Chapter 4 – Mechanical – Zonal Hqrs/Workshops/ Production units

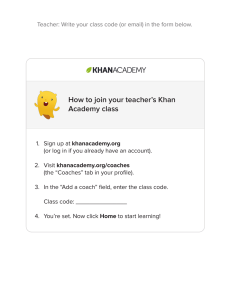

advertisement