EPC and PL R Series T00 and T42 Racks - Support On Line

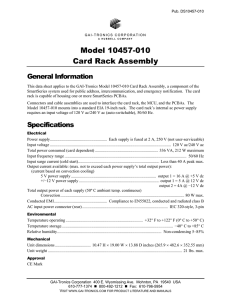

advertisement