White Paper

End-to-End Monitoring Systems

Historically, substation assets are loaded beyond nameplate ratings. The need to accommodate

emergency, or contingency, conditions are best served using End-to-End apparatus monitoring systems.

INTRODUCTION

For many years the limit for normal apparatus loading was based on the maximum

nameplate rating or an arbitrarily set value, called ‘the red line.’ On-line monitoring

of power transformers and circuit breakers, for condition assessment, has gained

popularity over the past twenty years.

Long-Time Emergency Loading

Until recently, the operation of electrical apparatus would fit into one of the following

loading categories: Continuous Load or Cyclical Load.

Long-term emergency loading of transformers occurs and may persist for extended

periods. This can lead to significantly increased aging of the solid insulation system including:

• Deterioration of the mechanical properties of conductor insulation will accelerate

at higher temperatures. This aging acceleration is also impacted by the moisture

content of the conductor insulation. Taken together, it is an exponential function in

terms of the aging rate of transformer insulation, reducing the effective life of the asset.

• Cooling systems operating for extended periods, increasing maintenance &

reducing life expectancy.

• Contact resistance of the breaker and/or OLTC will increase at elevated currents

and temperatures and, in extreme cases thermal runaway could occur.

• Gasket materials may become more brittle as a result of elevated temperatures.

Continuous Load

END-TO-END PERFORMANCE

Loading Management

Today’s sophisticated monitoring solutions continuously calculate the maximum safe

load capability of the assets and display (locally or via embedded web servers) and

communicate with other systems and SCADA.

This is the constant loading at rated nameplate output in (MVA) when the apparatus is

operated under a constant 20°C ambient condition. Of course, this loading condition

rarely happens over the life of a transformer, where both load and ambient temperature

vary over time.

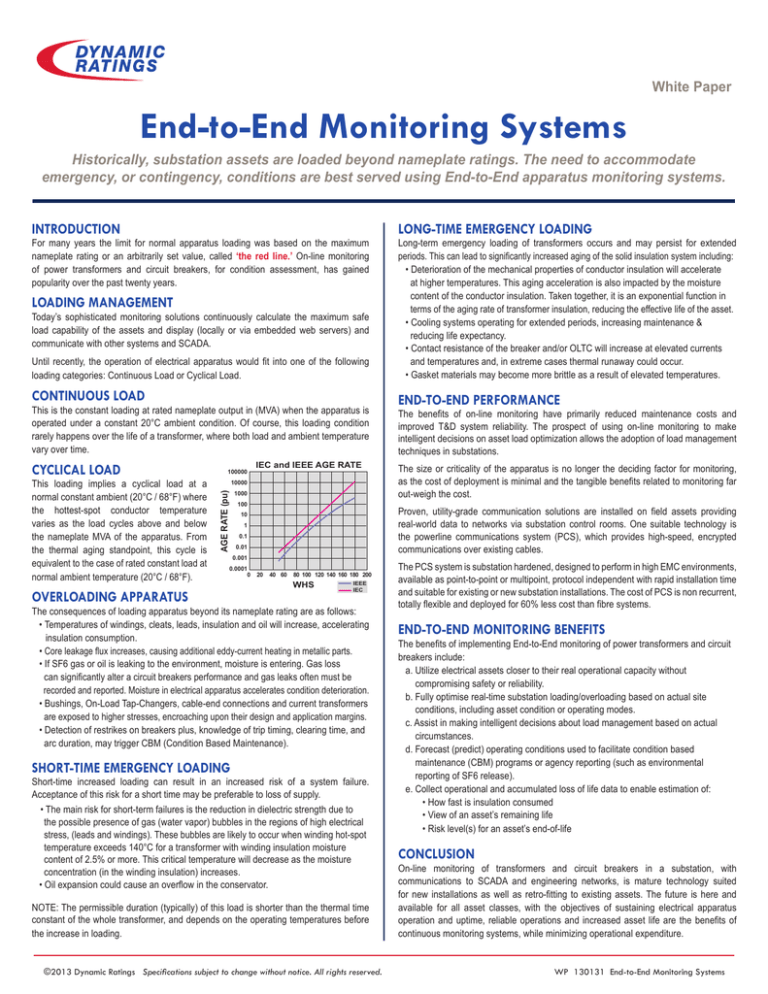

This loading implies a cyclical load at a

normal constant ambient (20°C / 68°F) where

the hottest-spot conductor temperature

varies as the load cycles above and below

the nameplate MVA of the apparatus. From

the thermal aging standpoint, this cycle is

equivalent to the case of rated constant load at

normal ambient temperature (20°C / 68°F).

100000

IEC and IEEE Age Rate

10000

Age Rate (pu)

Cyclical Load

1000

100

1

0.1

0.01

0.001

Overloading Apparatus

The size or criticality of the apparatus is no longer the deciding factor for monitoring,

as the cost of deployment is minimal and the tangible benefits related to monitoring far

out-weigh the cost.

Proven, utility-grade communication solutions are installed on field assets providing

real-world data to networks via substation control rooms. One suitable technology is

the powerline communications system (PCS), which provides high-speed, encrypted

communications over existing cables.

10

0.0001

0

The benefits of on-line monitoring have primarily reduced maintenance costs and

improved T&D system reliability. The prospect of using on-line monitoring to make

intelligent decisions on asset load optimization allows the adoption of load management

techniques in substations.

20

40 60

80 100 120 140 160 180 200

WHS

IEEE

IEC

The consequences of loading apparatus beyond its nameplate rating are as follows:

• Temperatures of windings, cleats, leads, insulation and oil will increase, accelerating

insulation consumption.

• Core leakage flux increases, causing additional eddy-current heating in metallic parts.

• If SF6 gas or oil is leaking to the environment, moisture is entering. Gas loss

can significantly alter a circuit breakers performance and gas leaks often must be

recorded and reported. Moisture in electrical apparatus accelerates condition deterioration.

• Bushings, On-Load Tap-Changers, cable-end connections and current transformers

are exposed to higher stresses, encroaching upon their design and application margins.

• Detection of restrikes on breakers plus, knowledge of trip timing, clearing time, and

arc duration, may trigger CBM (Condition Based Maintenance).

Short-Time Emergency Loading

Short-time increased loading can result in an increased risk of a system failure.

Acceptance of this risk for a short time may be preferable to loss of supply.

• The main risk for short-term failures is the reduction in dielectric strength due to

the possible presence of gas (water vapor) bubbles in the regions of high electrical

stress, (leads and windings). These bubbles are likely to occur when winding hot-spot

temperature exceeds 140°C for a transformer with winding insulation moisture

content of 2.5% or more. This critical temperature will decrease as the moisture

concentration (in the winding insulation) increases.

• Oil expansion could cause an overflow in the conservator.

NOTE: The permissible duration (typically) of this load is shorter than the thermal time

constant of the whole transformer, and depends on the operating temperatures before

the increase in loading.

©2013 Dynamic Ratings Specifications subject to change without notice. All rights reserved. The PCS system is substation hardened, designed to perform in high EMC environments,

available as point-to-point or multipoint, protocol independent with rapid installation time

and suitable for existing or new substation installations. The cost of PCS is non recurrent,

totally flexible and deployed for 60% less cost than fibre systems.

end-to-end monitoring benefits

The benefits of implementing End-to-End monitoring of power transformers and circuit

breakers include:

a. Utilize electrical assets closer to their real operational capacity without

compromising safety or reliability.

b. Fully optimise real-time substation loading/overloading based on actual site

conditions, including asset condition or operating modes.

c. Assist in making intelligent decisions about load management based on actual

circumstances.

d. Forecast (predict) operating conditions used to facilitate condition based

maintenance (CBM) programs or agency reporting (such as environmental

reporting of SF6 release).

e. Collect operational and accumulated loss of life data to enable estimation of:

• How fast is insulation consumed

• View of an asset’s remaining life

• Risk level(s) for an asset’s end-of-life

CONCLUSION

On-line monitoring of transformers and circuit breakers in a substation, with

communications to SCADA and engineering networks, is mature technology suited

for new installations as well as retro-fitting to existing assets. The future is here and

available for all asset classes, with the objectives of sustaining electrical apparatus

operation and uptime, reliable operations and increased asset life are the benefits of

continuous monitoring systems, while minimizing operational expenditure.

WP 130131 End-to-End Monitoring Systems