Improvement in the Frequency Response of Loudspeakers by Using

advertisement

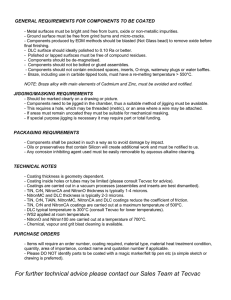

Materials Transactions, Vol. 52, No. 10 (2011) pp. 1966 to 1971 #2011 The Japan Institute of Metals EXPRESS REGULAR ARTICLE Improvement in the Frequency Response of Loudspeakers by Using Diamond-Like Carbon Film Coatings Chii-Ruey Lin1 , Shin-Hwa Liu2 , Wang-Jeng Liou1; * and Chien-Kuo Chang1 1 Graduate Institute of Mechanical and Electrical Engineering, National Taipei University of Technology, Taipei 10608, Taiwan, R. O. China 2 Graduate Institute of Vehicle Engineering, National Taipei University of Technology, Taipei 10608, Taiwan, R. O. China It is well known that a diamond-like carbon (DLC) film has a high mechanical hardness and Young’s modulus. One of the beneficial properties of a DLC film is its ability to change the sound velocity in loudspeakers through its application as a hard coating. In the present study, DLC films were coated onto polyetherimide (PEI) diaphragm substrates at low temperature with radio-frequency (RF) magnetron sputtering. Amorphous DLC films deposited at an RF power of 150 W and with a deposition time of 3 h have a high ID =IG ratio and a low surface roughness. The ID =IG ratio and surface roughness were 2.27 and l.21 nm (Ra), respectively. From frequency response analysis of the DLC film on the diaphragm, we found that the frequency response increased by 0:21:2 dB on average. This confirmed the excellent adhesion of DLC films onto PEI (or polymer) substrates for future potential applications in acoustic wave devices. [doi:10.2320/matertrans.M2011080] (Received March 10, 2011; Accepted July 11, 2011; Published September 25, 2011) Keywords: diamond-like carbon (DLC) thin-film coatings, acoustic, frequency response, diaphragm 1. Introduction The mini dynamic loudspeaker was successfully developed by Mr. Eugen Beyer, a German scientist, during the 1930s. We now find its ubiquitous application to mobile devices, such as mobile phones, MP3 and MP4 players, and laptops. The more we become accustomed to these technological conveniences, the more we rely upon mini loudspeakers of better quality. The total quality of the loudspeaker depends on the performance indexes of its 4 main constituent subsystems: the vibration system, magnetic system, the coupling system between the aforementioned two systems, and support systems. We must see it from a holistic viewpoint instead of a compartmentalized viewpoint. Apart from the vibration system, the other 3 systems have been well developed. The quality of the diaphragm of the vibration system will be based on 3 essential requirements, outlined below.1,2) (1) The modulus of the diaphragm material will be as high as possible to provide a wider range of frequency responses and lower distortion. (2) The density of the diaphragm material will be as low as possible in order to increase the fidelity. (3) The intrinsic damping capacity of the diaphragm material will be such that loudspeaker partition vibration is attenuated. The audible frequency of human hearing ranges from 20 Hz to 20 kHz.3) Since the demarcations of low, medium, and high frequency ranges are not clearly defined, this study assigns a definition of low frequency (LF) as 100710 Hz, mid-frequency (MF) as 7505:6 kHz, and high frequency (HF) as 640 kHz. Each frequency band is further divided into three discrete narrow bands, LF: 100180 Hz, 190355 Hz, 375710 Hz; MF: 750 Hz1:4 kHz, 1:5 2:8 kHz, 35:6 kHz; and HF: 611:2 kHz, 11:822:4 kHz, *Corresponding author, E-mail: s3669014@ntut.edu.tw Fig. 1 The Impedance curve and fo from the examination. 23:640 kHz. Resonance frequency fo of a loudspeaker is representative of the loudspeaker at the initial point of the frequency response. According to this theory, we could find out the resonance frequency fo by eq. (1). This research used a CLIO audio test system to conduct sampling and measurement by tracing through the characteristic impedance curve, as shown in Fig. 1. sffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi 1 1 fo ¼ ð1Þ 2 mo Co where fo : Resonance frequency (Hz) Co : Compliance mo : Total mass of vibration system mo ¼ md þ mc þ mad md : Mass of diaphragm mc : Mass of coil mad : Mass of additional air, equal to 8a d 3 =3 a : Density of air d: Effective diameter of diaphragm Improvement in the Frequency Response of Loudspeakers by Using Diamond-Like Carbon Film Coatings Table 1 Physical properties of different vibration diaphragm materials. Material Young’s modulus E (1011 Pa) Density (g/cm3 ) Coil Suspending Sound velocity C (km/s) Paper 0.002 0.5 2.0 PEI Stainless steel 0.03 1.27 0.13 2.0 7.9 5.1 Al. 0.74 2.7 5.2 Ti. 1.1 4.5 5.2 1967 carrier Dome (Cap) edge 3.25mm 10.5mm Fig. 2 Coil Sectional view of a loudspeaker. W.C. 7.2 15.6 6.8 Al2 O3 4.3 3.9 10.4 Be. DLC 2.8 3.3 1.8 1.8 12.3 18.3 Coating pattern (PEI) RF Power (W) Ar. flow rate (sccm) Pressure (Pa) Deposited time (h) Diamond 11.5 3.5 18.5 C2aC4a 150 25 1.3 3 Since 1887, beryllium has been used innovatively by Yamaha for loudspeaker diaphragms in treble units. In 1968, they accomplished automatic completion of cone and forming equipment used in low-frequency diaphragms material from plant fiber to animal fibers, man-made fibers, and reinforced fiber polymer. The qualities of the frequency response and the maximum frequency have therefore increased significantly. In the late 1970s, many kinds of polymers and ceramic materials were developed, such as carbon fiber (1973), beryllium composites (1976), aluminum, titanium, boron alloy, magnesium alloy, pure beryllium (1978), carbon-graphite (1979), ceramic graphite (1987), graphite composite materials, and all-crystalline diamond material (1989). In 1986, Japan Sumitomo Electric Company primary produced a DLC/Ti composite cone. A loudspeaker diaphragm needs to have high rigidity, low density, high sound propagation velocity, and high heat conduction, as shown in Table 1.4,5) The mass of the diaphragm plays an important role in determining the frequency response directly; that is, a lighter loudspeaker diaphragm manifests better frequency response. A highquality tweeter diaphragm must be made of highly rigid, thin, and light material. In recent years, DLC films have been used in loudspeaker diaphragms, which would improve the frequency response drastically. DLC films retain most diamond properties, such as chemical inertness, high mechanical hardness, high Young’s modulus, and high sound conduction velocity.6) The properties of DLC films are conducive for their use in loudspeaker diaphragms owing to the fact that their properties can vary from those of diamond (sp3 bonding) to those of graphite (sp2 bonding). The diamond (sp3 bonding) properties can be used to increase the sound velocity (E=) in the loudspeakers.7,8) Microelectronics and measuring systems (MEMSs),9) and electro-optical systems, piezoelectric systems10–12) have been previously employed in acoustic wave device studies. Furthermore, materials combined with various kinds of metal-substrates, such as aluminum13) and titanium,14) have been developed and investigated to enhance frequency response performance. Moreover, improvement has been made through studies15) that used finite element methods (Abaqus) to simulate the diaphragm coating with DLC in different areas and to study the frequency response that is influenced by different coating areas on the diaphragm,16) and Table 2 Parameters of R.F. sputter deposition. through studies that investigated issues related to the sputtering process, such as substrate holder rotation, in order to achieve uniform deposition. DLC films can be deposited by various physical vapor deposition (PVD) methods in combination with radio frequency (RF) plasma and chemical vapor deposition (CVD) methods. RF magnetron sputtering was used in this study because of its advantages such as deposition of large areas with uniformity and processing at room temperature.17) In this study, we deposited DLC coatings on polyetherimide (PEI) diaphragm substrates with varying parameters for instance deposition area. The corresponding microstructural properties of DLC films were identified by Raman spectroscopy, atomic force microscopy (AFM), and scanning electron microscopy (SEM). 2. Experimental Methods and Procedures The aim of this research was to deposit DLC onto PEI diaphragm films to improve the performance of mini loudspeaker frequency response. Because the glass transformation temperature of PEI materials (216 C) is relatively lower than the CVD working temperature (600 C–800 C), we could not use the CVD process with such materials. We as an alternative used RF magnetron sputtering to deposit DLC thin films to avoid deformation or deterioration of the diaphragm. RF magnetron sputtering was employed to deposit a DLC thin film onto a PEI substrate with a diameter of 17.0 mm and a thickness of 25 mm. Owing to the use of the vibration technique, the suspending edge (Fig. 2) areas should not be coated. Appropriate flexibility of suspending edge should be maintained. For verification, documentation on this experiment is included in following section. With the aim of obtain the relevant coating parameters, data on composition and thickness was acquired using a Si wafer, through Raman spectroscopy, AFM, and SEM. Experimental parameters are listed in Table 2. Next, the PEI substrate was replaced with the Si-wafer, and its surface was cleaned with methanol in ultrasonic equipment for 3 min so as to remove contaminants from the surface to guarantee adhesion. The substrates were placed at a distance of about 9 cm to 12 cm from the target. The PEI substrates were rotated at a speed of 15 rpm. And two shields 1968 C.-R. Lin, S.-H. Liu, W.-J. Liou and C.-K. Chang 8.5mm 5.25mm Diaphragm No. C1 Diaphragm No.C2a Diaphragm No.C3a Diaphragm No.C4a Note 1. Diaphragm type P2024 - 25 BPEI, thickness 25 µm 2. Deposition area Fig. 5 Frequency response before and after DLC coating. (C1, without coating, C2aC4a coated). Fig. 3 4 types DLC coating pattern of diaphragm in this study: (C1) without coating, (C2a) whole area coating, (C3a) suspending edge coating, (C4a) dome coating. Fig. 4 Photos of coated with DLC thin films show (a) Diaphragm, and (b) Loudspeaker assembly. model were designed for three different coated areas, as shown in Fig. 3. After assembly, the mini loudspeakers were tested at a distance of 10 cm from microphone in a semi-anechoic chamber having the SoundCheck and CLIO audio test system, B&K microphone, and other equipment, for sound measurement and validation. 3. Results and Discussion (1) After several previous failed studies, including tests that used shielded fixtures, readjusted the sputtering parameters, and fixed the sputtering chamber diaphragm, the present study succeeded in depositing a 120-nm DLC film on PEI diaphragms by sputtering. Some finish diaphragm assemblies are shown in Fig. 4. The color and uniformity of coatings can be observed clearly. (2) The frequency responses before and after sputtering are shown in Fig. 5. Regardless of whether sputtering was carried out, the frequency bands remained above 75 dB. In particular, at more than 30 kHz, the reduction trend of frequency response of the diaphragms after sputtering is lower than that of uncoated one. (3) Figure 6 shows the cross-sectional SEM images of the amorphous DLC film deposited for 3 h. The film thickness was found to be 120 nm. Further, the detailed bonding structure of the carbon samples was observed Fig. 6 Shows that the SEM cross-sectional view of DLC film had been deposited for 3 h, 1.3 Pa, with Ar. 25 sccm sputtering. clearly by Raman scattering. Raman spectroscopy is a non-destructive method to characterize the structure of graphite, diamond, and DLCs. The single Raman peak located at 1580 cm1 in this study is attributed to highly crystalline graphite in an as-deposited DLC film structure. The peak located at 1350 cm1 is attributed to micro-crystalline graphite with disordered sp3 sites. The ID =IG ratio of the DLC film was calculated by two Gaussian-fitted peaks in the Raman spectra. An ID =IG ratio of 2.27 was obtained at a deposition time of 3 h, as shown in Fig. 7. For comparison of the surface topography under varying parameters of the DLC films, the surface roughness values of DLC films were obtained by AFM analysis. The surface topography was analyzed by AFM in a scanning area of 10 mm 10 mm of the DLC film under an RF power of 150 W and deposition time of 3 h, as shown in Fig. 8. The surface of the DLC film was very flat, with an average roughness (Ra) of 1.21 nm. The Young’s modulus and density of the film were around 3:3 1011 Pa and 1.82 g/cm3 , which the Young’s modulus of DLC film was obtained by adopting nano indenter, and the density of as-grown DLC thin film was estimated as corresponded to their hardness,18) respectively. Improvement in the Frequency Response of Loudspeakers by Using Diamond-Like Carbon Film Coatings 1969 Fig. 9 Impedance compares curves. Fig. 7 Raman spectra of the DLC films deposited with deposition time of 3 h. (with Gaussian fitting of D and G peaks). Table 3 Impedance comparison table. Coating pattern Impedance () Frequency (Hz) Fre. Ratio E (C a/C1) C1 C2a 13.32 14.77 714.4 783.0 1 1.09 C3a 14.45 749.9 1.05 C4a 14.08 718.2 1.01 (5) Assume that the mass (mo ) of the diaphragm is unchanged; then, according to eq. (2), if the Young’s modulus of the material at the suspending edge is doubled (E2 =E1 ¼ 2), then the resonance frequency of the diaphragm increases by 1.4 times (E ¼ 1:4).19) Assume mo ¼ const. sffiffiffiffiffiffi sffiffiffiffiffiffi fo2 C1 E2 ð2Þ E ¼ ¼ ¼ fo1 C2 E1 Fig. 8 AFM surface topography images for the DLC films deposited at RF power of 150 W and with deposition time of 3 h with a scanning area (10 mm 10 mm), and the average roughness (Ra) value is 1.21 nm. (4) For this study, the loudspeaker resonance frequency fo was 714.4 Hz. The result of measured fo was shown in Fig. 9. Table 3 presents data obtained after the sputtering process and testing. All of the resonance frequencies were found to have increased significantly, which is supported by the principle in eq. (1). where mo : Effective mass of vibration system fo1 , fo2 : Resonance frequency of raw and coated vibration systems, respectively. C1 , C2 : Compliance of raw and coated diaphragm, respectively. E1 , E2 : Young’s modulus of raw and coated diaphragms, respectively. (6) The DLC film thickness of 120 nm, in comparison to the PEI diaphragm thickness of 25 mm, is about 1/200 of the thickness of the raw materials, and according to eq. (3), density increments (2.07/1000) of the film are considered to be negligible. However, according to the transformed-section method,20) eq. (4), and eq. (5), the Young’s modulus of the DLC film is evaluated to be 1.496 times that of the raw materials. According to eq. (2), resonance frequency should be 1.223 times the original frequency. Instead, the C2a resonance frequency increased only 1.09-fold, C3a increased 1.05fold, and C4a increased 1.01-fold during experiments. This is because the transformed-section method assumes that the diaphragm section is a flat plate, but the section is actually an arc. Moreover, for the computations in this study, we assumed that the whole area was coated, i.e., the C2a coating pattern was followed. 1970 C.-R. Lin, S.-H. Liu, W.-J. Liou and C.-K. Chang Table 4 Frequency response comparison table in individual central frequency of type Ca. No. fc .(Hz) Type C1 C2a C3a C4a Note (dB) (dB) (dB) (dB) (Hz) 125 66.2 64.5 62.9 65.5 100180 250 78.4 76.3 74.9 77.5 190355 500 1k 92.5 96.2 91.0 97.4 88.7 97.6 91.2 97.0 375710 7501:4k 1:5k2:8k 2k 93.5 94.1 94.8 94.7 4k 93.8 93.9 87.4 93.0 3k5:6k 8k 94.5 95.3 86.6 88.8 6k11:2k 16k 95.2 95.7 91.5 94.2 11:8k22:4k 31.5k 90.0 90.3 88.8 90.1 23:6k40k Fig. 10 Frequency response comparison in individual central frequency of type Ca. Note: Bold letters are meaning larger than original. However, C3a and C4a coatings were only partial. The Young’s modulus for a partial coating will be inevitably lower than that for a whole-area coating. Therefore, the change in fo reduced along with the reduction in coating area. It is reasonable that fo will increase with a small increase in the Young’s modulus. Essentially, they are well matched. C4a sputter only a ‘‘dome’’-shaped part. Theoretically, it should not affect the initial fo . 1 t1 þ 2 t2 c ¼ ð3Þ t1 þ t2 E2 n¼ ð4Þ E1 E1 I 1 þ E1 I 2 Ec ¼ ð5Þ I0 Where c : Compound density t1 , t2 : Thickness of raw and coated materials, respectively I1 , I2 : Moment of inertia of raw and coated materials, respectively E1 , E2 : Young’s modulus of raw and coated materials, respectively Ec : Compound Young’s modulus I 0 : Moment of inertia of real shape at its neutral axis. (7) The purpose of our research was to improve the performance of mini loudspeakers, whose low frequency response is well known to be poor. The lower limit of frequency in the study was 100 Hz. To evaluate performance across every range of frequency, the study divided the frequencies into nine bands, in high frequency, intermediate frequency, and low frequency ranges, as shown in Table 4. The band of the center frequency, fc , was defined the same as the Acoustics. The value of each band frequency response (sound pressure level) adopts its arithmetic mean so as to avoid the interference of noise and ensure objectivity, as in Fig. 10. A. This type of loudspeaker cannot have acoustic fidelity at a frequency lower than 714.4 Hz Fig. 11 Frequency response curve of C3a diaphragm. ( fo ). Below 714.4 Hz, the frequency response decreased by 0:73:8 dB on average (indicated by the curve shift to the right). This is because fo increases with an increase in the Young’s modulus relative to diaphragm sputtering. B. Except in the case of the C3a and C4a resonance frequencies at 4 kHz. The effect of sputtering was greater at frequencies between 750 Hz and 5.6 kHz, where the increases were from 0.1 to 1.4 dB. C. Except for the increase in frequency response in the case of C2a from 0.3 to 0.8 dB, the highfrequency range was generally ineffective in improving frequency response. First, for C3a, a DLC film with a high Young’s modulus was deposited on the suspending edge, which was likely to increase the stiffness (K) of the vibration system, as shown in Fig. 11. The result was not good as we had expected. Second, for C4a at 3.5 kHz and between 5 kHz and 9 kHz, the 2nd and 3rd harmonics caused a large distortion because of the partition vibration, as shown in Fig. 12. Above 31.5 kHz, the frequency response of uncoated diaphragm was decrease faster than that of coated diaphragms. Improvement in the Frequency Response of Loudspeakers by Using Diamond-Like Carbon Film Coatings 1971 the properties of DLC films. These results also offer useful parameters for devising modern applications of acoustic wave devices. REFERENCES Fig. 12 Distortion curve of C4a diaphragm. 4. Conclusions In this study, DLC films were successfully deposited on polymer substrates at a low temperature (around 100 C) by RF magnetron sputtering. The physical behavior of DLC/PEI structures could be improved to bring their average frequency response values up to 0:21:2 dB, their ID =IG ratio up to 2.27, and their roughness to less than 1.21 nm (Ra). At frequencies over and above 20 kHz, which is beyond human hearing, a remarkable improvement is expected, because this frequency is related to auditory compliance of human. Moreover, the C2a coating pattern was found to be optimum for sputtering over the whole area of the substrate, simplifying the manufacturing process, and improving yield. On the basis of the results of this study, we validated that it was practicable to sputter DLC thin films onto PEI diaphragms for commercial processing, with the aim of improving highfrequency response. The investigations reported here have highlighted the importance of RF power deposition for tuning 1) Y. W. Zhou: China Avphile. 07 (1998) 37. 2) C. H. Jian and K. L. Lin: Audio Technology, (Chuan Hwa Book Co. Ltd., Taipei, 1976) p. 131. 3) C. M. Harris: Handbook of Noise Control, 2nd ed., (MeGraw-Hill, USA, 1979) pp. 1–6. 4) G. N. Luo, Z. W. Xie, J. H. Zhen, Z. H. Yuan, Q. S. Deng and D. H. Dai: J. Function. Mater. 26 (1995) 417–420. 5) Z. H. Yuan, S. S. Lin, H. J. Hou, S. C. Li and X. G. Zhu: Audio Eng. 4 (2003) 21–23. 6) S. Shikata, S. Fujii and T. Sharda: Diamond Relat. Mater. 18 (2009) 253–257. 7) J. R. Du: Audio Eng. 09 (2006) 21–22. 8) T. Yoshioka, O. Imai, H. Ohara, A. Dol and N. Fujimori: Surf. Coat. Technol. 36 (1988) 311–318. 9) D. W. Galipeau, P. R. Story, K. A. Vetelino and R. D. Mileham: Smart Mater. Struct. 6 (1997) 658–667. 10) S. S. Lee, R. P. Ried and R. M. White: J. Microelectromechan. Systems 5 (1996) 238–242. 11) S. H. Yi and E. S. Kim: Jpn. J. Appl. Phys. 44 (2005) 3836–3841. 12) I.-T. Tang, H.-J. Chen, W. C. Hwang, Y. C. Wang, M.-P. Houng and Y.-H. Wang: J. Crystal Growth 262 (2004) 461–466. 13) B. J. Zhang and B. R. Sun: Audio Eng. 02 (1997) 23–25. 14) Z. W. Zhang, R. Z. Li and H. S. Zhu: Chin. J. Mater. Res. 8 (1994) 330–336. 15) K. C. Chang: Master Thesis, (National Taiwan University, Taipei, 2007). 16) Z. W. Xie, J. H. Zheng, Z. H. Yuan, Q. S. Deng, G. N. Luo, D. H. Dai and Z. Q. Fu: Mater. Res. Appl. 8 (1998) 52–56. 17) B. R. Pujada, F. D. Tichelaar and G. C. A. M. Janssen: Surf. Coat. Technol. 203 (2008) 562–565. 18) Y. Oka et al.: Nuclear Instruments and Methods in Physics Research Section B. 242 (2006) 335–337. 19) X. J. Que and H. Z. Fu: Technical Acoustics 8 (1989) 25–28. 20) J. M. Gere and S. P. Timoshenko: Mechanics of Materials, (Wadsworth, California, 1986) 2nd ed., pp. 252–255.