R. D. S. O.

advertisement

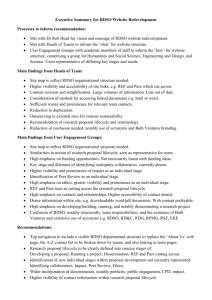

OF SYMMETRY U3 U2 U2 U1 OF SYMMETRY ARCH B L1 L0 OF BEARING OF BEARING A HAND RAIL L2 L3 L2 L1 L0 KEY ELEVATION - BOW STRING GIRDER (SCALE 1:300) WEIGHT OF STEEL REMARKS THIS VALUE IS APPROXIMATE SO SHOULD NOT BE USED FOR PAYMENT PURPOSE 136 ton HANGER S.NO. BEARING CONCRETE PEDESTAL A U1 B DRG. NO. DESCRIPTION 1. RDSO/B - 10407 GENERAL ARRANGEMENT 2. RDSO/B - 10407/1 DETAILS OF STEEL FRAME 3. RDSO/B - 10407/2 DETAILS OF ARCH & TOP JOINTS 4. RDSO/B - 10407/3 DETAILS OF TOP TIE BEAM 5. RDSO/B - 10407/4 DETAILS OF HANGER & JOINT L0 6. RDSO/B - 10407/5 DETAILS OF BOTTOM LONG. BEAM 7. RDSO/B - 10407/6 DETAILS OF BOTTOM CROSS BEAM 8. RDSO/B - 10407/7 DETAILS OF CONCRETE DECK SLAB 9. RDSO/B - 10407/8 SPLICING LOCATIONS NOTE: ELEVATION 1. All dimensions are in mm. (SCALE 1:100) SUITABLE FOUNDATION SUITABLE FOUNDATION 2. No dimensions shall be scaled from this drawing, only written dimension shall be followed. 3. This bridge span is designed for 70R and A-class loading as per IRC:6-2010. 4. This bridge span is designed for earthquake zone V. 5. Analysis and design of steel frame is as per IRC:24-2001. 6. Analysis and design of composite concrete deck is as per IRC:22-1986. 7. This bridge shall not be converted into three lane after removal of RCC crash barrier because it is designed for two lane loading only ( as per IRC:6-2010). 6. All steel plates used in fabrication of this bridge are of grade Fe 490B. Only ISMB 600 is of grade Fe 410C. 7. Grade of concrete for deck, crash barrier and concrete panels shall be M40. OF CARRIAGE WAY 8. All material shall pass test/analysis prescribed by relevant IS specifications. 9. All steel work fabrication shall be done in accordance with Indian Codes. 10. Workshop welding: ARCH a. All workshop fabrication shall be done using SAW (Submerged Arc Welding) process only. TOP TIE BEAM ARCH 11. On site welding: a. All welding, other than workshop welding, shall be done through Gas Shielded M. S. HAND RAIL WITH WELD MESH FCAW (Flux Core Arc Welding) process only. SMAW (Shielded Metal Arc Welding) also known as Manual Metal Arc Welding shall NOT be permitted RCC CRASH BARRIER anywhere in the structure. b. The gas Shield to be used in the FCAW process may be CO POT/PTFE BEARING Argon or CO -Argon mixture. c. In FCAW process, wind screen and/or enclosures shall be provided around the BOTTOM CROSS BEAM welding location to prevent shielding gas from blown out. RCC BEARING PEDESTAL STAIR CASE IS SITE SPECIFIC d. Welding shall be performed on prepared metal surfaces free from rust, dust, moisture etc. and before every new pass, slag must be carefully chipped off from weld surface. 12. Radiography test shall be conducted to ensure weld quality. RCC PIER CAP 13. Method of launching shall be approved by RDSO. 14. Pier and foundation used here are to represent arrangement of bow string girder. DRAIN PIPE Actual dimensions of pier and foundation is site specific. CARRIAGE WAY 15. Staircase is optional and may be modified as per site requirement. 200 THK. WEARING COAT HANGER 65 MM THK. WEARING COAT R. RCC CRASH BARRIER EXISTING ROAD/OGL 2.5% SLOPE 2.5% SLOPE RCC PIER BOTTOM LONG. BEAM DRAIN PIPE BOTTOM CROSS BEAM GENERAL ARRANGEMENT RCC SHUTTERING PROVISIONAL SECTION B-B (SCALE 1:60) (PAPER SIZE A1) (SCALE 1:100) CALCULATION REGISTER NO. DD/2014/8 AutoCAD FILE NO.: B-10407 DRAWN BY: M/S Abhinav Associates DESIGNED BY: CHECKED BY: V.K.PANDEY (SSE) VIVEK KUMAR (ADEN/NCR/B&S/RDSO) SCRUTINIZED & CHECKED BY: SRIJAN TRIPATHI (DBS /SB-I) O. 36m CLEAR SPAN PCC LEVELING COURSE SECTION A-A S. ROAD OVER BRIDGE BOW STRING STEEL GIRDER M.S HANDRAIL RCC PILE CAP SUITABLE FOUNDATION D. APPROVED BY: A. K. DADARYA (EDBS) RDSO/B - 10407 "THIS DRAWING IS THE PROPERTY OF RESEARCH DESIGN AND STANDARD ORGANIZATION ( MINISTRY OF RAILWAY ), LUCKNOW-226011, INDIA, AND SHALL NOT BE USED, COPIED OR REPRODUCED IN PART OR WHOLE, WITHOUT PRIOR CONSENT IN WRITING."