TRANSMITTAL

5995 Greenwood Plaza Blvd.

Suite 100

Greenwood Village, CO 80111-4710

303-571-5377

303-629-7467 (fax)

PROJECT:

TO:

ATTN:

Ph/Fax:

JCS-Jefferson High School Mechanical Upgrade & Bldg Imprv

SHP Leading Designs

1675 Broadway

Denver CO 80202

No. 13D1346-0058

DATE: 06/11/2013

RE:

26000-Electrical

Elisabeth Hunt

JOB:

303-209-7866

WE ARE SENDING:

SUBMITTED FOR:

13D1346

ACTION TAKEN:

Shop Drawings

Approval

Approved as Submitted

Letter

Your Use

Approved as Noted

Prints

As Requested

Returned After Loan

Change Order

Review and Comment

Resubmit

Submit

Plans

SENT VIA:

Samples

Returned

Specifications / Product Data

Attached

Returned for Corrections

Other:

Separate Cover Via:

Due Date:

NOTES:

Item

Package

Code

Submittal

Submittal

26000

26000

260580-08

262813-11

Rev. Copies Date

1

1

06/11/2013

06/11/2013

Description

Status

Electrical Identification

Fuses

Architect Review

Architect Review

CC:

Signed:

Christopher DuHadway

Submittal Stamp Sheet

Project: Jefferson High School Building Improvement

Phipps’ Job #: 13D1346

Submittal #: 26000 8,11

Gerald H. Phipps, Inc.:

SHP Leading Designs

1675 Broadway

Denver Co 80202

Architect:

SUBMITTED

GH Phipps

Construction Companies

GH Phipps has reviewed, approved, and

herby submits the attached in accordance

with the contract documents.

Note to Subcontractor/Material Supplier:

Subcontractor/Material Supplier remains

responsible for the confirmation and

correlation of dimensions at the jobsite;

fabrication processes and construction

techniques; coordination of the work with

the work of other trades; and satisfactory

performance of the work.

Engineer:

Other:

NOTES:

Signed:

Chris DuHadway

GH Phipps Representative

LEEDing the way in electrical construction

JEFFERSON HIGH SCHOOL

SUBCONTRACT # D1345-003

JOB # SP1-038

WEIFIELD GROUP CONTRACTING LLC

SPEC. SECTION # 260000

SUBMITTAL # 13

June 10, 2013

Owners Project # 13D1345/13D1346

Date of documents: 3/18/2013

Submittal Form - Electrical Identification

CONTACT INFORMATION SHEET

SPEC. SECTION # 260000

SUBMITTAL # 13

June 10, 2013

GENERAL CONTRACTOR:

OWNER:

GH Phipps

5995 Greenwood Plaza Blvd, Suite 100

Greenwood Village, CO 80111

Phone: 303-389-3850

Fax: 303-629-7467

Jeffco Public Schools

809 Quail St, Building #4

Lakewood, CO 80212

Phone: 303-982-2436

Fax: 303-982-2400

ARCHITECT:

ELECTRICAL CONTRACTOR:

SHP Leading Design

1675 Broadway, Suite 2480

Denver, CO 80202

Phone: 303-2097866

Fax: 303-209-7865

Weifield Group Contracting, LLC

146 Yuma Street

Denver, CO 80223

Phone: 303.428.2011

Fax: 303.202.0466

ELECTRICAL ENGINEER:

SUPPLIER:

BCER

5420 Ward Road, Suite 200

Arvada, CO 80128

Phone: 303-422-7400

Fax: 303-422-7900

varies

Submittal Form - Electrical Identification

APPROVAL FORM

SPEC. SECTION # 260000

SUBMITTAL # 13

June 10, 2013

ELECTRICAL CONTRACTOR:

Weifield Group Contracting, LLC

GENERAL CONTRACTOR:

GH Phipps

LEEDing the way in electrical construction

Reviewed By: Troy Blackford

Date Reviewed: _______________

Approved

Approved as noted

Approved/Resubmittals Required

ELECTRICAL ENGINEER:

BCER

ARCHITECT:

SHP Leading Design

Submittal Form - Electrical Identification

INDEX OF ITEMS

SPEC. SECTION # 260000

SUBMITTAL # 13

June 10, 2013

260553

260580 Electrical Identification

2.1B Color-Coded Emergency Power Conduit Markers

2.1C Underground Type Plastic Line Marker

2.1D Cable/Conductor Identification Bands

2.1E Plasticized Tags

2.1F Baked Enamel Danger Signs

2.1G Engraved Plastic-Laminate Signs

Submittal Form - Electrical Identification

ELECTRICAL SOLUTIONS

A.

System

Overview

Thermal Transfer Continuous Tapes

• Tapes offer crisp, clear legends with superior legibility

• Available in continuous color vinyl or clear polyester and supplied

on rolls

• Panduit labeling software packages include all label formats for

quick and easy label production

B1.

Cable Ties

B2.

Cable

Accessories

B3.

Stainless

Steel Ties

C1.

Wiring

Duct

Part Number System for Continuous Tapes

T

4

Label Type

0

0

X

“X”

Width

(In.)

0

0

Length

(Ft.)

T = Continuous Tape

0

V

X

1

Material

Print Method

YK = Polyester

1 = Thermal

Transfer,

1.00" core

Y2 = Photoluminescent

Polyester

FJ = Polyolefin

VX = Vinyl

T= Thermal

Transfer,

3.00" core

Vinyl, Yellow (VX)

Black (VY)

Blue (VQ)

Brown (VR)

Gray (VT)

Green (VS)

Orange (VU)

Purple (VV)

Red (VW)

White (VP)

C3.

Abrasion

Protection

C4.

Cable

Management

D1.

Terminals

Material/Print Method Selection Guide

Material

Polyester, Clear (YK)

C2.

Surface

Raceway

Print Method

Temperature

Range

-51°F to 275°F

(-46°C to 135°C)

-58°F to 176°F

(-50°C to 80°C)

Features

Indoor/outdoor rated; provides durability, high temperature

resistance, and dimensional stability; does not stretch or

easily tear

Indoor/outdoor rated; conformable material for flat

applications and safety and facility identification; can be

overlaminated to increase durability

Thermal Transfer (T)

D2.

Power

Connectors

D3.

Grounding

Connectors

E1.

Labeling

Systems

E2.

Labels

E3.

Pre-Printed

& Write-On

Markers

E4.

Permanent

Identification

E5.

Lockout/

Tagout

& Safety

Solutions

Table continues on page E2.22

For technical assistance in the U.S., call 866-405-6654 (outside the U.S., see inside back cover for directory)

F.

Index

E2.21

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

ELECTRICAL SOLUTIONS

A.

System

Overview

Thermal Transfer Continuous Tapes (continued)

B1.

Cable Ties

B2.

Cable Accessories

B3.

Stainless

Steel Ties

C1.

Wiring

Duct

C2.

Surface Raceway

C3.

Abrasion

Protection

C4.

Cable

Management

D1.

Terminals

D2.

Power Connectors

D3.

Grounding

Connectors

Part Number

T100X000VP1Y

T100X000VQ1Y

T100X000VS1Y

T100X000VU1Y

T100X000VW1Y

T100X000VX1Y

T100X000VY1Y

T100X000YK1

T200X000VP1Y

T200X000VQ1Y

T200X000VS1Y

T200X000VU1Y

Part Description

White, vinyl tape.

Blue, vinyl tape.

Green, vinyl tape.

Orange, vinyl tape.

Red, vinyl tape.

Yellow, vinyl tape.

Black, vinyl tape.

Clear, polyester tape.

White, vinyl tape.

Blue, vinyl tape.

Green, vinyl tape.

Orange, vinyl tape.

In.

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

2.00

2.00

2.00

2.00

mm

25.4

25.4

25.4

25.40

25.4

25.40

25.4

25.4

50.8

50.80

50.8

50.8

Ft.

100.0

100.00

100.00

100.0

100.00

100.0

100.00

100.00

100.0

100.0

100.0

100.0

m

30.5

30.5

30.5

30.5

30.5

30.5

30.5

30.5

30.5

30.5

30.5

30.5

Std.

Pkg.

Qty.

1

1

1

1

1

1

1

1

1

1

1

1

T200X000VV1Y

T200X000VW1Y

T200X000VX1Y

T200X000VY1Y

T200X000YK1

T225X000YK1

T400X000VP1Y

T400X000VQ1Y

T400X000VS1Y

T400X000VU1Y

T400X000VV1Y

T400X000VW1Y

T400X000VX1Y

T400X000VY1Y

T400X000YK1

T425X000YK1

Purple, vinyl tape.

Red, vinyl tape.

Yellow, vinyl tape.

Black, vinyl tape.

Clear, polyester tape.

Clear, polyester tape.

White, vinyl tape.

Blue, vinyl tape.

Green, vinyl tape.

Orange, vinyl tape.

Purple, vinyl tape.

Red, vinyl tape.

Yellow, vinyl tape.

Black, vinyl tape.

Clear, polyester tape.

Clear, polyester tape.

2.00

2.00

2.00

2.00

2.00

2.25

4.00

4.00

4.00

4.00

4.00

4.00

4.00

4.00

4.00

4.25

50.8

50.8

50.8

50.8

50.8

57.2

101.6

101.6

101.6

101.6

101.6

101.6

101.6

101.6

101.6

107.9

100.0

100.0

100.0

100.0

100.0

100.0

100.0

100.0

100.0

100.0

100.0

100.0

100.0

100.0

100.0

100.0

30.5

30.5

30.5

30.5

30.5

30.5

30.5

30.5

30.5

30.5

30.5

30.5

30.5

30.5

30.5

30.5

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Height

Length

Std.

Ctn.

Qty.

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

Order number of rolls required.

Use with Panduit thermal transfer ribbons.

Labels roll mounted on 3.00" cores; when using the TDP43MY printer and 3.00" cores, the roll stand (TDP43M-RS) is required.

E1.

Labeling Systems

E2.

Labels

E3.

Pre-Printed

& Write-On

Markers

E4.

Permanent

Identification

E5.

Lockout/

Tagout

& Safety

Solutions

F.

Index

E2.22

Order number of pieces required, in multiples of Standard Package Quantity.

Prime items appear in BOLD.

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

ELECTRICAL SOLUTIONS

A.

System

Overview

B1.

Cable Ties

Thermal Transfer Military Grade Heat Shrink Labels

• Labels offer crisp, clear legends with superior legibility

• Meets UL Standard 224 for flammability and AMS-DTL-23053/5C

(Class 1 and Class 3)

• Will meet MIL-M-81531, MIL-STD202F, and MIL-STD-883E

when printed with RMH4BL or RHH4BL-S ribbons

• Shrink ratio 3:1

• Pre-cut flattened polyolefin is both thermal transfer and dot matrix

printable and supplied roll mounted on plastic carrier

• Panduit labeling software packages include all label formats

for quick and easy label production

B2.

Cable Accessories

B3.

Stainless

Steel Ties

C1.

Wiring

Duct

Part Number System for Heat Shrink Labels

H

1

0

0

X

0

4

4

H

1

T

C2.

Surface Raceway

Label Type

C3.

Abrasion

Protection

C4.

Cable

Management

D1.

Terminals

Width

(In.)

“X”

Length

(In.)

H = Heat Shrink

Wire/Cable Label

Material/Print Method Selection Guide

Material

Heat Shrinkable Polyolefin,

White (H1)

Yellow (H2)

Black (H3)

Red (H4)

Print Method

Thermal Transfer (T)

Temperature Range

-67°F to 275°F

(-55°C to 135°C)

Features

Durable flattened polyolefin, high quality heat shrink

wire/cable labels.

H050X025H1T*

Part Description

White, 1/8" diameter polyolefin, 2000/roll.

Width

In.

mm

0.50

12.7

Length

In.

mm

0.25

6.4

Min. Cable

O.D.

In.

mm

0.04

1.0

Max. Cable

O.D.

In.

mm

0.13

3.3

H050X025H1T-B

White, 1/8" diameter polyolefin, 10000/roll.

0.50

12.7

0.25

6.4

0.04

1.0

0.13

3.3

1

H050X034H1T*

White, 3/16" diameter polyolefin, 2000/roll.

0.50

12.7

0.34

8.6

0.06

1.5

0.19

4.8

1

H050X034H1T-B

White, 3/16" diameter polyolefin, 10000/roll.

0.50

12.7

0.34

8.6

0.06

1.5

0.19

4.8

1

H050X044H1T*

White, 1/4" diameter polyolefin, 2000/roll.

0.50

12.7

0.44

11.2

0.08

2.0

0.25

6.4

1

H050X044H1T-B

White, 1/4" diameter polyolefin, 10000/roll.

0.50

12.7

0.44

11.2

0.08

2.0

0.25

6.4

1

Part Number

E1.

Labeling Systems

Print Method

H* = Heat

T = Thermal Transfer,

Shrinkable

3.00" Core

Polyolefin

D2.

Power Connectors

D3.

Grounding

Connectors

Material

Std.

Pkg.

Qty.

1

H050X064H1T*

White, 3/8" diameter polyolefin, 2000/roll.

0.50

12.7

0.64

16.3

0.13

3.3

0.38

9.7

1

E2.

Labels

H050X064H1T-B

H075X025H1T*

H075X034H1T*

White, 3/8" diameter polyolefin, 10000/roll.

0.50

12.7

0.64

16.3

0.13

3.3

0.38

9.7

1

White, 1/8" diameter polyolefin, 1000/roll.

White, 1/8" diameter polyolefin, 1000/roll.

0.75

0.75

19.1

19.1

0.25

0.25

6.4

6.4

0.04

0.04

1.0

1.0

0.13

0.13

3.3

3.3

1

1

E3.

Pre-Printed

& Write-On

Markers

H075X044H1T*

White, 1/8" diameter polyolefin, 5000/roll.

0.75

19.1

0.25

6.4

0.04

1.0

0.13

3.3

1

H100X025H1T*

White, 1/8" diameter polyolefin, 1000/roll.

1.00

25.4

0.25

6.4

0.04

1.0

0.13

3.3

1

H100X025H1T-B

White, 1/8" diameter polyolefin, 5000/roll.

1.00

25.4

0.25

6.4

0.04

1.0

0.13

3.3

1

H100X034H1T*

White, 3/16" diameter polyolefin, 1000/roll.

1.00

25.4

0.34

8.6

0.06

1.5

0.19

4.8

1

H100X034H1T-B

White, 3/16" diameter polyolefin, 5000/roll.

1.00

25.4

0.34

8.6

0.06

1.5

0.19

4.8

1

H100X044H1T*

White, 1/4" diameter polyolefin, 1000/roll.

1.00

25.4

0.44

11.2

0.08

2.0

0.25

6.4

1

H100X044H1T-B

White, 1/4" diameter polyolefin, 5000/roll.

1.00

25.4

0.44

11.2

0.08

2.0

0.25

6.4

1

H100X064H1T*

White, 3/8" diameter polyolefin, 1000/roll.

1.00

25.4

0.64

16.3

0.13

3.3

0.38

9.7

1

H100X064H1T-B

White, 3/8" diameter polyolefin, 5000/roll.

1.00

25.4

0.64

16.3

0.13

3.3

0.38

9.7

1

E4.

Permanent

Identification

E5.

Lockout/

Tagout

& Safety

Solutions

*Other colors available, replace H1T with H2T (Yellow), H3T (Black), and H4T (Red).

Order number of rolls required.

F.

Index

E2.12

Order number of pieces required, in multiples of Standard Package Quantity.

Prime items appear in BOLD.

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

ELECTRICAL SOLUTIONS

A.

System

Overview

Thermal Transfer Military Grade Heat Shrink Labels (continued)

Part Number

Width

In.

mm

1.00

25.4

Length

In.

mm

0.84

21.3

Min. Cable

O.D.

In.

mm

0.170

4.3

Max. Cable

O.D.

In.

mm

0.50

12.7

Std.

Pkg.

Qty.

1

H100X084H1T*

Part Description

White, 1/2" diameter polyolefin, 1000/roll.

H100X165H1T*

White, 1" diameter polyolefin, 500/roll.

1.00

25.4

1.65

41.9

0.33

8.4

1.00

25.4

1

H150X025H1T*

White, 1/8" diameter polyolefin, 500/roll.

1.50

38.1

0.25

6.4

0.04

1.0

0.13

3.3

1

H150X034H1T*

White, 3/16" diameter polyolefin, 500/roll.

1.50

38.1

0.34

8.6

0.06

1.5

0.19

4.8

1

H150X044H1T*

White, 1/4" diameter polyolefin, 500/roll.

1.50

38.1

0.44

11.2

0.08

2.0

0.25

6.4

1

H200X025H1T*

White, 1/8" diameter polyolefin, 500/roll.

2.00

50.8

0.25

6.4

0.04

1.0

0.13

3.2

1

H200X025H1T-B

White, 1/8" diameter polyolefin, 2500/roll.

2.00

50.8

0.25

6.4

0.04

1.0

0.13

3.2

1

H200X034H1T*

White, 3/16" diameter polyolefin, 500/roll.

2.00

50.8

0.34

8.6

0.06

1.5

0.19

4.8

1

H200X034H1T-B

White, 3/16" diameter polyolefin, 2500/roll.

2.00

50.8

0.34

8.6

0.06

1.5

0.19

4.8

1

H200X044H1T*

White, 1/4" diameter polyolefin, 500/roll.

2.00

50.8

0.44

11.2

0.08

2.0

0.25

6.4

1

H200X044H1T-B

White, 1/4" diameter polyolefin, 2500/roll.

2.00

50.8

0.44

11.2

0.08

2.0

0.25

6.4

1

H200X064H1T*

White, 3/8" diameter polyolefin, 500/roll.

2.00

50.8

0.64

16.3

0.13

3.3

0.38

9.7

1

H200X064H1T-B

White, 3/8" diameter polyolefin, 2500/roll.

2.00

50.8

0.64

16.3

0.13

3.3

0.38

9.7

1

H200X084H1T*

White, 1/2" diameter polyolefin, 500/roll.

2.00

50.8

0.84

21.3

0.170

4.3

0.50

12.7

1

H200X084H2T

Yellow, 1/2" diameter polyolefin, 500/roll.

2.00

50.8

0.84

21.3

0.170

4.3

0.50

12.7

1

H200X165H1T*

White, 1" diameter polyolefin, 250/roll.

2.00

50.8

1.65

41.9

0.33

8.4

1.00

25.4

1

*Other colors available, replace H1T with H2T (Yellow), H3T (Black), and H4T (Red).

Order number of rolls required.

B1.

Cable Ties

B2.

Cable

Accessories

B3.

Stainless

Steel Ties

C1.

Wiring

Duct

C2.

Surface

Raceway

C3.

Abrasion

Protection

C4.

Cable

Management

D1.

Terminals

D2.

Power

Connectors

D3.

Grounding

Connectors

E1.

Labeling

Systems

E2.

Labels

E3.

Pre-Printed

& Write-On

Markers

E4.

Permanent

Identification

E5.

Lockout/

Tagout

& Safety

Solutions

F.

Index

For technical assistance in the U.S., call 866-405-6654 (outside the U.S., see inside back cover for directory)

E2.13

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

Raised Panel Labels

S P E C I F I C AT I O N S H E E T

specifications

Raised panel labels shall be die-cut, microcellular

foam with a polyester printable surface and

high-tack adhesive. The polyester surface shall

readily accept thermal transfer print. Product shall

be resistant to scratching, smearing, and rubbing

and meet print performance requirements of

UL969 and MIL-STD-202G. Optional clear

overlaminate shall provide additional print

protection in harsh environments.

Part Numbers

Raised panel

push button

labels:

Raised panel

half push

button labels:

technical information

Material:

Print method:

High service

temperature:

Low service

temperature:

Minimum

application

temperature:

Adhesive

performance:

Print

performance:

Recommended

ribbon:

UL recognized:

RoHS

compliance:

High-tack microcellular foam with thermal transfer printable polyester

surface (0.03" thick)

Thermal transfer

1000 hours at 212°F (100°C), no visible change observed

Raised panel

component

labels:

1000 hours at -40°F (-40°C), no visible change observed

50°F (10°C)

Tested per ASTM D1000

20 minute dwell

24 hour dwell

Stainless steel

100 oz./inch

150 oz./inch

Powder-coated

100 oz./inch

150 oz./inch

ABS

100 oz./inch

150 oz./inch

Product meets print performance of MIL-STD-202G, method 215K,

solution A, B and D

TDP43ME series printer – black resin RMER4BL and

white resin RMER4WH

File No. MH14979

Material is RoHS compliant per European Directive 2002/95/EC on the

Restriction of Hazardous Substances (RoHS)

key features and benefits

Raised thermal transfer

printable surface

High-tack adhesive

Delivers the look of engraved laminated plates with the

convenience of printing on demand

Variety of sizes and colors

Flexible and easy to implement for a wide range

of applications

Thermal transfer

print technology

Designed for Easy-Mark ™

Labeling Software

Provides crisp, clear, and durable legends for reliable,

high performance identification needs

Strong holding power for rough, textured, and powder

coated surfaces

Assists in the creation of optimum identifiers and labels

enabling the generation of labels quickly, easily and with

fewer errors resulting in reduced costs

applications

Panduit raised panel labels are designed to

meet the control panel and communication

infrastructure labeling needs of organizations

that would normally use engraved plates.

The labels are available in a variety of sizes

and colors, ready to print-on-demand using

Easy-Mark ™ Labeling Software and a

TDP43ME thermal transfer desktop printer. The

product is designed to have high resistance to

w w w. p a n d u i t . c o m

scratches, smearing, and rubbing and meet

print performance of UL969 and MIL-STD-202G

when printed with RMER4BL and RMER4WH

resin thermal transfer ribbons. Product solution

also has an optional clear overlaminate to

function in harsh environments. When used

in conjunction with Easy-Mark ™ Labeling

Software, time-savings and reduced errors can

be realized when creating legends and text.

Pre-printed

raised panel

labels:

Raised panel

overlaminates:

C120X150APT-22*

C180X180APT-30*

C120X190APT-22*

C240X240APT-30*

C180X130APT-30H

C240X200APT-30H

C100X050APT*

C200X100APT*

C300X100APT*

C300X250APT*

C350X300APT*

C400X100APT*

C252X030APT*

C379X030APT*

C235A8-30ES

C235AW-30-ES

C350A8-30-ES

C350AW-30-ES

C120X150YK-22

C120X190YK-22

C180X180YK-30

C240X240YK-30

C100X150YK

C200X100YK

C300X250YK

C400X100YK

*Other colors available. See back for color options

Labeling Software

Easy-Mark ™

Labeling

Software:

PROG-EMCD3

CAD-Connect ™

Labeling

Software:

PROG-CCCD

Thermal Transfer Desktop Printers

Medium volume

300 DPI:

TDP43ME

External roll

stand required: TDP43ME-RS

Recommended Ribbons

TDP43ME

Black resin:

RMER4BL

White resin:

RMER4WH

Raised Panel Labels

Raised Panel Push Button Labels

Raised Panel Component Labels

• Foam-backed polyester with a permanent acrylic adhesive

• 500 labels per roll

• Optional overlaminates shown below

• Foam-backed polyester with a permanent acrylic adhesive

• 500 labels per roll

• Optional overlaminates shown below

A

C

B

A

C

B

A

C

B

A

C

B

Part Number

C120X150APT-22

C120X150A8T-22

C120X150AST-22

C120X150AWT-22

C120X150A0T-22

C120X190APT-22

C120X190A8T-22

C120X190AST-22

C120X190AWT-22

C120X190A0T-22

C180X180APT-30

C180X180A8T-30

C180X180AST-30

C180X180AWT-30

C180X180A0T-30

C240X240APT-30

C240X240A8T-30

C240X240AST-30

C240X240AWT-30

C240X240A0T-30

Color

White

Yellow

Green

Red

Black

White

Yellow

Green

Red

Black

White

Yellow

Green

Red

Black

White

Yellow

Green

Red

Black

Hole Width Height Print-On

Dia.

A

B

Height C

In.

In.

In.

In.

(mm) (mm) (mm)

(mm)

0.87

1.20

(22.0) (30.5)

1.50

(38.1)

0.45

(11.4)

A

B

0.87

1.20

(22.0) (30.5)

1.90

(48.3)

0.85

(21.6)

A

B

1.18

1.80

(30.0) (45.7)

1.80

(45.7)

0.36

(9.1)

A

B

1.18

2.40

(30.0) (61.0)

2.40

(61.0)

0.90

(22.9)

A

Raised Panel Half Push Button Labels

B

• Foam-backed polyester with a permanent acrylic adhesive

• 500 labels per roll

A

C

B

Print-On

Height C

In. (mm)

0.73

(18.5)

1.43

(36.3)

Width A Height B

Part Number

Color In. (mm) In. (mm)

C180X130APT-30H White

1.80

1.30

(45.7)

(33.0)

C240X200APT-30H White

2.40

2.00

(61.0)

(50.8)

ER

GEN

CY

EM

• Foam-backed polyester with a permanent acrylic adhesive

• 25 labels per roll

S

TOP

Color

Black on Yellow

White on Red

Black on Yellow

White on Red

B

A

Pre-Printed Raised Panel Labels

Part Number

C235A8-30-ES

C235AW-30-ES

C350A8-30-ES

C350AW-30-ES

A

B

Label Dia.

In. (mm)

Hole Dia.

In. (mm)

2.35

(60.0)

1.18

(30.0)

B

3.50

(89.0)

1.18

(30.0)

B

A

A

Part Number

C100X050APT

C100X050A8T

C100X050AST

C100X050AUT

C100X050AWT

C100X050A0T

C100X050AMT

C200X100APT

C200X100A8T

C200X100AST

C200X100AUT

C200X100AWT

C200X100A0T

C200X100AMT

C300X100APT

C300X100A8T

C300X100A0T

C300X100AUT

C300X250APT

C300X250A8T

C300X250AST

C300X250AUT

C300X250AWT

C300X250A0T

C300X250AMT

C350X300APT

C350X300A8T

C350X300A0T

C350X300AUT

C400X100APT

C400X100A8T

C400X100AST

C400X100AUT

C400X100AWT

C400X100A0T

C400X100AMT

C252X030APT

C252X030A0T

C379X030APT

C379X030A0T

Color

White

Yellow

Green

Orange

Red

Black

Silver

White

Yellow

Green

Orange

Red

Black

Silver

White

Yellow

Black

Orange

White

Yellow

Green

Orange

Red

Black

Silver

White

Yellow

Black

Orange

White

Yellow

Green

Orange

Red

Black

Silver

White

Black

White

Black

Width A

In.

(mm)

Height B

In.

(mm)

1.00

(25.4)

0.50

(12.7)

2.00

(50.8)

1.00

(25.4)

3.00

(76.2)

1.00

(25.4)

3.00

(76.2)

2.50

(63.5)

3.50

(88.9)

3.00

(76.2)

4.00

(101.6)

1.00

(25.4)

2.52

(64.0)

0.30

(7.6)

3.79

(96.3)

0.30

(7.6)

Raised Panel Push Button Label Overlaminates

Raised Panel Component Label Overlaminates

• Not printable, clear polyester overlaminate material, only

used to provide additional protection in harsh environments

• 500 labels per roll

• Not printable, clear polyester overlaminate material, only

used to provide additional protection in harsh environments

• 500 labels per roll

Part Number

C120X150YK-22

C120X190YK-22

C180X180YK-30

C240X240YK-30

Width A

In. (mm)

1.20 (30.5)

1.20 (30.5)

1.80 (45.7)

2.40 (60.9)

Height B

In. (mm)

1.50 (38.1)

1.90 (48.3)

1.80 (45.7)

2.40 (60.9)

Width A

In. (mm)

1.00 (25.4)

2.00 (50.8)

3.00 (76.2)

4.00 (101.6)

Part Number

C100X050YK

C200X100YK

C300X250YK

C400X100YK

Height B

In. (mm)

0.50 (12.7)

1.00 (25.4)

2.50 (63.5)

1.00 (25.4)

WORLDWIDE SUBSIDIARIES AND SALES OFFICES

PANDUIT CANADA

Markham, Ontario

cs-cdn@panduit.com

Phone: 800.777.3300

PANDUIT EUROPE LTD.

London, UK

cs-emea@panduit.com

Phone: 44.20.8601.7200

PANDUIT SINGAPORE PTE. LTD.

Republic of Singapore

cs-ap@panduit.com

Phone: 65.6305.7575

PANDUIT JAPAN

Tokyo, Japan

cs-japan@panduit.com

Phone: 81.3.6863.6000

PANDUIT LATIN AMERICA

Guadalajara, Mexico

cs-la@panduit.com

Phone: 52.33.3777.6000

PANDUIT AUSTRALIA PTY. LTD.

Victoria, Australia

cs-aus@panduit.com

Phone: 61.3.9794.9020

For a copy of Panduit product warranties, log on to www.panduit.com/warranty

For more information

Visit us at www.panduit.com

Contact Customer Service by email: cs@panduit.com

or by phone: 800.777.3300 and reference IDSP65

©2011 Panduit Corp.

ALL RIGHTS RESERVED.

WW-IDSP65

5/2011

ELECTRICAL SOLUTIONS

A.

System

Overview

Permanent Marking Pens

• Fast drying, permanent ink – legible identification on nylon

• Used with marker ties, write-on labels and tags, where ordinary

marking pens will not work

B1.

Cable Ties

B2.

Cable

Accessories

B3.

Stainless

Steel Ties

C1.

Wiring

Duct

C2.

Surface

Raceway

Part Number

PFX-0

Part Description

Permanent marking pen – fine tip.

PFX-2

Permanent marking pen – fine tip.

Ink

Color

Black

Red

Std. Std.

Pkg. Ctn.

Qty. Qty.

12

144

12

144

Lockout/Tagout Safety Signs

Indoor/Outdoor Sub-Surface Printed Adhesive Polyester

(Type PPS)

• High quality signs for use indoors and outdoors

• Excellent resistance to UV light, chemical atmosphere,

and abrasion

• Excellent life and adhesion properties

• Printed graphics are protected by clear polyester laminate

C3.

Abrasion

Protection

Indoor/Outdoor Rigid Polyethylene (Type PRS)

• Rugged signs for indoors and outdoors

• Abrasion resistant

• Used where adhesives will not work

Indoor Adhesive Vinyl (Type PVS)

• Economical general purpose signs for use in most environments

• Very good adhesive properties when applied to a clean,

dry surface

Material Chart

C4.

Cable

Management

Material

Print Method

Polyester (PPS)

D1.

Terminals

Rigid Polyethylene

(PRS)

Pre-Printed

Vinyl (PVS)

D2.

Power

Connectors

Temperature

Range

Features

-40°F to 275°F

(-40°C to 135°C)

Indoor/outdoor rated; laminated label material

protects legend from abrasion and chemicals;

resistant to UV light, chemical atmosphere, and

abrasion; excellent life and adhesion properties.

-105°F to 250°F

(-76°C to 121°C)

Indoor/outdoor rated; high quality, rugged material

resistant to abrasion; use where adhesives will

not work.

-40°F to 200°F

(-40°C to 93°C)

Indoor rated; economical general purpose material;

excellent adhesion properties when applied to a

clean, dry surface.

Size Reference Chart

D3.

Grounding

Connectors

E1.

Labeling

Systems

E2.

Labels

E3.

Pre-Printed

& Write-On

Markers

E4.

Permanent

Identification

Signs

per

Card

1

2

1

Part

Number

*0109*

*0204*

*0209*

Width

In.

mm

9.00 228.60

4.50 114.30

9.00 228.60

Height

In.

mm

1.50

38.10

2.25

57.15

2.25

57.15

*0305*

*0503*

*0507*

*0509*

*0710*

5.00

3.00

7.00

9.00

10.00

127.00

76.20

177.80

228.60

254.00

3.50

5.00

5.00

5.00

7.00

88.90

127.00

127.00

127.00

177.80

1

2

1

1

1

*1014*

14.00

355.60

10.00

254.00

1

*Denotes the part numbers’ prefix and suffix.

HIGH VOLTAGE

PPS0204W2100

PPS0305W2100

PPS0507W2100

PVS0305W2101^

PVS0507W2101^

PRS1014B364

PVS0509B364Y

PVS0710B364Y

PPS0710B364

PRS0710B364

PVS0305C174Y

PVS0505C174Y

PPS0305C174

PVS0710C173Y

PVS0204D100Y

PPS0710D72

PRS0710D72

PRS1014D72

PVS0109D72Y

PVS0204D72Y

PVS0710D72Y

PVS0209D445Y

LOCK OUT

BEFORE SERVICING

PVS0204C176Y

PVS0204C171Y

THE FOLLOWING STEPS MUST

BE PERFORMED WHEN LOCKING

OUT EQUIPMENT:

1 - Identify all potential hazards

and energy sources.

2 - Inform operator / supervisor about

work to be performed.

PVS0710C180Y

3 - Prepare equipment for shutdown.

E5.

Lockout/

Tagout

& Safety

Solutions

4 - Shutdown / turn off equipment.

5 - Isolate and LOCKOUT energy sources.

PVS0204C177Y

6 - Release all stored energy.

7 - Test equipment for zero energy state.

8 - Clear personnel / tools before

and after job.

9 - Remove locks and tags when work

completed.

PVS0503N458Y

F.

Index

E5.20

PVS0204C179Y

PVS0204W172Y

PVS0204C178Y

^Can be clearly identified with PANDUIT permanent marking pens.

Order number of pieces required, in multiples of Standard Package Quantity.

Prime items appear in BOLD.

Physical Properties

Ultra-Mattes Front Physical Properties

Typical

Values

ASTM

Method

1.10 ft lbs/in

D-256

5,500 psi

D-638

50%

D-638

10,300 psi

D-790

Specific Gravity

1.15

D-792

Rockwell Hardness

M45

D-785

175oF

(79.44oC)

D-648

Physical Properties

IZOD Impact Strength

Notched at 73°F (22.78°C)

Tensile Strength

To break

Elongation before break

Flexural Strength

Loan to stretch outer surface

5%

Deflection Temperature

Temperature at which material

deflects .010" (.254mm) at 264

psi

Coefficient of Thermal Expansion

5.6 x 10-5

D-696

Temperature for needle to

penetrate 1mm (90°F/hr, 2.2

lbs)

208°F

(97.78°C)

D-1525

Temperature for needle to

penetrate 1mm (90°F/hr, 11.0

lbs)

187°F

(86.11°C)

D-1525

Inch/inch/°F

Vicat Softening Point

ULTRA-MATTES (FRONT) engraving

material softens at about 200°F (93.33°C)

sufficiently so that it can be bent as needed.

It can be sawed, drilled and bonded, but not

sheared. For best appearance, sawed

edges should be buffed on material 1/8"

(3.0mm) and thicker.

Physical Properties

Ultra-Mattes Front Physical Properties

The base and cap materials were tested for flammability

by Underwriters Laboratories. The base and cap materials

are rated 94 HB on the UL 94 test.

Under the ASTM Standard G-155, Ultra-Mattes (front)

engraving material was tested with a Xenon Arc Light

Apparatus under specific, reproducible conditions. Testing

resulted in no noticeable change in color after 300 hours

of exposure to the Xenon Arc. Exposure to the Xenon Arc

for 300 hours is supposedly the equivalent of

approximately 3 years of exposure in a normal, mild

climate, such as the Midwestern States of the United

States.

This is not intended as a statement of warranty, rather a

statement of general comparison.

NOTE: The above information is given in good faith, but no warranty,

express or implied, is given.

Kroy 5100 Handheld Label Printer Specifications

Page 1 of 2

Label Printers and Supplies

Call Today: 1-800-788-5572

Fast, Friendly Customer Service

Home

Kroy Labelers &

Supplies

Specials

New Products

Site Map

About Us

Contact

Kroy 5100

Handheld Label and Wiremarking Printer

K2500 Supplies

K3100 Supplies

K4100 Labeler &

Supplies

z

K4350 Supplies

z

z

z

K5100 Labeler &

Supplies

K182 Supplies

z

z

K5100 Series Features:

K600 / K650

Supplies

z

K240SE / K244RS

Supplies

z

z

z

Request

Brochures or

Information

Free Pipe

Labeling Guides

K5100 Features

K5100 Printing Specifications

K5100 Media Specifications

K5100 Physical Specifications

K5100 Electrical Specifications

K5100 Environmental Specifications

z

z

z

z

Free Guide to

the NFPA

Diamond

z

Free Tech

Support

z

z

z

Supply is easy loading

Easily print graphics, logos, bar codes, and data

records

Internal battery charger

Use as stand alone or connect to your personal

computer

Compatible with Win95/Win98/2000/XP

Comes with Kroy Label Designer Software(KLDS)

and

Windows drivers

Uses continuous and die cut media

Built in cutter and feed controls

Audible key clicking

Flash upgradable firmware

Real time clock with time/date stamper

Alpha Numeric sequencing (A-Z, 1-999)

K5100 Series Printing Specifications:

z

z

z

z

z

z

z

z

z

z

z

z

Thermal transfer and direct thermal printing

Text auto-sizing feature

Built in cutter and feed control

2 x 16 line Character LCD display

6-72 Point with downloadable and size adjustable fonts

10 resident bar codes including code 39 and 128

On board memory for storing fonts and label formats

Print speeds vary by content up to 2 inches per second

300 dots per inch resolution (12 dots per mm)

Maximum print width: .97" (24.7mm)

Maximum label width: 1" {25.4mm}

Maximum label length: 20" {508mm}

K5100 Series Labeling Tape Specifications:

z

z

z

Tape supply widths: .5", .8", 1"

Tape supply length: 40 feet (12.2m)

Shrink Tube supply length: 110" (2.8m)

http://www.electroniclabeling.com/k5100-specifications.htm

3/18/2010

Kroy 5100 Handheld Label Printer Specifications

z

z

Page 2 of 2

Media type: Self-laminating wire wraps, polyolefin shrink tubing, polyester industrial labels, laminated

labels, tamper evident labels, cast vinyl labels, component and terminal block die cut labels

All supplies are housed in a self contained cartride for quick and painless supply changes

K5100 Series Physical Specifications:

z

Printer: 11.0" L x 6" W x 4" H

K5100-PC Series Electrical Specifications:

z

z

z

z

z

Available with AC adapter.

Optional Batteries - "C" size rechargeable 2500mAh Ni-Cad

AC adapter version: Output: 12VDC - UL Listed, C-UL, CE Recognized

Meets VDE-B and FCC Part 15 class B RFI limits

RS 232 Serial port, 9600-115200 baud.

K5100 Series Environmental Specifications:

z

z

z

Operating temperature: 45 F to 105 F (7 C to 40 C)

Supply cartridge storage temperature: - 60 F to 105 F (15 C to 40 C) shelf life is reduced at higher

temperatures - damage may occur at temperatures as high as 120 F (50 C)

Operating /storage humidity limit: 90% RH non-condensing

K5100 Introduction

Applications

Kroy Labelers Home

Kroy Label Printers Shipped ASAP

http://www.electroniclabeling.com/k5100-specifications.htm

3/18/2010

LEEDing the way in electrical construction

JEFFERSON HIGH SCHOOL

SUBCONTRACT # D1345-003

JOB # SP1-038

WEIFIELD GROUP CONTRACTING LLC

SPEC. SECTION # 260000

SUBMITTAL # 12

June 10, 2013

Owners Project # 13D1345/13D1346

Date of documents: 3/18/2013

Submittal Form - Fuses

CONTACT INFORMATION SHEET

SPEC. SECTION # 260000

SUBMITTAL # 12

June 10, 2013

GENERAL CONTRACTOR:

OWNER:

GH Phipps

5995 Greenwood Plaza Blvd, Suite 100

Greenwood Village, CO 80111

Phone: 303-389-3850

Fax: 303-629-7467

Jeffco Public Schools

809 Quail St, Building #4

Lakewood, CO 80212

Phone: 303-982-2436

Fax: 303-982-2400

ARCHITECT:

ELECTRICAL CONTRACTOR:

SHP Leading Design

1675 Broadway, Suite 2480

Denver, CO 80202

Phone: 303-2097866

Fax: 303-209-7865

Weifield Group Contracting, LLC

146 Yuma Street

Denver, CO 80223

Phone: 303.428.2011

Fax: 303.202.0466

ELECTRICAL ENGINEER:

SUPPLIER:

BCER

5420 Ward Road, Suite 200

Arvada, CO 80128

Phone: 303-422-7400

Fax: 303-422-7900

varies

Submittal Form - Fuses

APPROVAL FORM

SPEC. SECTION # 260000

SUBMITTAL # 12

June 10, 2013

ELECTRICAL CONTRACTOR:

Weifield Group Contracting, LLC

GENERAL CONTRACTOR:

GH Phipps

LEEDing the way in electrical construction

Reviewed By: Troy Blackford

Date Reviewed: _______________

Approved

Approved as noted

Approved/Resubmittals Required

ELECTRICAL ENGINEER:

BCER

ARCHITECT:

SHP Leading Design

Submittal Form - Fuses

INDEX OF ITEMS

SPEC. SECTION # 260000

SUBMITTAL # 12

June 10, 2013

262813 - Fuses

Submittal Form - Fuses

Electronic — PCB & Small Dimension Fuses

1

⁄4” Dia. x 11⁄4” length fast-acting ferrule fuses

AGC-V (axial leads)

ABC-V (axial leads)

GBB-V (axial leads)

AGC

ABC

GBB

Specifications

Description: Fast-acting fuse.

Dimensions: 1⁄4” x 11⁄4”

(6.4 x 31.7mm).

Construction: Glass

tube with nickel-plated

brass endcaps.

Ratings:

Volts — 250Vac (1⁄20-10A)

— 32Vac (11-45A)

Amps — 1⁄20-30A

IR* — 35A (1⁄20-1A @ 250Vac)

— 100A (11⁄4-3A @ 250Vac)

— 200A (4-10A @ 250Vac)

— 1000A (15-30A @ 32Vac)

Specifications

Description: Fastacting fuse.

Dimensions:

1

⁄4” x 11⁄4”

(6.4 x 31.7mm).

Construction:

Ceramic tube with

nickel-plated brass

endcaps.

Ratings:

Volts — 250Vac/125Vdc (1⁄4-20A)

— 125Vac/125Vdc (25-30A)

Amps — 1⁄4-30A

IR** — 35A (1⁄4-1A @ 250Vac)

— 10kA (1⁄4-20A @ 250Vdc)

— 100A (11⁄2-3A @ 250Vac)

— 200A (4-10A @ 250Vac)

— 750A (15A @ 250Vac)

— 400A (20A @ 250Vac)

— 400A (25-30A @ 250Vdc)

— 1kA (25-30A @ 125Vac)

Specifications

Description: Very

fast-acting fuse.

Dimensions:

1

⁄4” x 11⁄4”

(6.4 x 31.7mm).

Construction:

Ceramic cartridge

with nickel-plated

brass endcaps.

Ratings:

Volts — 250Vac/125Vdc

Amps — 1-30A

IR — 200A @ 250Vac

— 200A (20-30A @ 125Vac/dc)

— 10,000A (1A -15A @

125Vac/dc)

Agency Information: CE, Std. 24814, UL Recognized, 1-30,

125Vdc/250Vac, File E56412, Guide

JFHR2, CSA Certified, 1-10,

125Vdc/250Vac, File 53787, Class

1422-01.

*Interrupting ratings were measured at 70% – 80% power

factor on AC, and at a time constant described in UL 248.

Agency Information: CE, Std.

248-14, UL Listed, Guide JDYX, File

E19180, 0-10A UL Recognized, Guide

JDYX2, File E19180, 15-30A CSA

Certification, Class 1422-01, File

53787.

Features and Benefits

• Original electronic glass tube fuse.

• Fast-acting for maximum protection.

• Wide amp/volt ratings allow versatility

of protecting electronic circuits.

Typical Applications

• Electronic Circuits

Catalog Numbers (Amps)

With Axial Leads

AGC-V-1⁄20

AGC-V-1⁄16

AGC-V-1⁄10

AGC-V-1⁄8

AGC-V-3⁄16

AGC-V-2⁄10

AGC-V-1⁄4

AGC-V-3⁄10

AGC-V-3⁄8

AGC-V-45⁄100

AGC-V-1⁄2

AGC-V-3⁄4

AGC-V-1

AGC-V-1 1⁄4

AGC-V-1 1⁄2

AGC-V-2

AGC-V-2 1⁄4

AGC-V-2 1⁄2

AGC-V-3

AGC-V-4

AGC-V-5

AGC-V-6

AGC-V-7

AGC-V-8

AGC-V-9

AGC-V-10

AGC-V-15

AGC-V-20

AGC-V-25

AGC-V-30

**Interrupting ratings were measured at 70% – 80% power factor on AC, and at a time constant described in UL 248.

Agency Information: CE, Std. 248-14

UL Listed, Guide JDYX File E19180,

0-15A UL Recognized, Guide JDYX2,

File E19180, 20-25A CSA Certification,

Class 1422-01, File 53787, 0-15A, Class

1422-30, File 53787, 20-25A.

Features and Benefits

• Ceramic body allows for higher amp/volt

rating combinations.

• Consolidate inventory by replacing AGC

fuses for reduced SKU investment and

minimizing potential for misapplying fuse.

Typical Applications

• Electronic Circuits

Catalog Numbers (Amps)

With Axial Leads

Without Axial Leads

ABC-V- 1⁄4

AGC- ⁄20

AGC-1⁄16

AGC-1⁄10

AGC-1⁄8

AGC-3⁄16

AGC-2⁄10

AGC-1⁄4

AGC-3⁄10

AGC-3⁄8

AGC-45⁄100

ABC-V- ⁄2

ABC-V- 3⁄4

ABC-V-1

ABC-V-1 1⁄2

ABC-V-2

1

1

AGC- ⁄2

AGC-3⁄4

AGC-1

AGC-1 1⁄4

AGC-1 1⁄2

AGC-2

AGC-2 1⁄4

AGC-2 1⁄2

AGC-3

AGC-4

Data Sheet: 2001

58

1

AGC-5

AGC-6

AGC-7

AGC-8

AGC-9

AGC-10

AGC-15

AGC-20

AGC-25

AGC-30

ABC-V-2 1⁄2

ABC-V-8

ABC-V-3

ABC-V-4

ABC-V-5

ABC-V-6

ABC-V-7

ABC-V-10

ABC-V-15

ABC-V-20

ABC-V-25

ABC-V-30

Features and Benefits

• Very fast-acting performance allows

protection of highly sensitive

electronic circuitry.

Typical Applications

• Electronic Circuits

Catalog Numbers (Amps)

With Axial Leads

GBB-V-1

GBB-V-6

GBB-V-1 1⁄4

GBB-V-7

GBB-V-2

GBB-V-8

GBB-V-3

GBB-V-9

GBB-V-4

GBB-V-10

GBB-V-5

GBB-V-12

Without Axial Leads

GBB-1

GBB-6

GBB-1 1⁄4

GBB-7

GBB-2

GBB-8

GBB-3

GBB-9

GBB-4

GBB-10

GBB-5

GBB-12

Without Axial Leads

ABC- 1⁄4

ABC- 1⁄2

ABC- 3⁄4

ABC-1

ABC-1 1⁄2

ABC-2

ABC-2 1⁄2

ABC-3

ABC-4

ABC-5

ABC-6

ABC-7

Data Sheet: 2000

ABC-8

ABC-10

ABC-15

ABC-20

ABC-25

ABC-30

Data Sheet: 2013

For product data sheets, visit www.cooperbussmann.com/products/datasheet.asp

GBB-V-15

GBB-V-20

GBB-V-25

GBB-V-30

GBB-15

GBB-20

GBB-25

GBB-30

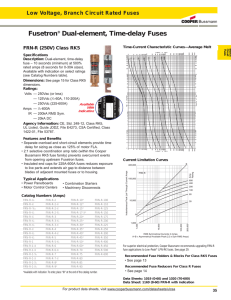

Low Voltage, Branch Circuit Rated Fuses

Fusetron® dual-element, time-delay fuses

FRN-R (250V) Class RK5

Current Limitation Curves

AMPERE

RATING

FRN-R (250V)

100,000

600

400

200

100

60

10,000

30

200,000

10,000

1,000

100,000

A

1,000

Features and Benefits

• Separate overload and short-circuit elements provide time

delay for 125% of motor FLA sizing, linked with RK5 current

limitation.

• 2:1 selective coordination ratio (within the Cooper

Bussmann® RK5 fuse family) prevents electrical shutdowns

from extending beyond the failed circuit.

• Insulated end caps for 110A-600A fuses reduces exposure

to live parts and extends air gap to distance between

blades of adjacent mounted fuses or to housing.

B

400,000

INSTANTANEOUS PEAK LET-THRU CURRENT AMPERES

Specifications

Description: Dual-element, time-delay

fuse – 10 seconds (minimum) at 500%

rated amps.

Dimensions: See page 11 for Class RK5

dimensions.

Construction: Fiberglass tube.

Ratings:

Volts — 250Vac (or less)

— 125Vdc (1⁄10-200A)

— 250Vdc (201-600A)

Amps — 1⁄10-600A

IR — 200,000A RMS Sym.

— 20,000A dc

Agency Information: CE, Std. 248-12, Class RK5, UL

Listed, Guide JDDZ, File E4273, CSA Certified, Class

1422-01, File 53787.

PROSPECTIVE SHORT CIRCUIT CURRENT

SYMMETRICAL RMS AMPERES

Typical Applications

• Power Panelboards

• Motor Control Centers

• Combination Starters

• Machinery Disconnects

Catalog Numbers (Amps)

FRN-R-1⁄10

FRN-R-2

FRN-R-10

FRN-R-100

FRN-R-1⁄8

FRN-R-2 1⁄4

FRN-R-12

FRN-R-110

FRN-R-15⁄100

FRN-R-2 1⁄2

FRN-R-15

FRN-R-125

FRN-R-2⁄10

FRN-R-2 8⁄10

FRN-R-17 1⁄2

FRN-R-150

FRN-R-1⁄4

FRN-R-3

FRN-R-20

FRN-R-175

FRN-R-3⁄10

FRN-R-3 2⁄10

FRN-R-25

FRN-R-200

FRN-R-4⁄10

FRN-R-3 1⁄2

FRN-R-30

FRN-R-225

FRN-R-1⁄2

FRN-R-4

FRN-R-35

FRN-R-250

FRN-R-6⁄10

FRN-R-4 1⁄2

FRN-R-40

FRN-R-300

FRN-R-8⁄10

FRN-R-5

FRN-R-45

FRN-R-350

FRN-R-1

FRN-R-5 6⁄10

FRN-R-50

FRN-R-400

FRN-R-1 1⁄8

FRN-R-6

FRN-R-60

FRN-R-450

FRN-R-1 1⁄4

FRN-R-6 1⁄4

FRN-R-70

FRN-R-500

FRN-R-1 ⁄10

FRN-R-7

FRN-R-75

FRN-R-600

FRN-R-1 1⁄2

FRN-R-7 1⁄2

FRN-R-80

FRN-R-1 6⁄10

FRN-R-8

FRN-R-85

FRN-R-1 ⁄10

FRN-R-9

FRN-R-90

4

8

For superior electrical protection, Cooper Bussmann recommends upgrading

FRN-R fuse applications to Low-Peak® LPN-RK fuses See page 16.

Recommended Fuse Holders & Blocks For Class

RK5 250V Fuses

• See page 9

Recommended Fuse Reducers For Class R Fuses

Data Sheets: 1019 (0-60) and 1020 (70-600)

22

• See page 10

For product data sheets, visit www.cooperbussmann.com/products/datasheet.asp

Low Voltage, Branch Circuit Rated Fuses

Fusetron® dual-element, time-delay fuses

Time-Current Characteristic Curves—Average Melt

FRS-R (600V) Class RK5

Specifications

Description: Dual-element, time-delay

fuse – 10 seconds (minimum) at 500%

rated amps.

Dimensions: See page 11 for Class RK5

dimensions.

Construction: Fiberglass tube.

Ratings:

Volts — 600Vac (or less)

— 300Vdc

Amps — 1⁄10-600A

IR — 200,000A RMS Sym.

— 20,000A @ 300Vdc

Agency Information: CE, Std. 248-12, Class RK5, UL

Listed, Guide JDDZ, File E4273, CSA Certified, Class

1422-02, File 53787.

Features and Benefits

• 2:1 selective coordination ratio (within RK5 fuse family)

prevents electrical shutdowns from extending beyond the

failed circuit.

• Insulated end caps for 70-600A fuses reduces exposure to

live parts and extends air gap to distance between blades

of adjacent mounted fuses or to housing.

Typical Applications

Power Panelboards

Motor Control Centers

Combination Starters

Machinery Disconnects

Current Limitation Curves

FRS-R-125

FRS-R-15⁄100

FRS-R-2 1⁄2

FRS-R-15

FRS-R-150

FRS-R- ⁄10

FRS-R-2 8⁄10

FRS-R-17 1⁄2

FRS-R-175

FRS-R-1⁄4

FRS-R-3

FRS-R-20

FRS-R-200

FRS-R-3⁄10

FRS-R-3 2⁄10

FRS-R-25

FRS-R-225

FRS-R-4⁄10

FRS-R-3 1⁄2

FRS-R-30

FRS-R-250

FRS-R- ⁄2

FRS-R-4

FRS-R-35

FRS-R-275

FRS-R-6⁄10

FRS-R-4 1⁄2

FRS-R-40

FRS-R-300

FRS-R-8⁄10

FRS-R-5

FRS-R-45

FRS-R-325

FRS-R-1

FRS-R-5 6⁄10

FRS-R-50

FRS-R-350

FRS-R-1 1⁄8

FRS-R-6

FRS-R-60

FRS-R-400

FRS-R-1 1⁄4

FRS-R-6 1⁄4

FRS-R-70

FRS-R-450

FRS-R-1 4⁄10

FRS-R-7

FRS-R-75

FRS-R-500

FRS-R-1 1⁄2

FRS-R-7 1⁄2

FRS-R-80

FRS-R-600

FRS-R-1 6⁄10

FRS-R-8

FRS-R-90

FRS-R-1 8⁄10

FRS-R-9

FRS-R-100

2

1

For superior electrical protection, Cooper Bussmann recommends upgrading

FRS-R fuse applications to Low-Peak® LPS-RK fuses See page 16.

AMPERE

RATING

FRS-R-110

FRS-R-12

FRS-R (600V)

100,000

600A

400A

200A

100A

60A

30A

10,000

15A

A

1,000

PROSPECTIVE SHORT CIRCUIT CURRENT

SYMMETRICAL RMS AMPERES

Recommended Fuse Holders & Blocks For Class RK5

600V Fuses

Recommended Fuse Reducers For Class R Fuses

• See page 9

• See page 10

24

Data Sheet: 1017 (0-60), 1018 (70-600)

For product data sheets, visit www.cooperbussmann.com/products/datasheet.asp

200,000

FRS-R-10

FRS-R-2 1⁄4

100,000

FRS-R-2

FRS-R-1⁄8

10,000

FRS-R-1⁄10

B

400,000

1,000

Catalog Numbers (Amps)

INSTANTANEOUS PEAK LET THRU CURRENT AMPERES

•

•

•

•

Low Voltage, Branch Circuit Rated Fuses

T-Tron® fast-acting fuses

600A

400A

200A

100

10

1

100

20

10,000

.1

RMS SYMMETRICAL CURRENT IN AMPERES

JJN-600

JJN-2

JJN-20

JJN-45

JJN-90

JJN-175

JJN-350

JJN-700

JJN-3

JJN-25

JJN-50

JJN-100

JJN-200

JJN-400

JJN-800

JJN-6

JJN-30

JJN-60

JJN-110

JJN-225

JJN-450

JJN-1000

JJN-10

JJN-35

JJN-70

JJN-125

JJN-250

JJN-500

JJN-1200

Data Sheet: 1025

Recommended Fuse Holders & Blocks For Class T

300V Fuses

B

400,000

JJN

(300V)

AMPERE

RATING

JJN-300

100,000

1200

800

600

400

200

100

10,000

60

30

15

1,000

A

200

100,000

JJN-150

200,000

JJN-80

10,000

JJN-40

1,000

JJN-15

100

JJN-1

INSTANTANEOUS PEAK LET-THRU CURRENT IN AMPS

Current Limitation Curves

Catalog Numbers (Amps)

• See page 9

100A

60A

30A

15A

JJN

(300V)

.01

Typical Applications

• Large Apartment Complexes

• Multi-Family Meter Stacks

• VFD Line Protection

AMPERE

RATING

1,000

Features and Benefits

• Series combination ratings with branch circuit breakers

allows broad range of coverage, independent of breaker

manufacturer.

• Current limitation for non-inductive circuits provides Class T

current-limiting response to maximum ground fault and

short-circuit conditions.

• 200,000A interrupting rating provides high ratings at all

circuit locations.

• Small footprint allows more efficient use of available space.

300

TIME IN SECONDS

Specifications

Description: Very fast-acting, currentlimiting fuse.

Dimensions: See page 12 for Class T

dimensions.

Construction: Melamine tube with silver

fuse element.

Ratings:

Volts — 300Vac (or less)

— 160Vdc (15-600A)

— 170Vdc (601-1200A)

Amps — 1-1200A

IR — 200,000 RMS Sym.

— 20,000A dc @ 160Vdc

— 100,000A dc @ 170Vdc

Agency Information: CE, Std. 248-15, Class T, UL Listed,

Guide JDDZ, File E4273, CSA Certified, Class 1422-02, File

53787.

Low Voltage

Branch

Circuit

Fuses

Time-Current Characteristic Curves—Average Melt

JJN Class T

RMS SYMMETRICAL CURRENTS IN AMPERES

A-B = ASYMMETRICAL AVAILABLE PEAK (2.3 x SYMM RMS AMPS)

For product data sheets, visit www.cooperbussmann.com/products/datasheet.asp

33

Low Voltage, Branch Circuit Rated Fuses

Low-Peak® dual-element, time-delay fuses

600A

400A

125A

200A

250A

60A

80A

100A

30A

15A

6A

10A

3A

1A

Now Available

AMPERE

RATING

300

With Optional

Low Voltage

Branch

Circuit

Fuses

Time-Current Characteristic Curves–Average Melt

LPJ_SP Class J

200

Indication

100

10

TIME IN SECONDS

Specifications

Description:

Dual-element, time-delay fuse;

10 seconds (minimum) at 500% rated amps. Now

available with optional permanent indication on

select ratings (see Catalog Numbers table).

Dimensions: See page 11 for Class J dimensions.

Construction: Copper fuse element.

Ratings:

Volts — 600Vac (or less)

— 300Vdc (or less)

Amps — 1-600A

IR — 300,000A RMS Sym.

— 100,000A dc

Agency Information: CE, UL Listed - Special Purpose*,

Guide JFHR, File E56412, CSA Certified (200,000 AIR)

Class J per CSA-22.2 No. 248.8, Class 1422-02, File 53787.

1

.1

LPJ-35SP**

LPJ-175SP**

LPJ-1 8⁄10SP

LPJ-6SP**

LPJ-40SP**

LPJ-200SP**

LPJ-2SP

LPJ-7SP**

LPJ-45SP**

LPJ-225SP**

LPJ-2 1⁄4SP

LPJ-8SP**

LPJ-50SP**

LPJ-250SP**

LPJ-2 1⁄2SP

LPJ-9SP**

LPJ-60SP**

LPJ-300SP**

LPJ-2 8⁄10SP

LPJ-10SP**

LPJ-70SP**

LPJ-350SP**

LPJ-3SP

LPJ-12SP**

LPJ-80SP**

LPJ-400SP**

LPJ-3 2⁄10SP

LPJ-15SP**

LPJ-90SP**

LPJ-450SP**

LPJ-3 1⁄2SP

LPJ-17 1⁄2SP**

LPJ-100SP**

LPJ-500SP**

LPJ-4SP

LPJ-20SP**

LPJ-110SP**

LPJ-600SP**

*Meets all performance requirements of UL Standard 248-8 for Class J fuses.

**Available with optional permanent replace fuse indication. To order, place “I” at end of

catalog number. Example: LPJ-6SPI.

Available with silver plated terminals. Add SP/ in front of Catalog Number.

Data Sheets: 1006 (0-60) and 1007 (70-600)

With indication 1062 (6-60) and 1063 (70-600)

15

10,000

1,000

100

30A

AMPERE

RATING

15A

1,000

A

100

200,000

LPJ-5 6⁄10SP

10,000

300,000

LPJ-1 6⁄10SP

200A

100A

60A

100,000

LPJ-150SP**

600A

400A

10,000

LPJ-30SP**

B

100,000

1,000

LPJ-125SP**

LPJ-5SP

Current Limitation Curves

100

LPJ-25SP**

LPJ-1 ⁄4SP

1

CURRENT IN AMPERES

INSTANTANEOUS PEAK LET-THRU CURRENT IN AMPS

LPJ-4 1⁄2SP

LPJ-1SP

10

1

.01

Features and Benefits

• Separate overload and short-circuit elements provide time

delay for sizing of high inrush loads linked with Class J

current limitation.

• Selective coordination ratio of 2:1 (within Low-Peak fuse

family) prevents electrical shutdowns from extending

beyond the failed circuit.

• Series combination ratings with branch circuit breakers

allows broad range of coverage, independent of breaker

manufacturer.

Typical Applications

• Power Panelboards

• Branch Circuit Breaker Panelboard Mains

• Machinery Disconnects

• Industrial Control

Catalog Numbers (Amps)

PROSPECTIVE SHORT-CIRCUIT CURRENT

SYMMETRICAL RMS AMPS

Recommended Fuse Holders & Blocks For Class J 600V Fuses

• See page 10

For product data sheets, visit www.cooperbussmann.com/products/datasheet.asp

15

Low Voltage, Branch Circuit Rated Fuses

Low-Peak® dual-element, time-delay fuses

LPN-RK_SP (250V) Class RK1

LPS-RK_SP (600V) Class RK1

Now Available

With Optional

Indication

Specifications

Description:

Current-limiting, dual-element,

time-delay fuse; 10 seconds

(minimum) at 500% rated

amps (8 seconds for 0-30A

sizes). Now available with

optional permanent indication

on select ratings (see Catalog

Numbers table).

Dimensions: See page 11 for Class RK1 dimensions.

Construction: Copper fuse element.

Ratings:

Volts LPN-RK:

— 250Vac (or less)

— 125Vdc (0-60A)

— 250Vdc (70-600A)

LPS-RK:

— 600Vac (or less)

— 300Vdc

Amps — 1⁄10-600A

IR — 300,000A RMS Sym.

— 100,000A dc

Agency Information: CE, UL Listed – Special Purpose*,

Guide JFHR, File E56412, CSA Certified (200,000 AIR),

Class RK1 per CSA C22.2, No. 248.12, Class 1422-02, File

53787.

Features and Benefits

• Separate overload and short-circuit elements provide time

delay for close sizing of high inrush loads linked with K1

current-limitation and selective coordination ratio of 2:1

(within Low-Peak fuse family) prevents widespread

blackouts.

• Inventory consolidation of Class RK1, RK5 and H fuses for

reduced SKU investment and minimizing potential for

misapplying fuse.

• 300,000A RMS symmetrical interrupting rating provides

adequate ratings without obsolescence for all electrical

systems, big or small.

• Insulated end caps reduces exposure to live parts and

extends air gap to distance between blades of adjacent

mounted fuses or to housing.

Data Sheets: LPN-RK — 1003 (0-60) and 1004 (70-600)

LPN-RK with indication — 1066 (70-600)

LPS-RK — 1001 (0-60) and 1002 (70-600)

LPS-RK with indication — 1061 (0-60) and

1064 (70-600)

16

Typical Applications

• Large Distribution Switchboards

• Power Panelboards

• Motor Control Centers

• Machinery Disconnect Switches

LPN Catalog Numbers (Amps) (250Vac/125Vdc)

LPN-RK-1⁄10SP

LPN-RK-15⁄100SP

LPN-RK-2⁄10SP

LPN-RK-3⁄10SP

LPN-RK-4⁄10SP

LPN-RK-1⁄2SP

LPN-RK-6⁄10SP

LPN-RK-8⁄10SP

LPN-RK-1SP

LPN-RK-1 1⁄8SP

LPN-RK-1 1⁄4SP

LPN-RK-1 4⁄10SP

LPN-RK-1 6⁄10SP

LPN-RK-1 8⁄10SP

LPN-RK-2SP

LPN-RK-2 1⁄4SP

LPN-RK-2 1⁄2SP

LPN-RK-2 8⁄10SP

LPN-RK-3SP

LPN-RK-3 2⁄10SP

LPN-RK-3 1⁄2SP

LPN-RK-4SP

LPN-RK-4 1⁄2SP

LPN-RK-5SP

LPN-RK-5 6⁄10SP

LPN-RK-60SP**

LPN-RK-70SP****

LPN-RK-80SP**

LPN-RK-90SP**

LPN-RK-100SP**

LPN-RK-6SP

LPN-RK-6 1⁄4SP

LPN-RK-110SP**

LPN-RK-125SP**

LPN-RK-8SP

LPN-RK-9SP

LPN-RK-10SP

LPN-RK-12SP

LPN-RK-15SP

LPN-RK-17 1⁄2SP

LPN-RK-150SP**

LPN-RK-175SP**

LPN-RK-200SP**

LPN-RK-225SP**

LPN-RK-250SP**

LPN-RK-300SP**

LPN-RK-20SP

LPN-RK-25SP

LPN-RK-30SP

LPN-RK-35SP**

LPN-RK-350SP**

LPN-RK-400SP**

LPN-RK-450SP**

LPN-RK-500SP**

LPN-RK-40SP**

LPN-RK-45SP**

LPN-RK-50SP**

LPN-RK-600SP**

*Meets all performance requirements of UL Standard 248-12 for Class RK1 fuses.

**Available with optional permanent indication. To order, place “I” at end of Catalog Number.

Example: LPN-RK-35SPI.

0-60A fuses available with Nickel plate option. (Ex: LPS-RK30SPNP) 70-600A fuses available

with Tin plate option. Example: LPS-RK-100SP-TP.

LPS Catalog Numbers - (Amps) (600Vac/300Vdc)

LPS-RK-1⁄10SP

LPS-RK-2⁄10SP

LPS-RK-3⁄10SP

LPS-RK-4⁄10SP

LPS-RK-1⁄2SP

LPS-RK-6⁄10SP

LPS-RK-8⁄10SP

LPS-RK-1SP

LPS-RK-1 1⁄8SP

LPS-RK-1 1⁄4SP

LPS-RK-1 4⁄10SP

LPS-RK-2 1⁄2SP

LPS-RK-12SP**

LPS-RK-110SP**

LPS-RK-2 8⁄10SP

LPS-RK-3SP

LPS-RK-3 2⁄10SP

LPS-RK-3 1⁄2SP

LPS-RK-15SP**

LPS-RK-17 1⁄2SP**

LPS-RK-20SP**

LPS-RK-25SP**

LPS-RK-125SP**

LPS-RK-150SP**

LPS-RK-175SP**

LPS-RK-200SP**

LPS-RK-4SP

LPS-RK-4 1⁄2SP

LPS-RK-5SP

LPS-RK-5 6⁄10SP

LPS-RK-6SP**

LPS-RK-30SP**

LPS-RK-35SP**

LPS-RK-40SP**

LPS-RK-45SP**

LPS-RK-50SP**

LPS-RK-225SP**

LPS-RK-250SP**

LPS-RK-300SP**

LPS-RK-350SP**

LPS-RK-400SP**

LPS-RK-60SP**

LPS-RK-70SP**

LPS-RK-80SP**

LPS-RK-450SP**

LPS-RK-500SP**

LPS-RK-600SP**

LPS-RK-6 1⁄4SP**

LPS-RK-1 1⁄2SP LPS-RK-7SP**

LPS-RK-1 6⁄10SP LPS-RK-8SP**

LPS-RK-1 8⁄10SP LPS-RK-9SP**

LPS-RK-2 1⁄4SP LPS-RK-10SP**

LPS-RK-90SP**

LPS-RK-100SP**

*Meets all performance requirements of UL Standard 248-12 for Class RK1 fuses.

**Available with optional permanent replace fuse indication. To order, place “I” at end of

Catalog Number. Example: LPS-RK-15SPI.

Recommended Fuse Holders & Blocks For Class RK1 600V

& 250VFuses

• See page 9

For product data sheets, visit www.cooperbussmann.com/products/datasheet.asp

16

Low Voltage, Branch Circuit Rated Fuses

Plug fuses

S and T Series

Fustat Fuse Adapters

Specifications

Description:

Dual-element, time-delay

plug fuse.

Dimensions:

S — Rejection base

T — Edison base

Construction:

S — Ceramic base with rejection threads

T — Brass threads with ceramic body

Ratings:

Volts — 125Vac

Amps — S Series: 1⁄4-30A

— T Series: 3⁄10-30A

IR — 10,000A RMS Sym.

Agency Information: CE, Std. 248-11, Type S and T: UL

Listed (0-61⁄4) Guide JFHR, File E56412 (7-30A) Guide JEFV,

File E12112; CSA Certified, Class 1423-01, File 53787.

Features and Benefits

• Time-delay, dual-element T Series Edison base plug fuses

provide small motor overload protection when used with

box cover units.

• Time-delay, dual-element S Series plug fuses provide a

rejection feature (when used alone or with Fustat adapters

to retrofit Edison base holders) to prevent overfusing of

branch circuits.

Specifications

Description: Adapters for using Type S and SL rejection

fuses in Edison base fuse sockets.

Features and Benefits

• Fustat adapters screw into the “Edison” thread fuse sockets

of standard fuse boxes making it easy to retrofit existing

fuse installations

• Available in various amp ratings to cover a wide range of

rating requirements

Typical Applications

• Plug fuse installations where it is desirable to restrict fuse

amp ratings

Catalog Numbers (Amps)

SA-1*

SA-32⁄10*

SA-4*

SA-11⁄4*

SA-5*

SA-16⁄10*

SA-2*

SA-61⁄4*

SA-8*

SA-21⁄2*

ENA (Edison base neutral)

EDA (Edison base dummy)

* Single motor circuits.

** Branch circuits.

Fustat® Adapters for Small Motor Protection*

Typical Applications

• S Series — Residential Load Centers

• T Series — Box Cover Units for small motor overload

protection

• Applications benefiting from fuse rejection (S Series only)

Catalog Numbers (Amps)

Adapter

Accepts Fuses

SA-1

S-1 or smaller

SA-1 1⁄4

S-1 1⁄4 or smaller

S Series

S-1⁄4

S-1

S-3⁄10 S-1

S-4⁄10 S-1

S-1⁄2

S-1

S-6⁄10 S-1

S-8⁄10 S-1

SA-3 2⁄10

S-3 2⁄10 to S-1 8⁄10

SA-4

S-4 to S-3 1⁄2

T Series

T-3⁄10 T-1

T-4⁄10 T-1

T-1⁄2

T-1

T-6⁄10 T-1

T-8⁄10 T-1

T-1

T-2

⁄8

1

⁄4

4

⁄10

6

⁄10

8

⁄10

1

⁄8

1

⁄4

4

⁄10

6

⁄10

8

⁄10

1

S-2

S-2

S-5

S-2

S-2

S-3

T-2

T-2

T-2

T-3

T-3

T-3

S-3 ⁄10

S-3 1⁄2

S-4

S-4 1⁄2

S-5

S-6

2

⁄4

6

⁄10

1

⁄2

8

⁄10

1

⁄4 T-4

1

⁄2 T-4 1⁄2

8

⁄10 T-5

T-5 6⁄10

2

⁄10 T-6

1

⁄2 T-6 1⁄4

1

S-6 ⁄4

S-7

S-8

S-9

S-10

S-12

1

T-7

T-8

T-9

T-10

T-12

T-14

S-14

S-15

S-20

S-25

S-30

T-15

T-20

T-25

T-30

Data Sheet: 1032 (S) & 1034 (T)

SA-10*

SA-15**

SA-20**

SA-30**

SA-1 6⁄10

S-1 6⁄10 or smaller

SA-2

S-2 or S-1 8⁄10

SA-2 1⁄2

S-2 1⁄2 to S-1 8⁄10

SA-5

S-5 to S-3 1⁄2

SA-6 ⁄4

S-6 1⁄4 to S-3 1⁄2

SA-8

S-8 to S-7

SA-10

S-10 to S-7

SA-15

S-15 to S-7

SA-20

S-20

SA-30

S-30 to S-20

1

* Both motor running and short-circuit protection.

Fustat® Adapters for Branch Circuit Protection

Adapter

Accepts Fuses

SA-15

S-15 to S-7

SA-20

S-20

SA-30

S-25

SA 30

S-30 to S-20

Recommended Fuse Holders For S & T Series Plug Fuses

• See page 10

• See next column for Fustat adapters for use with S Series

38

For product data sheets, visit www.cooperbussmann.com/products/datasheet.asp

Fuse Holders and Blocks

Box cover units for plug fuses

SOU, SRU, SSU, SOW, SRW, SSW, SOX,

SRX, SSX, SOY, SRY, SSY, SSY-RL,

SSY-L, STY, SCY, SOY-B & SKA

Specifications

Description: Box covers for standard electrical boxes that

provide fused outlet, fused switch or circuit fuse protection.

Ratings:

Volts: — 125V/250V (See Catalog Numbers table)

Amps: — 0-15A (See Catalog Numbers table)

Agency Information: CE, See Catalog Numbers table.

Features/Benefits

• Cooper Bussmann® Box Cover Units provide a low-cost

method of controlling and protecting small motors when

used with Cooper Bussmann® Type T, Fusetron® ,

dual-element fuses.

• Provide low-cost supplementary protection and

disconnection of 125V or less, single phase circuits.

Typical Applications

• Fractional Horsepower, 125 Volt Single-Phase Motor Circuits

• General 125 Volt Supplemental Circuits

Catalog Numbers

Catalog

Numbers

SOU

SRU

SSU5

SOW

SRW

SSW

SOX

SRX

SSX

SOY

SRY

SSY

SSY-RL

STY3

SCY

SOY-B

SKA

Type Box

Handy

221⁄41"⁄4"Handy

223⁄43"⁄4"Switch

Switch

4"Octagon

Octagon

4"

Square

4"4"Square

411⁄16" Square

Fuse holder

Single Double

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Receptacle

Outlet to Load Switch

125V 250V

Control1

Switch

Light2

X

X

X

X

X

X

X

X

X

X

X(2)

X

X

Motor

Size

(Max)

3

⁄4hp

1

⁄2hp

1

⁄2hp

3

⁄4hp

1

⁄2hp

1

⁄2HP

3

⁄4hp

1

⁄2hp

1

⁄2hp

3

⁄4hp

1

⁄2hp

1

⁄2hp

1

⁄2hp

1

⁄2hp

1

⁄2hp (2)

⁄4hp

2hp

3

X(15A)

General Data

125V, 15A

125V, 15A

125Vac, (do not use on dc), 15A

125V, 15A

125V, 15A

125Vac, (do not use on dc), 15A

125V, 15A

125V, 15A

125Vac, (do not use on dc), 15A

125V, 15A

125V, 15A

125Vac, (do not use on dc), 15A

125Vac, (do not use on dc), 15A

125Vac, (do not use on dc), 15A

125Vac, (do not use on dc),

can protect two motors, 15A

125V, protects two motors, 15A

250V, 15A single phase

Agency4

Listing/

Certification

UL, CSA

UL

UL, CSA

UL, CSA

UL

UL, CSA

UL, CSA

UL

UL, CSA

UL, CSA

UL

UL, CSA

—

UL

UL

UL

UL

1 Switch turns power to fused load OFF or ON.

2 Switch light indicates power to load (dark when switch OFF or fuse open).

3 Double-pole switch opens both side of circuit. STY can be used for two separate 125V motors not larger than 1⁄2hp with the common switch, or a single motor not larger than 2hp at

250V (Maximum of 150V to ground).

4 UL Guide JAMZ, File IE6491; CSA Class 6225-01, File 47235.

5 Weatherproof version available, Part No. SSN.

Data Sheet: 1129

258

For product data sheets, visit www.cooperbussmann.com/products/datasheet.asp