Cree Edge™

LED High Output Luminaire

Includes: XAK Series

IMPORTANT SAFEGUARDS

INSTALLATION INSTRUCTIONS

When using electrical equipment, basic safety precautions should always be

followed including the following:

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

1. To avoid the possibility of electrical shock, turn off power supply before

installation or servicing.

2. Product must be installed in accordance with NEC or your local electrical

code. If you are not familiar with these codes and requirements, consult a

qualified electrician.

3. If NEMA Photo Control is installed refer to NEMA Receptacle Section for

instructions.

4. Ensure the mounting surface is capable of supporting the weight of the

luminaire after installation.

5. Due to the weight of the luminaire, 2 people may be necessary during

installation.

6. WARNING: This luminaire is intended to be mounted to a vertical tenon only.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

TO INSTALL:

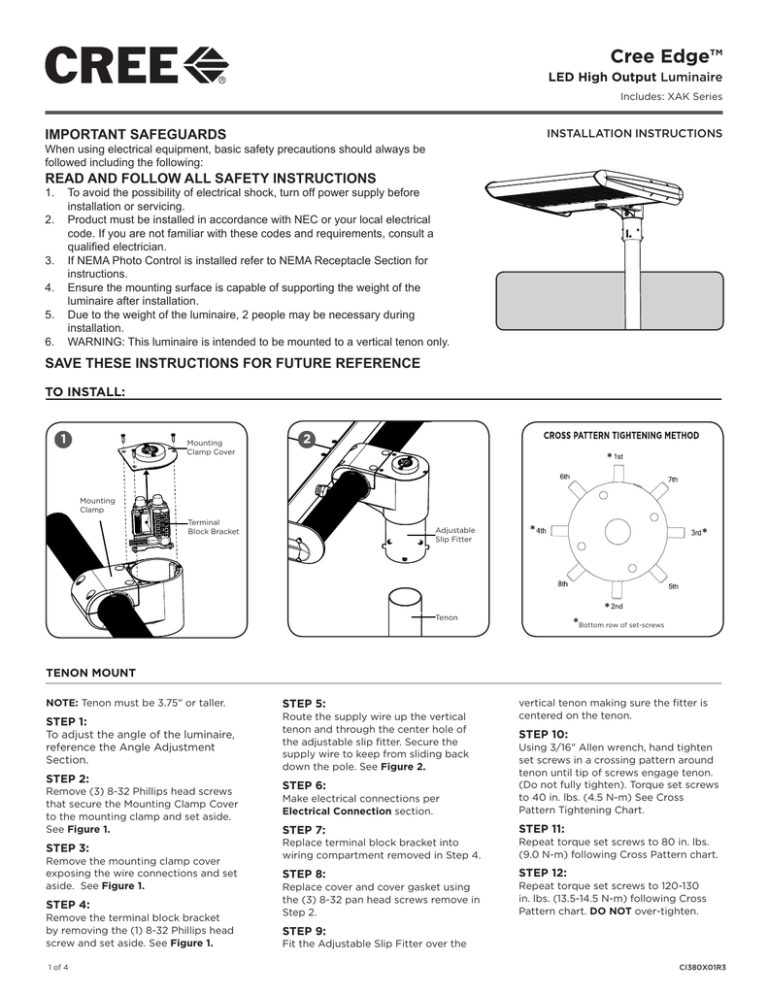

1

Mounting

Clamp Cover

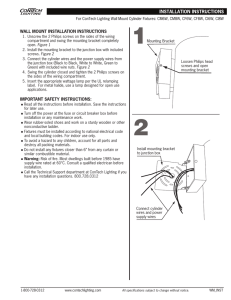

2

*

Mounting

Clamp

Terminal

Block Bracket

Adjustable

Slip Fitter

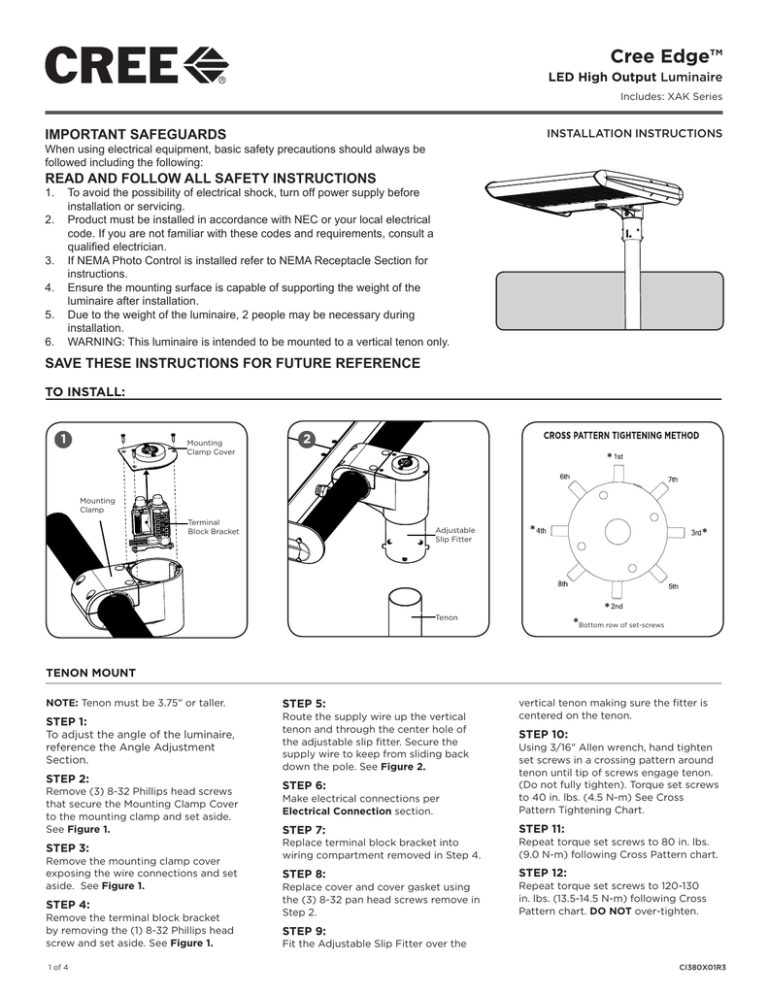

*

*

*

*Bottom row of set-screws

Tenon

TENON MOUNT

NOTE: Tenon must be 3.75" or taller.

STEP 5:

STEP 1:

Route the supply wire up the vertical

tenon and through the center hole of

the adjustable slip fitter. Secure the

supply wire to keep from sliding back

down the pole. See Figure 2.

To adjust the angle of the luminaire,

reference the Angle Adjustment

Section.

STEP 2:

Remove (3) 8-32 Phillips head screws

that secure the Mounting Clamp Cover

to the mounting clamp and set aside.

See Figure 1.

STEP 3:

Remove the mounting clamp cover

exposing the wire connections and set

aside. See Figure 1.

STEP 4:

Remove the terminal block bracket

by removing the (1) 8-32 Phillips head

screw and set aside. See Figure 1.

1 of 4

vertical tenon making sure the fitter is

centered on the tenon.

STEP 10:

Make electrical connections per

Electrical Connection section.

Using 3/16" Allen wrench, hand tighten

set screws in a crossing pattern around

tenon until tip of screws engage tenon.

(Do not fully tighten). Torque set screws

to 40 in. lbs. (4.5 N-m) See Cross

Pattern Tightening Chart.

STEP 7:

STEP 11:

STEP 6:

Replace terminal block bracket into

wiring compartment removed in Step 4.

Repeat torque set screws to 80 in. lbs.

(9.0 N-m) following Cross Pattern chart.

STEP 8:

STEP 12:

Replace cover and cover gasket using

the (3) 8-32 pan head screws remove in

Step 2.

Repeat torque set screws to 120-130

in. lbs. (13.5-14.5 N-m) following Cross

Pattern chart. DO NOT over-tighten.

STEP 9:

Fit the Adjustable Slip Fitter over the

CI380X01R3

SURFACE MOUNT

3

STEP 1:

Using the provided mounting plate, mark the

intended installation surface with the bolt pattern.

See Figure 3

STEP 2:

Remove (3) 8-32 Phillips head screws that secure the

Mounting Clamp Cover to the mounting clamp and

set aside. See Figure 1.

STEP 3:

Remove the mounting clamp cover exposing the wire

connections and set aside. See Figure 1.

STEP 4:

Remove the terminal block bracket by removing the

(1) 8-32 Phillips head screw and set aside. See

Figure 1.

STEP 5:

Place a minimum ¼" bead of silicone rubber on the

bottom of the mount casting. See Figure 4.

STEP 6:

Using (4) 5/16"-18 customer supplied fasteners

suitable for mounting surface, secure the luminaire to

mounting surface.

4

STEP 7:

Make electrical connections per Electrical

Connection section.

NOTE: (2) ½-14 threaded holes are available for

electrical connections and through wiring.

STEP 8:

Replace terminal block bracket into wiring

compartment removed in Step 3.

STEP 9:

Silicone

SILICONE

Replace cover and cover gasket using the (3) 8-32

pan head screws remove in Step 1.

SURFACE MOUNT TO 5" SQUARE POLE

STEP 1:

Complete Steps 1-5 of the Surface Mount Instructions

to mount the luminaire to a 5" square pole capable

of supporting the weight of the luminaire.

5

STEP 2:

Insert the Square Mounting Plate into the top of the

5" square pole as seen in Figure 5.

STEP 3:

Using (4) supplied 5/16"-18 fasteners secure the

luminaire to square mounting plate.

STEP 4:

Complete Steps 7-9 of the Surface Mount

Instructions.

2 of 4

CI380X01R3

ANGLE ADJUSTMENT

6

STEP 1:

After the luminaire is installed, the angle of the

luminaire can be adjusted approximately 90° up or

down in 5° increments.

Mounting

Clamp

STEP 2:

Angle

Bracket

Socket Head

Cap Screws

To adjust the angle, loosen the four 3/8 – 16 X 1.5"

Socket Head Cap Screws located in the top section

of the Mounting Clamp using the provided 5/16” Hex

Wrench.

STEP 3:

Using the Angle Bracket, shown in Figure 6, as a

guide rotate the luminaire to the desired position and

retighten the screws loosened in Step 2 to 120 in.-lbs.

LATERAL ADJUSTMENT

STEP 1:

The position of the luminaire can also be adjusted

laterally. To adjust the Lateral position, loosen the four

3/8 – 16 X 1.5" Socket Head Cap Screws located in the

top section of the Mounting Clamp using the provided

5/16" Hex Wrench. See Figure 6.

STEP 2:

Angle Markings

Remove the Angle Bracket and (2) screws and set aside.

See Figure 6

Numbers on angle bracket are shown for illustration

purpose only. Actual bracket doesn’t show numbers.

STEP 3:

The Angle Bracket can be secured using the existing

holes on the luminaire bar. Set the Mounting Clamp to

desired lateral adjustment using the following positions

on the bar (See Figure 9):

• Position 2 - Left justification.

• Position 4 - Center position (when angle bracket

is on the left side of the mounting clamp).

• Position 5 - Center position (when angle

bracket is on the right side of the mounting

clamp).

9

Angle Bracket is Shown in Position 5 in This

Illustration

• Position 7 - Right justification.

NOTE: Positions 1,3,6 and 8 will not be able to be used.

NOTE: Mounting two luminaires to a 24” Bullhorn Tenon

will require one luminaire mounted in position 2 and one

luminaire mounted in position 7.

STEP 4:

Once desired position is achieved reinstall the Angle

Bracket using (2) screws that were removed in Step 2.

Mounting Clamp

STEP 5:

Retighten screws that were loosened in Step 1 to 120

in-lbs.

NEMA RECEPTACLE (OPTIONAL)

1

2

3

4

5

6

7

8

STEP 1:

DO NOT loosen/tighten pan head screws for the NEMA

receptacle.

STEP 2:

Rotational adjustment of the photo control is tool-less.

STEP 3:

Engage/install photo control into NEMA receptacle on

top of the fixture.

STEP 4:

Firmly rotate photo-control with its photo-eye

approximately in the ‘N’ north direction. Some

photo-controls operate best somewhere between

NW and NE.

3 of 4

CI380X01R3

FIELD ADJUSTABLE DIMMING - OPTIONAL

8

STEP 1:

This luminaire may be provided with field adjustable dimming.

Luminaires leave the factory adjusted to the maximum setting

which is Position 9 as shown in Figure 8.

STEP 2:

Locate the luminaires electrical label and verify the luminaires

LED count and the maximum current available.

STEP 3:

The Dimming module is located inside the Mounting Clamp

on the Terminal Block Bracket. Remove (3) 8-32 Phillips

head screws that secure the Mounting Clamp Cover to the

Mounting Clamp and set aside. See Figure 1 on page 1.

STEP 4:

Remove the mounting clamp cover exposing the wire

connections and set aside. See Figure 1 on page 1.

STEP 5:

Remove the terminal block bracket by removing the (1) 8-32

Phillips head screw and set aside. See Figure 1 on page 1.

STEP 6:

Establish the desired input power multiplier by referring to

the product dimming spec sheet and turn the switch to the

correlating position.

STEP 7:

Adjust the Dimming Module to the selected position, replace

the terminal block bracket and the Mounting Clamp Cover

ensuring no wires are pinched and reinstall the screws that

were removed in Step 3.

ELECTRICAL CONNECTIONS

STEP 1:

For 120/277V applications make the following Electrical

Connections to the terminal block:

For 208/240/347/480 applications, make the following

Electrical Connections to the terminal block:

LINE

OR HOT 1

For Dimming on all voltage applications:

a. If Dimming is an option; connect the violet dimming

positive lead to the supply dimming positive lead.

b. If Dimming is an option; connect the grey dimming

negative lead to the supply dimming negative lead

© 2013 Cree, Inc. All rights reserved. For informational purposes only. Content is subject to change. See

www.cree.com/lighting/products/warranty for warranty and specifications. Cree®, and the Cree logo are

registered trademarks, and Cree Edge™ is a trademark of Cree, Inc.

LINE-BLACK

GREEN

GROUND-GREEN

NEUTRAL

OR HOT 2

NEUTRAL-WHITE

VIOLET

GREY

DIM (+) VIOLET

DIM (-) GREY

(DIMMING OPTIONAL)

a. Connect Hot 1 supply lead to the black lead.

b. Connect Hot 2 supply lead to the white lead

c. Connect the green or green/yellow ground lead

to the supply ground lead.

4 of 4

LUMINAIRE

TERMINAL

BLOCK

SUPPLY WIRING

a. Connect the black fixture lead to the voltage

supply position of the terminal block.

b. Connect the white fixture lead to the neutral supply

position of the terminal block.

c. Connect the green or green/yellow ground lead to

the green wire position of the terminal block.

www.cree.com/lighting

CI380X01R3