REHAU EVERLOC Technical Manual

advertisement

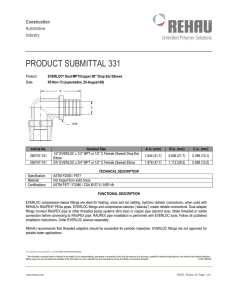

REHAU EVERLOC™ HEATING AND PLUMBING SYSTEMS TECHNICAL MANUAL www.rehau.co.uk Building Solutions Automotive Industry 1 Introduction 6 2 2.1 2.2 2.2.1 2.2.2 2.2.3 Polymer Pipe – Cross Linked Polyethylene Polymerisation PE-Xa Characteristics Chemical Resistance Oxygen Permeability/Opacity A Widely Used Engineering Polymer 8 8 8 8 10 10 3 3.1 3.1.1 3.2 3.2.1 3.2.2 3.3 3.3.1 3.3.2 3.3.3 3.3.4 3.3.5 Product Range Pipe Range and Descriptions Pipe Markings Jointing Technology Tooling Jointing Method Fittings and Ancillaries Pipe-in-Pipe Modular Manifolds Heating Manifolds Wall Plate Fittings and Brackets Branch/Cross Fittings 11 11 11 12 12 12 13 13 13 13 14 14 4 4.1 4.2 4.3 4.4 4.5 Standards, Approvals and Performance General Approvals Water Quality Statement Disinfection of REHAU Pipework Approvals Quality Systems 15 15 15 16 16 16 5 5.1 5.2 5.3 5.3.1 5.3.2 5.3.3 5.3.4 5.3.5 5.3.6 5.3.7 5.3.8 5.3.9 5.3.10 5.3.11 5.3.12 5.3.13 5.3.14 Applications – The System in Use Principle Advantages Typical Layouts System Design Information Flow Rates Pipe Sizing Pipe-in-Pipe Fixing Distances – Concealed Pipework Pipe Support Corrosion Inhibitors Anti Freeze Connection to Boilers Expansion and Contraction Bending RAU PE-Xa Pressure Testing Insulation Requirements Trace Heating Storage Conditions 19 19 20 21 21 24 24 24 24 24 24 24 25 26 26 26 26 26 6 Summary 27 7 Appendix 28 5 1. INTRODUCTION THE REHAU EVERLOC™ HEATING AND PLUMBING SYSTEM IS AN INTEGRATED RANGE OF RELIABLE AND HIGH QUALITY FLEXIBLE POLYMER PIPES. THE TOTALLY RELIABLE, SLIM, NEAT BRASS FITTINGS ARE ALL DESIGNED SPECIFICALLY TO WORK TOGETHER. Manufactured by REHAU since the early 1980’s, the system is used extensively worldwide and is considered to be one of the most effective systems available. From the Far East and Asia to Australia and the Americas, the system meets all performance standards and requirements. No other company comes close to REHAU flexible pipework for quality, reliability and performance. Removing the need for traditional copper pipework and fixings, REHAU flexible heating and plumbing pipework is proven to save time, money and effort. There is no heating or plumbing application that REHAU flexible pipework can’t do more simply than traditional materials, bringing with it a host of benefits: 6 1 2 3 1 REHAU EVERLOC™ joint 2 Cut away 3 Pipe-in-Pipe - One pipe serves all service applications from 16 to 32mm, with 40 to 63mm options available for mains, risers and other applications. Larger sizes are available on request. - High quality system allows the discerning engineer to achieve an effective system, with features making it easy to conceal. - Pipe flexibility means easy routing, as long lengths of pipe (available as coils or straight lengths) can be threaded and pulled through walls and floors effortlessly. - The extensive range of superbly engineered DZR brass compression sleeve fittings form part of the unique REHAU cold jointing system which allows assembly of joints quickly, securely and permanently. - The REHAU Pipe-in-Pipe option offers even greater flexibility by offering ‘in-floor’ pipe installations. The combined pipe and sleeve can be fitted prior to laying the floor screed, removing the need to construct special ducts, thereby saving a considerable amount of time and money. - Delivered on a roll, REHAU flexible pipe maximises efficiency by reducing the number of joints and minimising waste from cut-offs. - No naked flames and no swarf, flux, grease or oil means a safer working environment. Also the absence of heavy pipework lying around a building means accidents are less likely. - The durable flexible pipework has a service life in excess of 50 years, due to its excellent heat age resistance, high tensile strength and resistance to deformation and impact damage. - The jointing tools that work with REHAU flexible pipe are available to contractors from REHAU and other outlets. Robust and easy to use, the tools are available in foot pump hydraulic and electrical versions. - A REHAU manifold keeps the heart of the installation in one place, allowing services to be run from a central point out to radiators or sanitary fixtures, and allowing for simple fault finding and maintenance. The ability to run all pipework out from a single point keeps installation simple and saves time. - Ultra smooth inner lining minimises limescale build up, for long life and consistent flow rates. The pipework has an in-service pressure rating of 6 bar at 95˚C and 12 bar at 20˚C (BS7291:1990). Corrosion free, as EVAL polymer oxygen diffusion barrier prevents oxygen getting into the system to corrode ferrous components. The growth of micro-organisms within the pipe is inhibited by the opacity barrier which blocks out light. - REHAU offers a full range of purpose made brackets enabling firm and secure fixing of fittings, for all common heating and plumbing application, for example, showers and washbasins. The brackets provide convenient junctions for fixture connections and can be concealed or left visible, according to preference and/or task. Support channeling and stainless steel radiator tails are available for specific tasks. 7 2. POLYMER PIPE CROSS LINKED POLYETHYLENE 2.1 Polymerisation REHAU Heating and Plumbing Pipes are based on RAU PE-Xa, high pressure cross-linked polyethylene. The base material is polyethylene, with a high molecular weight and a high density, which is then cross-linked by a special process which dramatically improves its physical properties. Hydrogen Carbon The process used by REHAU is based on the Peroxide crosslinking process, giving an optimal and consistent level of crosslinking. The resulting pipes are designated RAU PE-Xa. HDPE Polymer prior to crosslinking Simplified Cross linking PE-Xa 2.2 PE-Xa Characteristics - Optimally cross-linked for flexibility and long-term heat aged performance - Can tolerate short exposure to operating temperatures up to 110˚C at normal operating pressure - Resistant to abrasion and impact - Resistant to crack formation - Exhibits a memory effect, as once deformed it can be returned undamaged to its extruded shape. - Chemically inert - Non corroding - Free of heavy metals and halogens Physical Properties of RAUTHERM Universal Pipe (RAU PE-Xa) Density (to DIN 53497) 0.93g/cm3 Modulus of elasticity (to DIN 53457) 600 N/mm approx. Impact resistance (to DIN) at 20°C at -20°C No damage No damage Co efficient of expansion at 20°C at100°C 1.4 x 10-4K-1 2.0 x 10-4K-1 Thermal conductivity 0.35 W/mK Oxygen diffusion at 40°C ≤ 0.1 mg/lxd Pipe internal roughness 0.007mm The smooth bore of RAU PE-Xa, the long radius made bends and fitting design mean that flow rates are improved over copper and steel. The flexible nature of the pipe means that it absorbs fluctuations in pressure, thereby significantly reducing noise transmission through fluid flow and water hammer compared to other pipe systems. 70 60 bar er pp Ste 50 Pressure (bar) Pressure shock level 60 Co el/ 40 30 PVC-C 20 PP Typ 10 PE-Xa 3 15 bar 0 0 1 2 3 4 Flow rate (m/s) PE-Xa: 25 x 3,5 8 2.2.1 Chemical Resistance The pipes described in this brochure are designed for use in heating and plumbing applications. The base material has excellent chemical resistance due to the chemical bonding of the polymer chains. Contact with chemicals to which the polymer is not resistant, usually results in swelling or some dissolving of the polymer. The results of exposure tests are given below. PVC-C: 25 x 2,8 PP Typ 3: 25 x 5,0 Steel/Copper 5 The data given here is general and cannot be taken as typical of the performance of a pipe filled with the chemical and placed under pressure. If non-standard pressurised applications are being considered, please contact the REHAU Technical Department for further details. Chemical Resistance Substance 20˚C 60˚C Substance 20˚C 60˚C Substance 20˚C 60˚C Acetic acid + + Diethyl ether 0 Petroleum + 0 Acetone + Engine oil + 0 Phenol + 0 Acrylonitrile + + Ethyl acetate + 0 Phosphates, hydrous + + Allyl alcohol + 0 Ethyl alcohol + + Phosphoric acid 95% + + Aluminium chloride, anhydrous + + Ethylene glycol + + Phthalic acid 50% + + Aluminium sulphate, hydrous + + Esters, aliphatic + 0 Plant protection agents + + Ammonia, hydrous + + Esters, aromatic 0 0 Polyglycols + + Ammonium chloride, hydrous + + Fluorine -- -- Potassium bichromate 40% + + Ammonium sulphate, hydrous + + Formic acid + + Potassium chloride, hydrous + + Aniline, pure + + Formaldehyde 40% + + Potassium hydroxide, 30% solution + + Aqua regia -- -- Freon 0 -- Potassium permanganate, 20% solution + + Beer + + Glycerine + + Propanol + + Benzene 0 + Glycols + + Propionic acid, 50% + + Benzoic acid, hydrous + + Heating fuel oil + 0 Propyl alcohol + + Bitumen + + Bleach + Bromine + -- Hexane + + Pyridine + 0 Hydrochloric acid, concentrated + + Silicon fluid + + Hydrofluoric acid 70% + 0 Butane diol + + Hydrogen peroxide 30% + + Butanol + 0 Hydrogen peroxide 100% + -- Soap solution + + Butanone + + Hydrogen sulphide + + Sodium hypochlorite + 0 Butter + + Linseed oil + + Styrene 0 -- Butyl acetate + 0 Liquid paraffin + + Sulphuric acid, up to 50% + + Butyric acid + 0 Magnesium salts, hydrous + + Sulphuric acid, up to 98% 0 -- Carbon tetrachloride 0 -- Maleic Acid + + Sulphur trioxide -- -- Carbonic acid + + Mercury + + Tetrahydrofurane 0 -- Chlorine, liquid -- -- Methanol + + Tetralin + 0 Chlorine gas, damp 0 -- Methylene chloride 0 -- Tincture of iodine + 0 Chloroform 0 -- Milk + + Toluene 0 -- Chromic acid 50% + -- Naphtha + 0 Transformer oil + 0 Chromic acid/sulphuric acid + -- Naphthalene + -- Trichloroethylene 0 -- Citric acid + + Natron + + Turpentine oil + 0 Cod liver oil + + Nitric acid, 30% + + Vaseline + 0 Cresols + 0 Nitric acid, 50% 0 -- Washing agents + + Cyclohexane + 0 Nitrobenzene + 0 Water + + Cyclohexanol + + Oils, essential + 0 Wine + + Cyclohexanon + 0 Oils, vegetable + 0 Xylene 0 -- Dekalin + -- Oleum -- -- Detergents, synthetic + + Oxalic acid 50% + + Dibutyl phthalate + 0 Ozone 0 -- Dichlorethylene 0 -- Ozone, hydrous <0.1% + -0 Dichlorobenzene 0 -- Petrol + Diesel oil + 0 Petroleum ether + Key to symbols + = resistant 0 = partial resistance -= not resistant 9 2.2.2 Oxygen Permeability/Opacity Heating applications demand that the pipe is impermeable to oxygen to prevent corrosion of ferrous components, such as radiators and heat exchangers. RAUTHERM pipes use an EVAL oxygen barrier tested to BS 7291:1990 and DIN 4726. 1 2 Water Regulations Advisory Scheme (WRAS) and BS7291:1990 requirements are that water contained in pipes be screened from UV light, to prevent microbiological growth in potable water systems. RAUTHERM Universal Pipe has a deep red coloured layer which performs this function (16 to 32mm sizes) and RAUHIS pipes (40 to 63mm sizes) have a silver coloured layer which blocks all light. The EVAL and pigmented layers are co-extruded onto the pipe during manufacture. 3 1 The polyethylene pipe (REHAU VPE) 2 Deep red opacity barrier 3 The EVAL barrier coating 10 2.2.3 A Widely Used Engineering Polymer Aside from heating and plumbing applications, there are many other specialist applications served by REHAU pipes made in RAU PE-Xa. These including carrying water services and mains, district heating networks and compressed air systems. Please contact REHAU for further details. 3. PRODUCT RANGE THE COMPREHENSIVE RANGE OF PIPES AND FITTINGS MEANS THAT ANY HEATING OR PLUMBING APPLICATION CAN BE SUCCESSFULLY TACKLED WITH THE SYSTEM. THE VARIOUS ADAPTERS MAKE INTEGRATION POSSIBLE WITH COPPER AND STEEL, AS WELL AS OTHER MATERIALS. For sizes up to 32mm, a single type of pipe is suitable for both heating and plumbing applications. From 32mm to 63mm, there are two types of pipe for each diameter, one for heating and one for plumbing applications. 3.1 Pipe Range and Descriptions To select the correct pipe size, reference should be made to the flow rate required (rather than by comparing to equivalent copper pipe size). The inherent properties of the RAU PE-Xa Pipe (smooth bore, reduced friction through fittings and reduced furring) means that pipe sizes can normally be reduced compared to traditional pipe materials. Information on flow rates and head loss for the various pipes is given under Section 5.3 Design Information page 21. 3.1.1 Pipe Markings REHAU pipes are marked with the following information repeated at regular intervals along the pipe: - Manufacturers name: REHAU - Commercial name: REHAU RAU PE-Xa - Pipe diameter - Wall thickness - Temperature classification and maximum operating pressure - Production location reference and batch number - Production date reference - Metre markings for registering usage Description Application Size-OD/wall thickness (mm) I.D. (mm) Supply Format RAUTHERM Universal Pipe With EVAL and Opacity layer Heating and Plumbing 16 x 1.5 20 x 1.9 25 x 2.3 32 x 2.9 13.0 16.2 20.4 26.2 6m Straight lengths and coils 6m Straight lengths and coils 6m Straight lengths and coils 6m Straight lengths and coils RAUTHERM FW With EVAL layer Heating only 40 x 3.7 50 x 4.6 63 x 5.8 32.6 40.8 51.4 Straight lengths Coils to special order Straight lengths Coils to special order RAU HIS With silver coloured layer Plumbing 40 x 3.7 50 x 4.6 63 x 5.8 32.6 40.8 51.4 Straight lengths Coils to special order Straight lengths Coils to special order 11 3.2 Jointing Technology With the development of the REHAU EVERLOC System, the use of PE-Xa in heating and plumbing applications has increased dramatically. This system gives totally secure, reliable joints, in seconds. Manufactured in traditional brass, with some in stainless steel, the fittings are neat, slim and attractive to the eye. Most of all, they are permanent, meaning that callbacks to projects to repair leaking connections are eliminated. 1 3.2.1 Tooling Central to the jointing method are the REHAU Compression Sleeve Tools. These are available as mechanical, mechanical hydraulic, electric hydraulic and rechargeable electric variants. Tooling is available to contractors working with the REHAU system. 2 3 4 The pipe must be cut square and without burrs. This is achieved quickly and easily by using REHAU pipe cutters. The end of the pipe is opened up using the expander pliers, expanding twice, offsetting by 45˚ for the second expansion. The compression sleeve is slid over the pipe with the square end of the sleeve first (the other side of the sleeve has an internal chamfer). The lining spigot of the fitting is inserted into the fitting and the compression sleeve clamped home. Due to the memory effect of the pipe, the pipe will start to return to its original size after expansion and start to grip the fitting shortly after it has been pushed into the pipe. During this time, fittings can be lined up before finally securing them. 2 3 Making a joint - 32mm pipe sizes 3.2.2 Jointing Method Joints are simple to make and the system can be learnt in minutes. The photo sequence shows how simple the process is. During the creation of a joint, the installer can hear and feel a very firm and secure connection being made. The joints are permanent. 1 4 1 to 7 Making a joint with RAUTOOL G1, 40 - 63mm pipe sizes 5 12 6 7 3.3 Fittings and Ancillaries The full fittings range is shown in the REHAU EVERLOC™ Heating and Plumbing Parts List 886:300. There is an extensive range of fittings for all heating and plumbing applications, manufactured mainly in brass, with stainless steel radiator tees and elbows. Brass fittings are dezincification resistant and the stainless steel fittings are made from DIN 2463 stainless steel. The extensive range includes copper adapters and male / female connectors making it easy to integrate REHAU pipework with traditional plumbing materials. Attractive stainless steel radiator tails are part of the range and should only be used for connecting radiators. They are not to be used in plumbing applications. 3.3.1 Pipe-in-Pipe This is essentially a corrugated pipe sleeve within which the pipe is held. It can be supplied separately to the pipe or with the pipe already in the sleeve. The Pipe-in-Pipe is run in a continuous length without joints, for example, between the manifold and a radiator. The Pipe-in-Pipe is fixed directly to the floor slab. At the manifold, the sleeve is taken out above the finished floor level. At the radiator end, a floor access box (available from REHAU) should be fitted. The floor can then be screeded. Should access be needed to the pipe, it can be cut at either end and a new length of pipe connected to the old, using a simple device fitted within the pipe. The old pipe can be withdrawn, pulling in the new pipe in one operation. The system complies with current water regulations and significantly reduces duct costs, both the costs of constructing the ducting and the costs associated with fitting pipework into ducts. 3.3.2 Modular Manifolds These are simple DZR manifolds in two or three port formats which can be screwed together to make up headers of any size. Pipe connection to the manifold is made using 16mm compression sleeves which are ideal for plumbing or heating applications. 3.3.3 Heating Manifolds These are brass headers with threaded connections, to which control valves may be connected. Controls may be fitted to the manifold (sited in a secure place) making it possible to supply and control radiators in situations where radiator mounted controls may be tampered with. 13 1 1 Radaitor bends not to be used in plumbing applications 110 3.3.4 Wall Plate Fittings and Brackets It is always a problem when installing appliances to find firm, secure fixing points. REHAU offer a range of brackets punched with holes for screws and tapped to take M5 fixings as used on wall plate elbows. These brackets facilitate installation in partition walls and timber frame construction. Carpentry work is minimised, installation is quick and easy. 75 220 700-800 500 130 ß One of the principle benefits of the bracketing system is that it enables pipework to be kept out of sight, and with the REHAU system it is possible to have a system with just female iron threaded fittings finishing flush with the wall finish. Number of Ports 2-3 Width (B) 400 Number of Ports 2 Length in mm 190 Overall width 295 14 4-6 550 3 245 350 4 300 405 7-9 750 5 355 460 10- 2 950 6 410 515 7 465 570 12 1150 8 520 625 3.3.5 Branch/Cross Fittings 16 x 16 x 16 fittings for branching off to appliances, in one slim unit, useful in areas of poor access. (Not to be used as part of the Pipe-inPipe system). 9 575 680 10 630 735 11 685 790 12 740 845 4. STANDARDS, APPROVALS AND PERFORMANCE 4.1 General Polymer pipe systems are covered by BS 7291: 1990 Thermoplastics pipes and associated fittings for use in hot and cold water systems. The REHAU Heating and Plumbing System conforms to BS 7291 Class S, for sealed systems, the highest level of specification under this standard. BS 7291:1990 categorises different system types and according to this standard, it is suitable for maximum operating pressures and temperatures of: - 12 Bar 20˚C for direct mains fed cold water - 6 Bar 95˚C for open vented systems - 3 Bar 105˚C for sealed systems The REHAU system also conforms to the French Avis Technique 15/95-217 issued by CSTB (The French Agrément Authority). 4.2 Water Quality Statement CAUTION Danger of corrosion! All REHAU plumbing fittings are made of dezincification-resistant brass, REHAU fulfils the highest level of requirements in accordance with WRAS, BS EN 12164, BS EN 12165 and BS EN 12168 and we continuing to develop this product further to fulfil ever greater quality requirements. Irrespective of the material used in the manufacture of fittings, corrosion can occur in the drinking water installation as a result of various influencing factors. In isolated cases, corrosion can even occur when water quality levels are within the permissible range set out by the Drinking Water inspectorate. The chloride content and the hydrogen carbonate content of the water have a considerable influence on this. A high chloride content in combination with a low hydrogen carbonate content may have a negative impact of the corrosion behaviour. 15 However, the interactions under the following factors in accordance with BS EN 12502-1:2005 (En) also affect corrosion resistance: - Material properties (chemical composition, surface condition) Water condition (physical and chemical properties, solids) Planning and execution (geometry, mixed installation, connections) Leakage test and commissioning (rinsing, emptying, disinfection) Operating conditions (temperature, temperature changes, flow ratios) The use of a water after-treatment system, for example water softening, will, in principle, lead to a change in the chemical corrosion behaviour of the water. To avoid corrosion damage due to incorrect use and operation of a water after-treatment system, we expressly recommend that you arrange for an expert, for example the system manufacturer, to check your individual situation in advance. To evaluate the probability of corrosion, practical experience of the intended area of use should also be called on for the distribution of the incoming water. Within the area of responsibility of system planning, the factors and influencing variables mentioned above with regard to corrosion protection and stone formation for specific application should be taken into consideration. If necessary, you may contact our technical department for support purposes in the area of use. If the drinking water quality is outside the limit values of the Drinking Water Ordinance, testing and approval by our technical department is necessary in all cases for the use of REHAU pipework systems Please contact your REHAU Sales Office regarding this matter. They are therefore also suitable for areas of application with special hygiene requirements in the area of drinking water. When the pipes are used the domestic, commercial and industrial plumbing system they have been proven not to lead to any increase in micro-organisms on the surface and therefore do not promote bacterial contamination or the growth of legionella bacteria. Due to errors in planning, construction and operation, due to stagnation or water of inadequate quality (e.g. dirty water, flood water or maintenance work on the pipe network), impurity can occur. Damage in the pipe network, e.g. supply line with infiltration water penetration, is a cause of possible contamination. Disinfection of a drinking water installation is only necessary in exceptional cases (in the event of contamination) and the priority is to eliminate all operating and technical system deficiencies. Repeated or continuous bacterial exposure of the water in the domestic plumbing system is often caused as a result of incorrect installation methods (e.g. dead leg pipelines) or the operating methods (e.g. long periods of inactivity causing stagnation periods) and, as such, does not justify continuous disinfection. 4.3.1 Thermal disinfection in the event of contamination In the case of well designed drinking water installations (no dead legs, etc.), most impurities can be removed by sufficient rinsing with water, as long as they remain water-soluble or dissolved in water. If contamination is suspected, then procedures for disinfection of water supply pipelines detailed in the UK Drinking Water Inspectorate Regulations must be followed. At water temperatures of at least 70°C, according to the current status of technology, it can be assumed that bacteria found freely in the water, even legionella, will be destroyed. Guidance from the water supply company must be obtained before using this method of disinfection in the UK 4.3 Disinfection of REHAU Pipework Disinfection REHAU drinking water and universal pipes and REHAU compression sleeve joint provide support during drinking water installation in line with hygiene regulations. They comply with the recommendations of the Drinking Water Inspectorate and the WRAS fittings directory. 16 It is important to prevent persons from being scalded by employing suitable safety measures. All pipes of REHAU’s Universal and RAU HIS domestic plumbing systems are suitable for thermal disinfection at 70°C. It is necessary to ensure that, during thermal disinfection, the permissible operating pressures are not exceeded. 4.3.2 Chemical disinfection in the event of contamination For decontamination, in addition to thermal disinfection, chemical disinfection is also being increasingly used. Chemical and thermal disinfection measures always put stress on the materials used in the drinking water installation. According to current knowledge, a number of disinfection measures are also unsuitable for modern materials of installation technology. Among other things, this also affects materials that were previously assumed to be sufficiently corrosion-resistant, for example rust-proof steel, copper and some plastics. Before such procedural measures are introduced, it is necessary to ensure that all parts of the installation system are thermally and chemically suitable for the relevant measure. If necessary, ask the manufacturer of the disinfectant about its suitability for all system parts of the installation. The disinfection measures can be carried out without impairing the functionality of a REHAU drinking water installation if the active substances, concentrations, application durations and maximum temperatures listed in table 1 are adhered to. It should be noted that combined thermal-chemical disinfection at temperatures greater than 25°C and permanent or regular disinfection cycles (e.g. monthly) are not permissible. In relation to the service life of the pipes, the overall number of disinfection cycles is limited to five “standing disinfection” cycles. Otherwise it is not possible to ensure that the specified service lives can be realised. The person carrying out the disinfection process must ensure that no drinking water is drawn during the disinfection phase, including the subsequent rinsing phase. 4.3.2.1 Chemical “standing disinfection” For chemical short-term disinfection (“standing disinfection”), only special active substances that are stipulated in the relevant regulations can be used. TABLE 1 Chemical “standing“ disinfection (active substances and concentrations in accordance with e.g. DVGW W 291) Name Commercial form Storage Safety information1 Max. application concentration2 Application duration and temperature in the pipeline Hydrogen peroxide H 2O2 Aqueous solution in various concentrations Light-protected, cool, dirt must be avoided For solutions >5%, safety gear essential 150mg/l H2O2 Max. 12h Tmax ≤ 25°C Sodium hypochlorite NaOCl Aqueous solution with maximum 150g/l chlorine Light-protected, cool, enclosed and in a collecting tray Alkaline, caustic, poisonous, safety gear essential 50 mg/l chlorine Max. 12h Tmax ≤ 25°C Calcium hypochlorite Ca(OCl) 2 Granulate or tablets approx. 70% Ca(OCl) 2 Cool, dry and enclosed Alkaline, caustic, poisonous, safety gear essential 50 mg/l chlorine Max. 12 h Tmax ≤ 25°C Chlorine dioxide ClO2 Two components (sodium chlorite, sodium peroxodisulphate) Light-protected, cool, enclosed Has oxidising effect, do not breathe in chlorine dioxide gas, safety gear 6 mg/l ClO2 Max. 12h Tmax ≤ 25°C 1) The relevant information in the safety datasheets of the manufacturer is to be observed. 2) Approval of REHAU; this value must not be exceeded anywhere in the installation over the entire application duration. 17 4.3.2.2 Continuous chemical disinfection Due to possible material damage on installation components, we do not recommend the use of systems operating without any time limits for chemical disinfection in the domestic plumbing installation, particularly as a measure for legionella prophylaxis. In such cases, no guarantee can be given. In a number of cases, chemical disinfection may be necessary over an extended period but for a limited time until complete structural renovation is carried out. These kinds of disinfection measures may only be carried out with permissible procedures. The parameters given in table 2 must be monitored by means of measurements over the entire duration of the disinfection measure directly downstream of the active substance feed and documented. If the active substances, concentration, application durations and maximum temperatures listed in table 2 are adhered to, it is possible to carry out disinfection without impairing the functionality of a REHAU drinking water installation. Before any such procedural measures are introduced, it is necessary to ensure that all parts of the installation system are thermally and chemically suitable for the relevant measure. If necessary, please contact the manufacturer of the disinfectant about this. In the case of thermal disinfection, it is essential to prevent persons from being scalded by the appropriate measures. In the case of chemical “standing disinfection”, it is necessary to ensure that no drinking water is drawn during the disinfection phase, including the subsequent rinsing phase. The safety information of the disinfectant manufacturer should be observed. TABLE 2 Chemical disinfection with a time limit (active substances and concentrations in accordance with TrinkwV 2001) Name3 Max. application concentration4 Max. application duration in the pipeline5 Application temperature in the pipeline Chlorine Cl2 Max. 0.3 mg/l free chlorine 4 months 60°C Calcium hypochlorite Ca(OCl) 2 Max. 0.3 mg/l free chlorine 4 months 60°C Chlorine dioxide ClO2 Max. 0.2 mg/l CLO2 4 months 60°C 3) The relevant information in the safety datasheets of the manufacturer is to be observed. 4) Approval of REHAU; this value must not be exceeded anywhere in the installation over the entire application duration. 5) Maximum application duration accumulated over the entire service life of the system In relation to the service life of the pipes, the entire application duration is limited to four months. Otherwise it is not possible to ensure that the specified service lives can be achieved. We generally exclude the use of any other disinfectants not listed here, particularly strong oxidising agents (e.g. ozone). 18 Chemical and thermal disinfection measures that are carried out incorrectly may cause sustained damage to the components of a drinking water installation. 4.4 Approvals The system is approved by the Water Regulations Advisory Scheme (WRAS) for connection to the UK potable water supply system. 4.5 Quality Systems All REHAU Heating and Plumbing products are manufactured to ISO 9001 quality management procedures approved by TUV management services Certificate Nos ISO 9001-12 100 10634 / ISO 14001-12 104 19288 ensuring the products are manufactured to the highest standards. 5. APPLICATIONS THE SYSTEM IN USE THE PHYSICAL PROPERTIES OF RAU PE-XA, ITS TOUGHNESS, FLEXIBILITY AND THE FACT THAT IT IS CONTINUOUSLY EXTRUDED AND CAN BE SUPPLIED IN LONG COILS, MAKES IT THE IDEAL CHOICE FOR HEATING AND PLUMBING APPLICATIONS. These characteristics mean that a new approach has to be taken to the layout and design of installations. In particular, the system lends itself to the concealment of pipework. 5.1 Principle Advantages Inherent characteristics: Long life – Pressure stability across the temperature range gives a projected life in excess of 50 years – BS 7291:1990. Corrosion free – Chemically inert, there is no risk of corrosion, (often a problem with copper pipe in soft water areas). Non furring – The smooth internal walls and chemically inert nature of the pipework prevent scale build up. Application advantages: Overall ease of installation is one of the obvious reasons for using REHAU Universal Pipe. Pipe-in-Pipe – The pipe in sleeve installation method significantly reduces duct costs, both the costs of ducting and the costs associated with fitting pipework into ducts. Long pipe coils – Long lengths reduce the number of joints and allow the pipe to be pulled through awkward areas. Flexibility – When passing through joists. Reduced Theft – The pipe has no scrap value. 19 accessible metal luminaire accessible metal luminaire plastic pipe plastic soil pipe metal pipe metal shower metal soil pipe shower metal heater heater metal hand rail metal hand rail metal water radiator taps waste taps water radiator waste waste bath bath plastic pipes plastic pipes metal waste metal pipes metal soil pipes to be main bonded 1 2 1 Plastic Pipe Installation 2 Metal Pipe Installation Supplementary bonding in a bathroom Speed of installation – Flexible pipe can be installed quicker than rigid materials. Joints are made extremely quickly. Safe – No naked flames needed for jointing. Coils of pipe are safer to move around busy sites or occupied premises. Manifold systems – The location of the distribution centre in one central position simplifies maintenance and speeds up installation. Earth Bonding – According to IEE 16th Edition Regulations, earth bonding of PE-Xa pipes is unnecessary which further simplifies installation. 6 1 2 3 7 4 5.2 Typical Layouts Manifold Options Illustrated. Two pipe ring systems also possible. 5 2 Manifolds of brass construction with flow and return sections. 4 Pipes should be laid as shown and not direct between radiator to appliance. 6 Pipes can be completely concealed in floors or walls. 7 Floor screed placed after 1 Stainless steel or copper radiator tails with access to joints. 20 3 Continuous lengths of Pipe-in-Pipe – no joints. 5 Pipe-in-Pipe sleeve holding flow and return pipes. pipe installation. 1 Typical surface mounted plumbing application Ø16 Ø16 Ø16 Ø25 Ø16 Ø16 Ø16 Ø25 Ø20 Ø16 Ø16 Ø20 1 Radiator connection options 1 Top, bottom, opposite ends 2 Bottom, bottom, opposite ends 3 Combined flow/return valve 1 2 3 5.3 System Design Information 5.3.1 Flow Rates REHAU fittings are designed to give minimum restriction to flow rates and the pipes themselves have a smooth internal finish for maximised flow. The smooth internal bore of polymer pipes does not pick up scale, a common problem with metallic pipes. As a result, flow characteristics are maintained over the life of the pipe. Flow rates are higher than for the same ID size for copper pipe, due to the bore smoothness, the reduced number of fittings and the long radius made bends. 21 TABLE 1 TABLE 2 Pressure Loss Chart 16 X 1.5 mm RAUTHERM Universal Pipe Water at 80˚C - T = 10˚K Pressure Loss Chart 20 x 1.9mm RAUTHERM Universal Pipe Water at 80˚C - T = 10˚K Heat Output Mass Flow Velocity Pressure Drop Heat Output Mass Flow Velocity Pressure Drop Q W m l/h V m/s R pa/m Q W m l/h V m/s R pa/m 300 25.80 0.05 5.5 1,000 86.00 0.12 15.1 400 34.40 0.07 8.9 1,200 103.20 0.14 20.7 500 43.00 0.09 13 1,400 120.40 0.16 27 600 51.60 0.11 17.8 1,600 137.60 0.19 34.1 23.2 60.20 0.13 23.2 1,800 154.80 0.21 41.9 800 68.80 0.14 29.1 2,000 172.00 0.23 50.3 900 77.40 0.16 35.7 2,200 189.20 0.25 59.5 1,000 86.00 0.18 42.9 2,400 206.40 0.28 69.3 1,200 103.20 0.22 58.9 2,600 223.60 0.30 79.8 1,400 120.40 0.25 77.1 2,800 240.80 0.32 91 1,600 137.60 0.29 97.4 3,000 258.00 0.35 102.8 1,800 154.80 0.32 119.8 3,200 275.20 0.37 115.2 2,000 172.00 0.36 144.3 3,500 301.00 0.41 135.1 2,200 189.20 0.40 170.7 3,800 326.80 0.44 156.4 2,400 206.40 0.43 199.2 4,100 352.60 0.48 179 2,600 223.60 0.47 229.6 4,400 378.40 0.51 203.1 2,800 240.80 0.50 262 4,700 404.20 0.54 228.5 3,000 258.00 0.54 296.3 5,000 430.00 0.58 2.553 3,200 275.20 0.58 332.5 5,300 455.80 0.61 283.4 3,400 292.40 0.61 370.6 5,600 481.60 0.65 312.9 3,600 309.60 0.65 410.5 5,900 507.40 0.68 343.6 3,800 326.80 0.68 452.4 6,200 533.20 0.72 375.8 4,000 344.00 0.72 496.1 6,500 559.00 0.75 409.2 4,200 361.20 0.76 541.6 6,800 584.80 0.79 443.9 4,400 378.40 0.79 588.9 7,100 610.60 0.82 479.9 4,600 395.60 0.83 638.1 7,400 636.40 0.86 517.3 4,800 412.80 0.86 689.1 7,700 662.20 0.89 555.9 5,000 430.00 0.90 741.9 8,000 688.00 0.93 595.8 5,200 447.20 0.94 796.5 8,300 713.80 0.96 637 5,400 464.40 0.97 852.9 8,600 739.60 1.00 679.4 22 TABLE 3 TABLE 4 Pressure Loss Chart 25 x 2.3 mm RAUTHERM Universal Pipe Water at 80˚C - T = 10˚K Pressure Loss Chart 32 x 2.9 mm RAUTHERM Universal Pipe Water at 80˚C - T = 10˚K Heat Output Mass Flow Velocity Pressure Drop Heat Output Mass Flow Velocity Pressure Drop Q W m l/h V m/s R pa/m Q W m l/h V m/s R pa/m 4,000 344.00 0.29 56.6 8,000 688.00 0.35 58.3 4,300 369.80 0.31 64.3 8,500 731.00 0.38 64.9 4,600 395.60 0.34 72.5 9,000 774.00 0.40 71.9 5,000 430.00 0.37 84.1 9,500 817.00 0.42 79.2 5,400 464.40 0.39 96.4 10,000 860.00 0.44 86.8 5,800 498.80 0.42 109.5 10,500 903.00 0.47 94.7 6,200 533.20 0.45 123.3 11,000 946.00 0.49 103 6,600 567.60 0.48 137.9 11,500 989.00 0.51 111.5 7,000 602.00 0.51 153.2 12,000 1032.00 0.53 120.4 7,400 636.40 0.54 169.3 12,500 1075.00 0.55 129.6 7,800 670.80 0.57 186.1 13,000 1118.00 0.58 139 8,200 705.20 0.60 203.5 13,500 1161.00 0.60 148.8 8,600 739.60 0.63 221.8 14,000 1204.00 0.62 158.9 9,000 774.00 0.66 240.7 14,500 1247.00 0.64 169.3 9,400 808.40 0.69 260.3 15,000 1290.00 0.66 180 9,800 842.80 0.72 280.7 15,500 1333.00 0.69 191 10,200 877.20 0.75 301.7 16,000 1376.00 0.71 202.3 10,600 911.60 0.77 323.4 16,500 1419.00 0.73 213.9 11,000 946.00 0.80 345.9 17,000 1462.00 0.75 225.8 11,400 980.40 0.83 369 17,500 1505.00 0.78 237.9 11,800 1014.80 0.86 392.8 18,000 1548.00 0.80 250.4 12,200 1049.20 0.89 417.3 18,500 1591.00 0.82 263.2 12,600 1083.60 0.92 442.5 19,000 1634.00 0.84 276.3 13,000 1118.00 0.95 468.4 19,500 1677.00 0.86 289.6 13,400 1152.40 0.98 495 20,000 1720.00 0.89 303.3 20,500 1763.00 0.91 317.2 21,000 1806.00 0.93 331.4 21,500 1849.00 0.95 346 22,000 1892.00 0.97 360.8 22,500 1935.00 1.00 375.9 23 5.3.2 Pipe Sizing Methods for calculating pipe size are given by CIBSE and other bodies. The methods for RAU PE-Xa are similar to those for conventional pipes. Reference should be made to Section B4 of the CIBSE Guide, for information on the loading of different appliances and demand loading. 5.3.3 Pipe-in-Pipe In order to comply with pipe accessibility regulations, pipes within sleeving run within floor screed, must have accessible ends. At the manifold end, the sleeve should be run above the screed, leaving the pipe accessible. At the radiator end, the sleeve should terminate in a REHAU Floor Box or other termination giving accessibility. 5.3.4 Fixing Distances Concealed Pipework The flexibility of RAUTHERM Universal Pipes makes installation within suspended ceilings and partition walls very easy. Normal clips or pipe hangers can be used to fix the pipes. The recommended fixing distances within BS 5955 Part 8 shown in the table below are recommended – note different distances for supported and unsupported pipe. max. 0.5m Fixing Centres Pipe Diameter Horizontal Vertical 16 0.3 0.5 20 0.5 0.8 25 0.5 0.8 32 0.9 1.2 40 1 1.5 50 1 1.5 Pipe Diameter Fixing Centres Cable Tie Centres mm m m 16 and 20 1.5 0.3 25 and 32 1.5 0.4 40 2 0.5 50, 63 2 0.5 24 5.3.5 Pipe Support In situations where the pipe will be visible, REHAU Pipe Support Channel can be used to hold the pipe straight. It may be used in both horizontal and vertical runs of pipe. The sequence of drawings shows how to use the channel. Cable ties at the recommended centres should be used to hold the pipe firmly in the channel. max. 2.0m 5.3.6 Corrosion Inhibitors (Heating systems only) Although RAUTHERM pipes will not themselves corrode, it is sensible to include a corrosion inhibitor into the heating system. RAUTHERM pipes are unaffected by the leading brands of corrosion inhibitor. 5.3.7 Anti Freeze Anti freeze as used in heating circuits will not affect the pipework. Please refer to the table of chemical resistances. REHAU EVERLOC™ Plumbing and Heating systems are susceptible to the same freezing conditions as all plumbing and heating systems and should be protected against freezing. Note: Anti freeze not to be used in Plumbing systems. 5.3.8 Connection to Boilers RAUTHERM pipework must be installed in accordance with BS 5955 Part 8 and not connected directly to any boiler. Metallic pipe has to be used for the boiler connection and the transfer to polymer must be no closer than 350mm from the boiler. 1 2 3 4 L = Pipe length − Δλ1 /2 − Δλ1 FP + λ1 /2 + Δλ2 /2 − Δλ2 /2 + Δλ2 FP SC FP LS FP FP = Fixed Point LS FP = Fixed Point SC = Slip Clip Deflection leg length 1/2 x Ls GS L 5.3.9 Expansion and Contraction Cross-linked PE-Xa responds to changes in temperature, in common with other materials. With increases of temperature, expansion will cause slight distortion over the length of the pipe in long runs. RAUTHERM pipe work is designed to be fixed out of sight, it is therefore recommended that REHAU clip channel be used where the pipe will be visible. 160 Where expansion is likely to have an impact, the pipework should be installed with fixed points and pipe clamps with low friction linings or mineral wool sheathing. It may also be necessary to include an expansion loop in some circumstances. Generally, the pipe absorbs the movement itself, but some care should be taken against shrinkage, particularly in corners. D 160 16 20 25 32 40 50 63 75 90 110 80 140 140 70 Linear expansion (mm) 120 120 100 ure ?T ce en fer dif 60 100 50 rat pe m Te 80 80 40 60 30 60 40 20 40 10 20 20 α = 1.5* 104 C = 12 0 0 0 2 4 6 8 10 10 0 Pipe length (m) 400 600 800 1,000 1,200 1,400 1,600 Deflection leg length 160 These graphs determine thermal linear expansion of RAUTHERM PE-Xa Pipes. Refer to the graphs for guidance on the amount of expansion for run lengths and temperature differentials. 140 α = 0,15 mm/m K 120 Linear expansion (mm) 200 100 70 80 e tur nce ere diff 50 K era p Tem 60 K 60 K ΔT 40 The use of REHAU pipe support channel, by restraining natural movement, reduces the normal co efficient of thermal expansion by approximately 50%. 40 K 30 K 20 K 20 10 K 0 0 2 4 6 8 10 12 Pipe length (m) 25 max. 0.5m 1 Pipe support channel – Cutting 2 De-burring max. 2.0m 3 Fitting 4 Joint clip rail ca. 2mm 6 5.3.10 Bending RAU PE-Xa RAU PE-Xa in sizes to 32mm is easily bent, even when cold. Bend formers can be supplied to form tight bends for certain applications. For 40, 50 and 63mm pipe sizes, we recommend the use of elbow and other fittings. A hot air gun can be used. 5.3.11 Pressure Testing In accordance with good working practices, systems should be pressure tested to 6 bar or 2.5 x Maximum Working Pressure. Due to the expansion of the pipe, the pressure will drop slightly during pressure testing, shortly after reaching test pressure. The pressure will stabilise after re-pressurising the system up to test pressure two or three times. 5.3.12 Insulation Requirements The treatment of RAUTHERM pipes is no different to other pipe systems. Pipe work should be insulated in exposed locations (as recommended by BS 6700 and BS 5422). 7 Assembly detail in rising main 7 – distance from fitting Kinking of the pipe is to be avoided but, should this accidentally happen, it is possible to restore the pipe to its former shape by removing any stress from the pipe and then gently heating the pipe to its extrusion temperature of 135˚C, taking care not to overheat and damage the surface of the pipe. Due to the memory effect, the pipe will return to its original shape. Allow to cool before using. RAUTHERM Universal Pipe Radius Bend mm mm 16 x 1.5 80mm 20 x 1.9 100mm 25 x 2.3 125mm 32 x 2.9 160mm After pumping bar ∆P2< 0,2 bar ∆ P1< 0,6 bar 1,5 x Working pressure 5 5 Distance from fitting 6 Pipe clip spacing Preliminary test 10 20 30 5.3.13 Trace Heating RAUTHERM Pipes are suitable for trace heating. Main test 60 min 26 180 min Thermal Conductivity W/(m.k) of insulating material not exceeding: 0.035 5.3.14 Storage Conditions There are no special requirements. Pipes should be stored free of oil and grease. Once removed from its packaging, the pipe should not be left in direct sunlight. 120 min 0.04 0.055 0.07 Pipe Diameter OD Thickness of Insulation mm mm 16 and 20 22 32 50 75 25 and 32 22 32 50 75 6. SUMMARY As a market leader in the field of polymer processing, REHAU are involved in many diversified industries – for example medical, automotive, electrical and furniture to name a few. As an organisation one of its overriding philosophies is to provide full support in every market in which it operates – for the Flexible Pipework market this is provided in a number of ways. The UK market is serviced by a network of five regional sales offices strategically located to ensure a rapid, local response and to build long term partnerships. The Heating and Plumbing Area Sales Managers based at each of these offices form the first point of contact when assistance is required. They are backed by a dedicated Technical Applications Department based at the UK Headquarters in Ross-on-Wye, who provide technical support. A full range of support literature in the form of sales brochures, technical bulletins, installation guides and parts lists is available. This manual has been produced as a vital component of this package to provide concise technical information on all aspects of our Flexible Pipework System. To complete the support package offered, the REHAU EVERLOC™ Heating and Plumbing System is backed by a comprehensive warranty. This covers both products and consequential damage amounting to a total claim sum of £100,000 for a period of 10 years subsequent to putting a system into operation. Full details of our warranty are available on request – address details for our Sales Offices are provided on the back of this manual. 27 Pressure loss Pa/m 1.0 10.0 100.0 1 000.0 10 000.0 0.01 Water Temperature: 30˚C Head loss diagram for REHAU PE-Xa Pipes 0.10 m m Flow rate l/s /s 0.1 m 16 .5 x1 .9 x1 m m /s 0.2 m 20 /s .3 x2 0.3 m 25 /s 1.00 0.4 m m m m m /s x3 .7 m m 50 x4 .6 m m x5 .7 m m /s 63 2.0 1.9 m/s 1.8 m m/s 1.7 m /s /s 1.6 1.5 m m/s 1.4 m /s 1.3 m /s 1.2 m /s 1.1 m /s /s 1.0 m /s 0.9 m /s 0.8 m /s 40 0.7 m /s 0.6 m .9 x2 0.5 m 32 10.00 7. APPENDIX Pressure loss Pa/m 1.0 10.0 100.0 1 000.0 10 000.0 0.01 Water Temperature: 60˚C Head loss diagram for REHAU PE-Xa Pipes 0.10 m m Flow rate l/s /s 0.1 m 16 .5 x1 m m /s .9 x1 0.2 m 20 0.3 m 25 .3 /s x2 m /s 32 x2 m m /s .7 m m 50 x4 .6 m m x5 .7 m 63 2.0 1.9 m/s 1.8 m m/s /s 1.7 1.6 m/s 1.5 m m/s 1.4 m /s 1.3 m /s 1.2 m /s 1.1 m /s /s 1.0 m /s 0.9 m /s 0.8 m /s 40 x3 0.7 m /s /s 0.6 m .9 0.5 m 1.00 0.4 m m m 10.00 Pressure loss Pa/m 1.0 10.0 100.0 1 000.0 10 000.0 0.01 Water Temperature: 80˚C Head loss diagram for REHAU PE-Xa Pipes 0.10 .5 x1 m m Flow rate l/s /s 0.1 m 16 m m /s 0.2 m 20 .9 x1 .3 /s 0.3 m 25 x2 m /s 1.00 0.4 m m m m x3 .7 m m 50 x4 .6 m m x5 .7 m m 63 2.0 1.9 mm/s 1.8 m /s /s 1.7 1.6 m/s 1.5 m m/s / 1.4 m s 1.3 m /s 1.2 m /s /s 1.1 m /s 1.0 m /s 0.9 m /s 0.8 m /s 40 0.7 m /s /s 0.6 m /s 0.5 m 32 .9 x2 10.00 www.rehau.co.uk 890.610EN/927/DAIR/04.08