Mechanics Optical determination of velocity of sound in liquids 1.5

advertisement

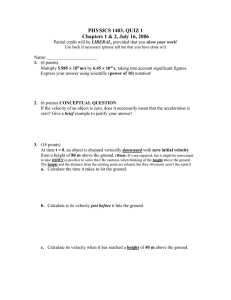

Mechanics Mechanical Vibration, Acoustics Optical determination of velocity of sound in liquids 1.5.10-00 What you can learn about … Ultrasonics Sound velocity Frequency Wavelength Sound pressure Stationary waves Debye-Sears effect Principle: A stationary ultrasonic wave in a glass cell full of liquid is traversed by a divergent beam of light. The sound wavelength can be determined from the central projection of the sound field on the basis of the refractive index which changes with the sound pressure. What you need: Ultrasonic generator 13920.99 1 Laser, He-Ne 1.0 mW, 230 VAC 08181.93 1 Glass cell, 150 x 55 x 100 mm 03504.00 1 Lens holder 08012.00 1 Lens, mounted, f = +20 mm 08018.01 1 Screen, metal, 300 mm x 300 mm 08062.00 1 Optical profile bench, l = 1000 mm 08282.00 1 Base for optical profile bench, adjustable 08284.00 2 Slide mount for optical profil bench, h = 80 mm 08286.02 1 Slide mount for optical profil bench, h = 30 mm 08286.01 4 Swinging arm 08256.00 1 Table top on rod 08060.00 1 Laboratory thermometers, -10...+ 30°C 05949.00 1 Right angle clamp -PASS- 02040.55 1 Support rod, stainless steel 18/8, l = 250 mm, d = 10 mm 02031.00 1 Universal clamp 37718.00 1 Glycerol, 250 ml 30084.25 3 Water, distilled 5 l 31246.81 1 Complete Equipment Set, Manual on CD-ROM included Optical determination of velocity of sound in liquids P2151000 PHYWE Systeme GmbH & Co. KG · D - 37070 Göttingen Image of a screen. Tasks: To determine the wavelength of sound in liquids, and from this calucate the sound velocity, from the structure of the centrally projected image. Laboratory Experiments Physics 69 LEP 1.5.10 -00 Optical determination of velocity of sound in liquids Related topics Ultrasonics, sound velocity, frequency, wavelength, sound pressure, stationary waves. Principle A stationary ultrasonic wave in a glass cell full of liquid is traversed by a divergent beam of light. The sound wavelength can be determined from the central projection of the sound field on the basis of the refractive index which canges with the sound pressure. Equipment Ultrasonic generator Laser, He-Ne 1.0 mW, 230 V AC Glass cell, 15055100 mm Lens holder Lens, mounted, f = +20 mm Screen, metal, 300300 mm Optical profile-bench, l = 1000 mm Base f. opt. profile-bench, adjust. Slide mount f. opt. pr.-bench, h = 80 mm Slide mount f. opt. pr.-bench, h = 30 mm Swinging arm Table top on rod, 18.511 cm Thermometer -10...+30 °C Right angle clamp -PASSSupport rod, l = 250 mm Universal clamp 11744.93 08181.93 03504.00 08012.00 08018.01 08062.00 08282.00 08284.00 08286.02 08286.01 08256.00 08060.00 05949.00 02040.55 02031.00 37715.00 1 1 1 1 1 1 1 2 1 3 1 1 1 1 1 1 Glycerol, 250 ml Water, distilled, 5 l 30084.25 31246.81 3 1 Tasks To determine the wavelength of sound in liquids, and from this calucate the sound velocity, from the structure of the centrally projected image. Set-up and procedure Fig. 1 shows the experiment set-up. The glass cell is 2/3 full of liquid, and the sound head is immersed in it to a depth of a few millimetres, with its face parallel to the bottom of the cell. The laser beam is enlarged with a lens of focal length +20 mm. The lens is approx. 0 – 20 cm, the projection screen about 50 cm, away from the cell. The laser and the lens are adjusted so that the beam traverses the liquid between the sound head and the cell bottom. The experiment is carried out in a semi-darkened room. With the generator amplitude on the medium setting, the depth of immersion of the sound head is so adjusted as to produce a well-defined system of light and dark bands in the projected image. The distance between the bands is determined for various liquids and the liquid temperature measured in each case. Any gas bubbles forming on the surface of the sound head and the walls of the cell are removed with a rod. Fig. 1: Experimental set-up for interference measurements. PHYWE series of publications • Laboratory Experiments • Physics • © PHYWE SYSTEME GMBH & Co. KG • D-37070 Göttingen P2151000 1 LEP 1.5.10 -00 Optical determination of velocity of sound in liquids Fig. 2: Localised distribution of the change in pressure or refractive index for four phases of a stationary wave. Phases t = 41 T and t = 43 T, in which the light passing through the liquid is not deflected, only cause the projected image to lighten. The spacing of the interference fringes (/2), and therefore the wavelength , can be measured from the height d of the projected image and the number N of fringes it contains, using the equation = 2 s1 s1 s2 where = d N1 as shown by Fig. 3. The sound propagation velocity is obtained from c=·f where f is the ultrasonic frequency. Table 1 Theory and evaluation Fig. 2 shows the relationship between variations in sound pressure p and the location x for four phases of a stationary wave. The refractive index of the liquid also changes because of the pressure variations, and the change in refractive index n can be regarded as proportional to the pressure variation p. In phases t = 0 and t = 12 T (where T is the vibration period), well-defined interference fringes occur, spaced apart by /2. Liquid N d mm a mm l mm c m >s ¢c m >s q °C Glycerol alcohol (ethanol) Water (dist.) Common salt solution (saturated) 12 20 19 47.5 48.5 57.0 3.65 2.31 2.85 2.37 1.50 1.85 1900 1200 1480 20 12 14 25 25 25 17 55.5 3.47 2.25 1800 20 25 Table 1, summarises typical examples of measurements. The distances are: s1’ = 50 cm s1 = 48 cm s2 = 148 cm The light passing through the liquid is deflected into the vibration nodes in the regions where there is a considerable local variation of the refractive index, whereas in the antinode areas it is hardly deflected at all. The vibration nodes thus appear as dark bands and the antinodes as light bands in the central projection. f = 800 kHz is used as the ultrasonic frequency. Fig. 3: Path of the rays in the central projection. Fig. 4: Image of a screen. 2 P2151000 PHYWE series of publications • Laboratory Experiments • Physics • © PHYWE SYSTEME GMBH & Co. KG • D-37070 Göttingen LEP 1.5.10 -00 Optical determination of velocity of sound in liquids The standard error is caluclated in accordance with the law of error propagation, the individual error values being estimated as: s1 s2 d f = = = = Bibliography * L. Bergmann, Der Ultraschall (Ultrasonics), Hirzel Verlag ** Handbook of Chemistry and Physics, The Chemical Rubber Co. 3 mm 3 mm 0.3 mm 5 kHz (see Operating Instructions for the Ultrasonic Generator). Remark Relationship between temperature and sound velocity: Liquid Glycerol+ Ethanol Water (Dist). + q °C c m>s ¢c ¢q m>s °C Source 20 25 20 25 25 25 1923 1904 1180 1207 1497 1498 – 1.8 – 2.2 – 3.6 –4 + 2.5 + 2.4 * ** * ** * ** As glycerol is hygroscopic, smaller values are often found for a glycerol which has been allowed to stand. PHYWE series of publications • Laboratory Experiments • Physics • © PHYWE SYSTEME GMBH & Co. KG • D-37070 Göttingen P2151000 3 LEP 1.5.10 -00 4 Optical determination of velocity of sound in liquids P2151000 PHYWE series of publications • Laboratory Experiments • Physics • © PHYWE SYSTEME GMBH & Co. KG • D-37070 Göttingen Mechanics Mechanical Vibration, Acoustics Temperature dependence of the Velocity of sound in liquids 1.5.12-00 What you can learn about … Wavelength Frequency Velocity of sound in liquids Compressibility Density Ultrasonics Piezoelectric effect Piezoelectric ultrasonic transducer Principle: Sound waves are radiated into a liquid by an ultrasonic transmitter and detected with a piezoelectric transducer. The wavelength of the sound is found by comparing the phase of the detector signal for different sound paths and, when the frequency is known, the velocity of sound as a function of the temperature of the liquid is determined. What you need: Ultrasonic pickup 13920.00 1 Ultrasonic generator 13920.99 1 Sliding device, horizontal 08713.00 1 Optical profile bench, l = 600 mm 08283.00 1 Base for optical profile bench, adjustable 08284.00 2 Slide mount for optical profil bench, h = 30 mm 08286.01 1 Swinging arm 08256.00 1 Insulating support 07924.00 1 Immersion thermostat TC10 08492.93 1 Accessory set for TC10 08492.01 1 Bath for thermostat, Makrolon 08487.02 1 Laboratory thermometers, -10...+100°C 38056.00 1 Oscilloscope 30 MHz, 2 channels 11459.95 1 Support rod, stainless steel 18/8, l = 100 mm 02030.00 2 Right angle clamp -PASS- 02040.55 2 Universal clamp with joint 37716.00 1 Screened cable, BNC, l = 750 mm 07542.11 2 Adapter BNC socket/4 mm plug pair 07542.27 1 Glycerol, 250 ml 30084.25 1 Water, distilled 5 l 31246.81 1 Connecting cable, 4 mm plug, 32 A, red, l = 10 cm 07359.01 1 Slide mount 08286.00 1 Velocity of sound in water as a function of the temperature. Complete Equipment Set, Manual on CD-ROM included Temperature dependence of the Velocity of sound in liquids P2151200 Tasks: The wavelength is found from the phase position of the sound pickup signal relative to the generator signal as a function of the sound path and the velocity of the sound is PHYWE Systeme GmbH & Co. KG · D - 37070 Göttingen determined when the ultrasonic frequency is known. The measurement is made for water and glycerol as the temperatures of the liquids are changed step-by-step. Laboratory Experiments Physics 71 LEP 1.5.12 -00 Temperature dependence of the velocity of sound in liquids Related topics Wavelength, frequency, velocity of sound in liquids, compressibility, density, ultrasonics, piezoelectric effect, piezoelectric ultrasonic transducer. Principle Sound waves are radiated into a liquid by an ultrasonic transmitter and detected with a piezoelectric transducer. The wavelength of the sound is found by comparing the phase of the detector signal for different sound paths and, when the frequency is known, the velocity of sound as a function of the temperature of the liquid is determined. Equipment Ultrasonic pickup Ultrasonic generator Sliding device, horizontal Optical profile bench l = 60 cm Base f. opt. profile-bench, adjust. Slide mount f. opt. pr.-bench, h = 30 mm Swinging arm Insulating support Immersion thermostat TC10 Accessory set for TC10 Bath for thermostat, Makrolon Lab thermometer, -10...+100°C Oscilloscope, 30 MHz, 2 channels Support rod, l = 100 mm Right angle clamp -PASS- 11744.00 11744.93 08713.00 08283.00 08284.00 08286.01 08256.00 07924.00 08492.93 08492.01 08487.02 38056.00 11459.95 02020.00 02040.55 1 1 1 1 2 2 1 1 1 1 1 1 1 2 2 Universal clamp with joint Screened cable, BNC, l = 750 mm Adapter, BNC-socket/4 mm plug pair Glycerol, 250 ml Water, distilled, 5 l Connecting cord, l = 100 mm, red 37716.00 07542.11 07542.27 30084.25 31246.81 07359.01 1 2 1 1 1 1 Tasks The wavelength is found from the phase position of the sound pickup signal relative to the generator signal as a function of the sound path and the velocity of the sound is determined when the ultrasonic frequency is known. The measurement is made for water and glycerol as the temperatures of the liquids are changed step-by-step. Set-up and procedure Fig. 1 shows the experimental set-up. The sound radiating face of the sound transmitter is wetted with glycerol or water for better acoustic coupling and lies flat against the wall of the bath vessel. In order to avoid standing waves due to sound reflection, the wall of the vessel opposite to the sound transmitter is covered with a sound-absorbing material such as foam material or crumpled paper. The ultrasonic generator is set to sine wave operation. The oscilloscope is triggered internally via channel 1 by means of the generator monitoring signal. The sound frequency is found with the oscilloscope which is connected to the ‘Synchr.’ Fig. 1: Experimental set-up: Temperature dependence of the Velocity of sound in liquids. PHYWE series of publications • Laboratory Experiments • Physics • © PHYWE SYSTEME GMBH & Co. KG • D-37070 Göttingen P2151200 1 LEP 1.5.12 -00 Temperature dependence of the velocity of sound in liquids generator output. The pickup and monitoring signals are set in phase on the screen by moving the sound pickup and adjusting the phase control on the generator. The sound pickup is moved from this starting position and the wavelength is determined from the distance l through which it has been moved and the number n of inphase transition points traversed in the process. Fig. 2: Velocity of sound in water as a function of the temperature. In order to obtain an interferencefree signal it is recommended to connect the thermostat heating coil to the oscilloscope earth socket with the crocodile clip. The experiment is carried out with water and glycerol. Theory and evaluation Provided that the oscillatory process is an adiabatic one, the relationship c 1 B r · bad (1) where is the density and ad the adiabatic compressibility, is obtained for the velocity of sound in liquids. The change of the velocity of sound with temperature is in the main determined by the temperature dependence of the compressibility. In all liquids with the exception of water the compressibility increases and the density decreases as the temperature rises. The velocity of sound decreases approximately linearly as the temperature rises. Water occupies a special position amongst liquids; the compressibility is reduced initially as the temperature rises to a minimum of approx. 60°C and only then increases. The velocity of sound in water therefore has a positive temperature coeffizient initially and, taking into account the density, which becomes lower as the temperature rises, reaches a maximum value of 1557 m/s at 74°C. Above this temperature the velocity of sound decreases. When there is a change of spacing l between the sound transmitter and the pickup relative to the starting position (relative phase = 0), the phase of the received signal is shifted relative to the transmitted signal by ¢£ ¢l ·2p . l (2) When the spacing is further changed, the signals come into coincidence again when l = n · ; n = 1, 2, . . . (3) From Eq. (2) and (3) the wavelength can be found to be l ¢l ¢l ·2p . ¢£ n (4) In Figs. 2 and 3 the velocities of sound found for water and glycerol in accordance with Eq. (4) and (5) are represented as a function of the liquid temperature. In the measurement example the wavelength of sound for a temperature of the liquid was determined from three separate measurements with the detector moved through 5 wavelengths each time. The error of the mean value is c = ±4 m/s for water and c = ± 7 m/s for glycerol. The measurement example yields a maximum velocity of sound in the case of water of cmax = (1554 ± 4) m/s at a liquid temperature of = 72°C. Note The liquid in the region of the acoustic field is heated up by ultrasonic absorption. The measurements should therefore be made with as small a sound amplitude as possible. Attention is also to be paid to thorough mixing of the bath. The sound wavelength is thus shown to be the slope of the regression straight lines, if the displacement of the detector l is plotted as a function of the number n. The phase velocity is obtained with the sound frequency f: c = · f. 2 P2151200 (5) PHYWE series of publications • Laboratory Experiments • Physics • © PHYWE SYSTEME GMBH & Co. KG • D-37070 Göttingen LEP 1.5.12 -00 Temperature dependence of the velocity of sound in liquids Fig. 3: Velocity of sound in glycerol as a function of the temperature. Velocities of sound with temperature coefficient Liquid Water (dist) Glycerol* q °C c m>s ¢c ¢q m>s °C Source 25 25 20 25 1497 1498 1923 1904 + 2.5 + 2.4 – 1.8 – 2.2 1) 2) 1) 2) * Since glycerol is hygroscopic, a lower velocity of sound is often measured for stale glycerol. Bibliography 1) L. Bergmann, Der Ultraschall (Hirzel Verlag) 2) Handbook of Chemistry and Physics (The Chemical Rubber Co.) PHYWE series of publications • Laboratory Experiments • Physics • © PHYWE SYSTEME GMBH & Co. KG • D-37070 Göttingen P2151200 3 LEP 1.5.12 -00 4 Temperature dependence of the velocity of sound in liquids P2151200 PHYWE series of publications • Laboratory Experiments • Physics • © PHYWE SYSTEME GMBH • 37070 Göttingen, Germany