G2500-WBE Direct Drive Generator Operators Manual

advertisement

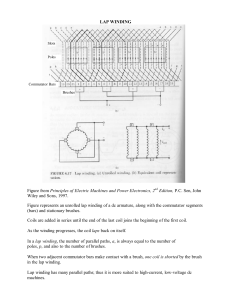

GENERATOR AND ELECTRICAL INFORIiIATION An e l e c t r i c a l generator is a machine s o constructed t h a t when its r o t o r i s revolved a voltage i s b u i l t up, which causes current t o flow. Generators a r e divided i n t o two classes: Direct current, i n which the current always flm in the same direction, and Alternating Current, i n which the current reverses its d i r e c t i o n 60 times a second i n a 60 cycle generator or 50 times a second i n a 50 cycle generator, etc. Voltage i s the force o r pressure which causes a flow of current through the conductor. Voltage can be compared t o pressure i n a pipe of water system. Amperage i s a measure of the r a t e of current f l o w through t h e conductor. can be compared t o the number of gallons per minute i n a water system. It An ohm i s a measure of the resistance i n a conductor t o the flow of current, If one v o l t can cause one ampere t o flow through a conductor the resistance of the conductor i s one ohm. This can be compared t o the manner i n which the resistance of a water pipe limits the flow of water a t a given pressure, CHANGING ROTATION OF GENERATORS To change the r o t a t i o n of Belt-Drive Generators, interchange the leads t o the DC brushes. I n other words, there a r e Cwo DC Brushes o r two airs of DC &shes. Take the lead or' leads from the f i r s t brush and fasten them t o the second brush and take the lead o r leads from the second brush and f a s t e n them t o the first brush, I n a d i r e c t current generator the current always f l m s i n the same direction. This i s accomplished by means of the commutator and brushes which a c t t o keep the current flowing i n a constant direction. The commutator and brushes a c t a s a group of double throw switches, reversing a c o i l ' s connection t o the l i n e j u s t a s it i s star.ting t o pass under a f i e l d pole of opposite polarity. The commutator and brushes of a D.C. rrachine carry a l l of the current generated within the machine. These a r e subject, therefore, t o a l l overloads. If overload continues t o eldst, the generator may become daxnaged. The commutator becomes hot and then arcing develops, v:hich, i n turn, continues t o r u i n the commutator. Therefore, never subject a D.C. generator t o overload a s it shortens t h e life of the unit. D.C. Generators a r e a l s o divided i n t o two types, namely, shunt and compound wound, The shunt wound type has only the shunt f i e l d coils. Therefore, the voltage of this type of machine w i l l drop a s load i s increased. The shunt wound generator is used most often f o r b a t t e r y charging plants. The compound wound machine, i n addition t o shunt f i e l d c o i l s , a l s o has the s e r i e s f i e l d coils. These c o i l s a r e i n s e r i e s with the load. A s the load increases, so does the current through the s e r i e s coils, automatically supplying e x c i t a t i o n and e i t h e r boosting the voltage s l i g h t l y o r maintaining it more o r l e s s constant. Therefore, ~ 5 t h a compound DeC, machine you can overload excessively *thou% causing voltage t o drop, T h i s c h a r a c t e r i s t i c of the compound wound D.c. generator makes it e a s i e r t o unknowingly overload the engine, It is, themfore, advisable t o carefully check the load a t regular i n t e r v a l s t o gather assurance t h a t overload does not e x i s t , GENERATOR TROUBLES - DeCo The most common source of D,C, generator trouble is overloading, Overloading, i n turn, causes commutator and brush troubles which can be very bothersome and costly. Overloading a machine beyond i t s rated capacity r e s u l t s i n sparking o r arcing brushes, accompanied possibly by heating and discolorat i o n of the commutator due t o the excessive current which they a r e carrying. !Chis sparking i s of such a nature a s t o damage both the brushes and commut a t o r whose surface w i l l be burned and discolored due t o overheating, espec i a l l y if the overload is.allowed t o continue. A healthy commutator w l l l acqilire a good polish and chocolate brown color, Black deposits on t h e commutator often indicate bad c o r n t a t i o n , Another source of commutator trouble is o i l and grease, If o i l o r grease gets on the commutator, the mica insulation of the commutator w l l l become o i l soaked r e s u l t i n g eventually i n ruined c o r n t a t o r , Ring f i r e is a v i s i b l e sympton of this condition; therefore, never lubricate the commutator, Arcing brushes may a l s o be caused by improper adjustnent of the brush ring, thus placing a l l the brushes i n wrong position with respect t o the f i e l d poles. Brush rings a r e adjustable, It is, of course, first necessary t o b o s e n the s e t screw, Then adjust the brush r i n g t o a position where l e a s t sparking e x i s t s , I n t h e case of some D,C. generators, individual adjustment of each brush may reduce arcing, Brushes should be equally spaced around the commutator, T h i s spacing should not vary more than 1/32 inch, Brush troubles which continually p e r s i s t due t o atmospheric conditions can usually be solved by some l o c a l e l e c t r i c a l expert, However, should the services of such an expert not be available, it i s possible t h a t the dealer, through suggestions received from the factory, can correct the trouble, Consistent overload, which overheats the insulation, exposure t o o i l y o r moist atmosphere, and a number of other causes dl1 eventually r u i n the insulation of the machine's windings. This w i l l cause short c i r c u i t s and grounds t o appear, These conditions must be eliminated a s f a u l t s of this type i n an e l e c t r i c a l machine a r e accumulative, When the commutator of a generator s h m bad condition from wear and improper operation, it should immediately be repaired, It never pays to wait, Bg having the commutator machined and brushes replaced a t the first signs of improper condition, considerable service costs can be avoided, Sanding the commutator with a f i n e grade of sandpaper (never use emery cloth) w i l l often stop sparking and r i n g f i r e , i f the damage is not already too great. Sometimes a d i r t y commutator is the primary source of sparking, and t h e removal of the blackening by sandpaper w i l l cure the trouble, Therefore, inspect the generator about once or twice a week and considerable trouble and expense w i l l be avoided, An exceptional hot commutator w i l l throw solder, and therefore connection between commutator bar and c o i l is broken. Should such a condition ever develop within the machine, it could be a d i r e c t r e s u l t of overload, Therefore, never averload a D.C, generator. It my r u i n t h e generator and a l s o shorten the l i f e of the engine. ALTERNATING CURRENT GENWATORS '1 ' A,C. generators, commonly called alternators, a r e b u i l t ' t o generate a voltage which periodically varies from a given positive t o the same negative value, T h i s i n turn w i l l cause the current t o reverse i t s direction a t the same frequency a s the voltage change, The number of these alternations o r cycles depends upon the s p e d of the machine and the number of oles, A s i x t y cycle alternator, having a speed of the 1800 R,P.K. is a -pole machine, while an a l t e r n a t o r of the same frequency operating a t 1200 R.F.M. is a 6-pole machineo E A self-exc'!ited generator has the D.C, e x c i t e r winding on the same armature with the A,C. winding. The D.C, and A,C. windings are, of course, f u l l y insulated from each other, The D.C, current generated i n the e x c i t e r windings supplies the current f o r the f i e l d poles. T h i s current i n the f i e l d poles builds up a magnetic flux, which causes voltage t o be generated by the The amount of current flcwing through the f i e l d may be conA.C, winding. t r o l l e d by a rheostat. More o r l e s s current i n the f i e l d c i r c u i t causes the A,C, voltage t o r i s e or d r o ~ . Variation i n e i t h e r t h e f i e l d resistance (rheostat) o r speed of the machine will cause a voltage drop, Reactance i n the load cikcuit causes a lagging current, T h i s current must come from the generator but t h i s lagging current tends t o oprose the magnetic f i e l d thus reducing the output voltage of the generator. Lagging current i s a subject t h a t is r a t h e r d i f f i c u l t t o conceive by the average u s e r of small power plants, It is, however, something t h a t must be considered. It should be remembered t h a t lagging current i s due e n t i r e l y t o e l e c t r i c a l equipment of t h e induction type, such a s induction motors, transformers, neon sign transformers, radio equipment, e t c o The mst common s i g n of a lagging current i n generator s e t s i s a condition where t h e engine does not seem t o be overloaded (engine does not smoke o r slaw down, but the ammeter shows a high current reading and t h e voltmeter s h m l e s s than rated voltage, Another point t o be considered i s t h a t of s t a r t i n g an e l e c t r i c motor, The reactance of an e l e c t r i c motor is bad while s t a r t i n g and i f the motor i s of o l d construction, it may stall, due t o the voltage drop caused by excessive s t a r t i n g current of the motor. The user should carefully read the above paragraphs and should he have any reason t o ' believe t h a t the capacity of his plant is being reduced by t h e reactance of h i s motors, should immediately comunicate with the dealer, Correcting capacitors a r e available a t reasonable cost and t h i s i n s t a l l a t i o n w i l l i n many cases prove t o be a n i d e a l solution. Prices on capacitors m y be obtained through your dealer. A capacitor a f f e c t s an a l t e r n a t i n g current c i r c u i t i n j u s t the opposite manner t h a t reactance does. A capacitor tends t o make t h e current "lead" t h e volt.age r a t h e r than make it ftlagtt. Therefore, if enough capacitors a r e i n s t a l l e d they w i l l n e u t r a i l i z e the bad e f f e c t s of lagging current, Remember, it is the reactance of t h e load (not the a l t e r n a t o r , which has i t s own e x c i t e r ) t h a t i s being corrected. Old and underloaded motors and transformers a r e the main cause of reactance. - GENERATOR TROUBLES - A.C. Most A.C. generator troubles a r e confined t o the e x c i t e r , which, a s s t a t e d previously, i s a d i r e c t current generator with commutator and brushes. Brush and commutator troubles a r e caused by any number of conditions, such a s dusty and sandy a i r , o i l y or moist atmosphere, grease g e t t i n g on commutator, improper brush spring tension, brushes of improper composition, excessive vib r a t i o n of the machine, running the machine too f a s t , e t c o Brush troubles which continually p e r s i s t due t o atnospheric conditions can usually be solved by some l o c a l e l e c t r i c a l expert. However, should the services of such an expert not be available, i t i s possible t h a t t h e dealer, through suggesti-ons received from the factory, can correct the trouble. Consistent overload, which overheats the insulation, exposure t o o i l y o r moist atmosphere, and a number of other causes, w i l l eventually r u i n t h e ins u l a t i o n of t h e machine's windings, T h i s w i l l cause short c i r c u i t s and grounds t o appear, These conditions must be eliminated a s f a u l t s of t h i s type a n e l e c t r i c a l machine a r e accumulative. GENEUTOR SERVICE The most common cause of a generator f a i l i n g t o produce current i s an extern a l s h o r t somewhere on t h e main like. I f it i s suspected t h a t t h i s is the , cause of f a i l u r e , t h e main l i n e c i r c u i t should be disconnected by throwing t h e main l i n e switch, and a t e s t lamp across the output of the generat o r , If the p l a n t f a i l s t o generate with the A,C, main l i n e d i s c m e c t e d from the plant, then t h e trouble l i e s i n t h e generator, With t h e trouble traced t o the generator, the following t e s t s w i l l indicate whether o r not the d i f f i c u l t y is due t o a s h o r t or a grounded f i e l d o r armature. COMMUTATOR: Mica is used f o r i n s u l a t i o n between the commutator bars, After t h e r e is machined, the mica i s cut away from 1/32" below the surface of t h e bars. The surface of the bars w i l l wear d m t o t h e l e v e l of t h e mica eventually. Mica i s harder than copper and it forms ridges which cause t h e brushes t o 'jump and make poor contact. High q i c a should be under-cut caref u l l y , and the commutator turned and cleaned. Loose brush wires can cause f a i l u r e of t h e generator t o produce current. Brushes in which t h e leads have become loosened should be replaced. . TESTING D.C. BPINDITJG OR ARllfiTURE FOR GROUNDS: First, disconnect b a t t e r y and A,C, l i n e wires from plant, RAISE ALL BRUSfBiS FROM COldMUTAT0R AND COLLECTOR RINGS, Place one end of t e s t lamp orire on comrrmtator, Touch other end of t e s t lamp w i r e on clean surface of armature shaft, If t e s t lamp burns, the commutator or D.C, winding is grounded. NOTE: A shorted o r grounded D,C, armature c i r c u i t P v i l l generally be indicated by overheating of the armature o r burned windings,, The p l a n t will run, but no current P v i l l be generated, TESTING A,C. WINDING OR ARMATURE FOR OPEN CIRCUITS: First, disconnect batAND t e r y and A.C. l i n e Poires from plant. RAISE ALL BRUSHES FROM C-ATOR If the generator i s single phase, 2 or 3 ring, place o m C O ~ ~ C T ORINGS. R t e s t lamp wire on the center r i n g then touch the other w i r e t o each other ring, The lamp should b u n when any tPro r i n g s a r e touched, If t e s t lamp does not burn an open c i r c u i t is indicated. On a t-fing s i n g l e phase generator t h e lamp should burn w h n r i n g No. 1and Ring No, 2, o r when r i n g No, 3 and No, 4 a r e touched. With any other combination, t h e lamp should not burn, On a 3-phase, b r i n g generator with one test lamp Kire on ring N, lamp should burn when touching any other rlng, Check a l l rings, On a 3 9 h a s e , 3-ring generator touching any combination of two rlngs should cause the lamp t o burn. If lamp f a i l s t o burn i n any of these cases an open c i r c u i t has developed. Check a l l combinations, Note: An open c i r c u i t in t h e A,C, armature winding w i l l r e s u l t i n the plant f a i l i n g to generate voltage. Placing one end of t e s t lamp wire on shaft, t h e lamp should not burn when other end of t e s t lamp are i s placed on any collector ring, If l i g h t burns, it indicates a ground i n A.C. winding, Any s h o r t o r ground i n the a r m a t m mans t h a t it must be rewound, - TESTING FIELDS FDR OPEN CIRCUITSa Disconnect b a t t e r y and A,C, l i n e wlres From plant, Raise a11 brushes from conmmtator and c o l l e c t o r rings, Disconnect D,C. f i e l d wires. Connect one t e s t Lamp wire t o f i e l d Prire leading t o brush holder, Connect other t e s t lamp wire t o wire i n o u t l e t box leading d i r e c t t o f i e l d coil. If t e s t lamp does not bum, D,C, f i e l d c i r c u i t is open, NOTE: Broken wires or loose connections between generator f i e l d and corrtrol panel should be checked f i r s t , An open c i r c u i t i n t h e f i e l d winding would prevent the plant from generating. SERVICE DIAGNOSIS POOR COMMUTATION_: Indication of poor commutation is excessive sparMng and/ - o r overheating of commutator, blackened o r p i t t e d commutator bars. CAUSES OF POOR COMMUTATIONt 1. The brushes not s e t c o r r e c t l y i n respect t o the f i e l d poles. 2. 3. Brushes may not be f i t t e d t o the surface of the c o r n t a t o r e Brushes binding i n t h e holders. 4. 6. 7, 8, 9. 10. Brushes may not be equally spaced around t h e commutator. Brushes may have reached t h e i r l i m i t of wear, with the r e s u l t t h a t there w i l l be a n i n s u f f i c i e n t amount of briish spring tension. Some brushes may have excessive pressure, thereby taking more than t h e i r share of t h e current. The car5on brushes, if replaced, may be of an unsuitable grade, Metal graphite brushes generally a r e not used on D O C * voltages higher than 30 t o 40 volts. Great care must be taken t o be sure t h a t the proper grade i s being used on the generator when replacements a r e made. Some commutator bars m y be loose o r projecting above the other. High mica, t h i s prevents a proper contacting surface between t h e brush and the commutator. A v a r i a t i o n i n the a i r gap of t h e machine o r strength of the f i e l d poles. This w i l l a l s o cause severe sparking a t the commutator. FAILURE OF GENERATOR TO BUIJ;D UP VOLTAGE: lo The speed of the s e t may be below normal. 2. Field c o i l s not connected i n proper sequence. T h i s could only occur if the wiring has been changed since leaving the factory. 30 A reversed shunt f i e l d , Switch wires leading t o DeC, brush holders. 'be Brushes i n c o r r e c t l y spaced, and not located on a n e u t r a l position, 5. An e x t e r n a l s h o r t c i r c u i t , 6, An open c i r c u i t i n the shunt f i e l d , . 7. Loss of r e s i d u a l magnetism. The process of building up voltage i n a l l types of generators requires t h a t there be a small amount of r e s i d u a l magnetism i n the i r o n p a r t s of t h e f i e l d e x c i t e r s t r u c t u r e when the machi n e i s standing s t i l l , This r e s i d u a l magnetism produces t h e i n i t i a l voltages i n the a r m t u r e c o i l s a s soon a s the armature i s rotated, which a r e b u i l t up u n t i l the f u l l magnetic f i e l d i s developed, and the mchine d e l i v e r s f u l l voltage, A l l generators leave the f a c t o r y with s u f f i c i e n t r e s i d u a l magnetism t o build up when s t a r t e d o However, through long periods of storage, and sometimes due t o rough handling i n t r a n s i t , a n occasional generator w i l l l o s e a l l or p a r t of i t s r e s i d u a l magnetism, and s o f a i l t o b u i l d up voltage, The following procedures w i l l usually c o r r e c t t h e trouble: (a) Carefully check t h a t . all brushes a r e free i n th brush holders, and a r e seated on the commutator, and t h a t no oSjectiona5le film has collected on the c o r n t a t o r , See t h a t brush shunts a r e not binding on adjacent p a r t s o r shorted t o ground. (b) With the generator running, apply l i g h t pressure t o the top of one o r two D O C . brushes with a wooden s t i c k , t o p o l i s h the c o r n t a t o r and break through commutator film. Often t h i s w i l l permit the generator t o build up when the r e s i d u a l f i e l d is weak, (c) If the machine s t i l l refuses t o build up, t h e r e s i d u a l magnetism can be restored by applying d i r e c t current t o the f i e l d s , Lift a l l t h e brushes c l e a r of t h e commutator. T i t h the generator a t stands t i l l , connect t h e positive terminal of a 6-volt storage b a t t e r y o r !'Hot Shotu dry b a t t e r y t o a p o s i t i v e brush holder, I n generators where one brush holder i s grounded this will be t h e grounded cormnut a t o r brush. Touch the negative connection from the battery t o t h e adjacent commutator brush holder. T h i s w i l l be a negative brush, Hold. the connection a few seconds, Remove battery connections, lower brushes and s t a r t generator. (d) Should the generator build up with reversed polarity, t h a t is, should the positive connection becorhe negative, or i n an A.C. machine s t i l l f a i l t o produce current, this can be overcome by reversing the connections b e w e n the b a t t e r y used t o build up the residual magnetism and repeating the process described above. I n e l e c t r i c a l l y cranked plants, where the generator serves a s t h e s t a r t i n g motor, r e s i d u a l magnetism is automatically restored when t h e s t a r t i n g windmg i s energized, NOISES I N THE BRUSHES: Noise i n brushes i s generally due t o a rough o r outof-round commutator, caused by high and lorn bars, This d i f f i c u l t y may only be corrected by machining t h e commutator i n a l a t h e o COMlUTATOR: Mica i s used f o r insulation between the commutator bars. After %he a m t u r e i s machined, the mica i s cut away about 1/32" beluw the surface of the bars. The surface of the bars w i l l wear down t o the l e v e l of the mica eventually, The mica i s harder than the copper, and it forms ridges which cause the brushes t o jump and make poor contact. High mica should be under cut carefully, and the c o r n t a t o r re-machined and polished. The commutator should maintain a polished surface. Blackening of all t h e bars indicates incorrect brush positions. Blaclcening of groups of bars a t regular i n t e r v a l s indicates rough, eccentric commutator. A s l i g h t , even discoloration of the commutator i s a normal condition* A severelyburned bar o r number of bars, indicates an open c i r c u i t i n the armature, which w i l l a P s o be noted by excessive f l a s h i n g when t h e machine i s operat i n g with load. This type of d i f f i c u l t y can only be corrected by competent armature r e p a i r senrice men. Ordinarily the commutator w i l l require only an occasional wiping with a nonl i n t i n g cloth, but i f blackening appears and grows worse, the cause must be determined and corrected. Use no lubricant on the commutator. The use of any lubricant w i l l only cause sparking and increase the commutation d i f f i c u l t i e s . BRUSHES: See t h a t the brushes move f r e e l y i n the holders and a t the same efirm even contact with the commutator. The brushes should a l l have t h e same spring tension t o prevent one from carrying more than its share of the load, An extra s e t of brushes should always be kept on hand, See t h a t both t h e i n t e r i o r and the e x t e r i o r of the machine a r e kept f'me from metal dust, d i r t of any description, o r water, GENFJRATOR HEATING: May be due t o one of t h e following causes: 1, Overload on the l i n e , 2, Short c i r c u i t of a c o i l o r number of c o i l s i n the winding, 3, Grounds i n the armature winding o r commutator, Lo Poor commutation, 5. Overheating of t h e e n t i r e u n i t , may be caused by: (a) Unequal a i r gap. (b) A shorted out o r grounded f i e l d winding, (c) A reversed f i e l d c o i l wtnding, NOTE: A n y of these troubles cause a large circulating current i n the e x c i t e r armature windings of the commutator, the brushes and brush connections, which, w i l l cause a r t i f i c i a l overloading of the armature. The a i r gap should not vary over a few percent e i t h e r way from the average value, A l l f i e l d c o i l s of the shunt type should have within 10% of t h e same resistance, a higher value than this indicates shorted turns i n the winding, F'IELD COIL HEATING: 1, Too high an operating s p e d of the plant, with a r e s u l t a n t high output voltage 20 A p a r t i a l short c i r c u i t of one coil. MAINTENANCE: A l l Generators a r e equipped with b a l l bearings. These bearings w i l l last f o r It i s very important t o keep the generator clean and f r e e from accumulations of d i r t and grease, It i s not necessary t o take the generator apart t o clean it, a s i n most cases the dust accwrmlations can be r e a d i l y blown out with an a i r hose and the h n g s and commutator be wiped with a clean cloth. The grooves between the commutator bars should be occasionally cleaned out and kept f r e e from accumulations of carbon, dust o r other foreign a very t h i n hack saw blade ground t o a matter. This can best be done ~ 5 t h hook shape o r a large needle o r h a t pin. maw years. MAINTENANCE SERVICE INSTRUCTIONS FOP DC Generators and Ekeiters AC Alternators build up rated ~ h e o s t a t ,f i e l d l i g h t up on f l e l d coils with many turns; consequently, DC should be used for testing.) A bank of b a t t e r i e s connected i n s e r i e s t o give 12 t o 24 storage battery f o r j u s t an 20 See t h a t brushes move f r e e l y holder tension springs which actuate t h e brush holder tension arms have beenaljusted a t t h e f a c t o r y f o r proper tension. However, a f t e r t h e brushes have been worn down t o half of t h e i r o r i g i n a l length, t h e spring tension may be increased one notch. Bushes should be cheeked periodically so when brushes have worn t o the point where brush holder tension arm i s almost a t t h e end of travel, the brush may be replaced, On small machines using fixed brush holders and f i b e r caps, the brush sprFng tension i s not adjustable, and when the brush has worn t o about 1/2 its original length it should be replaced, Care should be taken, however, see t h a t t h e shunt does n o t become pinched betwee of the b m h spring. MAINTENANCE smVICE INSTRUr3TIONS For DC Generators and Exciters AC Alternators Trouble Generator f a i l s t o b u i l d up r a t e d voltage (cont 'd) Cause Poor Brush contact (cont 'd) Armature shorted o r grounded. Remedy * 4, Replacigg brushes,, It is important t 5 a t a l l brushes be of t h e sane g~ade, preferzbly, t h e same kind and type a s s~zpplledwith t h e o r i g i n a l U t e A T t e r bruslies have been i n s t a l l e d i n 'c3e holde~?s,I t is necessary t h a t the br- shes be f ittec! t o the conmta-'ml: w c o n ec-tono ring, (See note 2,) ~ e r n o zazns.'~=c and t e s t on groxla-, If Lest shows short, o r o?en, a m , i a i ~ r ek i l l have -- F2) f r o n brxihes and armature l e a d s a i d c h c k f o r continui.ty and r e s i s t a n c e t o ground with cormect Lng generator to l i n e , Check f o r shorted f i l t e r con- due t o comuta-kzthrowing sol.der from riser, Due t o turned, a ~ 1-mderc~lt; d h a ~ i n ga ci ji:,s table plact*s the p o s i t i o n of -tihe brushes is f i x e d by desF,g, On the 12 and. 1Lim f i e l d frames t h e a d j n s t a b l e r i n g may be re?osi.tior.ed s o e l a t the brushes MAINTENANCE SERVICE INSTRUCTIONS For DC Generators and Exciters AC Alternators Trouble Generator f a i l s t o b u i l d up r a t e d voltage (cont td) Cause Wrong r o t a t i o n (cont Id) F a u l t y voltage regul a t o r operatlon, Low output voltage Excessive load Ensufficient excitat i o n due t o t o o much r e s i s t a n c e i n the f i e l d . High r e s i s t a n c e High Line Losses Low speed 1 0 Belt slipping 2, Defective governor 30 Defective bearing 46 Excessive load Remedv r o t a t e clockwise; engine driven p l a t s r o t a t e counter-clockwise, Tf it is desired t o run t h e machine i n the opposite direction to t h e way i t was ,adjusted a t t h e factory, t h e i n t e r n a l connections of t h e generator w i l l have t o be changed, and t h e commutating plane of t h e brushes readjusted, The sure way is t o take all the wires off t h e p o s i t i v e brushholder and place them on the negative brushholder and place a l l t h e wires which o r i g i n a l l y connected to the negative brushholder on t h e p o s i t i v e brushholder, On a st r a i ght shunt-wound machine, r o t a t i o n can be changed simply by interchanging t h e f i e l d leads, To a d j u s t the commutating plane of the brushes, s h i f t t h e brush spider or ring i n t h e direction which r e s u l t s i n the highest D.C, armature voltage w i t h minimum sparking a t the brushes when the f i e l d r h e o s t a t o r r e s i s t o r is a t minimum r e s i s t ance s e t t i n g , Try operating t h e plant without voitage r e G a t o r . See t h e i n s t r u c t i o n manual f o r t h e p a r t i c u l a r voltage regulator US ed., Reduce l o a d Reduce the amount of f i e l d resistance, Connections w i l l be warm o r hot t o t h e touch. Make b e t t e r e l e c t r i c a l and mechanical j o i n t s and connections, Increase s i z e of l i n e wires 1, Tighten Belt, 2, Adjust, repair, o r replace governor,, 3* Replace bearings, 4, Reduce load. PIAINTEXANCE SERVICE INS!l!RUCTIONS FOP DC Generators and Excite~s AC A l t e m t s ~ s ower-factors less (see nameplate data MAINTENANCE SERVICE INSTRUCTIONS For DC Generators and h c i t e r s AC Alternators Mote 3 0 ) A l l micas should be l a t h e ; however, when doing s o a competent machinist must be employed, Make a b s o l u t e l y sure t h a t the armature s h a f t i s centered concentric with t h e bearing s u r f ace. Dontt machine commutator u n t i l you have checked t o s e e t h a t s h a f t center is concentric with bearing, The surface of the commutator should be machined a s l i t t l e as possible and 2, A very e f f e c t i v e p o l i s h e r may be constructed by f o l d i n g s e v e r a l l a y e r s of canvas o r duck over t h e end of a s t r o n g piece of wood and tacking it Ln place, The canvas pad may be held on the commutator o r c o l l e c t o r rings, T h i s w i l l give a high p o l i s h without c u t t i n g t h e surface, however, if t h e commutator i s p i t t e d , it w i l l be necessary t o f i r s t p o l i s h with a f i n e grade of sandpapero (oo), following it with t h e canvas polisher, NEVER USE EMERY CLOTH TO POLISH, s i n c e it contains m e t a l l i c p a r t i c l e s which w i l l s h o r t o u t t h e commuta- MAINTENANCE SERVICE INSmCTIaNS For DC Generators and Exciters AC A l t erna t o r s w . Trouble Excessive sparking (cont f d ) Cause Brushes not i n commutating plane .Brushes s t i c k i n g i n brushholde~s berload Grounded, open, o r shorted f i e l d c o i l windings. Open Armature Eoose b m h h o l d e r irregular speed of engine. 'tinstable voltage regulator. 'nuttua t i n g DC voltage Remedy (See Page 20) Clean brushes and brushholders and a d j u s t b n ~ s h e s . Check ammeter readings w i t h ~ a m e p l a t er a t i n g , Reduce load. Replace o r r e p a i r defective coil, Repair o r replace armature. Re-slim and t i g h t e n holder. Adjust governing device* Try operating without voltage regulator, See voltage regulator i n s tr-JC ti on manual S t a b i l i z e load. F l u c t u a t i n g load (See Pages 19 & 20) Poor brush contact Ihke b e t t e r connections Loose terminal mechanically & e l e c t r i c a l l y . come c'Gions Generator overlosding Reiruce load Replace worn b e a r i n ~ s b e f e c t i v e bearing Raise UC brushes and contact P30lari+y-5,-fgenerato2 Long i n a c t i v i t y , positive and negative terminals short circuit, revorsod lightening s t d k i n g with 6 t o 12 v o l t s t o produce c m e c t polarity. system, etc. Connect .5 mfd condensers fron RadAo I~tarf'eronoe Kadio P'requency a l l brushes t o frame. Voltage interference due r a t i n g should be a t l e a s t ta sparking of donble t h e r a t e d voltage on brushes the c i r c u f t to which they are cor,iected. If condensers are already connected t o t h e s e points, replace with new condensers, I n s t a l l s h a f t grounding b d h Radio frequency interference caused assembly. by leakage of s t a t i c charge from generator s h a f t * Radio i n t e r f e r e n c e -SuppSs s radio in€erf erence caused by electrical. i n usual manner. It is suggested t h a t competent radio system of engine mar, o r e l e c t r i c i a n be consulted. - - t p~