FF 830 - Combimix

advertisement

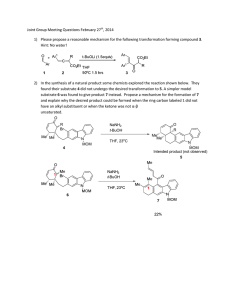

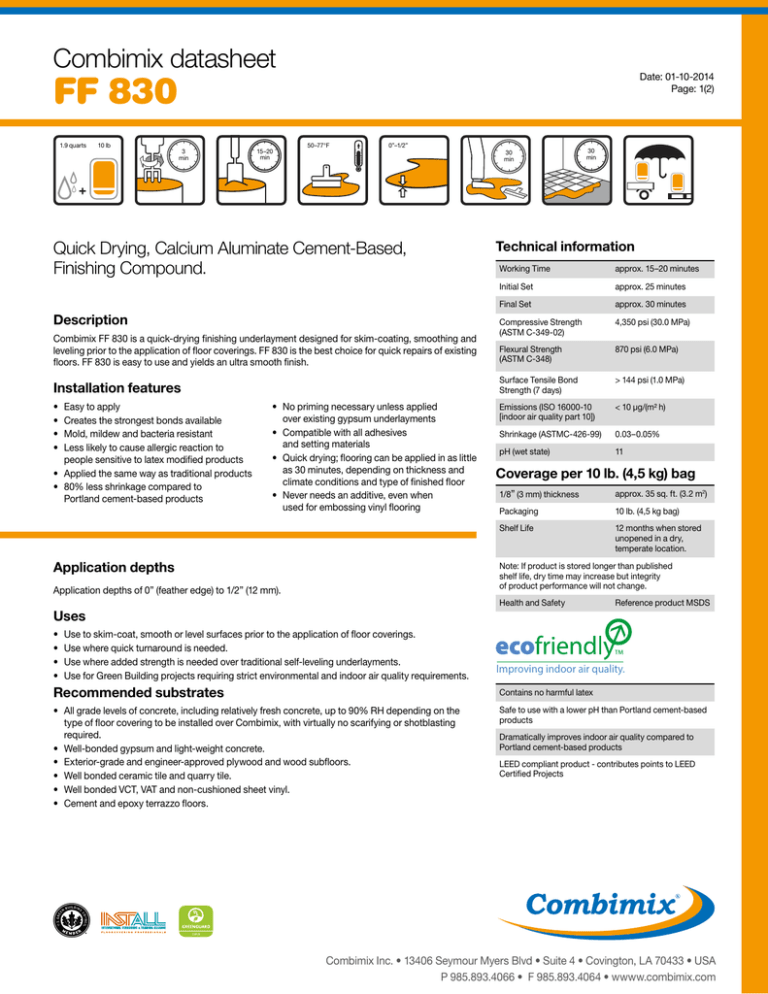

Combimix datasheet FF 830 1.9 quarts 10 lb 3 min 15–20 min Date: 01-10-2014 Page: 1(2) 50–77°F 0”–1/2” Quick Drying, Calcium Aluminate Cement-Based, Finishing Compound. Description Combimix FF 830 is a quick-drying finishing underlayment designed for skim-coating, smoothing and leveling prior to the application of floor coverings. FF 830 is the best choice for quick repairs of existing floors. FF 830 is easy to use and yields an ultra smooth finish. Installation features • • • • Easy to apply Creates the strongest bonds available Mold, mildew and bacteria resistant Less likely to cause allergic reaction to people sensitive to latex modified products • Applied the same way as traditional products • 80% less shrinkage compared to Portland cement-based products • No priming necessary unless applied over existing gypsum underlayments • Compatible with all adhesives and setting materials • Quick drying; flooring can be applied in as little as 30 minutes, depending on thickness and climate conditions and type of finished floor • Never needs an additive, even when used for embossing vinyl flooring Application depths 30 min Technical information Working Time approx. 15–20 minutes Initial Set approx. 25 minutes Final Set approx. 30 minutes Compressive Strength (ASTM C-349-02) 4,350 psi (30.0 MPa) Flexural Strength (ASTM C-348) 870 psi (6.0 MPa) Surface Tensile Bond Strength (7 days) > 144 psi (1.0 MPa) Emissions (ISO 16000-10 [indoor air quality part 10]) < 10 μg/(m² h) Shrinkage (ASTMC-426-99) 0.03–0.05% pH (wet state) 11 Coverage per 10 lb. (4,5 kg) bag 1/8” (3 mm) thickness approx. 35 sq. ft. (3.2 m2) Packaging 10 lb. (4,5 kg bag) Shelf Life 12 months when stored unopened in a dry, temperate location. Note: If product is stored longer than published shelf life, dry time may increase but integrity of product performance will not change. Application depths of 0” (feather edge) to 1/2” (12 mm). Health and Safety Uses • • • • 30 min Use to skim-coat, smooth or level surfaces prior to the application of floor coverings. Use where quick turnaround is needed. Use where added strength is needed over traditional self-leveling underlayments. Use for Green Building projects requiring strict environmental and indoor air quality requirements. Reference product MSDS Improving indoor air quality. Recommended substrates Contains no harmful latex • All grade levels of concrete, including relatively fresh concrete, up to 90% RH depending on the type of floor covering to be installed over Combimix, with virtually no scarifying or shotblasting required. • Well-bonded gypsum and light-weight concrete. • Exterior-grade and engineer-approved plywood and wood subfloors. • Well bonded ceramic tile and quarry tile. • Well bonded VCT, VAT and non-cushioned sheet vinyl. • Cement and epoxy terrazzo floors. Safe to use with a lower pH than Portland cement-based products Dramatically improves indoor air quality compared to Portland cement-based products LEED compliant product - contributes points to LEED Certified Projects Combimix Inc. • 13406 Seymour Myers Blvd • Suite 4 • Covington, LA 70433 • USA P 985.893.4066 • F 985.893.4064 • wwww.combimix.com Combimix datasheet FF 830 Date: 01-10-2014 Page: 2(2) Limitations Notice • Primer required when used of gypsum-based surfaces. • Designed for hand applications only. • Substrate temperature should be a minimum 43°F (6°C) and air temperature maintained between 50–77°F (10–25°C) during and up to 72 hours after application. • For interior use only. Information contained herein or otherwise administered by COMBIMIX or its affiliates is based on current and present knowledge of products when used under normal circumstances and according to COMBIMIX recommendations. Before using product, user will determine suitability of product for its intended use and assumes all related risks, responsibility and liability. Substrate prep Substrate must be free from dust, oil or any contaminants which may contribute to decreased bond. A tensile bond test should be taken in order to determine the surface bond strength on the substrate. If a tensile bond test is not performed or fails to meet the minimum of 72 psi (0.5 MPa), mechanical removal of weak surfaces must be completed to clean the surface down to a sound and solid substrate by shot blasting, scarifying or similar method. Remove any loose particles and then vacuum. Gypsum substrates should be primed with Combimix PP 600 Primer and allow to dry. The substrate temperature should be a minimum 43°F (6°C) and air temperature maintained between 50–77°F (10–25°C) during and up to 72 hours after application. Adequate ventilation should be provided to ensure uniform drying. Moisture content of substrate should be RH 90% or less prior to application of FF 830 floor leveling underlayment. Relative Humidity testing may occur after the installation of Combimix products. Mixing Mixing ratio: 2:1 (2 parts FF 830 per 1 part water). Add 10 lb. (4.5 kg) of FF 830 with a maximum 1.9 quarts (1.8 l) of cool, potable water (do not over-water, yellowish film will develop on the surface of product if over-watered.). Mix for 3 minutes with a heavy duty drill mixer (650 minimum rpm) to obtain a lump-free mix. Product can be freshened by remixing without any additional water. Application Apply blended material to substrate at a thickness of feather edge to 1/2” (12 mm) for all surfaces. After initial set of material (approx. 10–15 min.), remove any overlap marks, seams and inconsistencies by scraping with a steel trowel. Curing and protection/drying time Protect product from excessive heat or draft conditions during the curing process. Turn off all forced ventilation and radiant heating systems. Protect for up to 24 hours after completed installation. Material can be walked on after 30 minutes. Cleaning Clean hands and tools with water before material hardens. Material hardened will need to be mechanically removed. Use proper storage. Combimix Inc. • 13406 Seymour Myers Blvd • Suite 4 • Covington, LA 70433 • USA P 985.893.4066 • F 985.893.4064 • wwww.combimix.com