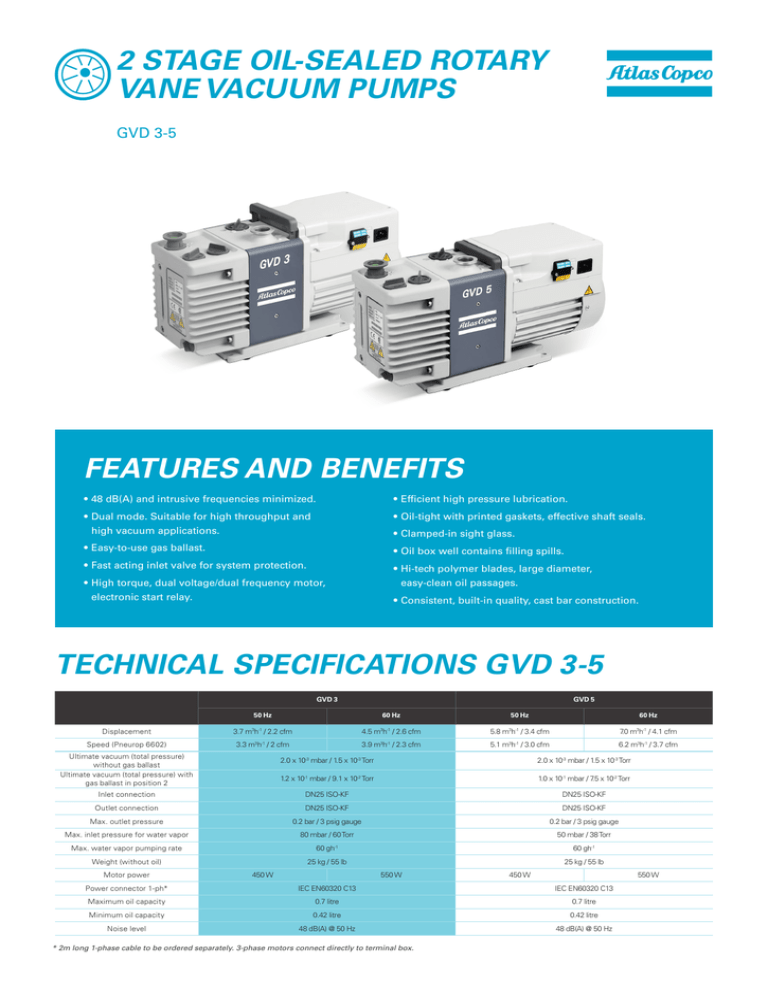

2 STAGE OIL-SEALED ROTARY

VANE VACUUM PUMPS

GVD 3-5

FEATURES AND BENEFITS

•48 dB(A) and intrusive frequencies minimized.

•Efficient high pressure lubrication.

•Dual mode. Suitable for high throughput and

high vacuum applications.

•Oil-tight with printed gaskets, effective shaft seals.

•Easy-to-use gas ballast.

•Oil box well contains filling spills.

•Fast acting inlet valve for system protection.

•Hi-tech polymer blades, large diameter,

easy-clean oil passages.

•Clamped-in sight glass.

•High torque, dual voltage/dual frequency motor,

electronic start relay.

•Consistent, built-in quality, cast bar construction.

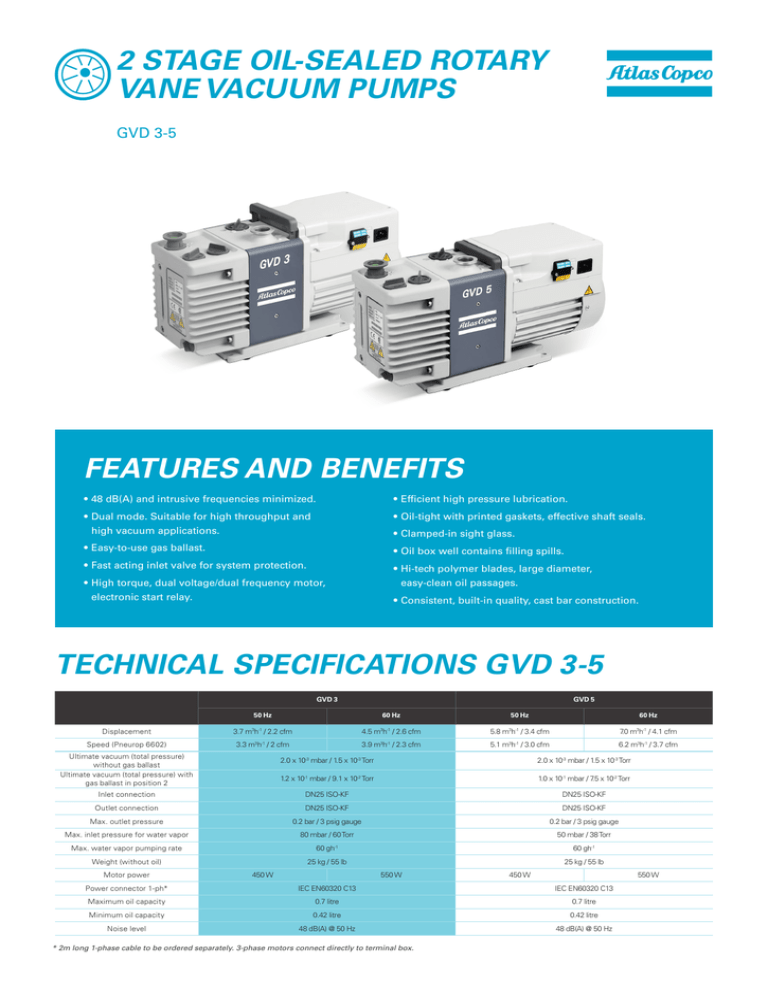

TECHNICAL SPECIFICATIONS GVD 3-5

GVD 3

GVD 5

50 Hz

60 Hz

50 Hz

60 Hz

Displacement

3.7 m h / 2.2 cfm

4.5 m h / 2.6 cfm

5.8 m h / 3.4 cfm

7.0 m h / 4.1 cfm

Speed (Pneurop 6602)

3.3 m3h-1 / 2 cfm

3.9 m3h-1 / 2.3 cfm

5.1 m3h-1 / 3.0 cfm

6.2 m3h-1 / 3.7 cfm

3 -1

Ultimate vacuum (total pressure)

without gas ballast

Ultimate vacuum (total pressure) with

gas ballast in position 2

3 -1

3 -1

3 -1

2.0 x 10-3 mbar / 1.5 x 10-3 Torr

2.0 x 10-3 mbar / 1.5 x 10-3 Torr

1.2 x 10 mbar / 9.1 x 10 Torr

1.0 x 10-1 mbar / 7.5 x 10-2 Torr

-1

-2

Inlet connection

DN25 ISO-KF

DN25 ISO-KF

Outlet connection

DN25 ISO-KF

DN25 ISO-KF

Max. outlet pressure

0.2 bar / 3 psig gauge

0.2 bar / 3 psig gauge

Max. inlet pressure for water vapor

80 mbar / 60 Torr

50 mbar / 38 Torr

Max. water vapor pumping rate

60 gh-1

60 gh-1

Weight (without oil)

Motor power

Power connector 1-ph*

25 kg / 55 lb

450 W

25 kg / 55 lb

550 W

IEC EN60320 C13

450 W

550 W

IEC EN60320 C13

Maximum oil capacity

0.7 litre

0.7 litre

Minimum oil capacity

0.42 litre

0.42 litre

Noise level

48 dB(A) @ 50 Hz

48 dB(A) @ 50 Hz

* 2m long 1-phase cable to be ordered separately. 3-phase motors connect directly to terminal box.

APPLICATIONS

• Analytical instruments

• Gas bottle filling/emptying

• Centrifuges, ultra-high speed

• Gel drying

•Coating

• Glove boxes, ovens

AIR OUTLET

• Leak detectors, Helium

• Freeze drying

• Load locks and transfer chambers

•Furnaces

• Refrigeration manufacture

9

8

1

2

10

3

4

4

5

6

• SEM/FIB (ion beam repair)

• Surface science instruments

5

6

224

225

• Turbomolecuar backing pumps

SLOT FOR

M8 (4x)

4

14(4x)

80

230

430

7

9

8

10

AIR INLET

AIR OUTLET

A

A

ON/OFF

SWITCH

GAS BALLAST

CONTROL

12

12

29

39

4

127

DN25 ISO-KF

4

14(4x)

230

D

64

OIL FILLER

SLOTPLUG

FOR

M8 (4x)

1

OIL DRAIN

PLUG

DN25 ISO-KF

120

19

C

60

115

158

Ed

D

Position

Date

Modified from

Intr./Appd.

Parent 3D model

PERFORMANCE CURVES

DN25 ISO-KF

9820720231

ON/OFF

SWITCH

GAS BALLAST

CONTROL

29

39

127

E

E

MOTOR COOLING

AIR IN

69

64

TOR COOLING

IN

69

CONFIDENTIAL:

430

OIL SIGHT

GLASS

10

C

80

226

224

This document is our property and shall not without our permission be altered,

copied, used for manufacturing or communicated to any other person or company.

158

All materials supplied are in compliance with the

requirements of the List of Prohibited Substances

SLOT FOR

M8 (4x)

OIL DRAIN

PLUG

120

19

MOTOR COOLING

AIR IN

B

225

226

B

OIL SIGHT

GLASS

ATLAS COPCO STANDARD CLASS

Treatment

Not applicable

Scale

Parent 3D model

STATUS

Ed . Version 3D

Preliminary

1

DN25 ISO-KF

Version Drwg

Blank wt

Des checked.

Prod checked. Approved.

Kg

INV

Date

12/5/2013

ATLAS COPCO STANDARD CLASS

Name

Material

Treatment

Sheet

1

9820720231

Ed

Position

1: Without gas ballast.

2: With gas ballast open in position 1.

3: With gas ballast open in position 2.

Class

1 PHASE Confidentiality

acc. to 1102 K

PUMP

Internal

Not applicable

Scale

Drawing owner

API

87,266 Kg Designation -

Fini wt.

Tolerances, if not indicated, according to:

115

G

Replaces

Blank nr.

60

10

OIL FILLER

PLUG

Internal

A2 Compare

Family

1:2

Drawn by INEansa

9820720231

F

Class

1 PHASE Confidentiality

acc. to 1102 K

PUMP

CONFIDENTIAL:

Name

Material

This document is our property and shall not without our permission be altered,

copied, used for manufacturing or communicated to any other person or company.

F

Tolerances, if not indicated, according to:

9820720231

Modified from

Date

Intr./Appd.

Parent 3D model

STATUS

Ed . Version 3D

Preliminary

A2 Compare

Family

1:2

Drawn by INEansa

/ 1

7

12

OIL SIGHT

GLASS

All materials supplied are in compliance with the

requirements of the List of Prohibited Substances

7

3

AIR INLET

226

•Distillation/extraction/filtration

4

• Laboratory bench top vacuum

• Scanning electron microscopes - SEM

6996 0022 00 © 2014, Atlas Copco Vacuum Solutions Division. All rights reserved. Designs and specifications are subject to change without notice or obligation. Read all safety instructions in the manual before usage.

• Rotary, centrifugal evaporators

2

1

• Degassing/curing - oil, epoxy resin

DIMENSIONS

6

• Research and development

Version Drwg

Blank wt

Des checked.

Prod checked. Approved.

Kg

INV

G

Drawing owner

API

Replaces

Blank nr.

Fini wt.

87,266 Kg Designation

Date

12/5/2013

Sheet

1

9820720231

/ 1

Available motor voltages:

• 1-ph 100-115 V 50/60 Hz

• 1-ph 200-230 V 50/60 Hz

• 3-ph 200-230 V, 380-415 V 50 Hz & 200-230/460 60 Hz

For ultimate vacuum figures, please consult the technical specification table on the front page.

www.atlascopco.com/vacuum

Ed . Version 3D

19

Tolerances, i

ATLAS COP

Name

Material

Treatment

STATUS

Prelimin