Product Introduction of Triple Linear LED Controller

Family E522.80/84 for Automotive

Copyright © 2015 Elmos Semiconductor AG. All rights reserved. Confidential

No redistribution without prior admission.

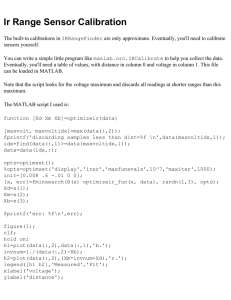

Elmos 522.8x Linear LED Controller Family

Evolutionary Introduction to Product Features

E522.8x Linear LED Controller Family

Excerpts of Features in the Datasheet

Source: Elmos

2

Starting Point: Classical Linear LED Control Topology

e.g. for Rearlight Modules

Rearlamp Module

Control

Module

Topology based on Discretes only

A master Driver modulates a PWM signal to via a single supply line

Properties of this implementation are

Source: Elmos

Weak diagnostic features (only total current consumption)

Current in LEDs depends on actual temperature and battery voltage

3

Starting Point: Classical Linear LED Control Topology

e.g. for Rearlight Modules

Rearlamp Module

Control

Module

Topology based on ICs driving LEDs

Compatible interface to the discrete solution

Improvements over the discrete-built solution

Source: Elmos

Diagnostics within rearlamp module are possible

Current in LEDs can be controlled independent of supply voltage

4

Starting Point: Classical Rearlight Module Topology

Exemplary Integrated IC Solution

Parallel ICs operate one or more channels of LEDs in parallel

Usually 2 or 3 LEDs are operated per channel to survive typ. battery drop transients

Source: Elmos

General requirements include operation <150mA, open-detection, short-circuit

detection, over-temperature handling and wide input voltage range

5

Starting Point: Puzzle Pieces for Evolution of IC

Properties

2

1

3

Puzzle Pieces

4

1: How to handle linear power-dissipation?

2: If using a power-shunt, how to provide full current for low supply voltages?

3: Lowside feedback: How can a GND shift (e.g. at connectors) be handled?

4: If diagnostics are available, how can modules behave in a single-bulb manner?

Source: Elmos

6

Piece 1: Internal Power Dissipation of the Driver

?

Question: High Linear Power Dissipation, what can be done?

The linear power in the ICs is directly proportional the to supply voltage

A typical exposed die pad package assembly may provide RTH,J-A of 15...30K/W

Source: Elmos

At VVS supply of 14V and VLED= 6V @100mA the power to be handled is 0.8W,

thus resulting in a rise of ~ 25K/W * 0.8W = 20°C

How can the power be handled for e.g. VVS=18V and ILED=150mA?

=> Power of 1.8W per string in driver IC!

7

Piece 1: Internal Power Dissipation of the Driver

!

Answer: Power can be shared with external Power-Sinks

Export power to some external heat-dissipating element, e.g. a resistor

Power up to ILED2 * REXT can be dissipated in the external element

Source: Elmos

But if handled in this way, ….

8

Piece 2: Low-Voltage Operation

?

Question: How is Undervoltage Behaviour affected?

…. low-voltage performance degrades, because the current becomes limited by the

resistor REXT in case of cranking pulses etc.

How can the under-voltage performance of the linear-regulator be re-covered?

Which way is the open-detection for low supply managed?

Source: Elmos

9

Piece 2: Low-Voltage Operation

!

Answer: A redundant Output Path is provided

Provide a parallel, redundant path for the current flow in case the current cannot be

delivered by the primary output!

The current can be kept fully controlled down to the VLED forward-voltage

… and the thermal performance / distribution features remain

Source: Elmos

10

Piece 1+2: E522.8x High-Power Handling

Power Distribution Principle in E522.80/81/82/83 Applications

Power as a function of V ( VS )

Exemplary for V ( LED ) = 6V and different ext. Shunts

( Single-Channel Calculation, 120mA )

2,00

PLED

P(R1=33Ohm)

P(E522.8x)@R1

P(R2=56Ohm)

P(E522.8x)@R2

P(R3=82Ohm)

P(E522.8x)@R3

1,60

P [W]

1,20

0,80

0,40

0,00

5,0

10,0

15,0

20,0

25,0

30,0

V (VS) [ V ]

Source: Elmos

11

2,00

Piece 1+2: Power Sharing, Zoom and Math

1,60

PLED

P(R3=82Ohm)

P(E522.8x)@R3

P [W]

1,20

PR,EXT

PLED

0,80

„Zero Power #2“

0,40

P522.8x

0,00

5,0

10,0

15,0

20,0

V (VS) [ V ]

25,0

→ If VVS fulfills the condition

VVS =30,0

VFW,LED + ILED * REXT

the power across the driver is

again theoretically „zero“

Intermediate Power-Maximum

„Zero Power #1“

→ Below conducting voltage VFW,LED

of the LED, there is theoretically

no drop-voltage across the driver

Source: Elmos

→ The maximum power occures, if half of

ILED is driven by the bypass ouput, thus it is

¼ of the maximum resistor power ILED2 * REXT

(half of the current times half of the voltage)

12

Piece 1+2: E522.8x High-Power Handling

VREF

VREF,NOM

dVJ,DERATE

Nom. Operating Range for

external VREF = VENA /2

VENA,ON /2

-40°C

Limited

by abs.

max. Ratings

522.8x disabled by ENA

TJ,DERATE

150°C

TJ,OT

TJ

Internal Derating of Reference „regulates“ Junction Temperature

Internal derating function limits the reference voltage provided at IR to generate

reference-current for the LED Driver

Typical numbers: TJ,DERATE = 138°C and dVJ,DERATE = 26,7mV/K @ VREF,NOM = 1.5V

Source: Elmos

13

Piece 1+2: E522.8x High-Power Handling

VREF

VREF,NOM

dVJ,DERATE

VIN Overvoltage Reference Derating

0.6 * VREF,NOM

Over-Voltage Operating Range for

external VREF = VENA /2

VENA,ON /2

-40°C

Limited

by abs.

max. Ratings

522.8x disabled by ENA

TJ,DERATE

150°C

TJ,OT

TJ

Internal Derating of Reference decreases at excessive VVS

In case the supply voltage at VS exceeds 27V, the internal reference voltage derates to

60% of nominal level VREF,NOM

The maximum power in the package is kept below a given maximum at VVS = 27V

Source: Elmos

14

System Design: “Open Detection” Concepts

based on either relative Voltage or Current?

Issue : Relative Voltage System :

ILED

ISPAN,VOLT

MIN

Simple and intuitive implementation approach, usually

relative to the supply voltage

Drawback: Usually IC vendors do not specify the

remaining current flow at the „open threshold“→

information not available for system designers

TYP

MAX

VLED,MIN,V

VLED,MAX,V

VLED

ILED

Solution :

Relative Current Threshold in

E522.8x :

ISPAN,CUR

MIN

TYP

MAX

VLED,MIN,C

Source: Elmos

Wide window for max. potential LED voltage to be

considered, even if the remaining current

tolerance is known !

VLED,MAX,C

VLED

More precise, narrow current-span can be taken into

account by system engineers

Maximum forward voltage at LEDs way better

defined, allowing more precise description of lowvoltage behaviour of the system !

15

Piece 3: Current Configuration and Feedback

?

Question: What Ground Potential Difference can be handled?

Is „cathode-to-GND“ Topology possible?

For e.g. the use of connectors or even wiring to connect LEDs within rearlamp a

feedback can be critical regarding GND potential differences between driver circuit

and LEDs

Dual-wire interface per string potentially necessary to avoid GND differences

Compensation capacitors may be required or limiting the freedom of designers choice

Source: Elmos

16

Piece 3: Current Configuration and Feedback

!

Answer: GND at LEDs as reference potential is not required,

and „cathode-to-GND“ Topology is possible

The configuration can be made via a single, low-power resistor connected to the

controlling IC. The current source becomes a true current source

Cathode-To-GND topologies provide handling of connectors and wire resistances

Reduced the minimum operation supply voltage by the amount of feedback voltage

Source: Elmos

17

Piece 4: Behavior of a Single Bulb in case of Failures

?

Question: How can the Fault-Behavior of a Bulb be

immitated by a LED Cluster?

Failure information must be distributed between ICs

Restart mechanisms must be available to avoid deadlock situation

Important: Glowing or glimming of LEDs must be prevented

Source: Elmos

18

Piece 4: Behaviour of a Single Bulb in case of Failures

?

Question: How many Components are necessary?

There are solutions on the market, that may require 20...30 external discretes.

LEDs are potentially glowing due to lack of option to store failure information

Source: Elmos

19

Piece 4: Behaviour of a Single Bulb in case of Failures

!

Answer: No external Components are required for “Single Bulb!“

A private bus connects all ICs, distributing the information of a failure on a channel

All ICs enter low-power standby mode, allowing the control module to diagnose via

current consumption only!

Failure information is stored as long as VVS remains, thus preventing glowing effects

Source: Elmos

20

Piece 4: Statediagram Excerpt from Datasheet

Global, Prio 1:

VVS < VVS,ERR

VS RESET

Global, Prio 3:

if all [ y ] are statically

disabled for 64ms

RUN active low

SLM set to pulldown

LED Outputs pulldown

IR Driver off

ERR[ 2:0 ] = '000'

Global, Prio 3:

RUN pullup enabled

and RUN state 'Low'

Thermal

Shutdown

Global, Prio 2:

Junction OverTemperature

Two ways to handle FaultDetection:

RUN active low

LED Outputs pulldown

IR Driver disabled

Overtemperature

Recovery

Global, Prio 2:

ENA Low

VVS > VVS,ERR

Standby Mode

ENA High

No ERR stored

RUN pullup enabled

LED [ x ] pulldown

IR Driver off

ERR[ x | ='0'

Sleep Mode

RUN active low

All LED pulldown

All IR disabled

SLM driving low

ERR[ 2:0 ] unmodified

RUN

High

All ERR [ y ]

cleared by

Diagnosis

After 6ms :

Re-Diagnosis at

enabled [ y ]

for 64us

Rising VIR,X > VIR,DIS

Channel [ x ] disabled

→ Transition

[x→z]

Active,

„Failure Feedback Mode“

RUN active low

LED, IR [ x ] enabled

Diagnosis for [x] active *)

LED, IR [ y, z ] disabled

ERR [ y ] set to '1'

Re-Start Counter running

SLM driving PWM

Falling VIR,Y,Z < VIR,DIS

Channel [ y or z ] re-enabled

With 64us ERR tolerance

Transition [ y, z → x ]

ENA High,

ERR flag stored

any VIR,Y < VIR,DIS

RUN active low

LED, IR [ y ] enabled for 64us,

if VIR,Y < VIR,DIS *)

SLM driving low

Other channels in [ z ] state

Any ERR[ y ]

still present,

SLM held low

Any ERR[ y ]

still present,

SLM high

ERR [ y ] flag

cleared by

Re-Diagnosis

ERR at channel [ y ]

SLM held low

ERR detected

at channel [ y ≠ z ]

SLM held low

Active,

Full Diagnosis

RUN pullup enabled

LED, IR [x] driving *)

( if VIR,X < VIR,DIS )

→ SLM drives high if

ERR[ x ] = '1' after 64us

After 64us:

No ERR[ x ]

detected

Active,

Selective

Diagnosis

ERR at channel [ y ]

SLM driven high

Standby

„Single Lamp“

Mode, Counting

RUN active low

All LED Outputs pulldown

All IR Drivers disabled

SLM driving high

→ ERR [ y ] set to '1'

Re-Start Counter running

ERR detected

at channel [ y ≠ z ]

SLM driven high

Active Mode.

Normal Operation

Index Usage:

x: Active Channel [2:0]

y: Faulty Channel [2:0]

z: Disabled Channel [2:0]

Rising VIR,X > VIR,DIS

Channel [ x ] disabled

→ Transition [ x → z ]

RUN pullup enabled

LED,IR [ x ] driving

Diagnosis at [ x ] enabled *)

LED,IR [ z ] disabled

SLM driving low

if all ERR [ x ] = '0'

Channel [ y ] re-enabled

by either falling VIR,Y or

Re-Start Counter ( 6ms )

( VIR,Y < VIR,DIS )

Falling VIR,Z < VIR,DIS

Channel [ z ] re-enabled

With 64us ERR tolerance

Transition [ z → x ]

Need a simple, downward

compatible cluster?

E522.8x can be configured to

operate in „Single-LampMode“ to allow simple LEDcluster definition !

Need more feedback?

E522.80 be set into failure

feedback mode,

providing the channels with

fault-detections !

*) „LED Open“ error

diagnosis is active

only in case VVS > VTST

Source: Elmos

21

Before and After Comparison of Topologies

2

?

1

Starting

Toplogy

3

4

?

2

1

3

4

Source: Elmos

22

E522.80 Product Family Features

Features of E522.80 / 81 / 82 / 83

Three independent Linear Current Drivers ( 3*150mA ),

allowing parallel Output Operation for up to 450mA

Independent Thermal Management Option per Channel

Operating Input Voltage Range 5V to 25V, max. 40V and

Low Power Standby / Sleep Mode of typ. 12.5µA per IC

External Reference Voltage / Derating supported

PWM Dimming (all channels or separate Channels)

Load Diagnostics ( LED Driver Open/Short, IR Config Open/Short, Junction Temperature,

Supply Voltage ) featuring relative Open-Detection Currents per Driver

Diagnostic Bus to link ICs for a combined Fault-Reaction in "Single Lamp Behaviour" plus

alternative Option to read back the faulty Channels via PWM protocol

Narrow SO16 Package with Exposed Pad for low RTH,J-C

Source: Elmos

23

E522.80 Product Family Features

What´s the family members

Difference?

Family Members provide different

levels of VVS,DIAG to adapt to

the level of voltage VLED,MAX

that is needed to operate the LEDs

Product Version

VVS

Nominal System Operation

- Full Diagnostic

- Full LED current available

Typ. VVS,DIAGx

VVS,DIAG

E522.80

7.5V

VLED,MAX

E522.81

9V

VLED,MIN

E522.82

10V

E522.83

15V

Open Detection Monitor Enable Tolerance Window

LED Voltage Tolerance Range for Open Current

Non-Operating Range

(LEDs not conducting)

0V

Source: Elmos

24

E522.81 Automotive Cluster Example

E522.81

1

RUN

LED1B

VS

LED1A

GND

LED2B

ENA

LED2A

IR1

LED3B

IR2

LED3A

IR3

SLM

2

E522.81

3

4

Source: Elmos

RUN

LED1B

VS

LED1A

GND

LED2B

ENA

LED2A

IR1

LED3B

IR2

LED3A

IR3

SLM

5

25

E522.81 Automotive Cluster Example

E522.81

1

RUN

LED1B

VS

LED1A

GND

LED2B

ENA

LED2A

IR1

LED3B

IR2

LED3A

IR3

SLM

Cloud 1:

2

E522.81

3

4

RUN

LED1B

VS

LED1A

GND

LED2B

ENA

LED2A

IR1

LED3B

IR2

LED3A

IR3

SLM

5

or to define an undervoltage

threshold using bandgap

accurate enable handling

Cloud 2:

Source: Elmos

Power Supply Dimming is

possible. The Resistive

divider can be used for

analog low-voltage current

derating …

Seperate Current configuration

per channel allows different

currents and digital dimming

per channel

26

E522.81 Designers Reference Generation Options

ENA

Current Configuration

+

1.2V

VREF,NOM

ENABLE

-

VREF,HV

VS Overvoltage

Channel

Current

Reference

250kW

+

+

+

-

250kW

IRX

VIR,DIS

-100mV

Internal

Temperature

Derating

+

VIR,DIS

Source: Elmos

-

6V

Channel

Disable

Different Mechanisms define the

voltage that is applied to the

current configuration resistor

The internal amplifier accepts the

lowest reference applied and

re-produces the voltage at IR

driver pin

Potential Sources are:

Voltage at ENA

Linear temperature derating

at typ. TJ > 138°C

For excessive VVS the

reference is derated to

60% to decrease power

27

E522.81 Automotive Cluster Example

Cloud 3:

E522.81

1

RUN

LED1B

VS

LED1A

GND

LED2B

ENA

LED2A

IR1

LED3B

IR2

LED3A

IR3

SLM

Cloud 4:

2

E522.81

3

4

Ceramic type inductive supply

handling / damping proposal

RUN

LED1B

VS

LED1A

GND

LED2B

ENA

LED2A

IR1

LED3B

IR2

LED3A

IR3

SLM

5

Simple permanent disable

option if less than 3

channels of E522.8x are

used

Cloud 5:

Source: Elmos

Parallel operation of channels

for single high-power LED

separated by connector or

wiring

28

E522.8x Product Family Extension

Features of E522.84 / 85 / 86 / 87

Extension IC for System-designers to driver smaller Currents per channel

Three independent Linear Current Drivers ( 3*60mA ),

allowing parallel Output Operation for up to 180mA

Low-RTH SO8EP Package for cost-optimized integration, no external thermal sinks needed

All channels configured via a single resistor

Dimming via Supply

RUN concept compatibility to the higher current family E522.80

Same diagnostics features as for E522.80

Source: Elmos

29

E522.8x Product Family Extension II

Outlook

Interested in lower currents, but need the full feature set of E522.80 ?

Like to discuss your system-concept with product-experts ?

Get in contact with Elmos – we support your ideas !

Datasheets are available on www.elmos.com/.....

Source: Elmos

30

Disclaimer / all material shown is based on assumptions and actual views of Elmos

Semiconductor AG and may be adapted without further notice, depending on

market situation or technical requirements as necessary, up to discontinuation

of products presented herein. Schematics or drawings do not imply full

compliance to customer requirements and are to be evaluated

or used on own responsibility

Elmos Semiconductor AG

Heinrich-Hertz-Str. 1 | 44227 Dortmund | Germany | phone: + 49 231 75

49 100 | fax: + 49 231 75 49 149 | info@elmos.com | www.elmos.com

Confidential