Document No. 10860038 Rev. D

Line Terminating Unit

P/N: 108600

Eurocom D/1 Interface A/B

To

Eurocom D/1 Interface C

Tactical Communications System

B

C

EOW

24 VDC

512

256 1024

OFF

2048

C SYNC

B SYNC

ERROR

POWER

Operations Manual

Line Terminating Unit

P/N: 108600

Eurocom D/1 Interface A/B

To

Eurocom D/1 Interface C

Tactical Communications System

Operations Manual

Moog Components Group

www.moog.com/components

750 West Sproul Road

Springfield, PA 19064-4084

(610) 328-4000

Doc. No. 10860038, January 20, 2006, Rev. D

Copyright (c) 2006 Moog Components Group

All Rights Reserved.

Any unauthorized duplication or use, in whole or in part, in print or in any other

storage retrieval system is prohibited. No part of this material may be

reproduced, transmitted, transcribed, stored in a retrieval system, or translated

into any language in any form by any means for any purpose other than licensed

use without the express written permission of Moog Components Group.

REVISION HISTORY

Revision

Description

Date

Approval

A

Original Release

04/17/02

R. Stenzel

B

Revised to incorporate 05/11/02

improvements submitted

by users of this manual.

R. Stenzel

C

Revised Figures 1 & 8

to show new positions

of rear DATA IN / DATA OUT

binding posts.

08/26/02

R. Stenzel

D

Revised logo and

name from Northrop

Grumman Component

Technologies, PolyScientific, to Moog

Components Group.

01/20/06

R. Stenzel

LTU Operations Manual

Page i

Rev. D / January 20, 2006

Special Notice

The material contained in this manual is solely for the

information of customers and potential customers

of Moog Components Group, and in no way be

construed to constitute specifications, warranties, or

other contractual terms.

At the time of printing, the information contained in

this document was believed to be accurate to the

best of Moog Components Group knowledge. Moog

Components Group may not be held responsible for

inadvertent errors. Moog Components Group reserves

the right to change the contained information without prior

notice.

This data shall not be disclosed outside the addressee’s

organization and shall not be duplicated, used, or

disclosed, in whole or in part, for any other purpose than

to evaluate, operate, or maintain Moog Components

Group equipment. This restriction does not limit the

addressee’s right to use the information contained herein

if it is obtained from another source without restriction.

The data subject to this restriction is contained in all

pages of this document.

LTU Operations Manual

Page ii

Rev. D / January 20, 2006

Table of Contents

1.0 Introduction .............................................................. 1

1.1 General ...................................................................... 1

1.2 Abbreviations & Definitions ........................................ 2

2.0 Technical Data.......................................................... 3

2.1 Definition .................................................................... 3

2.2 Physical Dimensions .................................................. 3

2.3 Electrical Data ............................................................ 4

2.4 Electrical Interface...................................................... 5

3.0 Design & Functions ................................................. 8

3.1 General ...................................................................... 8

3.2 Mounting .................................................................... 9

3.3 Connections ............................................................... 9

4.0 Operation & Handling .............................................. 10

4.1 General ...................................................................... 10

4.2 Connection & Operation............................................. 10

4.3 Regenerator ............................................................... 11

4.4 Error Indicator ............................................................ 12

4.5 C-Sync Indicator......................................................... 12

4.6 B-Sync Indicator......................................................... 12

4.7 Power Indicator .......................................................... 12

5.0 Maintenance ............................................................. 13

5.1 General ...................................................................... 13

5.1 Cleaning..................................................................... 13

5.3 Inspection................................................................... 13

5.4 Troubleshooting ......................................................... 14

LTU Operations Manual

Page iii

Rev. D / January 20, 2006

List of Figures

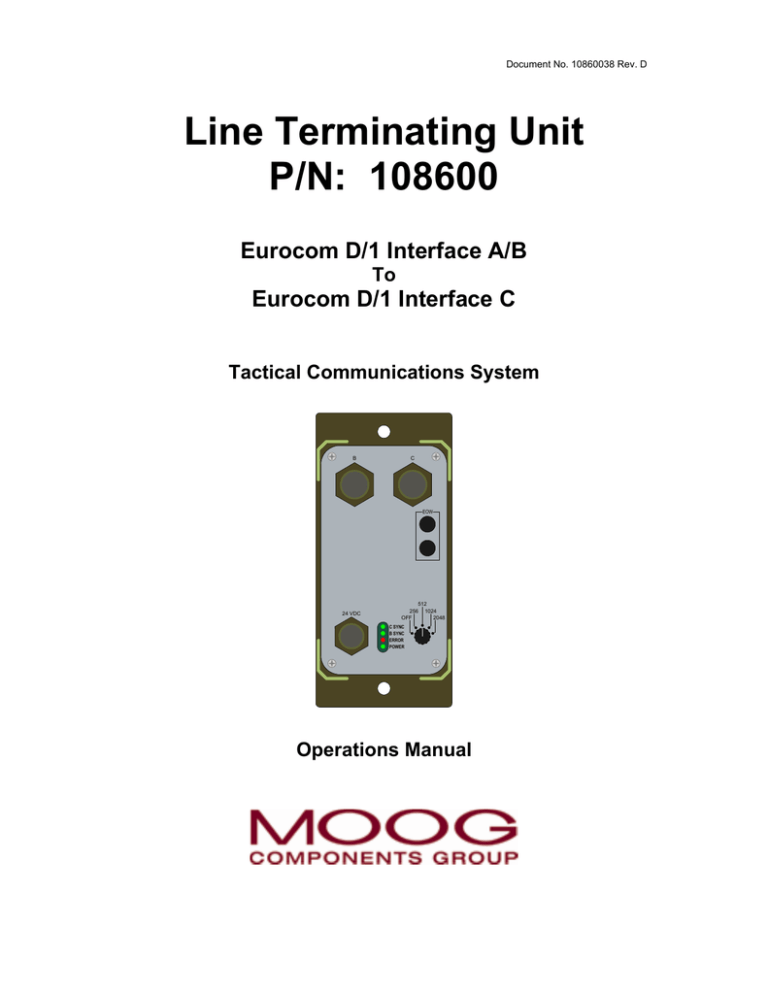

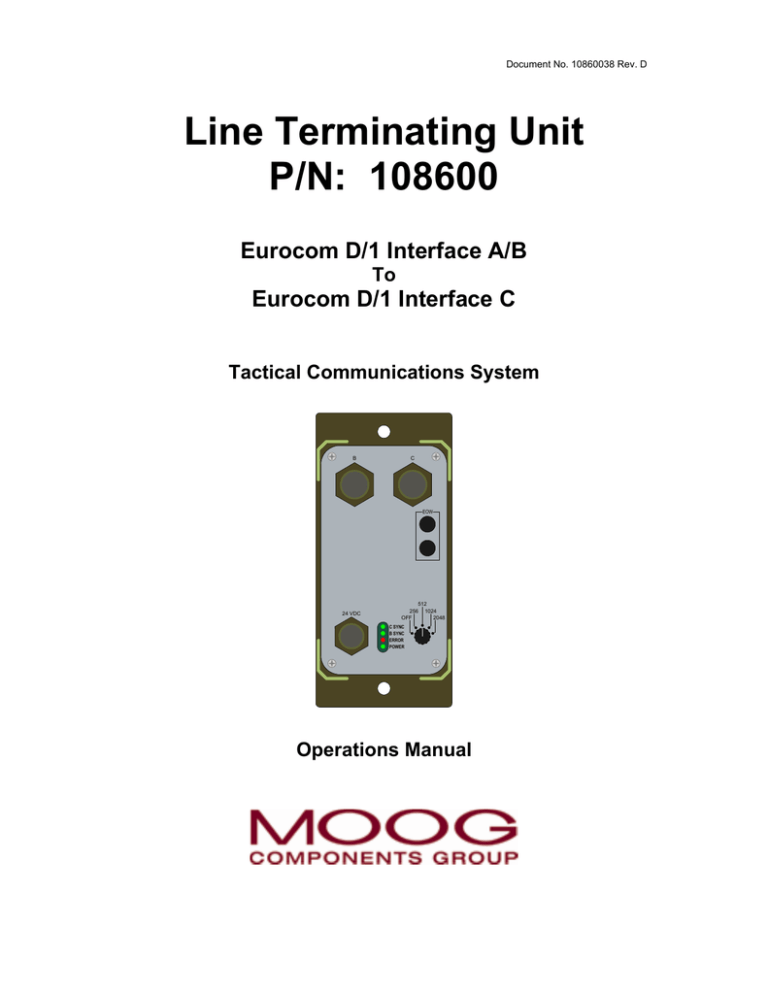

Figure 1: 108600 Line Terminating Unit ......................... 1

Figure 2: B Interface Contact Arrangement .................... 5

Figure 3: C Interface Contact Arrangement.................... 6

Figure 4: Power Supply Contact Arrangement ............... 7

Figure 5: System Interconnect........................................ 8

Figure 6: Rack Mounted (19” Rack)................................ 9

Figure 7: Front Panel...................................................... 10

Figure 8: Connection of Field Cable at Rear .................. 11

Figure 9: Connection of Regenerators............................ 11

Figure 10: Main Troubleshooting Flowchart ..................... 14

Figure 11: Troubleshooting the Power Indicator............... 15

Figure 12: Troubleshooting the B-Sync Indicator ............. 15

Figure 13: Troubleshooting the C-Sync Indicator ............. 16

Figure 14: Troubleshooting the Error Indicator ................. 16

List of Tables

Table 1:

EUROCOM B Interface ................................... 5

Table 2:

EUROCOM C Interface ................................... 6

Table 3:

Power Supply Interface ................................... 7

LTU Operations Manual

Page iv

Rev. D / January 20, 2006

1.0

Introduction

1.1

General

The purpose of this manual is to give the user the

necessary knowledge for connection and operation of

the Line Terminating Unit, part number 108600.

Figure 1: 108600 Line Terminating Unit

LTU Operations Manual

Page 1

Rev. D / January 20, 2006

1.2

Abbreviations & Definitions

AMI

Alternate Mark Inversion, a special

line code used in TDM interface,

EUROCOM A or EUROCOM B.

BFOM

Fiber Optic Modem (FOM) which

provides

electrical

to

optical

conversion

of

EUROCOM

B

electronic communication and data

signals for transmission using

tactical fiber optic cable. For more

information, visit our website at:

www.moog.com/components

EUROCOM

European standard for signaling

between military communications

equipment.

EUROCOM A

Interface for TDM-signaling. Range

of approximately 50 meters on a

multi-pair cable.

EUROCOM B

Encrypted EUROCOM A signal.

EUROCOM C Interface for signaling with a range

of approximately 1000 meters.

HDB-3

High Density Bipolar 3, a special

line code used in the TDM interface,

EUROCOM, with field cable WD1/TT.

LTU

Line Terminating Unit

TDM

Time Division Multiplexing

LTU Operations Manual

Page 2

Rev. D / January 20, 2006

2.0

Technical Data

2.1

Definition

The Line Terminating Unit includes the following:

Part Number

Description

108600

Line Terminating Unit

107715

TDM Signal Cable

108607-01

Power Cable (24 VDC)

10860038

Operations Manual

The 108600 is a unit which converts digital signals

from the EUROCOM A/B interface to the EUROCOM

C interface for full duplex transmission via a maximum

of 1000 meters of new, dry WD-1/TT field cable.

The TDM bit-rate can be selected between 256, 512,

1024, or 2048 kilobits per second.

2.2

Physical Data

4 units fit side-by-side in a standard 19” rack.

Metric

English

Width:

110 mm

4.32 Inches

Height:

235 mm

9.25 Inches

Depth:

89 mm

3.50 Inches

Weight:

1.14 kg

2.5 Pounds

Page 3

Rev. D / January 20, 2006

LTU Operations Manual

2.3

Electrical Data

Time Delay:

<12 bits per second between the

A/B and C interfaces.

Synchronization: Corrects up to ±60 ppm deviation

related to bit-rate.

B-interface:

Balance inputs, AMI-code 256, 512,

1024, or 2048 kilobits per second.

Input line length is 50 meters

maximum.

C-interface

Maximum cable length is 1000

meters with new, dry cable.

Maximum bit-rate error is 1X10-6.

Connection to socket on front panel

or binding posts on the rear of the

unit.

Power supply:

24 VDC nominal, 12 to 36 VDC Max

(independent of polarity)

Power

consumption:

5 Watts Maximum

Operation temp: -40°C to +55°C

Storage temp:

-55°C to +70°C

EOW:

Connection for field telephone (LB).

LTU Operations Manual

Page 4

Rev. D / January 20, 2006

2.4

Electrical Interface

Table 1: EUROCOM B Interface

Pin

E

F

G

H

J

K

L

M

V

A, B, C, D, N, P,

R, S, T, & U

B

C

D

A

P

R

E

F

V

M

L

U

T

G

No Connection

M

N

S

Function

Data Tx (a)

Data Tx (b)

Data Rx (a)

Data Rx (b)

Clock Tx (a)

Clock Tx (b)

Clock Rx (a)

Clock Rx (b)

Shield

L

K

K

J

N

U

J

H

B

P

V

T

H

LTU CONNECTOR:

AMPHENOL 71-533724-19S

A

C

R

S

G

D

E

F

MATING CONNECTOR:

MS3126F14-19P

Figure 2: B Interface Contact Arrangement

LTU Operations Manual

Page 5

Rev. D / January 20, 2006

2.4

Electrical Interface (continued)

Table 2: EUROCOM C Interface

Pin

A

B

C

D

E, F, G, H, J, K,

L, M, N, P, R, S,

T, U, & V

B

C

D

A

P

R

E

F

V

M

L

U

T

G

No Connection

M

N

S

Function

Data Tx

Data Tx

Data Rx

Data Rx

L

K

K

J

N

U

J

H

B

P

V

T

H

LTU CONNECTOR:

AMPHENOL 71-533724-19S

A

C

R

S

G

D

E

F

MATING CONNECTOR:

MS3126F14-19P

Figure 3: C Interface Contact Arrangement

LTU Operations Manual

Page 6

Rev. D / January 20, 2006

2.4

Electrical Interface (continued)

Table 3: Power Supply Interface (24VDC)

Pin

Function

A

DC Input (polarity independent)

B

Case Ground

C

DC Input (polarity independent)

C

A

A

C

B

B

LTU CONNECTOR:

AMPHENOL 71-533723-03P

MATING CONNECTOR:

MS3126F14-19S

Figure 4: Power Supply Contact Arrangement

LTU Operations Manual

Page 7

Rev. D / January 20, 2006

3.0

Design & Functions

3.1

General

The 108600 is a rugged, light weight transmission unit

for Eurocom networks, which converts digital signals

from EUROCOM A/B to EUROCOM C and visa

versa. It is used when the distance between relevant

equipment units is too long for EUROCOM A/B

transmissions, or when standard cable lengths are too

short. It is also used when equipment units with

different interface types are to be connected.

Note!

If EUROCOM A is connected directly to the

108600, this will operate as EUROCOM B,

but without encryption.

Engineering

Order Wire

B

Telephones

PTT / PBX

Terminals

Switches

Engineering

Order Wire

C

B

C

EOW

EOW

BFOM,

Radio,

or

Radio Relay

MUX

or

Switch

24 VDC

512

256 1024

OFF

2048

24 VDC

C SYNC

B SYNC

ERROR

POWER

EUROCOM A/B

512

256 1024

OFF

2048

C SYNC

B SYNC

ERROR

POWER

EUROCOM C

EUROCOM A/B

Figure 5: System Interconnect

When transmitting at the highest bit rate (2048 kbits/s)

and with the use of a dry field cable, the cable length

can be up to 1000 meters. At lower bit rates, the

cable length may be increased.

LTU Operations Manual

Page 8

Rev. D / January 20, 2006

3.2

Mounting

The 108600 is primarily used in mobile installations

and has therefore a mechanical construction which is

prepared for field vehicle mounting and / or transport.

Four units can be mounted side by side in a 19” rack.

B

C

B

C

EOW

24 VDC

512

256 1024

OFF

2048

C SYNC

B SYNC

ERROR

POWER

B

C

EOW

24 VDC

512

256 1024

OFF

2048

C SYNC

B SYNC

ERROR

POWER

B

C

EOW

24 VDC

512

256 1024

OFF

2048

EOW

24 VDC

C SYNC

B SYNC

ERROR

POWER

512

256 1024

OFF

2048

C SYNC

B SYNC

ERROR

POWER

Figure 6: Rack Mounted (19” Rack)

3.3

Connections

The 108600 is easily connected to the rest of

the communications network. Adjustments are not

necessary to make the unit operative.

All operations are done at the front panel. Connection

of field cable (EUROCOM C) is done through the

binding posts for data in / out at the rear of the unit.

All other connections are on the front panel.

LTU Operations Manual

Page 9

Rev. D / January 20, 2006

4.0

Operation & Handling

4.1

General

All connections / controls are clearly marked. All

connections shall be made before the 108600 is

switched ON. Protection caps shall be on, and

ON/OFF knob switched to the OFF position when the

unit is not in use.

4.2

Connection & Operation

Take the protection caps off and connect the 108600

as shown in Figures 7 and 8.

A/B Interface (In / Out)

Connect to switch, radio

link or multiplexer. Cable

length is 50 meters max.

B

C Interface (In / Out)

Parallel in/out connection

with rear panel field cable

connection.

Length is

maximum 1000 meters of

dry field cable.

C

EOW

Engineering Order Wire

Connection for field

telephone

24 VDC

24 Volts DC

Connection to

power supply

512

256 1024

OFF

2048

C SYNC

B SYNC

ERROR

POWER

Indicator LED's

C Sync: Shall be lit

B Sync: Shall be lit

Error: Shall not be lit

Power: Lights when ON

ON/OFF Switch

Selector switch

for TDM bitrate

Figure 7: Front Panel

LTU Operations Manual

Page 10

Rev. D / January 20, 2006

Line Data In / Out

C Interface

Maximum length:

1000 meters of

dry field cable

LINE TERMINIATING UNIT

CUST PN

REV

CAGE

DATE

______________ MFG PN 108600

______________

REV

--______________

CAGE 1K426

MM/YY

SN 1001

POLY-SCIENTIFIC

SPRINGFIELD, PA 19064

LINE TERMINATING UNIT

CUST PN

REV

CAGE

DATE

______________ MFG PN 108600

______________

REV

--______________

CAGE 1K426

MM/YY

SN 1001

POLY-SCIENTIFIC

SPRINGFIELD, PA 19064

MADE IN U.S.A.

MADE IN U.S.A.

CAUTION:

CONTAINS PARTS AND ASSEMBLIES

SUSCEPTIBLE TO DAMAGE BY

ELECTROSTATIC DISCHARGE (ESD)

CAUTION:

CONTAINS PARTS AND ASSEMBLIES

SUSCEPTIBLE TO DAMAGE BY

ELECTROSTATIC DISCHARGE (ESD)

LINE

DATA OUT

LINE

DATA IN

DATA OUT

Data in

DATA IN

Data out

Data out

Data in

Figure 8: Connection of Field Cable at Rear

4.3

Regeneration

If a field cable of more than 1000 meters is needed, a

regenerator consisting of two 108600’s must be

connected to the field cable after the first 1000 meters.

A power supply of 24 Volts DC must be available for

each unit. See Figure 9 for connection details.

Short cable connected between B Interface connections

B

C

B

C

EOW

Maximum

1000 meters

field cable

24 VDC

EOW

512

256 1024

OFF

2048

24 VDC

C SYNC

B SYNC

ERROR

POWER

512

256 1024

OFF

2048

Maximum

1000 meters

field cable

C SYNC

B SYNC

ERROR

POWER

24 Volts DC

Figure 9: Connection of Regenerators

LTU Operations Manual

Page 11

Rev. D / January 20, 2006

4.4

Error Indicator

When the 108600 detects bit errors from the

EUROCOM C line, the error indicator (Red LED) in

the window on the front panel will light up for one

second after detection of the last bit error. Therefore

the LED may be constantly lit, even at a relatively low

bit error rate.

Even if the error indicator is constantly lit, it does not

necessarily have any significance for the ongoing

data transmission.

The error indicator will be constantly lit in the absence

of EUROCOM C signals, or if there is physical

damage to the EUROCOM C line (field cable).

4.5

C-Sync Indicator

The C-Sync indicator (Green LED) in the window on

the front panel will light up when synchronization is

obtained on the EUROCOM C line.

4.6

B-Sync Indicator

The B-Sync indicator (Green LED) in the window on

the front panel will light up when synchronization is

obtained on the EUROCOM A/B line.

4.7

Power Indicator

The Power indicator (Green LED) in the window on

the front panel will light up when 24 Volts DC is

applied and the unit is switched on.

LTU Operations Manual

Page 12

Rev. D / January 20, 2006

5.0

Maintenance

5.1

General

Maintenance of the 108600 is limited to 1st echelon

maintenance. If the unit fails, it is not to be opened in

the field, but shall be returned for 3rd or 4th echelon

maintenance and troubleshooting.

5.2

Cleaning

The surface of the 108600 and connection cables are

to be cleaned with a soft cloth dampened with water.

Detergents and solvents are not to be used.

Cleaning of the electrical contacts may be made with

a dry brush or cloth. Contact cleanser may be used

when necessary.

5.3

Inspection

Check that the ON / OFF switch is working properly.

Connectors on the front panel that are not in use shall

have protective caps put on. The window on the front

panel shall be free from cracks or other defects, and

shall be transparent.

The cables shall be in good condition and not have

any cracks in the insulation, sharp bends, or be

otherwise damaged. The connectors shall be clean

and secure to their cables. Connector pins shall not

be bent or damaged, sockets shall be void of debris

and contaminants.

LTU Operations Manual

Page 13

Rev. D / January 20, 2006

5.4

Troubleshooting

Refer to Figure 10 through Figure 14 and follow the

procedures specified in the Troubleshooting flowcharts

to isolate the failure in the communications link.

Start

Power

Indicator Lit

NO

YES

Inspect power cable

and replace if

damaged. Clean

connector contacts

Power

Indicator Lit

NO

See Figure 11,

Troubleshooting

the

Power Indicator

NO

See Figure 12,

Troubleshooting

the

B-Sync Indicator

NO

See Figure 13,

Troubleshooting

the

C-Sync Indicator

YES

See Figure 14,

Troubleshooting

the

Error Indicator

YES

B-Sync

Indicator Lit

NO

YES

Inspect B Interface

cable and replace if

damaged. Clean

connector contacts.

B-Sync

Indicator Lit

YES

C-Sync

Indicator Lit

NO

YES

Check field wire

connections.

Re-terminate if

necessary.

C-Sync

Indicator Lit

YES

Error

Indicator Lit

YES

NO

Check field wire

connections.

Re-terminate if

necessary.

Error

Indicator Lit

NO

Unit Functioning

properly - No

further action

required

Figure 10: Main Troubleshooting Flowchart

LTU Operations Manual

Page 14

Rev. D / January 20, 2006

Continued from

Figure 10

Measure VDC at

power connector

pins "A" and "C"

12 - 36 VDC

present

NO

Troubleshoot

power source

YES

Return LTU for

repair

Figure 11: Troubleshooting the Power Indicator

Continued from

Figure 10

C-Sync

Indicator Lit

YES

Connect a

loopback on the

LTU B-Interface.

B-Sync

Indicator Lit

NO

Subtitute

near-end signal

source

YES

Troubleshoot

near-end signal

source

NO

B-Sync

Indicator Lit

NO

Return LTU for

repair

YES

Continue at

"START" in

Figure 10

Figure 12: Troubleshooting the B-Sync Indicator

LTU Operations Manual

Page 15

Rev. D / January 20, 2006

Continued from

Figure 10

Disconnect the

field cable from

the LTU

Connect a

loopback on the

C Interface.

C-Sync

Indicator Lit

NO

Return LTU for

repair

YES

Troubleshoot

field wire or far

end C Interface

Figure 13: Troubleshooting the C-Sync Indicator

Continued from

Figure 10

Disconnect the

field cable from

the LTU

Connect a

loopback on the

C Interface.

Error

Indicator Lit

YES

Return LTU for

repair

YES

Errors are

present at an

acceptable rate

(<1 X 10-6)

NO

Re-connect the

field cable to the

LTU

LTU

B-Output

data OK

NO

Troubleshoot

field wire or far

end C Interface

Figure 14: Troubleshooting the Error Indicator

LTU Operations Manual

Page 16

Rev. D / January 20, 2006

Feedback Form

Mail to: Moog Components Group

Attention: Customer Service

750 West Sproul Road

Springfield, PA 19064-4084

USA

From:

Reference Product:

Reference Document:

Comments / Recommendations:

Signature:

Date:

Use this form (add additional pages as necessary) to submit comments and

recommendations for product improvement, or to request additional information.

LTU Operations Manual

Feedback Form

Rev. D / January 20, 2006