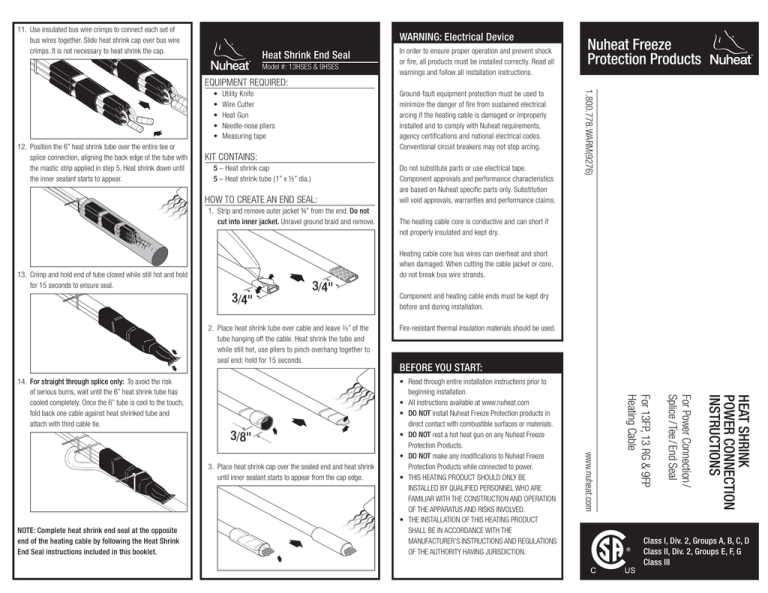

11. Use insulated bus wire crimps to connect each set of

bus wires together. Slide heat shrink cap over bus wire

crimps. It is not necessary to heat shrink the cap.

WARNING: Electrical Device

Heat Shrink End Seal

Model #: 13HSES & 9HSES

In order to ensure proper operation and prevent shock

or fire, all products must be installed correctly. Read all

warnings and follow all installation instructions.

Nuheat Freeze

Protection Products

EQUIPMENT REQUIRED:

12. Position the 6” heat shrink tube over the entire tee or

splice connection, aligning the back edge of the tube with

the mastic strip applied in step 5. Heat shrink down until

the inner sealant starts to appear.

Utility Knife

Wire Cutter

Heat Gun

Needle-nose pliers

Measuring tape

Ground-fault equipment protection must be used to

minimize the danger of fire from sustained electrical

arcing if the heating cable is damaged or improperly

installed and to comply with Nuheat requirements,

agency certifications and national electrical codes.

Conventional circuit breakers may not stop arcing.

KIT CONTAINS:

5 – Heat shrink cap

5 – Heat shrink tube ( 1” x ½” dia.)

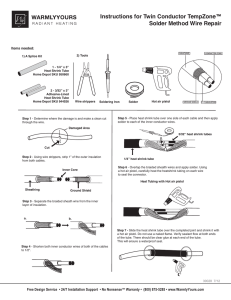

HOW TO CREATE AN END SEAL:

1. Strip and remove outer jacket ¾” from the end. Do not

cut into inner jacket. Unravel ground braid and remove.

The heating cable core is conductive and can short if

not properly insulated and kept dry.

Heating cable core bus wires can overheat and short

when damaged. When cutting the cable jacket or core,

do not break bus wire strands.

13. Crimp and hold end of tube closed while still hot and hold

for 15 seconds to ensure seal.

2. Place heat shrink tube over cable and leave 3/8” of the

tube hanging off the cable. Heat shrink the tube and

while still hot, use pliers to pinch overhang together to

seal end; hold for 15 seconds.

BEFORE YOU START:

HEAT SHRINK

POWER CONNECTION

INSTRUCTIONS

• Read through entire installation instructions prior to

beginning installation.

• All instructions available at www.nuheat.com

• DO NOT install Nuheat Freeze Protection products in

direct contact with combustible surfaces or materials.

• DO NOT rest a hot heat gun on any Nuheat Freeze

Protection Products.

• DO NOT make any modifications to Nuheat Freeze

Protection Products while connected to power.

• THIS HEATING PRODUCT SHOULD ONLY BE

INSTALLED BY QUALIFIED PERSONNEL WHO ARE

FAMILIAR WITH THE CONSTRUCTION AND OPERATION

OF THE APPARATUS AND RISKS INVOLVED.

• THE INSTALLATION OF THIS HEATING PRODUCT

SHALL BE IN ACCORDANCE WITH THE

MANUFACTURER’S INSTRUCTIONS AND REGULATIONS

OF THE AUTHORITY HAVING JURISDICTION.

www.nuheat.com

3. Place heat shrink cap over the sealed end and heat shrink

until inner sealant starts to appear from the cap edge.

Fire-resistant thermal insulation materials should be used.

For Power Connection /

Splice / Tee / End Seal

Component and heating cable ends must be kept dry

before and during installation.

For 13FP, 13 RG & 9FP

Heating Cable

14. For straight through splice only: To avoid the risk

of serious burns, wait until the 6” heat shrink tube has

cooled completely. Once the 6” tube is cool to the touch,

fold back one cable against heat shrinked tube and

attach with third cable tie.

NOTE: Complete heat shrink end seal at the opposite

end of the heating cable by following the Heat Shrink

End Seal instructions included in this booklet.

Do not substitute parts or use electrical tape.

Component approvals and performance characteristics

are based on Nuheat specific parts only. Substitution

will void approvals, warranties and performance claims.

1.800.778.WARM (9276)

•

•

•

•

•

Class I, Div. 2, Groups A, B, C, D

Class II, Div. 2, Groups E, F, G

Class III

Heat Shrink

Power Connection

Model #: 13HSPC & 9HSPC

EQUIPMENT REQUIRED:

•

•

•

•

•

Utility knife

Wire cutter

Multi-head screwdriver

Pipe wrench

Wire stripper — optional

•

•

•

•

Measuring tape

Crimp tool

Heat gun

Needle-nose pliers

5. Lightly score around and down the inner jacket 6.5”

from the end of the heating cable and remove.

6. Remove 1 ½” of the conductive core from the tip of the

cable exposing the bus wires. Cut down the center of

the conductive core to separate the two bus wires. Trim

away just enough conductive core to allow the bus wire

to fit in a black heat shrink tube.

NOTE: Repeat steps 1 to 4 for each cable section.

Heat Shrink Splice / Tee

Model #: 13HSST & 9HSST

EQUIPMENT REQUIRED:

•

•

•

•

Utility knife

Wire cutter

Wire stripper — optional

Measuring tape

• Crimp tool

• Heat gun

• Needle-nose pliers

5. Stretch and wrap a mastic strip around the outer jacket

on each heating cable section, 1” from inner jacket cut.

6. Wrap a mastic strip around the heating cable extending

¼” past the end.

KIT CONTAINS:

ADDITIONAL MATERIALS REQUIRED:

• Certified junction box for suitable location

KIT CONTAINS:

3 – Wire nuts

2 – 1” black heat shrink tubes

2 – Black bus wire heat shrink tubes

1 – Green / Yellow ground wire heat shrink tube

1 – End seal heat shrink cap

1 – Compression washer, grommet & sealing gasket

1 – Lock nut

1 – Caution label (End seal)

7. Slide a black heat shrink tube over each trimmed bus wire

until the tube meets the inner jacket. Heat shrink.

8. Slide green / yellow heat shrink tube over pigtailed braid

and heat shrink.

9. Slide the 1” heat shrink tube over both covered bus wires

until the tube meets the outer jacket. Heat shrink until

inner sealant flows from both ends. Using pliers, pinch

tube between the two bus wires and hold for 15 seconds.

HOW TO CREATE A TEE / SPLICE:

NOTE: All illustrations show a tee connection. To perform a

splice, follow all instructions using only 2 heating cables.

1. Allow 12” of extra heating cable. Trim cables evenly.

HOW TO CREATE A POWER CONNECTION:

NOTE: Nuheat recommends conducting continuity

testing at this point of the installation.

1. Slide the compression washer, sealing gasket and

grommet onto cable.

6 – Mastic strips

3 – Cable ties

3 – End seal heat shrink caps

2 – 1” black heat shrink tubes

2 – Insulated bus wire crimps

2 – Caution labels (End seal & Splice / Tee)

1 – Un-insulated braid crimp (copper)

1 – Over-jacket heat shrink tube (6” long)

1 – Black cloth tape (6” long)

4. Position braid on one side of cable and twist into a pigtail.

7. Align the heating cable sections together; ensure all

braids are on the same side of the cables. Press mastic

strips firmly together and fasten cable ties 6” and 9”

from end.

8. Twist together braid pigtails and slide un-insulated

braid crimp to within ¼” of cable. Compress the

un-insulated braid crimp and remove excess pigtail.

10. Slide compression washer, grommet and sealing gasket

over heat shrinked wires.

2. At the end of the cable, strip away 2” of outer jacket.

Do not cut into inner jacket.

2. Lightly score around and down outer jacket 7” from the

end of the heating cable. Bend heating cable to break

jacket at score; peel off outer jacket.

3. Push back braid to loosen. Spread apart braid, bend the

heating cable and work it through the opening in the braid.

11. Insert the heating cable into a junction box approved for

the application. Use the sealing gasket and lock nut to

securely connect the cable to the junction box.

12. Make the final electrical connections within the junction

box and ensure the box is sealed in accordance to

manufacturer’s instructions.

3. Unravel the braid back to outer jacket. Position braid to

one side of the heating cable section.

9. Fold the crimped braid back against the heating cables.

Wrap cloth tape evenly around un-insulated braid crimp

and heating cables covering crimp completely.

10. Select one bus wire from each cable and twist together.

Repeat with remaining bus wires (do not twist bus wires

from the same cable together).

4. At the end of the cable, strip away 1” of inner jacket

and remove conductive core, exposing bus wires.

NOTE: Complete heat shrink end seal at the opposite

end of the heating cable by following the Heat Shrink

End Seal instructions included in this booklet.

NOTE: Nuheat recommends conducting continuity

testing at this point of the installation.

Copyright of Nuheat Industries Ltd. All rights reserved.

Updated Oct 2009