A novel test rig for in situ and real time optical measurement of the

advertisement

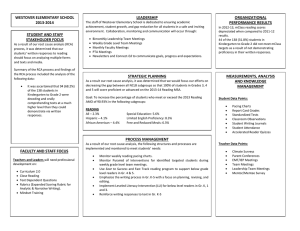

55 Tribology Letters, Vol. 23, No. 1, July 2006 (Ó 2006) DOI: 10.1007/s11249-006-9113-9 A novel test rig for in situ and real time optical measurement of the contact area evolution during pre-sliding of a spherical contact A. Ovcharenkoa, G. Halperina, I. Etsiona,* and M. Varenbergb b a Mechanical Engineering Department, Technion, Haifa 32000, Israel Max Planck Institute for Metals Research, Heisenbergstr. 3, Stuttgart 70569, Germany Received 31 May 2006; accepted 18 July 2006; published online 22 August 2006 An experimental test rig was developed in order to investigate elastic–plastic single micro-spherical contact under combined normal and tangential loading. This novel apparatus allows in situ and real time direct optical measurement of the real contact area (RCA) evolution in pre-sliding. It also allows relative displacement measurements under very low rates of tangential loading (down to 0.01 N/s) to capture accurately the fine details at sliding inception. This is achieved by piezoelectric actuation in closed loop feedback control in addition to synchronization with data and image acquisition to obtain real time measurement. The RCA measurement is realized by direct optical observation technique, whereas two different image processing algorithms were implemented for the elastic and the elastic–plastic contact regimes. The various features and capabilities of the test rig are presented along with some preliminary experimental results of RCA and friction behavior to assess its performance. KEY WORDS: spherical contact, elastic–plastic contact, real contact area, in situ real time measurement, image processing 1. Introduction Contacting surfaces are rough on micro-scale and consist of micro-asperities that, under normal load, form contact junctions at their summits. The elastic– plastic deformation behavior of such contacting micro-asperities plays an important role in several contact mechanics problems such as friction, adhesion, wear, electrical and thermal contact conductance to name a few. A key parameter in all theses problems is the real contact area (RCA). An accurate knowledge of the RCA and its evolution under varying normal and tangential loading is important for studies involving many tribology and contact mechanics issues [1]. Two review papers [2,3] that were published in 1980 and 1985, respectively, describe various experimental techniques to measure contact area, which include both indirect and direct methods. Of all the various techniques mentioned in Refs. [2] and [3] the most practical ones are: the electrical contact resistance, optical, and ultrasonic techniques. All these three techniques are considered in situ measurements of the RCA but only the optical and ultrasonic methods are direct ones. The measurement of electrical contact resistance can be used indirectly [4] for estimation of contact area evolution under combined normal and tangential loading of contacting surfaces. However, this method requires perfectly clean noble metals, because oxide and con*To whom correspondence should be addressed. E-mail: etsion@tx.technion.ac.il taminant layers can distort significantly the calculated contact area. The widely used ultrasonic technique is based on measuring the ultrasonic wave reflection coefficient from the interface of two contacting surfaces [5–6]. Ultrasonic waves are reflected from solid/air boundaries but pass through solid contacts. Hence, this difference can be used to distinguish air gaps from RCA in rough surfaces contact. The main advantage of this method is the fact that it is not limited to conducting or transparent surfaces as in the case of electrical resistance or optical methods. However, the lateral resolution of the acoustic reflection measurement with conventional transducers and equipment is relatively low (about 0.2 mm) [7]. This poor resolution can be improved by deconvolution signal processing techniques but this adds complexity to the measurement. In addition, this technique requires a coupling medium, like water, between the acoustic transducer and specimen, which further complicates the measurement. Moreover, the RCA is obtained by time consuming scanning of the contact zone with the ultrasonic probe. Therefore, this technique is suitable for static loading only and does not permit real time dynamic measurements. The optical observation technique is a prevalent method for RCA estimation. It requires that one of the surfaces will be transparent to light but contrary to the ultrasonic technique the integration of optics in an experimental setup is quite simple. The optical method can be used discretely or in real time, according to the optical apparatus. 1023-8883/06/0700–0055/0Ó 2006 Springer Science+Business Media, Inc. 56 A. Ovcharenko et al./Real time optical measurement Perhaps the first publication on discrete optical measurement of single spherical contact is from 1950 by Parker and Hatch [8]. The contact area images at various normal loads were still photographed on film through a microscope at regular discrete increments of tangential loading until gross sliding begun. The tangential load was applied through a string, which pulled a glass flat by means of suspended beaker that was gradually filled with water. No image processing technique was used and hence, only the apparent area of the contact could be estimated from the still photographs. Two more publications [9,10] from 1981 and 1984, respectively, describe optical measurements of RCA by still photography under normal load only. In Ref. [9] the spherical contact was limited to elastic deformation whereas in Ref. [10] the deformation was purely plastic. Reference [11] describes a pin on disc apparatus that was used to study the contact area between polymer layers and glass hemispheres during sliding. As in the previous cases, the contact images were still photographed through a microscope. An experimental setup for the RCA evolution in presliding regime of spherical and conical contacts of metals and polymers is described in [12]. The experimental system is similar to that employed in [8]. The contact images were still photographed throughout a microscope and analyzed graphically taking into consideration non-contact areas within the contact zone. Since the tangential load was applied discretely and not continuously, it was not possible to obtain contact images in real time and to identify properly the instant of sliding inception. Laser profilometry [13] is yet another optical method for RCA measurement that, similar to the acoustic method, consumes relative long time due to the required scanning of the contact zone. Real time optical observation of RCA in sliding regime using CCD camera for digital acquisition of contact images is described in Ref. [14]. A fixed rough surface of metallic specimen was loaded against a moving glass flat. The glass flat was pulled by a servomotor at pre-selected relatively large velocities (above 10 mm/s). Image processing tools were employed to estimate the RCA evolution during the sliding. Another real time investigation of initiation, propagation and distribution of micro-slip at the contact interface of rubber spherical specimen against glass flat is described in [15]. The CCD acquired images were analyzed using correlation method of image processing technique, in order to identify microslip in the contact interface during pre-sliding. The tangential force was gradually increased by pouring water into a container (see also [8]) until gross sliding begun. A very recent publication [16] describes real time optical observation of contact area evolution under normal loading only. The normal load was increased continuously by a loading system that was synchronized with a CCD camera. Image processing was used to obtain the RCA. As can be seen from the above, no published literature exists so far on in situ and real time direct measurement of RCA evolution during pre-sliding. Consequently, the main goal of the present work is to fill this gap by developing an apparatus which will allow such direct optical measurements. The novel apparatus should also allow simultaneous measurements of RCA and friction force, during continuous and smooth application of tangential loading at pre-selected desired low rates. It should also allow RCA measurements in both elastic and elastic–plastic contact regimes by means of appropriate image processing techniques. 2. Description of the test rig In general the test rig allows studying the evolution of RCA between a rigid flat and a deformable sphere under combined normal and tangential loading in both elastic and elastic–plastic contact modes. It was designed to fulfill the goals mentioned in the introduction, i.e.: Variable normal loads to achieve pure elastic or elastic–plastic contact mode. Smooth and continuous application of tangential load at low rates to accurately detect fine details during pre-sliding and sliding inception. Synchronization of data and video acquisition with piezoelectric actuation to allow real time measurement of normal and friction force, RCA, relative displacement, and instant of sliding inception. The test rig consists of four main modules that are shown in figure 1: An actuation module that holds a transparent rigid flat and applies the tangential load to the spherical contact. A tangential force module (5), which holds a sphere and measures the tangential friction force applied to it by the flat. A normal force Optical module 7 Direction of actuation 5 6 1 2 F 3 P 4 Thin plate s Figure 1. Schematic representation of the experimental setup with 4 modules: (I) Actuation module consisting of: parallelogram frame (1), mechanical lever (2), piezoelectric actuator (3), and proximity probe (4). (II) Friction force measurement module (5). (III) Normal force module (6). (IV) Optical module (7). 57 A. Ovcharenko et al./Real time optical measurement module (6), which applies and measures the normal loading of the contact, and an optical module (7) for accurate measurement of the contact area evolution. The actuation module consists of four main components: a frame (1), a mechanical lever (2), a piezoelectric actuator (3), a proximity probe (4), and a motion control board (National Instruments PCI-7352, USA). The frame, in the form of a parallelogram, includes a rigid upper member that holds the rigid sapphire flat, and is supported on two vertical thin plates (see figure 1). This parallelogram frame ensures horizontal motion of the rigid flat with respect to the sphere as indicated by the ‘‘direction’’ arrow shown in the figure. Moreover, such frame excludes any undesired vertical micro-vibrations that can exist in experimental setups that are based on linear bearings support. The horizontal actuation is obtained by means of a mechanical lever (see figure 1) that is pushed by a piezoelectric actuator (Piezomechanik PSt 150/7/100 VS12 VbS, Germany). The maximum possible displacement of the actuator is only about 130 lm, however, the mechanical lever provides a gain of four times which is sufficient to compensate for various clearances in the system and ensure sliding inception. The piezoactuator is controlled through a closed PID feedback loop to provide a desired displacement of the rigid sapphire flat at a pre-selected constant velocity in spite of the lump non-linear stiffness, c, of the system and the contact. It was found that during pre-sliding the rate Q_ of the tangential force behaves according to the _ relation Q½N=s ¼ c V½lm=s, where V is the pre-selected velocity (in the range 0.05–220 lm/s), and c = 0.184[N/lm]. Hence, Q_ could be varied between 0.01 and 40 N/s. A proximity probe (4) (SKF CMSS60, USA), with 0.1 lm resolution, was mounted on the sapphire holder while its target was fixed to the lever holding the sphere (see picture in figure 2) in order to obtain the exact relative displacement between the sphere specimen and the sapphire flat. It should be noted that during horizontal displacement of the parallelogram frame the upper member with the sapphire flat moves down a few micrometers. This vertical displacement is accommodated by the normal loading module, which allows free vertical displacement of the sphere while maintaining a constant normal force. Figure 2 shows a picture and a corresponding scheme of the friction force measurement module. It consists of a lever, piezoelectric friction force sensor, and a holder with a sphere specimen. Because of the required low rate of the tangential loading a sensitive piezoelectric friction force sensor (Kistler 9215, Switzerland) was used. It provides quasistatic measurement of the friction force without any built-in pre-amplifier and hence, has negligible drift of the measured signal in time. This friction force sensor can operate in two distinct ranges of tangential loads: 0–20 N and 0–200 N with resolutions of 10 and 50 mN, respectively. The friction force sensor was aligned with the contact interface plane (see the dashed line in the scheme of figure 2) in order to eliminate any possible bending moment due to the friction force. This arrangement ensures very accurate measurement of the true friction force. The normal force loading module, shown in figure 3, consists of a double-arm loading lever, a load cell and an eccentric loading mechanism. The load cell (Entran ELFS-3M-250N, France) was used for measurement of the normal load with a resolution of 0.2 N. Dead weights can be put on either guide (a), (b) or both for any desired normal load up to 250 N, which can cause plastic deformation of the sphere contact zone. The eccentric loading mechanism allows smooth manually controlled application and release of the normal force. a b Ball joint Load cell Counterweight Ball joint Friction force sensor Contact interface line Guides Dead weight Target of proximity probe Normal load, P Sapphire a Tangential load, Q F Lever Sphere specimen Holder Normal load, P Figure 2. Picture and scheme of the friction force measurement module. Lever b Eccentric mechanism Figure 3. Picture and scheme of the normal loading module. 58 A. Ovcharenko et al./Real time optical measurement The last module, shown in figure 4, is the optical module which allows in situ observation of the contact zone through a small circular window in the upper part of the frame. The optical module includes: a microscope (Navitar Zoom 6000, USA) with changeable zoom and a built-in beam splitter (BS), color CCD camera (Pulnix TMC-6i, USA), illumination source, and an image acquisition board (National Instruments PCI-1411, USA). The stand of the optical system allows preliminary rough focusing, whereas the optical microscope permits the final fine focusing onto the plane of contact in order to obtain sharp images. Since each sphere specimen replacement may deviate from the previous position of the contact zone, an accurate horizontal adjusting mechanism of drive screws was used to ensure that the contact area will always be located at the CCD field of view. The zoom of the optical system was then adjusted for best lateral resolution (from 1.2 to 3.6 lm corresponding to magnification range of 45 to 7, respectively) of the contact area image (maximum possible CCD pixels) according to the contact size at different normal loads. Further slight improvement of the image contrast (especially in the elastic regime of deformations) is obtained by application of polarized light. The assembly of all four modules is presented in figure 5. It can be seen that the normal loading module is perpendicular to the friction force measurement module in order to provide optimal modules arrangement and proper functioning. It is important to note that these two modulus are also autonomous so that normal and tangential force measurements are decoupled and do not affect each other. 3. Signal and image processing A data acquisition board (National Instruments PCI6221, USA) was used to acquire the measured signals (forces and displacement) from the various sensors. A CCD camera Microscope Illumination BS Tangential load, Q Normal load, P Microscope Illumination Figure 4. Picture and scheme of the optical module. Figure 5. Picture of the test rig assembly: Parallelogram frame (1), Mechanical lever (2), Piezoelectric actuator (3), Proximity probe (4), Friction force measurement module (5), Normal loading module (6), Optical module (7). low pass filter was used to remove high frequency noise in the above time domain signals. Signal and image processing along with full control of the test rig was realized on Labview 7.0 software. During the application of combined normal and tangential loading, contact area images were acquired at a constant video rate of up to 25 fps for short experiments (a few seconds corresponding to high Q_ values), or at a lower rate down to 0.1 fps for longer experiments (tens of minutes corresponding to low Q_ values). Then all images were saved to a computer memory for further analysis by image processing tools. A data file of time dependent normal load, friction force, relative displacement and RCA was created for each experiment for further analysis. Two image processing algorithms were used to estimate the RCA from the contact area images. The first method, suitable for mostly elastic contact, is based on analyzing interferometric patterns of Newton’s rings formed due to reflected light from the air gap between the sapphire flat and the lightly deformed sphere. The central dark spot of the Newton’s rings pattern (see figure 6a) represents the RCA since a destructive interference occurs at the points of contact [9,11]. Monochromatic and polarized light was used to enhance the sharpness and contrast of the interferometric images. The procedure of the RCA estimation consists of a few stages. First, the centroid [17] of the light intensity distribution of the Newton’s rings is determined (see figure 6b1). Then, two concentric circles are arbitrarily drawn with respect to the centroid such that one is smaller and the other is larger than the estimated RCA border. These two circles contain between them the region of interest where the sought border of RCA is located. Radial searching lines, originating from the centroid, are used to obtain the radial intensity distribution between the above two concentric 59 A. Ovcharenko et al./Real time optical measurement RCA (a) (c) (b) Original image Circular edge detection function RCA estimation Detected boundary points of RCA and doted circular white line of their mean radius Region of interest is between these two concentric circles Centroid (b1) Zoom of the image in (b) Figure 6. Image processing algorithm for real contact area (RCA) estimation from Newton’s rings pattern in elastically loaded sphere. circles. The points of the RCA boundary are determined when the intensity increases sharply and exceeds a preselected threshold level. These boundary points of the RCA are then fitted by a circle (using circular edge detection function [17]) whose radius represents the RCA mean radius (figure 6c). In the case of moderate and high normal loads, a relatively sharp edge is formed at the circumference of the contact area due to plastic deformations. Incident light outside the contact area reflects mostly in a wide angle and, thus, a very small amount of this light returns into the optical module (see figure 7a). As a result, there is a high contrast between the reflections form inside and outside the contact area as can be seen in figure 7b. For this case a quite simple image processing algorithm is used for RCA estimation by setting a proper threshold level [17] for image intensity distribution. Consequently, the pixels of the original contact area images are binarized (assigned 0 or 1) according to their intensity level with respect to the threshold and the total number of pixels of RCA (assigned 1) is calculated. Then, by using calibration coefficients for different optical magnifications, the total number of RCA pixels is converted to RCA in squared millimeters. An example of two different copper spheres in contact with the sapphire flat is presented in figure 8. A 5 mm mirror polished sphere and a 2.38 mm rough sphere are shown in figures 8a, b, respectively. It can be seen from figure 8b1 that the above image processing algorithm filters out non contact spots, and provides an accurate RCA. 4. Preliminary experimental results To assess the performance of the developed test rig, some preliminary experiments were carried out. All experiments were done in a configuration of a deformable sphere loaded against a rigid flat. The sphere specimens were made of bearing steel (AISI 52100) or copper (UNS C10200) and the rigid flat was of sapphire. The self measured (or reported in the literature) mechanical and geometrical properties of the sphere specimens and the sapphire flat, along with the critical normal load, Pc, at plastic yield inception of the spheres [18], are summarized in table 1. All the experiments were carried out at room temperature of 19–23 °C and relative humidity of 40–60%. Each experiment was performed on a new area of contact and both the sphere and sapphire surfaces were (b) Light beams do not enter the optical module (a) Optical module Sapphire Sphere Normal load, P Figure 7. The scheme of image formation of the contact area for elastic–plastic loaded sphere. 60 A. Ovcharenko et al./Real time optical measurement 100µm (a) (a1) Threshold application 70µm (b) (b1) Original images Binarized images Figure 8. Contact area original images of smooth (a) and rough (b) surfaces before, and corresponding binarized images (a1) and (b1) after threshold application for real contact area (RCA) estimation. Table 1. The mechanical and geometrical properties of bearing steel and copper spherical specimens, and sapphire flat. No 1 2 3 Material Bearing steel Copper Sapphire D (mm) 4.5 5, 10 Flat H (Gpa) Y (Gpa) 9.47 1.15 19* * 2 0.35 2.95* E (Gpa) m * 0.30 0.33* 0.27* * 205 139 435* Ra (nm) 200 100 5 Pc (N) 184 0.7, 2.9 – D – diameter, H – hardness, Y – yield strength, m – Poisson’s ratio, E – Young’s modulus, Ra – roughness average, Pc – critical normal load at plastic yield inception [18].*Values obtained from the literature. cleaned in acetone before each loading. The normal load was applied for 30 s before the measurements were taken. At least three repetitions of each experiment were made and data repeatability was better than 90%. Figure 9 shows a comparison between the measured contact area, A, and the Hertz analytical solution [19] for different normal loads, P, in the elastic regime of deformation (P<Pc, see Table 1). The experiment was carried out with a bearing steel ball of 4.5 mm. The slight deviation (less than 5%) of the measured RCA from the Hertz analytical solution, especially at low loads, is probably due to the accuracy of fitting boundary points by a circle, according to the image processing algorithm for analyzing Newton’s rings (see Section 3). Figure 10 shows a similar comparison between the measured RCA and the results from a numerical model by Kogut and Etsion [18] for different normal loads, P, in the elastic–plastic regime of deformation (P>Pc). For this case the experiment was carried out with a 5 mm diameter copper sphere. The model in [18] provides simple dimensionless expressions for the elastic–plastic RCA vs. applied normal load at a Poisson’s ratio of 0.3. It can be seen that the experimental results correlate quite well (less than 5% deviation) with the model results. Figure 11 shows the possible effect of dwell time (time under steady load) on RCA. The test was done with a 10 mm copper sphere under a relatively large normal load of 160 N, deep into the elastic–plastic regime of deformation. The measured RCA is normalized by A0, corresponding to the RCA at a dwell time of 40 s. As can be seen from the figure, the normalized RCA increases by no more than 1.2% even for a relatively long dwell time of 300 s (note that the resolution of the RCA measurement is better than 0.1%). It is interesting to note the linear relation between RCA and the logarithm of the dwell time as represented by the dashed line which fits well (R2 = 0.997) the normalized RCA results. Therefore, it can be safe to assume that contact creep has negligible effect on the RCA measurements even at long period of time corresponding to the lowest Q_ value. Figure 12 shows the effect of tangential loading on the RCA, relative displacement and friction evolution in time. In this experiment a steady normal load of 135 N 61 A. Ovcharenko et al./Real time optical measurement 2 Real Contact Area, A [mm ] 0.06 0.05 0.04 0.03 0.02 0.01 0.00 0 50 100 150 200 Normal Load, P [N] Figure 9. Real contact area (RCA) experimental results (circles) in comparison with the Hertz analytical solution (line) for an elastic contact of a 4.5 mm bearing steel ball (Pc = 184 N). 2 Real Contact Area, A [mm ] 0.20 0.16 0.12 0.08 0.04 0.00 0 50 100 150 200 Normal Load, P [N] Figure 10. Real contact area (RCA) experimental results (triangles) in comparison with the KE model [18] (line) for an elastic–plastic contact of a 5 mm copper sphere (Pc = 0.7 N). 1.012 Normalized RCA, A/A0 1.010 1.008 1.006 1.004 1.002 1.000 10 100 1000 Dwell Time [sec] Figure 11. Normalized real contact area (RCA) as a function of dwell time for 10 mm copper sphere (P = 160 N, Pc = 2.9 N). was first applied to a 5 mm copper sphere in order to cause plastic deformation of the contact zone. Then, a tangential load, Q, was applied gradually at a constant rate of Q_ = 2.25 N/s until sliding incepted between the sphere and the flat. A monotonic, non linear, increase in RCA of about 40% is observed in figure 12 as the friction force, F, increases linearly from zero to its maximum value (static friction) at the instant of sliding inception. The sliding inception, that occurred about 17.5 s after activation of the piezoelectric actuator, can be easily identified in the figure by the simultaneous maximum in the friction force and sharp transition in the slopes of both the RCA and relative displacement. Figure 13 presents images of the RCA corresponding to 62 0.23 40 0.22 35 30 0.21 25 0.20 Friction Force Relative Displacement RCA 20 0.19 15 0.18 10 0.17 5 0.16 Friction Force, F [N] Relative Displacement [ µm] 2 Real Contact Area, A [mm ] A. Ovcharenko et al./Real time optical measurement 0 0 5 10 15 20 25 30 Time, T [sec] Figure 12. The time evolution of friction and real contact area (RCA) for a 5 mm copper sphere (Pc = 0.7 N) under combined normal and tangential loading (P=135 N, Q_ = 2.25 N/s). F = 0 (normal load only) and sliding inception, as obtained in the experiment of figure 12. The arrow in figure 13b indicates the direction of friction on the sphere. The effect of the tangential loading on the size and shape of the RCA is clearly observed by comparing the two images in the figure. Figure 13c shows a superposition of the two images to facilitate the visualization of the RCA non-axisymmetric growth evolution. The results are very different from these presented in Ref. [20] where RCA of a copper spherical specimen was measured after the loads (normal and tangential) were removed and the residual contact trace on the sphere was examined with a remote optical microscope. It was concluded in [20] from the residual diameter of the contact area that RCA (a) (b) 100µm (c) Contact area at instant of sliding (b) is essentially unaffected by the tangential loading. This is clearly in contrast to our present more accurate in situ and real time observations that show ‘‘junction growth’’. The concept of ‘‘junction growth’’, which was introduced in 1959 by Tabor [21], was explained by the need to maintain a constant von Mises stress at yielded contact points. According to this requirement a contact area, which has already yielded plastically under a given normal load, must grow when subjected to additional tangential loading, in order to reduce its mean contact pressure and be able to accommodate the additional shear stresses. Finally, experiments that were performed over a wide range of tangential loading rates (0.03–37 N/s) showed 100µm Original contact area under normal load alone (a) Fig. 13. The contact area images obtained from the experiment in figure 12 under: (a) normal load alone, (b) at the instant of sliding inception (the direction of rigid flat motion is indicated by the arrow), and (c) their superposition to demonstrate the real contact area (RCA) growth evolution. A. Ovcharenko et al./Real time optical measurement basically very similar results to these presented in figure 12. Hence, it can be safely assumed that the fine details of RCA and friction evolution during pre-sliding are well captured with the current rate of tangential loading. 5. Conclusion A novel test rig, which allows accurate, real time and in situ direct RCA measurement, which is synchronized with motion and data acquisition, was described. A closed loop feedback motion control of a piezoelectric actuator allows accurate smooth and continuous application of tangential loading, differently from other existing setups that employ similar direct optical observation techniques. It was found that tangential loading at relatively low rate of 2.25 N/s is sufficient to accurately capture the fine details of RCA and friction evolution in pre-sliding and at sliding inception. The preliminary results showed good resolution (better than 0.1%) of RCA measurement with the test rig, using intensity threshold concept for image processing algorithms. The RCA evolution under normal loading, as measured by the test rig, correlates well with existing theoretical results for both elastic and elastic–plastic regimes of deformation. The test rig was found capable of capturing directly, in situ and in real time the exact size and shape evolution of RCA in pre-sliding. References [1] P.W. O’Callaghan and S.D. Probert, Wear 120 (1987) 29–49. [2] K.L. Woo and T.R. Thomas, Wear 58 (1980) 331–340. [3] B. Bushan, ASLE Trans. 28 (1985) 75–86. 63 [4] J. Cortney-Prat and E. Eisner, R. Soc. Lond. 238A (1957) 529–549. [5] F. Aymerich and M. Pau, J. Tribol. 126 (2004) 639–645. [6] M. Pau, F. Aymerich and F. Ginesu, Wear 253 (2002) 265–274. [7] R. Dwyer-Joyce and B. Drinkwater, Tribol. Lett. 14 (2003) 41–52. [8] R. Parker and D. Hatch, Proc. Phys. Soc. (Lond.) B63 (1950) 185–197. [9] M. Chaudhri, Philos. Magaz. A 44 (1981) 667–675. [10] M. Chaudhri, I. Hutchings and P. Makin, Philos. Magaz. A 49 (1984) 493–503. [11] K. Tanaka, Wear 100 (1984) 243–262. [12] C. Constantinou and M. Chaudhri, J. Mater. Sci. 24 (1989) 4279– 4292. [13] E. Diaconescu, M. Glovnea, Evaluation of contact area by reflectivity 3rd Aimeta International Tribology Conference, Italy 2002. [14] S. Lo and S. Tsai, J. Tribol. 124 (2002) 229–238. [15] K. Adachi, K. Kato, J. Liu, and H. Kawamura, The effect of contact morphology on initiation and propagation of micro-slip at contact interface ASME/STLE International Joint Tribology Conference, California USA 2004. [16] A. Azushima, S. Kuba, S. Tani and D. Olsson, Wear 260 (2006) 258–264. [17] T. Klinger, Image Processing with LabVIEWä IMAQä Vision (Prentice Hall PTR, 2003). [18] L. Kogut and I. Etsion, J. Appl. Mech. Trans. ASME 69 (2002) 657–662. [19] S. Timoshenko and J. Goodier, Theory of Elasticity 3rd ed. (McGraw-Hill, New York, 1970). [20] I. Etsion, O. Levinson, G. Halperin and M. Varenberg, J. Tribol. 127-1 (2005) 47–50. [21] D. Tabor, Proc. R. Soc. A 251 (1959) 378.