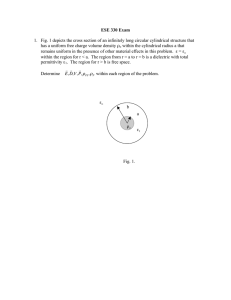

High Frequency dielectric Response of Paper/Oil Insulation L.E.Lundgaard1, D.Linhjell1, Ø.L.Hestad2, J-T.Borlaug2 1 2 SINTEF Energy Research, 7465 Trondheim, Norway Faculty of natural Sciences and Technology, The Norwegian University of Science and Technology, Trondheim, Norway Abstract- Dielectric response of oil impregnated kraft paper has been measured in the frequency range 8 Hz to 2MHz in a custom designed test cell. Temperature was varied between -17 and 60 °C, allowing master curves for 20 °C condition to be established for the frequency range 10 mHz to 10 MHz. Paper types and moisture was varied. The dielectric response showed losses in the low frequency region dominated by conduction and in the high frequency region, by a loss peak located around 10 MHz. The activation energy for the two relaxation mechanisms was found to be different: about 0. 9 eV for the conduction influenced part and between 0.4 and 0.7 for the part influenced by the high frequency peak. The low frequency part of the dielectric response is very dependent on the water content, while the high frequency part seems quite unaffected by water. I. INTRODUCTION The behavior of frequency dependent complex permittivity of materials is often denoted the dielectric response, and is explained in details by Jonscher [1, 2]. The response can be measured either in frequency domain or in time domain as a step response of polarization and depolarization [3], and it is within certain restrictions possible to calculate from one domain to the other using Fourier transform. Within the electric power community dielectric response measurements have become popular for diagnostic purposes and can be used for diagnosing water content of solid insulation both in transformers and mass impregnated cables [4, 5, 6, 7, 8]. The techniques used this far depict the average condition of the paper and oil insulation. Either by using polarization and depolarization measurements blind to high frequency effects, or using dielectric spectrometers measuring in the frequency range below 1 kHz. Lately the occurrence of copper sulfide which is unevenly distributed along windings has drawn attention to more high frequency characteristics of impregnated insulation. High frequency behavior of paper oil insulation is also interesting for calculating pulse propagation properties of oil insulated cables. Very little information is available of the dielectric response behavior of oil/paper insulation in the megahertz range. To make a diagnosis of a composite transformer insulation you need to know the dielectric characteristic of both the cellulose and oil insulation, and the dependence on temperature. This paper aims to study the dielectric response of kraft paper at frequencies up to 2 MHz. The main part of the study is done on Munksjö Termo 70, a non upgraded paper at varying moisture. Also some other paper brands were investigated. II. BACKGROUND In the frequency domain the dielectric response takes the form of a spectrum of the complex dielectric permittivity εr. Here we skip the subscript and use ε to denote the relative permittivity. The measured apparent complex permittivity consists of a real part ε ′ =1+ χ ′(ω ) and an imaginary part: σ ε ′′ = + χ ′′(ω ) ε 0ω where χ is the complex susceptibility, σ is the conductivity and ω the angular frequency. At low frequencies, below the range where susceptibility plays a role, the conductivity contribute more to the imaginary part of the measured apparent permittivity. The apparent permittivity increases inversely with falling frequency. In principle the real part should then remain constant. Often the real part is found also to vary as the inverse of the frequency. This is called low frequency dispersion. A dielectric spectrum is highly temperature dependent; increasing temperature shifts the spectra towards higher frequencies. Often the spectra plotted in a log-log plot have the same shape only being shifted in frequency systematically with temperature. When an Arrhenius analysis shows that this frequency shift is proportional to e-Ea/kT, where T is the absolute temperature and k is Boltzmann’s constant, we say that the process is thermally activated with an activation energy Ea. The higher the activation energy is, the stronger the temperature dependence is. This feature gives two advantages. First it is possible to design Master curves where temperature shifts are used to extend the spectrum outside the limits of the measurements. Second one gets a control of the quality of the measurement by intercomparison of spectra from different temperatures. One should however be aware that there may be several polarization mechanisms and that they could have different activation energies. Authorized licensed use limited to: Sintef. Downloaded on October 8, 2008 at 03:29 from IEEE Xplore. Restrictions apply. III. EXPERIMENTAL TECHNIQUES A. Test set-up The measurements were done using a Novocontrol Alpha A analyzer with a ZG4 4 wire impedance interface with an output of up to 3 V. The upper frequency limit of the instrument is 20 MHz and the lower limit depends on the capacitance of the test object. It was operated and controlled via software made in LabVIEW. Calibration and testing of the equipment and software was done with proprietary software from Novocontrol. The test cell was made of two circular Teflon dishes with 25 mm diameter stainless steel electrodes. One electrode had a spring system to give a high plateau pressure (1 kg/cm2) and tight fit to the sample. The cell was sealed with o-rings, and had a long oil-filled capillary for pressure compensation during temperature changes. The cell was connected to the ZG4 module in three-wire mode with three 30 cm long cables with QN-connectors. Calibration modules were used to compensate for the connection cables. The test-cell was lowered into a temperature controlled bath that was regulated down to -17 °C and up to 80 °C, earlier described in [8]. The test cell operates without guard and effect of stray capacitances and conduction at edges was not compensated for. However good correlation was found to earlier measurements where guard was used [8]. The whole set-up was controlled via a LabVIEW program that took care of temperature setting, measurement and data output. sequence at 20 °C, 40 °C, 60 °C, 80 °C, 20 °C, -1 °C, -10 °C, and 20 °C One series was also tested down to -17 °C. The temperature was measured at the outer surface of the cell and response measurement was started when 3 consecutive, 15 minutes interval measurements had stabilized within 0,1 °C. One total cycle took about 48 hours. Moisture content in paper was measured with Karl Fisher titration of a methanol extraction from larger paper samples treated in the same way as the tested samples. D. Treatment of results Fig. 1 shows the spectra of ε´ and ε´´ from one measurement series. Attempts to combine these to one master curve gave a poor fitting. We therefore split the spectra in two; below and above the minimum. Then the low frequency (LF) parts and the high frequency (HF) parts were separately fitted to master curves using 20 °C as a reference. Activation energies were then calculated for each of the parts. IV. RESULTS Fig. 2 shows the resulting HF master curve established by moving the various curves along the frequency axis to fit with the 20 °C spectrum. One can see that they fit quite well, except for the 80 °C. The curve now is extended from the 2 MHz measured range to a new range up to 20 MHz. Plotting the natural logarithm of the frequency shifts used to move the plots from Fig. 1 into the master curve of Fig. 2 versus the inverse temperature yields an Arrhenius plot as shown in Fig. 3. The activation energy is then found from the gradient of the curve. After calibration the system could be used up to 3 MHz with minimal errors. This was verified by measuring on a sample of 0,2 mm unplasticized PVC and comparing with results from the literature [9]. B. Objects The test samples were made as 25 mm circular cut sheets of kraft paper that were conditioned to a certain moisture content and impregnated with Nynäs 10X transformer oil. Three different paper types were used. • Munksjö Termo 70 specifically prepared for good ageing properties, thickness 60 µm. Two layers of paper were used in objects. • Munksjö Termotrans is a thermally upgraded paper, 90 µm, and two layers were used in objects. • Munksjö plain is a standard crude paper, thickness 142 µm, only one layer was used in objects. Different number of paper layers were used for the different paper types to get samples with a suitable capacitance. Fig. 1. Measured responses for Termo 70 with 3.4 % water content. Upper curve shows ε´ and lower curve shows ε´´. C. Test procedures All objects were first heated to 80 °C for ten hours to condition the papers and stabilize the response because of a conditioning effect [8]. Measurements were then performed in Authorized licensed use limited to: Sintef. Downloaded on October 8, 2008 at 03:29 from IEEE Xplore. Restrictions apply. Fig. 2. Master curve for high frequency part of spectra from Fig. 1. Reference temperature is 20°. Upper curve shows ε´ and lower curve shows ε´´. Fig. 4. Master curves for HF and LF parts of spectra for Termo 70 at varying water content. Upper curve shows ε´ and lower curve shows ε´´. Fig. 3. Arrhenius plot of logarithm of frequency shift for mastercurve fitting of spectra from Fig. 1 versus inverse temperature as basis for calculation of activation energy Ea.. This procedure was repeated for all experiments. TABLE 1 shows the activation energies found. Apparently the activation energy is different for the low frequency and high frequency parts. TABLE 1 ACTIVATION ENERGY CALCULATED FOR THE LF AND HF PART OF THE SPECTRA FOR DIFFERENT PAPER TYPESAT VARYING WATER CONTENT Paper Type Water content [%] 1.2 Termo 70 Plain Termotrans Activation energy Ea [eV] LF part HF part 0.92 0.40 1.2 3.4 5.0 0.88 0.80 0.42 0.59* 0.67 0.5 0.7 0.75 0.77 0.58 0.33 *measured in the range -17 - 40 °C Fig. 4 and Fig. 5 show the influence of the water and on paper types on the master curves. Fig. 5 Master curves for HF and LF parts of spectra for three different paper types at lowest water content. Upper curve shows ε´ and lower curve shows ε´´. V. DISCUSSION Earlier one has used only one master curve and activation energy for cellulose at one moisture level [4, 6, 8] assuming only one relaxation mechanism. All these studies have identified water as a major influence on the master curve. It has been proposed that the position of the minimum in the ε´´value could be used for diagnosing water content of the cellulose [6]. Authorized licensed use limited to: Sintef. Downloaded on October 8, 2008 at 03:29 from IEEE Xplore. Restrictions apply. Our results clearly show that the assumption of only one activation energy is wrong. The fact that the activation energy and that water dependence is different for the LF part and the HF part suggests two mechanisms, mainly conduction for the LF part and a relaxation mechanism for the HF part. The high frequency peak is wider than a Debye-relaxation, suggesting multiple synergetic effects. frequency region being influenced by conductive phenomenon and being sensitive to water content. Another in the high frequency region with a resonance peak in the 10-20 MHz region. The high frequency resonance peak is little influenced by water. REFERENCES The LF part seems to be mainly influenced by conduction mechanism, but the fact that the real component of the permittivity ε´ changes is not in line with this. If it had been pure conduction behavior it should not have influenced the real component. This behavior is usually called low frequency dispersion. Possibly this could be explained by cellulose being a porous material where the oil at low frequencies will short circuit the spaces between the cellulose fibers thus reducing the virtual thickness of the sample. It is no surprise that the conduction dominated LF part is influenced by the water content. Water will increase dissociation, increase the number of charge carriers (ions) and increase conductivity in the oil that surrounds the cellulose fibers. The activation energy found here being 0.8-0.92 eV is somewhat smaller than the 0.98 – 1.08 eV values found earlier [8], and shows that these values are uncertain. It is larger than the values earlier found for oil (about 0.5 eV), showing that it is not only dominated by the oil. Since the measurements were done without guard, the low value could be a sign of some influence of conduction in the oil around the object. Also the variation with water content was within 25 % of what found earlier [8]. The relaxation is not water dependent and seems to be more related to the cellulose fibers themselves. The results shown in Fig. 4 did not reveal the relaxation peak clearly. Measurements down to -17 °C extended the master curve a bit more than showed in Fig. 4, and suggest that it will be found in the 10-20 MHz range. To get a better identification of the peak we need either to improve the high frequency limit of the set-up or make measurements at lower temperatures. [1] A.K. Jonscher: ” Dielecttric Relaxation in Solids”, Chelsea Dielectric press Ltd, 33 Lynwood Road, London, 1983. [2] A.K. Jonscher: ”Universal Relaxation Law”, Chelsea Dielectric Press Ltd, 33 Lynwood Road, London, 1996 [3] Cigre SC TF D1.01.09 (S.Gubanski), “Dielectric Response Methods for Diagnostics of Power transformers”, Brochure No. 254, Paris 2004 [4] U.Gäfvert, G.Frimpong and J.Fuhr, “Modelling of Dielectric Measurements on Power Transformers”, Paper 15:1.2, CIGRÉ session, Paris, August 1998. [5] C.Ekanayake, “Diagnosis of Moisture in Transformer Insulation”, Thesis, Chalmers Univ. of Technology, Gothenburg, Sweden, Jan. 2006. [6] R.Neimanis: “On Estimation of Moisture Content in Mass Impregnated Distribution Cables”. Thesis, Royal Institute of Technology (KTH), Stockholm, Sweden, 2000. [7] V.d.Houhanessian “Measurement and Analysis of Dielectric Response in Oil-Paper Insulation Systems”, Thesis, Swiss Federal Institute of Technology, Zürich, Switzerland, 1998. [8] D.Linhjell, L.Lundgaard, U.Gäfvert:„Dielectric Response of Mineral Oil Impregnated Cellulose and the Impact of Aging”, IEEE TDEI [9] N.G.McCrum, B.E.Read, G.Williams: ”Anelastic and Dielectric Effects in Polymeric Solids – Dover Edition”, Dover Publications Inc, 31 East 2nd Street, Mineola, NY, 11501,1991 The comparison of the different cellulose types does not support any clear conclusion. The HF and LF parts do not fit as well as in Fig. 4. The water content was a bit different, but cannot explain the large difference between Termo 70 and Termotrans. The discontinuation seen in ε´´ for plain paper does also appear in the ε´ value. This is clearly an artifact and believed to stem from the curve fitting. For this paper also the gradient of the LF part is different. This sample had only one paper layer making oil channel bridging through the paper possible. The basic shape is the same for all paper types, but more work is needed to sort out potential differences between different paper qualities. VI. CONCLUSION It is shown that the dielectric response of oil impregnated cellulose is influenced by two mechanisms. One in the low Authorized licensed use limited to: Sintef. Downloaded on October 8, 2008 at 03:29 from IEEE Xplore. Restrictions apply.