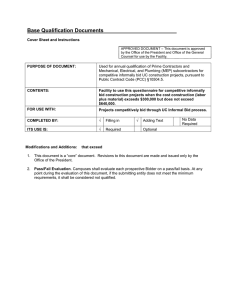

Cost Estimating Guideline

advertisement