Effects of oxygen content on ybco josephson junction structures

advertisement

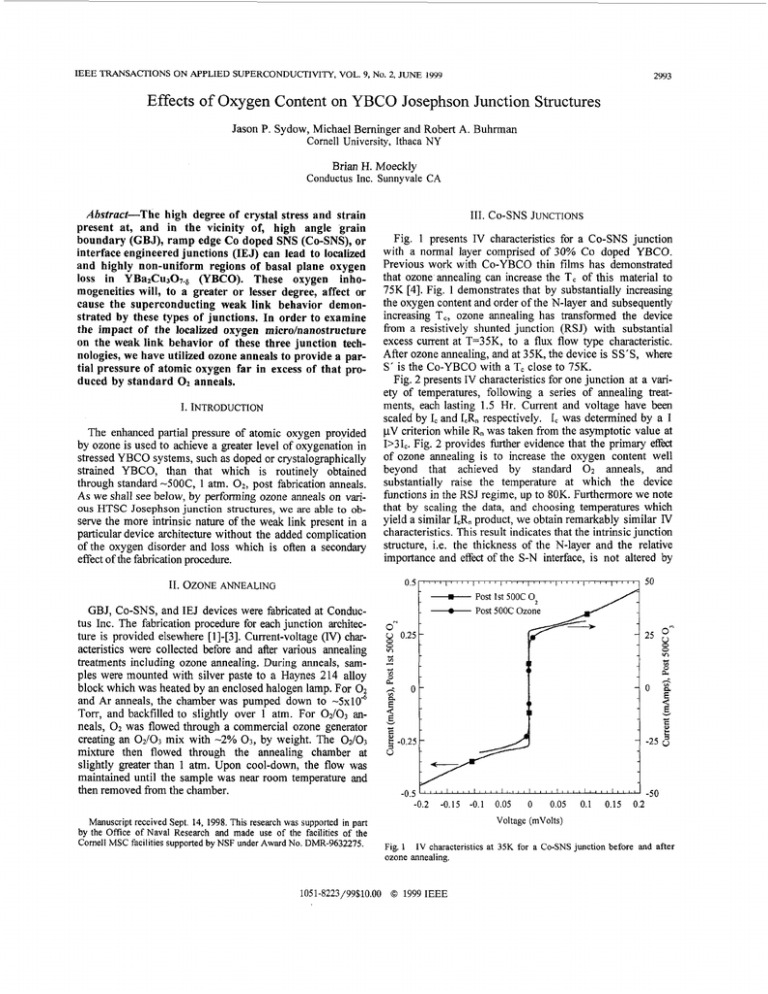

IEEE TRANSACTIONS ON APPLIED SUPERCONDUCTIVITY, VOL. 9, No. 2, JUNE 1999 2993 Effects of Oxygen Content on YBCO Josephson Junction Structures Jason P. Sydow, Michael Berninger and Robert A. Buhrman Cornell University, Ithaca NY Brian H. Moeckly Conductus Inc. Sunnyvale CA Abstract-The high degree of crystal stress and strain present at, and in the vicinity of, high angle grain boundary (GBJ), ramp edge COdoped SNS (CO-SNS),or interface engineered junctions (IEJ) can lead to localized and highly non-uniform regions of basal plane oxygen loss in YBa2Cu30,.6 (YBCO). These oxygen inhomogeneities will, to a greater or lesser degree, affect or cause the superconducting weak link behavior demonstrated by these types of junctions. In order to examine the impact of the localized oxygen microhanostructure on the weak link behavior of these three junction technologies, we have utilized ozone anneals to provide a partial pressure of atomic oxygen far in excess of that produced by standard O2 anneals. I. INTRODUCTION The enhanced partial pressure of atomic oxygen provided by ozone is used to achieve a greater level of oxygenation in stressed YBCO systems, such as doped or crystalographically strained YBCO, than that which is routinely obtained through standard -5OOC, 1 atm. 0 2 , post fabrication anneals. As we shall see below, by performing ozone anneals on various HTSC Josephson junction structures, we are able to observe the more intrinsic nature of the weak link present in a particular device architecture without the added complication of the oxygen disorder and loss which is often a secondary effect of the fabrication procedure. 111. CO-SNSJUNCTIONS Fig. 1 presents IV characteristics for a CO-SNS junction with a normal layer comprised of 30% CO doped YBCO. Previous work with CO-YBCO thin films has demonstrated that ozone annealing can increase the T, of this material to 75K [4]. Fig. 1 demonstrates that by substantially increasing the oxygen content and order of the N-layer and subsequently increasing T,, ozone annealing has transformed the device f?om a resistively shunted junction (RSJ) with substantial excess current at T=35K, to a flux flow type characteristic. After ozone annealing, and at 35K, the device is SS'S, where S' is the CO-YBCOwith a T, close to 75K. Fig. 2 presents IV characteristics for one junction at a variety of temperatures, following a series of annealing treatments, each lasting 1.5 Hr. Current and voltage have been scaled by I, and I,R, respectively. I, was determined by a 1 pV criterion while R, was taken from the asymptotic value at P31,. Fig. 2 provides further evidence that the primary eEct of ozone annealing is to increase the oxygen content well beyond that achieved by standard 0 2 anneals, and substantially raise the temperature at which the device functions in the RSJ regime, up to 80K. Furthermore we note that by scaling the data, and choosing temperatures which yield a similar I,R, product, we obtain remarkably similar IV characteristics. This result indicates that the intrinsic junction structure, i.e. the thickness of the N-layer and the relative importance and effect of the S-N interface, is not altered by 0.5 11. OZONE ANNEALING GBJ, CO-SNS, and IEJ devices were fabricated at Conductus Inc. The fabrication procedure for each junction architecture is provided elsewhere [ 11-[3]. Current-voltage (IV) characteristics were collected before and after various annealing treatments including ozone annealing. During anneals, samples were mounted with silver paste to a Haynes 214 alloy block which was heated by an enclosed halogen lamp. For O2 and Ar anneals, the chamber was pumped down to -Sx104 Torr, and backfilled to slightly over 1 atm. For 0 2 / 0 3 anneals, O2 was flowed through a commercial ozone generator creating an 0 2 / 0 3 mix with -2% 0 3 , by weight. The 0dO3 mixture then flowed through the annealing chamber at slightly greater than 1 atm. Upon cool-down, the flow was maintained until the sample was near room temperature and then removed from the chamber. Manuscript received Sept. 14, 1998. This research was supported in part by the Office of Naval Research and made use of the facilities of the Cornell MSC facilities supported by NSF under Award No. DMR-9632275. 1051-8223/99$10,00 ' - ~ ~ ~ I ~ I ~ II , *I *I ~ ~ ~ / ~ ~I ~ I ~50 J ~ ~ Post 1st 500C O2 Post 500C Ozone - 25 On 0 'I I) - 0 a A B E 5 I - -25 -0.5"""""'""'""'""'""'""""' -0.2 -0.15 -0.1 0.05 0 0.05 i? 5 -50 0.1 0.15 0.2 Voltage (mVolts) Fig. 1 IV characteristics at 35K for a CO-SNSjunction before and after ozone annealing. 0 1999 IEEE I I ~ ~ 2994 t _t_ 3 2 . IcRn.We also note that the fust 1.5 Hr., 500C 0 2 anneal is insufficient to return the junction to the as deposited state. Additional time at 500C in O2 is required to complete the oxygen loss necessary to regain the initial conditions. 35K, Post 1st 500C O2 80K, Post 500C Ozone JUNCTIONS IV. GRAINBOUNDARY The typical effect of ozone annealing on the IV characteristic for a GBJ at 4.2K (5 pm wide, -200 nm thick, misorientation angle -23") is demonstrated in Fig. 4. I, increased from 0.80 mA to 1.78 mA while R, decreased from 1.63 to 0.57 C2 for a net decrease in I,R, product ftom 1.31 to 1.02 mV. The general similarity of I,R, products in spite of the: more dramatic change in I, and R, is clarified in Fig. 5 which. portrays scaled IV characteristics for the same data. Again, E; in the case for CO-SNS junctions, the scaled data agrees; c 1 0 . 0 , , , , , , , , , , , , , , , , , , , , , , ,, ' , ,, , " ' , -10.0 " -8.0 ' i / " -6.0 ' - Post 500 C Ozone Anneal ~ " -4.0 ' ~ " -2.0 ' ~ " 0 ' ~ " 2.0 ' ~ 4.0 " ' i " 6.0 ' 8.0 Voltage (mVolts) Fig. 4 1V characteristics at 4.2K for a GBJ before and after ozone annealing at 500C for 1.5 Hours. 6 Post Ist500C02 Post500COzone EB A - - 4 - 2l Post 3rd 500C O2 !- 2 - 4 . +- 5 5 U 0 - - - - - - m- - - - Post 500 C O2 Anneal Post 500 C Ozone Anneal r./ -2 -4 20 30 40 50 60 Temperature (K) 70 80 90 Fig. 3 I,R, versus Temperature for three CO-SNS junctions following a series of O2 and ozone anneals. -6 Fig. 5 Scaled IV characteristics at 4.2K for the GBJ portrayed in Fig. 4. 2995 before and after ozone annealing. We attribute this to the fhct that the GBJ consists of at least two components; a relatively immutable barrier layer closely associated with the physical grain boundary which does not substantially change with ozone annealing, and regions of de-oxygenated YBCO on either side of the grain boundary which impact I, and R,, but not I,R, and the intrinsic RSJ behavior of the device. An important difference between the CO-SNSand GBJ devices is that the operating temperature is not affected by ozone annealing as demonstrated by Fig. 6 which portrays IcRn versus temperature after a series of anneals. This figure demonstrates that I,R, is relatively constant across the entire temperature range before and after ozone annealing. I,R, only begins to decrease with the substantial amount of oxygen loss induced by the 250 and 300C Ar anneals. Following these Ar anneals the 1,'s have substantially decreased to 116 and 33 pA respectively. The consistency of the I,R, product across a broad range of values for J, is portrayed in Fig. 7. The scaling of 1,R, with J, in the lower J, region has been observed in previous investigations, and has been attributed to a variety af mechanisms [ 11, [5-71. The newly observed plateau behavior for I,R, in the case of optimally and nearly optimally oxygenated devices can be explained by the limiting effect of the intrinsic barrier in the immediate vicinity of the grain boundary, which is not altered by ozone annealing. The eff'ect of ozone annealing is to increase the amount of completely oxygenated YBCO material adjacent to the grain boundary, and thus increase the effectivejunction area, which increases I, and decreases R, while holding I,R, constant. As de-oxygenation of the grain boundary continues with Ar anneals at higher temperatures, the volume of oxygen deficient YBCO spreads outwardly in a non-uniform manner from the grain boundary, eventually thickening the barrier, and decreasing the 1,R. product. It is important to note that 1-10 pm wide GBJ's have shown similar plateau behavior when oxygenated by ozone annealing and electromigration. The independence of junction width on the plateau discounts explanations 1400 I , . , ;.., 1000 I , , , I , , , I , e A a a 61 , , I , , Post 1st 500C O2 Post SOOC Ozone Post 2nd 500C 0 Post 250C Argon Post 300C Argon Post 5OOC Ozone Post 2nd 500C O2 - - d 100 = Post 2SOC Argon Post300CArgon ! Post325CArgon I v ,%b N h]' ' 10 " ' 1 ' 1 ' 1 ' ' " ' t l l ' l " " ' 1 ' 1 ' """' ' " ' , 1 1 1 1 , 1 h 1 v 'i 600 .. fl A*. e w * .? ../ -3 0 20 40 60 Temperature (K) 80 100 Fig. 6 I,R, versus temperature for a single GBJ following a series of anneals. 02 and 0 2 / 0 3 anneal were conducted for 1.5 Hr. while Argon anneals were lengthened to 3 Hr. -3 ~ ~ -2 ~ -1 " ~ " 0 Voltage / IcRn 1 " ~ 2 " " 3 Fig. 8 Scaled 4.2K IV characteristics for an IEJ before and after ozone annealing. ~ " " ~ 2996 fi-om 2.32 to 0.45 Ohms, and I,R, remains relatively constant, increasing from 1.51 to 1.56 mV. There is an increase in excess current following ozone annealing, but the RSJ behavior is largely unchanged. Fig. 9 portrays the I,R, product versus J, at 4.2K for all five junctions on the test chip which contained the device discussed above. A plateau behavior, reminiscent of that observed in GBJ’s is present, but with less data supporting its existence. The I,R, product is substantially more robust under ozone anneal than was the case for CO-SNS devices, indicating that like the GBJ’s, the IEJ’s contain a robust barrier layer which induces some secondary oxygen loss in the adjacent electrode that in turn affects the I, and R, of the junction. Fig. 10 portrays I,R, versus J, data for a separate test chip with a higher average I,, presumably due to a thinner barrier layer. In this case a series of 3 hr. Ar anneals were used to gradually de-oxygenate the IEJ’s following an initial ozone anneal. It is interesting to note that temperature excursions as mild as 175C are sufficient to induce oxygen loss in the highly oxygenated, ozone annealed samples as demonstrated by the factor of 4 decrease in J, for the devices. A similar susceptibility to oxygen loss at such moderate temperatures following optimal or near optimal oxygenation through ozone annealing is observed in Fig. 7 for GBJ’s and has been reported for CO-YBCOthin films [4]. This behavior appears to be common in a variety of stressed YBCO systems. An initial plateau behavior for this set of devices is actually surpassed through the effects of ozone annealing. This indicates that complete oxygenation of the electrode material may not be possible even with the elevated partial pressure of atomic oxygen provided by ozone, e.g. a higher I,R, plateau at -1.5 mV similar to that observed in Fig. 9 may exist. 2 - 0.5 0.4 0.3 E3 0 I t. H 8 .I ’ I I A I I IO‘ Rig. 9 I I 1o6 1Oj Jc (Amps/cm2) I,R, versus J, for five separate IEJ’s at 4.2K. Chip #L97357 1 I . 8 - E3 I I As Fabricated As Delivered Post 500COzone Post 150CAr Q . + B A N,,’ -f-- -tx-iF a @ o A ~ ----- -. h c 1 3 a 0 ’ 0 A Post 175C Ar Post200CAr v Post225CAr Post250CAr tx ANDCONCLUSIONS VI. DISCUSSION The ability to examine and compare various HTSC As Fabricated As Delivered Post 500C Ozone P0St500Co2 7,‘ I Josephson junction architectures independent of substantial variations in oxygen content, common in these structures, is necessary in order to accurately determine the most appropriate technology for a given application. We have shown that three different types of HTSC junctions behave differently, especially when comparing GBJ and IEJ to CO-SNS junctions. The operating temperature in which a CO-SNS junction will demonstrate RSJ behavior is highly dependent upon oxygen content. Once at an appropriate temperature for RSJ operation, scaled IV characteristics obtained for widely varying levels of oxygenation are similar; remarkably, even the amount of excess current scales. GBJ’s, on the other hand, maintain RSJ like behavior over a wide range of temperatures and oxygen content. After ozone annealing a greater number of optimally oxygenated regions of the YBCO electrodes make contact with the intrinsic barrier localized at the grain boundary. The consistency of the I,Rn product is attributed to a model in which the effective area of the junction is increased as the oxygen content is increased. A similar behavior is observed for IEJ’s, but in this case it is not clear that an oxygen saturation of the YBCO electrodes can be achieved for all critical current densities and barrier thicknesses. 1000 1 I 10‘ 1o5 I Jc (Amps/crn2) Fig. 10 I,R. versus J, for five separate IEJ’s at 4.2K Chip #L97359 REFERENCES [I] R. Gross, P. Chaudhari, M. Kawasaki and A. Gupta, Pbys. Rev. B, vol. 42, p. 10735, 1990 [2] K. Char, L. Antognazza and T.H. Geballe, Appl. Pbys. Lett., vol. 65, p. 904, 1994. [3] B.H. Moeckly and K. Char, Appl. Phys. Lett., vol. 71, p. 2526, 1997. [4] J.P. Sydow, R.A. Buhrman and B.H. Moeckly, Appl. Pbys. Lett., vol. 72, pp. 3512-3514, 1998. [5] S.E. Russek, D.K. Lathrop, B.H. Moeckly, R.A. Buhrman, D.H. Shin and J. Silcox, Appl. Pbys. Lett., vol. 57, pp, 1155-57, 1990. [6] H. Hilgenkamp and J. Mannhart, Appl. Phys. Lett., vol. 73, p. 265, 1998 [7] R. Gross and B. Mayer, Pbysrca C, vol. 180, p. 235, 1991