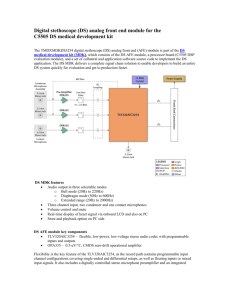

FacilitieS - MAMAC Systems

advertisement