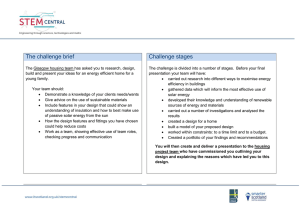

Residential Energy Conservation (Part 14 of 17)

advertisement