hancock place school district 200801.04 hs/ms

advertisement

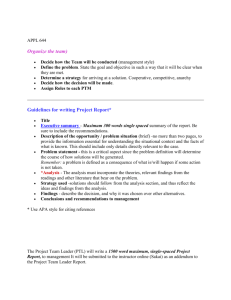

HANCOCK PLACE SCHOOL DISTRICT 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. ADDENDUM NO. 1 1.1 PROJECT INFORMATION A. Project Name: Hancock Place High School & Middle School Campus, Middle School Gym Addition and Dome Building Addition and Renovation. B. Owner: Hancock Place School District. C. Architect: Wm. B. Ittner, Inc. D. Architect Project Number: 200801.04. E. Date of Addendum: September 12, 2012. 1.2 NOTICE TO BIDDERS A. This Addendum is issued to all registered plan holders pursuant to the Instructions to Bidders and Conditions of the Contract. This Addendum serves to clarify, revise, and supersede information in the Project Manual, Drawings, and previously issued Addenda. Portions of the Addendum affecting the Contract Documents will be incorporated into the Contract by enumeration of the Addendum in the Owner/Contractor Agreement. B. The Bidder shall acknowledge receipt of this Addendum in the appropriate space on the Bid Form. C. The date for receipt of bids is unchanged by this Addendum, at same time and location. 1.3 ATTACHMENTS A. This Addendum includes the following attached Documents and Specification Sections: 1. 2. 3. 4. 5. B. Document 007349 “Labor Stabilization Agreement,” Attachment A - Letter of Assent, dated September 12, 2012, (reissued). Document 007373 “Statutory Requirements,” dated September 12, 2012, (reissued). Section 105300 “Aluminum Walkway Covers,” dated September 12, 2012, (new). Section 144200 “Wheelchair Lifts,” dated September 12, 2012, (reissued). Section 323113 “Chain Link Fences and Gates,” dated September 12, 2012, (new). This Addendum includes the attached Addendum/Supplemental Drawings: 1. 2. 3. 4. Civil Addendum Drawings SDC-1 and SDC-2, dated 09/12/2012. Architectural Addendum Drawings SDA-1 through SDA-5, dated 09/12/2012. Plumbing Addendum Drawings SDP-1 through SDP-3, dated 09/05/2012. Electrical Addendum Drawings SDE-1 through SDE-4, dated 09/04/2012 and 09/10/2012. ADDENDUM NO. 1 PAGE - 1 HANCOCK PLACE SCHOOL DISTRICT 1.4 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. REVISIONS TO DIVISION 00 PROCUREMENT REQUIREMENTS AND CONTRACTING REQUIREMENTS A. Document 005213 “Agreement Form – Stipulated Sum (Single-Prime Contract),” AIA Document A101 2007 Standard Form of Agreement between Owner and Contractor, (not reissued). 1. 1.5 Article 3, Paragraph 3.3: The DRAFT contract lists an incorrect substantial completion date of June 06, 2014. The contract executed with the successful bidder will indicate substantial completion in accordance with the Document 003113 “Preliminary Schedules,” Anticipated Construction Schedule Phasing Diagrams, which indicate a substantial completion date of August 2, 2013. REVISIONS TO DIVISION 01 GENERAL REQUIREMENTS A. Specification Section 011000 “Summary,” (not reissued). 1. B. Specification Section 015000 “Temporary Facilities and Controls,” (not reissued). 1. 1.6 Paragraph 1.4 OWNER-FURNISHED PRODUCTS, B., 1. Food Service Equipment: The Owner-Furnished portion of Work includes fabricating, shipping, unloading, handling, storing, protecting, and installing Owner-furnished food service equipment. The Contractor-Installed portion of Work includes coordination and making building services connections to the food service equipment. Paragraph 3.4 SECURITY AND PROTECTION FACILITES INSTALLATION: ADD paragraph “L. Existing Flooring Protection: Provide temporary protection of wood and resilient athletic flooring materials (Dome Building gyms and weight room), from construction operations, and similar activities, in the form of plastic sheeting and composite wood fiber board panels over cardboard packing materials. Tape edges and seams to prevent the penetration of dust and debris through to existing floor surfaces.” REVISIONS TO DIVISIONS 02 - 49 SPECIFICATION SECTIONS A. B. Specification Section 024119 “Selective Structure Demolition,” (not reissued). 1. Paragraph 3.8 SELECTIVE DEMOLITION SCHEDULE, 1. Existing Items to be Removed: ADD the sentence, Food Service Equipment indicated to be removed, shall be the work of the Contractor. 2. Paragraph 3.8 SELECTIVE DEMOLITION SCHEDULE, 2. Existing Items to be Removed and Salvaged: ADD the sentence, Food Service Equipment indicated to be removed and salvaged, shall be the work of the Food Service Equipment Contractor under separate contract with Owner-Furnished Products, as indicated in Section 011000 “Summary.” 3. Paragraph 3.8 SELECTIVE DEMOLITION SCHEDULE, 3. Existing Items to be Removed and Reinstalled: ADD the sentence, Food Service Equipment indicated to be removed and reinstalled, shall be the work of the Food Service Equipment Contractor under separate contract with Owner-Furnished Products, as indicated in Section 011000 “Summary.” Specification Section 087100 “Door Hardware,” (not reissued). ADDENDUM NO. 1 PAGE - 2 HANCOCK PLACE SCHOOL DISTRICT 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. 1. ADD Paragraph 2.7.D: “Provide removable cores and cylinders at all keyed devices, removable mullions, and exit device trim. Provide construction cores with construction master keying for use during construction.” 2. ADD Paragraph 2.11.A.2: “Provide special templates, drop plates, mounting brackets, or adapters for arms as required for details, overhead stops, and other door hardware items interfering with closer mounting.” 3. ADD Paragraph 2.11.A.3: “3. Mount closers on room side of corridor doors, inside of exterior doors, and stair side of stairway doors from corridors. Closers shall not be visible in corridors, lobbies and other public spaces unless approved by Architect.” DOOR HARDWARE SCHEDULE CHANGES HW SETs: 01 AND 02 1. CHANGE Vandl Classroom Security Lock designation as follows: ND95RDTD RHO HW SET: 03 1. CHANGE Vandl Office Lock designation as follows: ND91RD TD RHO HW SETs: 04, 05, 06, 07, 08, and 09 1. CHANGE Vandl Storeroom Lock designation as follows: ND96 RD TD SPARHO HW SET: 08 1. ADD Item: 2 EA KICK PLATE 8400 10" X 1" LDW B4E 630 IVE HW SET: 09 1. CHANGE Kickplate designation as follows: 8400 10" X 12" LDW B4E HW SET: 14 1. CHANGE Panic Hardware designation as follows: CD-9949-WDC-L-DT-996-06-LBL 2. CHANGE Panic Hardware designation as follows: CD-9949-WDC-L-NL-996-06-LBL HW SET: 16 1. CHANGE Panic Hardware designation as follows: CD-9949-WDC-L-NL-996-06-LBL HW SET: 20 1. CHANGE Power Supply designation as follows: PS914-2RS-4RL 2. ADD Item: 1 EA POWER TRANSFER EPT10 689 IVE ADD NEW: ADDENDUM NO. 1 PAGE - 3 HANCOCK PLACE SCHOOL DISTRICT 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. HARDWARE GROUP NO. 27 XM111 Qty 1 1 1 1 1 1 1 1 1 1 EA EA EA EA EA SET SET EA EA Description CONT. HINGE PANIC HARDWARE SURFACE CLOSER FLOOR STOP DRIP CAP SEALS SEALS DOOR SWEEP THRESHOLD Catalog Number 112HD LD-99-EO 4111 AVB SCUSH SRI MC FS444 16A 700ES 700SA 101VA 513HD X 4S BALANCE OF GASKETING BY DOOR MANUFACTURER Finish 628 626 689 626 CL AL CL CL AL Mfr IVE VON LCN IVE NGP NGP NGP NGP NGP Free Egress at all times. Push Bar retracts latchbolt. No exterior trim. No dogging included. Self-Closing. Templating allows Spring CUSH Arm to stop the door's swing between 85 and 110 degrees. Back check engages at approximately 45 degrees of the opening swing. 1.7 REVISIONS TO DRAWING SHEETS ARCHITECTURAL A. Sheet A10.0 – Room Finish Legend (not reissued). 1. Drawing Room Finish Legend: ADD Note #15 to the “Keyed Notes” column of the Room Finish Schedule for Room D314 Nurse. 2. Drawing Room Finish Legend: ADD Note #15 to “Keyed Finish Notes” below the Room Finish Schedule. Note 15 to read as follows: WDWT-1 at exterior windows this room. 3. Master Material and Finish Legend: REVISE CRTN-1 and CRTN-2 from the Master Material and Finish Legend. They will be listed as “NOT USED”. The stage curtains will be handled in a separate package along with stage lighting at a later date. MECHANICAL Sheet M1.2 1. Remove two 52x16 up and down ductwork in the weight room right side shaft from the project. Sheet MD1.1 1. Keyed Note 1; Add the following sentence: “Hazardous material contained within existing equipment removed as a unit is the sole responsibility of the Contractor. For example asbestos inside the boiler.” Sheet MD1.3 – CAFETERIA, KITCHEN AND DINING AREAS TEMPORARY HEATING & COOLING 1. Keyed Note 2; Change as follows. “Existing grade mounted rooftop unit shall be relocated to the west side of the building to provide temporary heating and cooling during construction phase. Relocate unit and re- ADDENDUM NO. 1 PAGE - 4 HANCOCK PLACE SCHOOL DISTRICT 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. connect hot water piping, ductwork and controls back to existing. Unit and related items shall be completely removed when new systems have been installed and are operating.” ELECTRICAL Sheet E0.1 1. Revise service feeders for Middle School Gym. Locate utility company pad mounted transformer and provide concrete pad per utility company requirements. Sheet ED1.3 1. Keyed Note 10; Add the following paragraph: “Existing grade mounted rooftop unit shall be relocated to the west side of the building to provide temporary heating and cooling during construction phase. Provide temporary power as required.” Sheet E2.5 2. Provide recessed junction boxes with dedicated circuits every two windows for future motorized window shades. Circuit to Panel L2. Refer to Supplemental Drawing SDE-3. 3. Revised Gymnasium Switch Panel Detail to include motorized shade control. Refer to Supplemental Drawing SDE-4. Sheet E4.1 1. Revise Middle School Gym Electrical One-Line Diagram to reflect the addition of a new utility company pad mounted transformer and revised service feeders. PLUMBING Sheet PD1.1 1. Removed existing water service and Key Note 5 from this sheet. Sheet PD1.3 1. Added the existing water service and Key Note 5 on this sheet. Sheet P1.2 1. Clarification on the new water connections and sewer connections. END OF ADDENDUM NO. 1 ADDENDUM NO. 1 PAGE - 5 ATTACHMENT A LETTER OF ASSENT All contractors and subcontractors of whatever tier (except those construction contractors who have directly signed the PLA) shall execute the following Letter of Assent prior to commencing work on the Project. Please forward this signed document to: Owner’s Representative: David Gill c/o Hancock Place School District Address: 9417 South Broadway, St. Louis, MO 63125 CM Phone / Fax: 314-974-8438 (phone) Also forward copy to: 314-631-3752 (fax) Mr. Jeffrey P. Aboussie, Asst Executive Secretary-Treasurer St. Louis Building and Construction Trades Council 2300 Hampton Ave. Suite B, St. Louis, Mo. 63139 RE: “Hancock Place Secondary Campus” Project Labor Agreement “PLA” The undersigned hereby agrees that it will be bound by and comply with all terms and conditions of said Project Labor Agreement applicable to subcontractors, including all amendments and attachments thereto. This Letter of Assent will remain in effect for the duration of the Project and shall thereupon automatically terminate. This Letter of Assent is subject to the Project Labor Agreement Attachment dated June 23, 2011 and amendments and attachments thereto. _____________________________________________ Name of Contractor or Subcontractor Date: ________________________________________ By: __________________________________________ Title: _____________________________________________ DL0010568 11 HANCOCK PLACE SCHOOL DISTRICT Copyright 2010 ARCOM 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. Procurement and Contracting Documents 08/10 DOCUMENT 007373 – STATUTORY REQUIREMENTS 1.1 FEDERAL WORK AUTHORIZATION PROGRAM A. The E Verify Program Addendum and Exhibit A – Program Affidavit for this Project are included in the Project Manual, bound following this Document. B. Contractor shall indicate compliance by executing and submitting the form Exhibit A. 1.2 EMPLOYEE SCREENING A. Before employment of any employee or retention of any independent contractor, subcontractor or supplier who is an individual for work on this Project, the Contractor shall conduct criminal background checks through the FBI, the St. Louis County Police Department (or the previous county of out-of-county residents) and all appropriate state agencies and any other background checks as may be standard for entities providing services to public schools, including without limitation, a thorough review of the list of registered sex offenders as provided by the St. Louis County Police Department, and any such individual who does not pass such background check as determined by the Owner in its sole discretion shall not be permitted to enter the premises where the Project is located or any other school district property or to work on the Project. In addition, the Contractor shall update its background check on a monthly basis to confirm its continued compliance with this requirement. Contractor shall include all of these requirements in its contracts with its subcontractors and suppliers. END OF DOCUMENT 007373 STATUTORY REQUIREMENTS 007373 - 1 HANCOCK PLACE SCHOOL DISTRICT 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. SECTION 105300 - ALUMINUM WALKWAY COVERS PART 1 - GENERAL 1.1 RELATED DOCUMENTS A. 1.2 Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 1 Specification Sections, apply to this Section. SUMMARY A. This Section includes the following: 1. 1.3 Design, fabrication and installation of complete welded, extruded aluminum walkway cover system. PERFORMANCE REQUIREMENTS A. Structural Performance: Provide aluminum walkway cover system capable of withstanding the effects of gravity loads and the following loads and stresses within limits and under conditions indicated: 1. Wind Loads: Determine loads based on the minimum design wind pressures indicated on Structural Drawings. B. Seismic Performance: Provide aluminum walkway cover system capable of withstanding the effects of earthquake motions determined according to IBC 2009 and ASCE 7-Current Edition, "Minimum Design Loads for Buildings and Other Structures": Section 9, "Earthquake Loads.". C. Thermal Movements: Provide aluminum walkway cover system that allows for thermal movements resulting from the following maximum change (range) in ambient and surface temperatures by preventing buckling, opening of joints, overstressing of components, failure of joint sealants, failure of connections, and other detrimental effects. Base engineering calculation on surface temperatures of materials due to both solar heat gain and nighttime-sky heat loss. 1. 1.4 Temperature Change (Range): 120 deg F, ambient; 180 deg F, material surfaces. SUBMITTALS A. Product Data: Include construction details, material descriptions, dimensions of individual components and profiles, and finishes for aluminum walkway cover system. B. Shop Drawings: For aluminum walkway cover system include plans, elevations, sections, details, and attachments to other Work. 1. Submit design calculations signed by a Registered Professional Engineer, licensed in the project state. Design calculations shall state that the protective cover system design complies with the wind requirements of ASCE 7-Current Edition, the stability criteria of applicable building code, and all other governing criteria. ALUMINUM WALKWAY COVERS 105300- 1 HANCOCK PLACE SCHOOL DISTRICT C. Include similar Samples of aluminum walkway cover system and accessories involving color selection. Samples for Verification: For each type of aluminum walkway cover system indicated. 1. Include aluminum walkway cover system samples to verify color selected. E. Welding certificates. F. Manufacturer Certificates: requirements. G. Qualification Data: For manufacturer. 1.5 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. Samples for Initial Selection: 1. D. 200801.04 Signed by manufacturers certifying that they comply with QUALITY ASSURANCE A. Manufacturer Qualifications: Protective Cover shall be wholly produced by a recognized manufacturer with at least five years experience in the design and fabrication of extruded aluminum walkway cover systems. Components shall be assembled in shop to greatest extent possible to minimize field assembly. Protective cover shall be installed by manufacturer. Third party installation is not acceptable. Protective cover system, including material and workmanship, shall be warranted from defects for a period of one year from substantial completion of installation B. Source Limitations: Obtain aluminum walkway cover system through one source from a single manufacturer. C. Product Options: Drawings indicate size, profiles, and dimensional requirements of aluminum walkway cover system and are based on the specific system indicated. Refer to Division 1 Section "Product Requirements." 1. D. 1.6 Do not modify intended aesthetic effects, as judged solely by Architect, except with Architect's approval. If modifications are proposed, submit comprehensive explanatory data to Architect for review. Welding: Qualify procedures and personnel according to AWS D1.2, "Structural Welding CodeAluminum" PROJECT CONDITIONS A. 1.7 Field Measurements: Verify by field measurements before fabrication and indicate measurements on Shop Drawings. WARRANTY A. Special Warranty: Manufacturer's standard form in which manufacturer agrees to repair or replace components of aluminum walkway cover system that fail in materials or workmanship within specified warranty period. Failures include, but are not limited to, the following: 1. 2. B. Structural failures. Deterioration of metals, metal finishes, and other materials beyond normal weathering. Warranty Period: One (1) years from date of Substantial Completion. ALUMINUM WALKWAY COVERS 105300- 2 HANCOCK PLACE SCHOOL DISTRICT 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. PART 2 - PRODUCTS 2.1 MANUFACTURERS A. Aluminum Walkway Covers: 1. 2.2 Basis-of-Design Product: Subject to compliance with requirements, provide Mapes Industries; Lumishade (wall-mounted) or comparable product by one of the following: a. Lawrence Fabric Structures. b. Peachtree. MATERIALS, GENERAL A. Aluminum Members: All sections shall be extruded aluminum 6063 alloy, heat treated to T-6 temper. B. Fasteners: Fasteners shall be aluminum, 18-8 stainless steel or 300 series stainless steel. C. Protective Coating: Aluminum columns embedded in concrete shall be protected by clear acrylic. D. Grout: Grout shall be 2000 p.s.i. compressive strength, 1 part Portland cement and 3 parts masonry sand. Add water to produce pouring consistency. E. Gaskets: Gaskets shall be dry seal santoprene pressure type. 2.3 COMPONENTS A. Beams shall be open-top tubular extrusion of size and shape shown on drawings, top edges thickened for strength and designed to receive deck members in self-flashing manner. Structural ties shall be installed in tops of all beams. B. Deck: Deck shall be extruded self-flashing sections interlocking into a composite unit. Closures at deck ends shall be welded plates. C. Fascia: Fascia shall be manufacturer’s standard shape. Size as indicated on drawings. D. Flashing: Flashing shall be .040 aluminum (min.). All thru-wall flashing by others. E. Downspouts: Downspouts shall be radius-cornered tubular extrusion. 2.4 FABRICATION A. Beam Construction: Beams shall be factory welded with neatly mitered corners. All welds shall be smooth and uniform using an inert gas shielded arc. Suitable edge preparation shall be performed to assure 100% penetration. Grind welds only where interfering with adjoining structure to allow for flush connection. Field welding is not permitted. Rigid mechanical joints shall be used when shipping limitations prohibit the shipment of fully welded bents. ALUMINUM WALKWAY COVERS 105300- 3 HANCOCK PLACE SCHOOL DISTRICT B. 2.5 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. Deck Construction: Deck shall be manufactured of extruded modules that interlock in a selfflashing manner. Interlocking joints shall be positively fastened at 8" O.C. creating a monolithic structural unit capable of developing the full strength of the sections. The fastenings must have minimum shear strength of 350 pounds each. Deck shall be assembled with sufficient camber to offset dead load deflection. Provide 300 series deck. ALUMINUM FINISHES A. General: Comply with NAAMM's "Metal Finishes Manual for Architectural and Metal Products" for recommendations for applying and designating finishes. B. Finish designations prefixed by AA comply with the system established by the Aluminum Association for designating aluminum finishes. C. High-Performance Organic Finish: AA-C12C42R1x (Chemical Finish: cleaned with inhibited chemicals; Chemical Finish: acid-chromate-fluoride-phosphate conversion coating; Organic Coating: as specified below). Prepare, pretreat, and apply coating to exposed metal surfaces to comply with coating and resin manufacturers' written instructions. 1. Fluoropolymer Three-Coat System: Manufacturer's standard three-coat, thermocured system consisting of specially formulated inhibitive primer, fluoropolymer color coat, and clear fluoropolymer topcoat, with both color coat and clear topcoat containing not less than 70 percent polyvinylidene fluoride resin by weight; complying with AAMA 605.2 a. Color and Gloss: Match Architect's Sample. PART 3 - EXECUTION 3.1 EXAMINATION A. Examine substrates areas and conditions for compliance with requirements for installation tolerances, and other conditions affecting performance of work. 1. 2. 3.2 For the record, prepare written report, endorsed by Installer, listing conditions detrimental to performance of work. Proceed with installation only after unsatisfactory conditions have been corrected. PREPARATION A. 3.3 Erection shall be performed after all concrete, masonry, and roofing work in the vicinity is complete and cleaned INSTALLATION A. 3.4 Erection: Protective cover shall be erected true to line, level and plumb. CLEANING AND PROTECTION A. All protective cover components shall be cleaned promptly after installation. Extreme care shall be taken to protect materials during and after installation. END OF SECTION 105300 ALUMINUM WALKWAY COVERS 105300- 4 HANCOCK PLACE SCHOOL DISTRICT 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. SECTION 144200 - WHEELCHAIR LIFTS PART 1 - GENERAL 1.1 RELATED DOCUMENTS A. 1.2 Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 01 Specification Sections, apply to this Section. SUMMARY A. Section Includes: 1. 2. B. Related Requirements: 1. 2. 1.3 Vertical platform lifts. Inclined platform lifts. Section 033000 "Cast-in-Place Concrete" for setting sleeves, inserts, and anchoring devices in concrete. Section 042000 "Unit Masonry" for setting sleeves, inserts, and anchoring devices in masonry. ACTION SUBMITTALS A. Product Data: For each type of product. B. Shop Drawings: For each lift. 1. 2. 3. 4. 1.4 Include plans, elevations, sections, details, attachments to other work, and required clearances. Indicate dimensions, weights, loads, and points of load to building structure. Include details of equipment assemblies, method of field assembly, components, and location and size of each field connection. Include diagrams for power, signal, and control wiring. CLOSEOUT SUBMITTALS A. Operation and Maintenance Data: For each type of lift to include in operation and maintenance manuals. 1. In addition to items specified in Section 017823 "Operation and Maintenance Data," include the following: a. b. B. Parts list with sources indicated. Recommended parts inventory list. Inspection and Acceptance Certificates and Operating Permits: having jurisdiction for normal, unrestricted use of lifts. WHEELCHAIR LIFTS As required by authorities 144200 - 1 HANCOCK PLACE SCHOOL DISTRICT 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. PART 2 - PRODUCTS 2.1 PERFORMANCE REQUIREMENTS A. Accessibility Requirements: Comply with applicable provisions in the U.S. Architectural & Transportation Barriers Compliance Board's ADA-ABA Accessibility Guidelines and ICC A117.1. B. Regulatory Requirements: Comply with ASME A18.1, "Safety Standard for Platform Lifts and Stairway Chairlifts." 2.2 VERTICAL PLATFORM LIFT A. Vertical Platform Lift, General: Preengineered lift system. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Garaventa LIft; Genesis OPAL model, or comparable product by one of the following: a. Giant Lift Equipment Mfg. Co., Inc. b. Inclinator Company of America. c. National Wheel-O-Vator Co., Inc. (The); a division of ThyssenKrupp Access. d. ThyssenKrupp Access. B. Platform Size: C. Rated Speed: 10 fpm. D. Power Supply: 120 V, 60 Hz, one phase, provide electrical disconnect pre-installed in accessible panel . E. Emergency Operation: Provide manual operation to raise or lower unit in case of malfunction or power loss. F. Self-Supporting Unit: Support vertical loads of unit only at base, with lateral support only at landing levels. G. Runway Enclosure: Manufacturer's standard enclosure assembly. H. Ramp: Retractable ramp matching platform to provide transition from lower floor to lift platform. Ramp lowers to floor automatically when lifts reach lower landing and door opens. Ramp rises automatically when lift control is activated for lift to leave lower landing. 2.3 36 x 48-7/8 inches. INCLINED PLATFORM LIFT A. Inclined Platform Lift, General: Preengineered lift system. 1. Basis-of-Design Product: Subject to compliance with requirements, provide Garaventa Lift; Genesis Xpress II model or comparable product by one of the following: a. b. Butler Dynamics, LLC. ThyssenKrupp Access. B. Platform Size: Nominal 30 by 48 inches. C. Power Supply: 240 V, 60 Hz, one phase. WHEELCHAIR LIFTS 144200 - 2 HANCOCK PLACE SCHOOL DISTRICT 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. D. Emergency Operation: Provide manual operation to raise or lower units in case of malfunction or power loss. E. Platform: flooring. F. Manual Folding Platforms: When not in use, platforms shall be capable of manually folding up against wall to minimize projection into stairway. G. Platform Guarding: Guard platform with passenger-restraining arms. 1. Steel sheet or galvanized-steel sheet with manufacturer's standard black rubber Passenger-Restraining Arms: Steel tubing, manually operated. H. Support to Structure: Provide framing and brackets to support vertical loads from floor or stair treads and only lateral loads from walls. Fabricate framing and brackets from steel rectangular tubing, plates, shapes, and bars. I. Guide Rails: Fabricate from steel tubing. 2.4 GENERAL FINISH REQUIREMENTS A. Protect mechanical finishes on exposed surfaces from damage by applying a strippable, temporary protective covering before shipping. B. Appearance of Finished Work: Noticeable variations in same piece are not acceptable. Variations in appearance of adjoining components are acceptable if they are within the range of approved Samples and are assembled or installed to minimize contrast. PART 3 - EXECUTION 3.1 EXAMINATION A. Examine substrates, areas, and conditions, with Installer present, for compliance with requirements for installation tolerances, critical dimensions, and other conditions affecting performance of the Work. B. Minimum Headroom Clearance: Verify that installed lift will have a minimum headroom of 80 inches above any point on platform floor at any point of travel. C. Prepare written report, endorsed by Installer, listing conditions detrimental to performance. D. Proceed with installation only after unsatisfactory conditions have been corrected. 3.2 INSTALLATION A. General: Comply with ASME A18.1 and manufacturer's written instructions for installation of lifts unless otherwise indicated. B. Wiring Method: Conceal conductors and cables within housings of units or building construction. Do not install conduit exposed to view in finished spaces. Bundle, lace, and train WHEELCHAIR LIFTS 144200 - 3 HANCOCK PLACE SCHOOL DISTRICT 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. conductors to terminal points with no excess and without exceeding manufacturer's limitations on bending radii. C. Coordinate runway doors with platform travel and positioning, for accurate alignment and minimum clearance between platforms, runway doors, sills, and door frames. D. Position sills accurately and fill space under sills solidly with nonshrink, nonmetallic grout. E. Coordinate platform doors with platform travel and positioning. F. Adjust stops for accurate stopping and leveling at each landing, within required tolerances. 1. Leveling Tolerance: 1/4 inch up or down, regardless of load and direction of travel. G. Adjust retractable ramps to meet maximum allowable slope and change-in-elevation requirements, and to lie fully against landing surfaces. H. Lubricate operating parts of lift, including drive mechanism, guide rails, hinges, safety devices, and hardware. I. Test safety devices and verify smoothness of required protective enclosures and other surfaces. 3.3 FIELD QUALITY CONTROL A. Acceptance Testing: On completion of lift installation and before permitting use of lifts, perform acceptance tests as required and recommended by ASME A18.1 and authorities having jurisdiction. B. Operating Test: In addition to acceptance testing, load lifts to rated capacity and operate continuously for 30 minutes between lowest and highest landings served. Readjust stops, signal equipment, and other devices for accurate stopping and operation of system. C. Advise Owner, Architect, and authorities having jurisdiction in advance of dates and times tests are to be performed on lifts. END OF SECTION 144200 WHEELCHAIR LIFTS 144200 - 4 HANCOCK PLACE SCHOOL DISTRICT 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. SECTION 323113 - CHAIN LINK FENCES AND GATES PART 1 - GENERAL 1.1 RELATED DOCUMENTS A. 1.2 Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 01 Specification Sections, apply to this Section. SUMMARY A. Section Includes: 1. 2. B. Related Sections: 1. 1.3 Chain-link fences. Gates: swing. Section 033000 "Cast-in-Place Concrete" for cast-in-place concrete post footings. PERFORMANCE REQUIREMENTS A. 1.4 Structural Performance: Chain-link fence and gate framework shall withstand the effects of gravity loads and the following loads and stresses within limits and under conditions indicated according to ASCE/SEI 7: 1. Minimum Post Size and Maximum Spacing: Determine according to CLFMI WLG 2445, based on mesh size and pattern specified and on the following: a. Fence Height: 6 feet. b. Material Group: IA, ASTM F 1043, Schedule 40 steel pipe. ACTION SUBMITTALS A. 1.5 Shop Drawings: Include plans, elevations, sections, details, and attachments to other work. Show accessories, hardware, gate operation, and operational clearances. PROJECT CONDITIONS A. Field Measurements: Verify layout information for chain-link fences and gates shown on Drawings in relation to property survey and existing structures. Verify dimensions by field measurements. CHAIN LINK FENCES AND GATES 323113 - 1 HANCOCK PLACE SCHOOL DISTRICT 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. PART 2 - PRODUCTS 2.1 CHAIN-LINK FENCE FABRIC A. General: Provide fabric in one-piece heights measured between top and bottom of outer edge of selvage knuckle or twist. Comply with CLFMI Product Manual and with requirements indicated below: 1. 2. Fabric Height: 72 inches. Steel Wire Fabric:. a. b. 3. 2.2 Mesh Size: 2 inches. Zinc-Coated Fabric: ASTM A 392, Type II, with zinc coating applied after weaving. Selvage: Twisted top and knuckled bottom. FENCE FRAMING A. Posts and Rails: Comply with ASTM F 1043 for framing, including rails, braces, and line; terminal; and corner posts. Provide members with minimum dimensions and wall thickness according to ASTM F 1043 based on the following: 1. Fence Height: 72 inches. 2. Horizontal Framework Members: Top and bottom rails complying with ASTM F 1043. 3. 4. Brace Rails: Comply with ASTM F 1043. Metallic Coating for Steel Framing: a. b. c. d. e. 2.3 Type A, consisting of not less than minimum 2.0-oz./sq. ft. average zinc coating per ASTM A 123/A 123M or 4.0-oz./sq. ft. zinc coating per ASTM A 653/A 653M. Type B, zinc with organic overcoat, consisting of a minimum of 0.9 oz./sq. ft. of zinc after welding, a chromate conversion coating, and a clear, verifiable polymer film. External, Type B, zinc with organic overcoat, consisting of a minimum of 0.9 oz./sq. ft. of zinc after welding, a chromate conversion coating, and a clear, verifiable polymer film. Internal, Type D, consisting of 81 percent, not less than 0.3-mil- thick, zinc-pigmented coating. Type C, Zn-5-Al-MM alloy, consisting of not less than 1.8-oz./sq. ft. coating. Coatings: Any coating above. SWING GATES A. General: Comply with ASTM F 900 for gate posts and single swing gate types. 1. 2. B. Gate Leaf Width: As indicated. Gate Fabric Height: 72 inches or less. Pipe and Tubing: 1. Zinc-Coated Steel: Comply with ASTM F 1043 and ASTM F 1083; protective coating and finish to match fence framing. CHAIN LINK FENCES AND GATES 323113 - 2 HANCOCK PLACE SCHOOL DISTRICT 2. 3. 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. Gate Posts: Round tubular steel. Gate Frames and Bracing: Round tubular steel. C. Frame Corner Construction: Welded or assembled with corner fittings. D. Hardware: 1. 2. 2.4 Hinges: 360-degree inward and outward swing. Latches permitting operation from both sides of gate with provision for padlocking accessible from both sides of gate. FITTINGS A. General: Comply with ASTM F 626. B. Post Caps: Provide for each post. 1. Provide line post caps with loop to receive tension wire or top rail. C. Rail and Brace Ends: For each gate, corner, pull, and end post. D. Rail Fittings: Provide the following: 1. 2. Top Rail Sleeves: Pressed-steel or round-steel tubing not less than 6 inches long. Rail Clamps: Line and corner boulevard clamps for connecting bottom rails in the fence line-to-line posts. E. Tension and Brace Bands: Pressed steel. F. Tension Bars: Steel, length not less than 2 inches shorter than full height of chain-link fabric. Provide one bar for each gate and end post, and two for each corner and pull post, unless fabric is integrally woven into post. G. Truss Rod Assemblies: Steel, hot-dip galvanized after threading rod and turnbuckle or other means of adjustment. H. Tie Wires, Clips, and Fasteners: According to ASTM F 626. 1. Standard Round Wire Ties: For attaching chain-link fabric to posts, rails, and frames, complying with the following: a. I. Hot-Dip Galvanized Steel: Galvanized coating thickness matching coating thickness of chain-link fence fabric. Finish: 1. Metallic Coating for Pressed Steel or Cast Iron: Not less than 1.2 oz. /sq. ft. zinc. CHAIN LINK FENCES AND GATES 323113 - 3 HANCOCK PLACE SCHOOL DISTRICT 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. PART 3 - EXECUTION 3.1 EXAMINATION A. Examine areas and conditions, with Installer present, for compliance with requirements for site clearing, earthwork, pavement work, and other conditions affecting performance of the Work. 1. B. 3.2 Do not begin installation before final grading is completed unless otherwise permitted by Architect. Proceed with installation only after unsatisfactory conditions have been corrected. PREPARATION A. 3.3 Stake locations of fence lines, gates, and terminal posts. Do not exceed intervals of 500 feet or line of sight between stakes. Indicate locations of utilities, lawn sprinkler system, underground structures, benchmarks, and property monuments. INSTALLATION, GENERAL A. Install chain-link fencing to comply with ASTM F 567 and more stringent requirements indicated. 1. 3.4 Install fencing on established boundary lines inside property line. CHAIN-LINK FENCE INSTALLATION A. Post Excavation: Drill or hand-excavate holes for posts to diameters and spacings indicated, in firm, undisturbed soil. B. Post Setting: Set posts in concrete at indicated spacing into firm, undisturbed soil. 1. 2. Verify that posts are set plumb, aligned, and at correct height and spacing, and hold in position during setting with concrete or mechanical devices. Concrete Fill: Place concrete around posts to dimensions indicated and vibrate or tamp for consolidation. Protect aboveground portion of posts from concrete splatter. a. Exposed Concrete: Extend 2 inches above grade; shape and smooth to shed water. C. Terminal Posts: Locate terminal end, corner, and gate posts per ASTM F 567 and terminal pull posts at changes in horizontal or vertical alignment of 30 degrees or more. D. Line Posts: Space line posts uniformly at 96 inches o.c. E. Post Bracing and Intermediate Rails: Install according to ASTM F 567, maintaining plumb position and alignment of fencing. Diagonally brace terminal posts to adjacent line posts with truss rods and turnbuckles. Install braces at end and gate posts and at both sides of corner and pull posts. F. Top Rail: Install according to ASTM F 567, maintaining plumb position and alignment of fencing. Run rail continuously through line post caps, bending to radius for curved runs and CHAIN LINK FENCES AND GATES 323113 - 4 HANCOCK PLACE SCHOOL DISTRICT 200801.04 HS/MS CAMPUS – MS GYM ADDITION AND DOME BLDG. ADDITION & RENOV. terminating into rail end attached to posts or post caps fabricated to receive rail at terminal posts. Provide expansion couplings as recommended in writing by fencing manufacturer. G. Intermediate and Bottom Rails: Install and secure to posts with fittings. H. Chain-Link Fabric: Apply fabric to outside of enclosing framework. Leave 1 inch between finish grade or surface and bottom selvage unless otherwise indicated. Pull fabric taut and tie to posts, rails, and tension wires. Anchor to framework so fabric remains under tension after pulling force is released. I. Tension or Stretcher Bars: Thread through fabric and secure to end, corner, pull, and gate posts with tension bands spaced not more than 15 inches o.c. J. Tie Wires: Use wire of proper length to firmly secure fabric to line posts and rails. Attach wire at one end to chain-link fabric, wrap wire around post a minimum of 180 degrees, and attach other end to chain-link fabric per ASTM F 626. Bend ends of wire to minimize hazard to individuals and clothing. 1. K. 3.5 Maximum Spacing: Tie fabric to line posts at 12 inches o.c. and to braces at 24 inches o.c. Fasteners: Install nuts for tension bands and carriage bolts on the side of the fence opposite the fabric side. Peen ends of bolts or score threads to prevent removal of nuts. GATE INSTALLATION A. 3.6 Install gates according to manufacturer's written instructions, level, plumb, and secure for full opening without interference. Attach fabric as for fencing. Attach hardware using tamperresistant or concealed means. Install ground-set items in concrete for anchorage. Adjust hardware for smooth operation and lubricate where necessary. ADJUSTING A. Gates: Adjust gates to operate smoothly, easily, and quietly, free of binding, warp, excessive deflection, distortion, nonalignment, misplacement, disruption, or malfunction, throughout entire operational range. Confirm that latches and locks engage accurately and securely without forcing or binding. B. Lubricate hardware, gate operator, and other moving parts. END OF SECTION 323113 CHAIN LINK FENCES AND GATES 323113 - 5 REF Addendum No. 611 N. Tenth Street Suite 200 Saint Louis, Missouri 63101 Tele: (314) 421-3542 Fax: (314) 421-4821 WBI 200801.06 Hancock Place School District High School & Middle School Additions and Renovations PD1.1 1 Description of Change: Removed exsting water service piping DATE: 09/05/12 SHEET NO. SDP-1 REF Addendum No. 611 N. Tenth Street Suite 200 Saint Louis, Missouri 63101 Tele: (314) 421-3542 Fax: (314) 421-4821 WBI 200801.06 Hancock Place School District High School & Middle School Additions and Renovations PD1.3 1 Description of Change: Added existing water service line DATE: 09/05/12 SHEET NO. SDP-2 REF Addendum No. 611 N. Tenth Street Suite 200 Saint Louis, Missouri 63101 Tele: (314) 421-3542 Fax: (314) 421-4821 WBI 200801.06 Hancock Place School District High School & Middle School Additions and Renovations P1.2 1 Description of Change: Clarification of new water connections DATE: 09/05/12 SHEET NO. SDP-3 REF WBI 200801.06 Hancock Place School District High School & Middle School Additions and Renovations E0.1 Addendum No. 1 Description of Change: Middle School Gym Electrical Service DATE: 09/04/12 SHEET NO. SDE-1 REF WBI 200801.06 Hancock Place School District High School & Middle School Additions and Renovations E4.1 Addendum No. 1 Description of Change: Middle School Gym Electrical Service DATE: 09/04/12 SHEET NO. SDE-2 REF WBI 200801.06 Hancock Place School District High School & Middle School Additions and Renovations E2.5 Addendum No. 1 Description of Change: Middle School Gym Window Shade Power DATE: 09/10/12 SHEET NO. SDE-3 REF WBI 200801.06 Hancock Place School District High School & Middle School Additions and Renovations E2.5 Addendum No. 1 Description of Change: Middle School Gym Window Shade Control DATE: 09/10/12 SHEET NO. SDE-4 AMENDMENTS TO CIVIL PLANS REF Addendum No. 611 N. Tenth Street Suite 200 Saint Louis, Missouri 63101 Tele: (314) 421-3542 Fax: (314) 421-4821 WBI 200801.06 Hancock Place School District High School & Middle School Additions and Renovations C1,C8,C9 1 Description of Change: Amend notes as indicated on the civil plans. DATE: 09/12/12 SHEET NO. SDC-1 Site #234 #240 LOCATION MAP REF Addendum No. 611 N. Tenth Street Suite 200 Saint Louis, Missouri 63101 Tele: (314) 421-3542 Fax: (314) 421-4821 WBI 200801.06 Hancock Place School District High School & Middle School Additions and Renovations C1 Description of Change: Amend location map. 1 DATE: 09/12/12 SHEET NO. SDC-2