Reliability of the Electric Power Distribution System

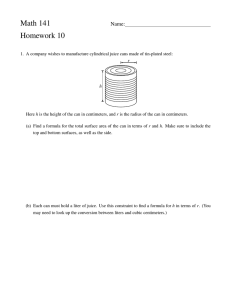

advertisement