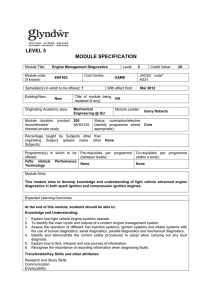

Training and Further Education in Automotive

advertisement