DEF STAN 00-35(PART 4)/Issue 3

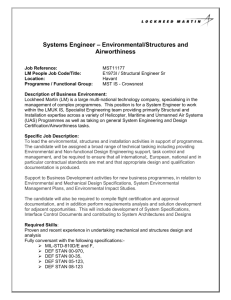

advertisement