Experiment 3 Procedure

advertisement

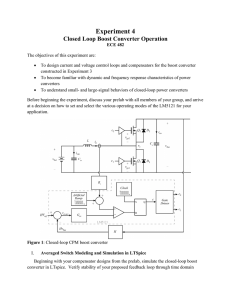

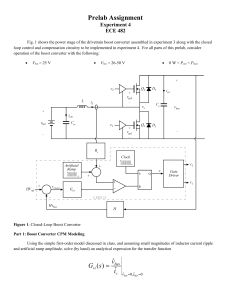

Experiment 3 Closed Loop Boost Converter Operation ECE 482 The objectives of this experiment are: To design current and voltage control loops and compensators for the boost converter constructed in experiment 2 To become familiar with dynamic and frequency response characteristics of power converters To understand small- and large-signal behaviors of closed-loop power convreters Figure 1: Closed-Loop Boost Converter I. Current Sensor Implementation Using the ACS714 hall sensor, implement the current sensor in series with L. Consider how you will implement the saturation of inductor current reference and, if necessary, add an additional gain stage. Determine the effective gain of the current sense circuitry, Rs. Configure the gain as necessary in order to produce a range of current reference voltages at its output which will allow operation in the range of 0 A < IL < 10 A, taking into account a single-ended +5V supply used throughout the control circuitry. Test the current sensor output in open loop by operating your boost converter and viewing the output voltage directly. Include these waveforms as well as a plot showing how the current sense amplifier output voltage relates to inductor current in your report. II. Averaged Switch Modeling and Simulation in LTSpice Beginning with your compensator designs from the prelab, simulate the closed-loop boost converter in LTspice using the provided averaged switch models, or in another tool using models of your own design. Verify stability of your proposed feedback loop through time domain simulations, across operating powers from 0-250 W and output voltages in the range 30 < Vbus < 75 V. Additionally, use frequency domain simulations to verify converter and compensator transfer functions and loop gains. Include basic models of important loss mechanisms from Experiment 2, and refine your compensator design as necessary to obtain desirable closed-loop behavior. III. Switching Model Simulation in LTSpice Using the included LTC6992 model in LTSpice, as well as a functional model of a gate driver, simulate the closed-loop boost in LTSpice. Again, verify stability and desirable behavior of the converter under a variety of conditions. In particular, verify the startup behavior of the circuit, ensuring that excessive inductor currents are not incurred at startup. IV. Measurement of Compensator Transfer Functions Construct voltage and current compensators using the op-amps provided in the parts kit, as well as any additional resistors and capacitors which are needed. Use the LMC6482 amplifier for the voltage loop compensator, and uses resistor dividers from the supply rail to set the voltage limits so that the current reference output implements the inductor current limits 0 A < IL < 10 A. Do not connect the compensators to the boost converter at this point. Instead, first use the oscilloscope function generator to supply a sinusoid to the input of each compensator. Vary the frequency of the sinusoid, measuring the gain and phase of the compensator output at each frequency, in order to construct plots of the transfer functions Gcv(s) and Gci(s) experimentally. Compare these measurements to your simulations in LTSpice and your analytical predictions from your design. V. Current Loop Testing and Measurement Connect the MOD input of the LTC6992 to the output of the current loop compensator. Connect the sensed inductor current output to the appropriate input of the current loop compensator. Do not connect the voltage loop compensator at this point, but instead leave the current reference open as the control input to the circuit. By supplying the current reference from an adjustable DC voltage source, test the steady-state behavior of the circuit with the current control loop implemented. Vary the current reference voltage and show that the current in the boost inductor tracks the reference appropriately. Note that, when tracking a reference in closed loop, the value and type of load presented by the electronic load is important; make sure that the operating mode and value that you select are consistent with the safe operating area of your converter. For example, at 26 V with a 1kΩ load and 10A current reference, the control loop will attempt to force Vbus to ~500 V. Make sure that the load connected at the output of the boost converter is of appropriate value such that the output voltage does not exceed 75 V at any time. When testing the current loop only, operating the electronic load as a voltage sink is often advantageous. Setting the electronic load to a constant 50 V voltage sink, and using a function generator at low frequency or independent supplies, generate a voltage step which will vary the current reference command to your compensator between voltages corresponding to 4 A and 8 A operation. Measure the inductor current and compare to your expected step response. Other than the ripple, which is not present in the averaged model, are the waveforms as expected? VI. Closed Loop Operation of Boost Converter Add the voltage loop compensator to the circuit. Select an appropriate resistor divider for the voltage feedback, and note the effective sensing gain H. Make sure that the DC gain in your voltage loop compensator is adjusted to take this value into account. Again verifying behavior in simulation prior to any test scenarios you wish to run, test the closed-loop boost converter and verify its ability to regulate the output voltage. Again measure the step response and compare to your predictions. Measure the load regulation of your closed-loop boost converter between output powers of 50 W and 250W. With a constant voltage reference, load regulation is defined as the percent change in output voltage over the specified load range: Δ 100% If the closed-loop gain at DC and low frequencies is very large, then the closed-loop regulation should be very good, i.e., very close to 0%. Include the measured value in your report. Also measure the line regulation of your boost converter for Vbat varied from 20 to 30 V, all with Pout = 150 W, again using the above formula.