Exploitation of Intelligent Slave Based on PROFIBUS-DP

advertisement

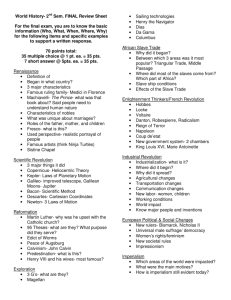

ISBN 978-952-5726-06-0 Proceedings of the 2009 International Workshop on Information Security and Application (IWISA 2009) Qingdao, China, November 21-22, 2009 Exploitation of Intelligent Slave Based on PROFIBUS-DP ZHAO Hui, LI Dan-dan (School of Electrical Engineering, Tianjin Key Laboratory of Control Theory and Applications in Complicated Systems (Tianjin University of Technology), Tianjin, 300384, China) Email: zhaohui3379@126.com üü Abstract This article focuses on an approach of Intelligent Slave which using microcomputer and spc3 what is Lean Siemens PROFIBUS Multiplexer. The development of slave is stable in performance, low cost and worth definite economic value. This paper discusses the hardware configuration and Software Architecture. In order to achieve the compete communication between the master and slave of profibus and ensure the stability and reliability of system, use spc3 what is Lean Siemens PROFIBUS Multiplexer to achieve the design of DP slave. Master Opt Bus coupler driver isolation Slave device Index Terms—PROFIBUS-DP, Intelligent Slave, Field Bus Figure 1. SPC3 P89V51 The overall structure of the hardware from the slave I. SPC3 ASIC PROFIBUS is an international, open-label, not relying on equipment manufacturers’ field bus standard, widely used in manufacturing automation, process automation and industrial buildings, transportation, electric power and other areas of automation. PROFIBUS consist of three parts which are PROFIBUS-FMS, PROFIBUS-PA and PROFIBUS-DP. FMS is mainly used for workshop control network, it is a token structure and real-time multi-master network; PA is specially designed for process-oriented, and has intrinsic safety specification; DP is a high-speed low-cost communicational link, used for device-level control system and distributed communication. PROFIBUS-DP have high-speed, low-cost advantages. PROFIBUS-DP can be used to replace the DC 24 V or 4 ~ 20 mA signal transmission, has a very short response time and high anti-interference performance. With these advantages, PROFIBUS-DP occupies vast Chinese market. In this paper, microcomputer plus PROFIBUS communicational ASIC solution developed intelligent slave. In order to ensure the shortest bus cycle time, the control system uses a single master network control system. Overall system architecture is shown in Figure 1. © 2009 ACADEMY PUBLISHER AP-PROC-CS-09CN004 RS485 PROFIBUS communication protocol in theory can be achieved by programming with microcontroller, however, because the protocol is too complicated, and even if the micro-controller can get the implementation, communication speed can hardly meet the requirement, so generally use a specialized ASIC chip to achieve, such as the SPC3. SPC3 (SIEMENS PROFIBUS CONTROLER) is a PROFIUBS-DP open industrial field bus intelligent interface chip, it can be widely used in industrial automation and building managerial automation in the MCU interface. SPC3 integrates a complete DP agreement, including mode registers, interrupt registers, status registers, variety of buffers and buffer pointers and so on. The chip contains 1.5 KB RAM, parallel 8-bit interface with 11 address lines. SPC3 supports all microprocessors and 8-bit processor. It can also be done automatically the "Byte conversion", which makes Motorola processor can directly read the 16-bit value correctly, usually reading and writing through the two port (8-bit data bus) to complete. SPC3 integrated a protection of watching timer WatchDog , operate in 3 different states: ‘DP_Control’, ‘Baud_Control’, and ‘Baud_Search’. When application processor ˄ 673 ˅ B fails, PROFIBUS-DP communication would be prohibited, so as not to endanger the peripherals. Micro-sequencer controls the entire working process. UART inside can achieve the mutual transformation between the string and the data flowing, SPC3 can automatically identify the bus baud rate (9.6 K ~ 12 M). Idle timer control the bus timer on the serial bus cable. [1] A Monitoring times between 2 ms and 650 s independent of the baud rate - can be implemented with the permissible watchdog factors. If the monitoring time runs out, the SPC3 goes again to ‘Baud_Control,’ and the SPC3 generates the ‘WD_DP_Control_Timeout-Interrupt’. In addition, the DP_State machine is reset, that is, generates the reset states of the buffer management. If another master accepts SPC3, then there is either a switch to ‘Baud_Control” (WD_On = 0), or there is adelay in ‘DP_Control’ (WD_On = 1), depending on the enabled response time monitoring (WD_On = 0). RAM Structure The integrated 1.5kB Dual-Port-RAM, is divided into 192 segments, 8 bytes per segment, the user can immediately address. Table I is the memory structure. The organizational parameters are located in RAM beginning with address 00H., as well as the internal workings cells, but users can not access to the internal workings cells. [2] Table I. Memory structure Address Function 000H Processor parameters II State Machine of a PROFIBUS DP Slave The sequence in principle of this state machine is helpful in understanding the firmware sequence. Details are found in the Standard. After power-on, CPU initialize the slave, when it is correct, the station can receive Set_slave_add telegram to change its address from the master, and then the slave get into the Wait_prm state to wait for its parameterization from master, in this status slave can also receive Slave_diag and Get_cfg telegram from the master. After parameterization, the slave get into the Wait_cfg state, waiting for Chk_cfg telegrams, while also receiving Slave_diag, Get_cfg and Set_prm telegram. Afer the Chk_cfg, the slave enter the Data_exch state to get into the data communications. If the configuration and data exchange is unsuccessful at any stage, then the state machine will return to the Wait_prm state, waiting to re-parameterization. (Figure 2)[3] internal work cells Latches/register (21 bytes) 016H Organizational parameters (42 bytes) 040H DP-buffer: Data in (3)* Data out (3)* Diagnostics (2) Parameter setting data (1) 5FFH Watchdog Timer Configuration data (2) Auxiliary buffer (2) SSA-buffer (1) In addition, in the processor parameter area, the user can set all processor parameters, and organizational parameters in mode register 0, such as SYNC, FREEZE and so on. Mode register 0 must be assigned offline, once turn on power, it can not be changed. The following 42 bytes (16H~39H) is the organization parameter area, the structures of the entire SPC3 buffer are located here, in addition, the data of general parameter setting (including address allowed to be change, the station address, user watchdog values and device identified number, etc.) is set in these units, the status displays are stored in these units (Universal control commands, etc.). Rest of the RAM are used by the user's buffer area for storing the user input and output data, parameter data, configuration data, diagnostic data. Power-on Set-Slave-Set Init-dp() Slave-Diag. WPRM Get-cfg. Slave-Diag. Set-Prm,ok WCFG Get cfg Chk-Cfg, not ok Set-Prm, not ok Chk-Cfg,ok DXCHG Figure 2. 674 State machine of a PROFIBUS DP slave ċ Structure of Hardware Start CPU is P89V51RD2, P89V51RD2 is a microprocessor produced by PHILIPS Corporation, including the 64 KB FLASH, and 1 KB RAM; an internal WDT (watchdog); operating frequency is 0~40 MHz; supporting the IAP (In Application Programming), and the ISP (In System Programming) feature. CPU and SPC3 interface is shown in Figure 3. Because the P89V51RD2 is belongs to the 8-bit microcontroller series, and the data bus multiplexing. SPC3 own internal address latch, so CPU-P0 port connect to DB7~DB0, P2 to AB7~AB0, AB8~AB10 connect to ground. The initialization of P89V51 and SPC3 N Whether collect the data Y The user equipment connect to I / O interface Data collection and processing, intelligent control algorithms and output Start SPC3 N SPC3 have data? Y Read the data update of SPC3 buffer SPC3 input buffer Figure 3. The CPU/SPC3 interface circuit Because P89V51RD2 integrate 1 KB RAM, there are 768B on-chip external memory, it need to be accessed by "MOVX", the address is 00H-2FFH; SPC3 is also the equivalent of an off-chip memory, so in order to avoid address duplication, P2.4 port connect to AB4 by adding a inverter, so the starting address of SPC3 change into 0x8000H. In order to eliminate the interference from outside and improve the accuracy of the signal, bus signal has to isolate by high-speed optocoupler, and then connect with RS-485 bus driver and 9-pin D-type sockets. The power supply of bus driver and optocoupler output should also take quarantine measures, such as using DC-DC Isolated module or transformer isolation.[4-7] N External diagnosed? Y Write the external diagnostic End Figure 4. Flowchart of main program In the beginning of the main program, SPC3 must be initialized first, including addresses of slaves, the buffer zone, all registers and the setting of watchdog’s initial value. Data output and input, and user input of diagnostic data can be placed in the main loop of application. Each cycle, it must refresh the data of BUF, ensuring that all input data is real-time data. When SPC3 received the output data from the master of PROFIBIUS, it will produce the interrupt flag of output data, CPU will receive the data from master after polling the flag in a loop. SPC3 will automatically real-time transfer the specific diagnostic information to the master. Č Software Design A Program flow The flow chart of main program is shown in Figure 4. 675 of the baud rate events. [10] If in the initialization process the user located diagnostic data, the main program in a loop determine whether there are available diagnostic BUF, when the BUF is in idle time, the application input the diagnostic information and request update. [8-9] The Flowcharts of interruption is shown in Figure 5. B Analysis of telegram The slave receive every telegram on the bus, if nothing to do with their own, then ignore it, while if it is issued in accordance with its state machine to respond. The following is a part of telegram data collected from the PROFIBUS-DP network; the network has a master addressed 2 and a slave addressed 3. And it explain the telegram combining the wording mechanism of slave 3. (The data of telegram is 16 hex.) Start N New PRM telegram …… 10 03 02 49 4E 16 Request frame that mast 2 sent to slave 3, searching whether slave 3 is “existence”. 10 02 03 00 05 16 Response frame that slave 3 sent to master 2, responding its "existence" or "alive." …… 68 05 05 68 83 82 5D 3C 3E DC 16 Diagnostic frame that master 2 sent to slave 3, getting the current state of slave 3. Y Dealing with PRM telegram N New CFG telegram Y Dealing with CFG telegram 68 0B 0B 68 82 83 08 3E 3C 02 05 00 FF 00 08 95 16 The same as the Response frame of slave 3, the last 6 bytes is diagnostic information. N original PRM ...... 68 0C 0C 68 83 82 7D 3D 3E 88 19 1A 0B 00 08 00 CB 16 Y Parametric frame that master 2 sent to slave 3, 7 bytes parametric data: 88 19 1A 0B 00 08 00 ACK frame Update the original CFG E5 …… 68 07 07 68 FF 82 46 3A 3E 00 00 3F 16 Global telegram that master 2 sent to slave 3 …… 68 07 07 68 83 82 5D 3E 3E 11 21 10 16 Configuration frame that master 2 sent to slave 3, 2 bytes configuration data: 11 21 E5 ACK frame …… 68 05 05 68 83 82 7D 3C 3E FC 16 The second diagnostic frame that master 2 sent to slave 3. N Have SSA telegram? Y Save into buffer Interrupt returning Figure 5. Flowchart of interruption The interrupt handler is used for handling all kinds of unexpected events occurred by SPC3, including the command of global controlling telegram events, new parameter telegram events, entered or exited the state of exchanging data events, the new configuration telegram events, the new address settings telegram events, watchdog overflowing events and the monitoring 68 0B 0B 68 82 83 08 3E 3C 00 0C 00 02 00 08 9D 16 6 bytes diagnostic frame: 00 0C 00 02 00 08 …… 676 68 05 05 68 03 02 5D 00 00 62 16 Master 2 sent 2 bytes data to slave3, and require slave 3 to input data. 68 05 05 68 02 03 08 00 00 0D 16 Response frame that slave 3 sent to master 2, including 2 bytes input data: 00 00 …… č Conclusion PROFIBUS-DP field bus has become the industry standard of Chinese mechanical industry, in recent years, it is paid attention by a number of institutions and manufacturers. This paper describes the design methods of PROFIBUS-DP slave hardware and software by using P89V51 and SPC3. The devices developed with the PROFIBUS-DP bus interface have a high stability, which can meet the interoperability and real-time communication requirements. REFERENCES [1] Siemens Simatic- Net SPC3 and DPS2 User Description (Siemens PROFIBUS Controller According to IEC 61158) Version: 2.0,2002:38-46. [2] SIMATIC PROFTBUS Interface Components. Siemens, 1998.11 [3] SIMATIC NET SPC3 SIEMENS PROFTBUS Controller User Description. Siemens, 2002.9 [4] Laurent Cauffrieza, Joseph Ciccotelli, Blaise Conrard. Design of intelligent distributed Control systems: a dependability point of view. Reliability Engineering and System Safety , 2004, 84; 19-32 [5] P .Marino, J .No gueira, C .Siguenza, etal. The PROFIBUS formal specification: a comparison between two FDTs. Computer Networks, 2001, 37(3-4), 345-362 [6] SIEMENS corporation. Configuring Hardware and Communication Connections STEP 7 V510 SIMATIC SoftwareManual [Z]. 1998 [7] Stephen Northcutt,Judy Novak.Network Intrusion Detection, Third Edition. New Riders Publishing,2002. [8] Device Description Data Files GSD 1999 [9] PROFIBUS Specification EN 50170 Vo1ume2 1999 [10] P.Vittur. Dp-Ethemet: the Probus DP Protocol implemented on Ethernet, Computer communications. 2003, 26(10): 1095-1104 ˈ ˈ 677