DeltaV SIS with Electronic Marshalling Project Execution Analysis

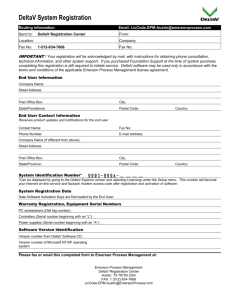

advertisement

DeltaV SIS Whitepaper DeltaV SIS Process Safety System September 2013 An Evaluation of the Impact of E ­ lectronic ­Marshalling on a Process Safety Project ­Execution Process This paper assesses the technical and commercial Impact of change on projects using traditional marshalling methods versus a DeltaV SIS with Electronic Marshalling technology. It will attempt to identify and quantify the impact and changes to work processes along with the cost and schedule benefits available to EPC contractors and end users. DeltaV SIS with Electronic Marshalling Project Execution Analysis September 2013 Introduction Project schedules today rarely allow for the exploration of alternative solutions or for the consideration of unique approaches. ­Traditional technology and work processes have constrained the ability to incorporate design changes during the engineering ­lifecycle which has led in many cases to rework, cost escalation, schedule extension and conflict amongst contracting partners. With the growing recognition of the importance of early integration of the process safety systems provider being crucial to ­successful project execution, the traditional contractor and supplier roles have changed. System suppliers have now become ­solution providers under the guise of a Main Automation Contractor (MAC), where they are responsible not only for the Integrated Control and Safety System (ICSS), but also the incorporation of a number of disparate systems and packages from various ­suppliers. This early integration presents opportunities to investigate new technologies that provide the best solution to meet client and ­project requirements, such as Emerson’s DeltaV SIS with Electronic Marshalling. The introduction of Electronic Marshalling technology for DeltaV SIS provides a modern flexible and innovative approach to project implementation that will provide significant benefits such as: Reduced costs Cost and schedule certainty Increased project efficiency Technical consistency Elimination of duplicate engineering activities Improved change control management This technology has the potential to significantly reduce the system footprint by removing the requirement for marshalling cabinets in traditional wired safety systems. More importantly it will have an effect on system design and configuration with the potential to improve change control management, reducing the cost of design changes throughout the project lifecycle. The flexibility offered by Electronic Marshalling technology allows the project team to make provision early in the execution for any future changes. The intent of this study is for Emerson to capture, document, and present the comparison between traditional safety hardware configurations, engineering processes, and the technological benefits of DeltaV SIS with Electronic Marshalling, when applied to a process safety project with traditional engineering. DeltaV SIS with Electronic Marshalling Technology Overview Since its inception, DeltaV SIS has been at the forefront of technological innovation and the release of Electronic Marshalling continues this trend. Whilst retaining the innovative functionality and features of previous releases, this technology addresses the following common issues encountered on projects: Late design changes or incomplete data Late cable information Late HAZOP and SRS completion Late mechanical package information Marshalling cabinet wiring changes Additional I/O Logic solver I/O allocation Changing I/O type Late design freeze and Factory Acceptance Test (FAT) FAT complexity Efficient and effective project execution. 2 DeltaV SIS with Electronic Marshalling Project Execution Analysis September 2013 Electronic Marshalling Project Impact DeltaV SIS with Electronic Marshalling provides the most differentiating element that will enable reduction of CAPEX (installation & commissioning efforts, cabling, footprint etc.) and project risk, as well as allowing a more flexible planning of design, installation, testing, and commissioning program. The use of this new product in the execution of the project will allow late release of I/O allocation to safety instrumented functions and enable easy implementation of late design changes and late cabling information, affecting the system marshalling cabinets. This capability has a significant impact on change management on the project and brings flexibility in the scheduling of “Design Freeze” milestones and hardware design activities. Figure 1 – Engineering tasks impacted by Electronic Marshalling The DeltaV SIS Electronic Marshalling system is a revolutionary solution that takes away the pains of cross-wiring designs and having to set early milestones for hardware design freeze related to the I/O and cabling information. As shown in Figure 2, it optimizes the marshalling cabinet space as this is done electronically, simplifying the overall cabinet designs and providing a footprint which is less susceptible to the impact of change as I/O and cabling design becomes more defined. 3 DeltaV SIS with Electronic Marshalling Project Execution Analysis September 2013 Figure 2 – Conventional Cabinets (Left) versus Electronic Marshalling (Right) The I/O backplane can be installed within a cabinet or directly in a field junction box and has integral terminals for landing the ­multi-core and field cables. This provides cost savings and schedule certainty. Figure 3 – The DeltaV SIS CHARMs Smart Logic Solver (CSLS) and CHARM design 4 DeltaV SIS with Electronic Marshalling Project Execution Analysis September 2013 Project Impact during Execution By applying the Electronic Marshalling technology to an SIS project, we are able to assess the impact of new technology. It should be recognized that implementation of Electronic Marshalling will require fundamental changes to existing engineering work processes. These work process changes will enable the benefits of embedded within DeltaV SIS Electronic Marshalling to be realized to their fullest extent. These work process changes are summarized below. What Would the Implications of DeltaV SIS with Electronic Marshalling be to a Project? The potential cost escalation on a project is in two main areas, namely: Physical hardware, cabinet and wiring plus associated software change and testing Associated time, resources and personnel required to implement change using traditional processes With Electronic Marshaling technology, the CHARMS hardware is in essence an “enabler” within the project execution process, allowing more time in the design phases and later freeze dates. Therefore, the major impact on the project will occur in the execution work processes and the time needed for their completion. Process Safety project execution is a bit different than BPCS design and scheduling. The design and engineer phase of the project still exists, but much of that design is based on the results or the Process Hazard Analysis (HAZOP and LOPA) and resulting generation of the Safety Requirements Specification (SRS). The SRS defines the number, type and allocation of Safety Instrumented Functions (SIF) required to deliver the level of safety required for the process. Once completed, detailed engineering can be accomplished. The ‘core process’ for the contractor when using traditional I/O technology is shown in figure 4. The P&ID’s are developed and from there the Instrument Database containing details required by the system vendor such as tag lists and cabling information, enabling the start of their own engineering design process activities is generated. Figure 4 –Contractor “Core Processes” for Conventional I/O Systems 5 DeltaV SIS with Electronic Marshalling Project Execution Analysis September 2013 The P&ID’s and instrument database continue to be developed during the project until close out. Therefore the scope and ­information required by Emerson is not fully defined and subject to change. Emerson will use preliminary cable data for system engineering in order to meet the system engineering and schedule milestones. Figure 5 shows the actual processes used during execution. This shows that much of the work for Emerson relied on having the final cabling data, which was not available until much later in the project execution. The resultant change and rework related to this issue is usually the source of cost escalation and schedule extension. Figure 5 –Emerson Project Process for Conventional I/O 6 DeltaV SIS with Electronic Marshalling Project Execution Analysis September 2013 The Application of Electronic Marshalling Technology to Core Processes For the EPC contractor, Electronic Marshalling technology has a significant impact in that Emerson does not require the final cabling data until much later in the project. Emerson only needs to have an indication of the anticipated size of the system in terms of I/O and the preliminary cable information. The contractor and Emerson can make an allowance for unknown or late preliminary design data at the very start of the project with little or no impact on future changes and cost escalation. This is illustrated in Figure 6. Figure 6 – Contractor Process with Electronic Marshalling For Emerson, the execution process becomes far less reliant on receiving final cabling information. Using the calculated system size, the cabinets are built and shipped to site when final cabling data is available. The addition of further I/O is a relatively simple task and has no major cost implication over and above any new system hardware. The site installation contractor can install and land multi-core cables. The CHARMS can be installed on site when final cabling details have been established and loop checking and a Site Acceptance Test (SAT) performed as shown in Figure 7. 7 DeltaV SIS with Electronic Marshalling Project Execution Analysis September 2013 Figure 7 – Emerson Core Process for I/O on Demand Electronic Marshalling In comparing figures 5 and 7, we can see that the execution work processes are significantly simplified for Emerson mitigating the potential for change, engineering rework and cost escalation. For the contractor the risk on moving forward with preliminary design data and understanding that design development will not unduly impact the execution and schedule is a major benefit. It also ­provides a significantly higher level of cost certainty, engineering consistency, improved management of any potential change and an optimal system architecture. Cost Implications of DeltaV SIS with Electronic Marshalling Although most projects incorporate a number of different systems into the overall solution, Electronic Marshaling technology is applicable to the DeltaV SIS portion only. Potential cost savings can be generated in areas such as physical hardware, engineering processes and the associated resources. Let’s look at an example of the level of cost savings one can expect by using Electronic Marshalling technology for implementation in a safety system. Consider a project comprised a total of 1536 safety I/O of various types as detailed in the following table, and this configuration is the base case against which other alternatives have been evaluated. A second, more significant case assumes the use of Electronic Marshalling with CHARMS installed in the field in standard enclosures. As such, the 1536 I/O are assumed to be implemented as follows: 8 DeltaV SIS with Electronic Marshalling Project Execution Analysis September 2013 Table 1: Electronic Marshalling with CHARMS in the field In this Total Installed Cost (TIC) analysis, cost savings come from significantly reduced cabling infrastructure (Ethernet cable from junction boxes rather than using conventional multi-core signal cables), elimination of marshalling cabinets, associated ­engineering and installation activity, and can significantly reduce overall engineering and design effort. It should be noted that even more ­savings could be realized if the system included thermocouples, RTDs, and high current devices, or intrinsically safe signals. When compared to traditional wired signal infrastructure, the installed cost saving per loop can be significant as shown in Figure 8. Figure 8 – DeltaV SIS Electronic Marshalling benefits in a traditional wired marshalling execution 9 DeltaV SIS Whitepaper DeltaV SIS Process Safety System September 2013 Conclusion It has been clearly demonstrated that if DeltaV SIS with Electronic Marshalling technology is applied, a project will produce many benefits and improve the change management process for both Emerson and the contractor when compared with using traditional hard-wired SIS I/O and marshalling. © Emerson Process Management 2013. All rights reserved. Emerson Process Management Asia Pacific: 65.6777.8211 Europe, Middle East: 41.41.768.6111 North America, Latin America: +1 800.833.8314 or +1 512.832.3774 www.DeltaVSIS.com Emerson is a trademark of Emerson Electric Co. The DeltaV SIS logo is a mark of one of Emerson Process Management family of companies. All other marks are property of their respective owners. The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and conditions, which are available on request. We reserve the right to modify or improve the design or specification of such products at any time without notice.