Operator Interface Users guide - Maxima Automation Solutions Pvt. Ltd

advertisement

559 and 1042 Series Operator Interface

For use with HC900 Hybrid Controller

User Guide

Honeywell Process Solutions

Doc. No.:

51-52-25-108

Revision:

12

Date:

11/08

Notices and Trademarks

Copyright 2008 by Honeywell

Revision 12 November 2008

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship. Contact

your local sales office for warranty information. If warranted goods are returned to Honeywell during the period of

coverage, Honeywell will repair or replace without charge those items it finds defective. The foregoing is Buyer's sole

remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a

particular purpose. Specifications may change without notice. The information we supply is believed to be accurate

and reliable as of this printing. However, we assume no responsibility for its use.

While we provide application assistance personally, through our literature and the Honeywell web site, it is up to the

customer to determine the suitability of the product in the application.

Honeywell Process Solutions

Honeywell

512 Virginia Drive

Fort Washington, PA 19034

HC900, 559 and 1042 are U.S. registered trademarks of Honeywell

Other brand or product names are trademarks of their respective owners.

ii

559 and 1042 Series Operator Interface User Guide

Revision 12

11/08

About This Document

Abstract

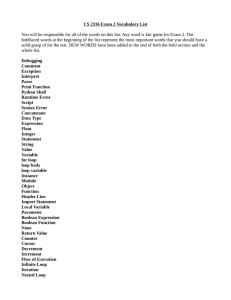

This manual describes the installation and operation of the 559 and 1042 Series Operator Interfaces.

References

The following list identifies all documents that may be sources of reference for material discussed in this

publication.

Document Title

Doc ID

HC900 Controller Installation and User Guide

51-52-25-107

Hybrid Control Designer User Guide

51-52-25-110

Hybrid Control Designer Function Block Reference Guide

51-52-25-109

HC900 Hybrid Controller Communications User Guide

51-52-25-111

HC900 Controller Redundancy Overview & System Operation

51-52-25-133

Contacts

World Wide Web

The following lists Honeywell’s World Wide Web sites that will be of interest to our customers.

Honeywell Organization

WWW Address (URL)

Corporate

http://www.honeywell.com

Honeywell Process Solutions

http://hpsweb.honeywell.com

Technical tips

http://content.honeywell.com/ipc/faq

Telephone

Contact us by telephone at the numbers listed below.

Organization

United States and Canada

Revision 12

11/08

Honeywell

559 and 1042 Series Operator Interface User Guide

Phone Number

1-800-423-9883

1-800-525-7439

Tech. Support

Service

iii

Symbol Definitions

The following table lists those symbols that may be used in this document to denote certain conditions.

Symbol

Definition

This DANGER symbol indicates an imminently hazardous situation, which,

if not avoided, will result in death or serious injury.

This WARNING symbol indicates a potentially hazardous situation, which, if

not avoided, could result in death or serious injury.

This CAUTION symbol may be present on Control Product instrumentation

and literature. If present on a product, the user must consult the

appropriate part of the accompanying product literature for more

information.

This CAUTION symbol indicates a potentially hazardous situation, which, if

not avoided, may result in property damage.

WARNING

PERSONAL INJURY: Risk of electrical shock. This symbol warns the user of a

potential shock hazard where HAZARDOUS LIVE voltages greater than 30 Vrms,

42.4 Vpeak, or 60 Vdc may be accessible. Failure to comply with these

instructions could result in death or serious injury.

ATTENTION, Electrostatic Discharge (ESD) hazards. Observe precautions for

handling electrostatic sensitive devices

Protective Earth (PE) terminal. Provided for connection of the protective earth

(green or green/yellow) supply system conductor.

Functional earth terminal. Used for non-safety purposes such as noise immunity

improvement. NOTE: This connection shall be bonded to protective earth at the

source of supply in accordance with national local electrical code requirements.

Earth Ground. Functional earth connection. NOTE: This connection shall be bonded

to Protective earth at the source of supply in accordance with national and local

electrical code requirements.

Chassis Ground. Identifies a connection to the chassis or frame of the equipment

shall be bonded to Protective Earth at the source of supply in accordance with

national and local electrical code requirements.

iv

559 and 1042 Series Operator Interface User Guide

Revision 12

11/08

Contents

Contents

Introduction ............................................................................................. 1

Overview.......................................................................................................................1

CE Conformity (Europe) ...............................................................................................2

Overview of Architecture ......................................................................... 3

Description of Components ..........................................................................................3

Specifications/Mounting/Wiring/Startup................................................... 5

Specifications ...............................................................................................................5

Site Preparation............................................................................................................8

OI Mounting ..................................................................................................................8

Wiring..........................................................................................................................16

Noise Protection .........................................................................................................20

Startup ........................................................................................................................20

Keys and Displays Overview................................................................. 21

Overview of Keys........................................................................................................21

Standard Keys ............................................................................................................23

Common Tasks Using Standard Keys .......................................................................25

User-assignable Keys.................................................................................................29

Relabeling Display Group Keys..................................................................................31

Overview of Displays ..................................................................................................33

Main Menu ............................................................................................ 39

Overview.....................................................................................................................39

Recipes ................................................................................................. 44

Setpoint Programmers .......................................................................... 46

Overview.....................................................................................................................46

Setpoint Program Setup .............................................................................................47

Select program ...........................................................................................................48

Edit program ...............................................................................................................49

Revision 12

11/08

559 and 1042 Series Operator Interface User Guide

v

Contents

Edit segments.............................................................................................................51

Save program .............................................................................................................52

Setpoint Program Operation.......................................................................................53

SPP operation - Model 1042 ......................................................................................54

SPP operation - Model 559 ........................................................................................56

Load program .............................................................................................................60

Edit segments.............................................................................................................63

Setpoint Scheduler ................................................................................ 65

Overview.....................................................................................................................65

Setpoint Scheduler Setup - Model 559 and 1042 ......................................................66

Edit schedule ..............................................................................................................67

Edit segments.............................................................................................................68

Edit setpoints ..............................................................................................................69

Edit segment events ...................................................................................................70

Edit guarantee hold ....................................................................................................71

Save schedule ............................................................................................................72

Setpoint Schedule Operation .....................................................................................74

Setpoint schedule operation - Model 1042.................................................................75

Setpoint schedule operation - Model 559...................................................................77

Load schedule ............................................................................................................81

View schedule events.................................................................................................83

View auxiliary data......................................................................................................84

Edit segments.............................................................................................................85

Sequencers ........................................................................................... 87

Overview.....................................................................................................................87

Sequencer Setup - Model 559 and 1042....................................................................88

Save Sequence ..........................................................................................................95

Sequencer Operation .................................................................................................96

Sequencer Operation - Model 1042 ...........................................................................97

Sequencer Operation - Model 559 .............................................................................98

Load Sequencer .......................................................................................................100

View/Edit Sequence .................................................................................................101

Edit Steps/Edit Step Details .....................................................................................102

vi

559 and 1042 Series Operator Interface User Guide

Revision 12

11/08

Contents

Loops .................................................................................................. 103

Overview...................................................................................................................103

What’s in this section................................................................................................104

Common Loop Tasks ...............................................................................................105

Loop Setup ...............................................................................................................106

Loop Operation Displays ..........................................................................................119

Summary Displays .............................................................................. 129

Analog Input Summary .............................................................................................129

Analog Output Summary ..........................................................................................131

Digital Input Summary ..............................................................................................132

Digital Output Summary ...........................................................................................133

Variable Summary ....................................................................................................134

Alarms ................................................................................................. 137

Overview...................................................................................................................137

Alarm indication ........................................................................................................137

Alarm Summary........................................................................................................138

Alarm Group .............................................................................................................139

Alarm Detail ..............................................................................................................140

Events ................................................................................................. 141

Event Summary ........................................................................................................141

Diagnostics.......................................................................................... 142

Overview...................................................................................................................142

Controller diagnostics ...............................................................................................143

I/O module diagnostics .............................................................................................147

I/O Module Diagnostics physical details...................................................................153

Panel diagnostic log .................................................................................................154

Communication Ports diagnostics ............................................................................155

Unit Setup ........................................................................................... 159

Controller Status.......................................................................................................160

Set Mode ..................................................................................................................160

Write Database to Flash Memory.............................................................................162

Set Time and Date....................................................................................................163

Revision 12

11/08

559 and 1042 Series Operator Interface User Guide

vii

Contents

Set Security/Review Security ...................................................................................163

Set Language ...........................................................................................................167

Communication Ports ...............................................................................................168

File Name Selection .................................................................................................183

Self Tests..................................................................................................................184

Calibrate AI...............................................................................................................185

Calibrate AO .............................................................................................................193

Calibrate Motor .........................................................................................................198

Display brightness ....................................................................................................207

Disk Utilities......................................................................................... 208

Overview...................................................................................................................208

List disk files .............................................................................................................209

Load/store SP profiles ..............................................................................................210

Load/store SP schedules .........................................................................................212

Load/Store sequences..............................................................................................214

Load/store recipes ....................................................................................................216

Format disk...............................................................................................................218

Set Controller Mode..................................................................................................219

Data Storage ....................................................................................... 221

Overview...................................................................................................................221

Data Storage Operation............................................................................................230

Log Off/Log On.................................................................................... 239

Other Operating Displays .................................................................... 241

Overview...................................................................................................................241

Pushbuttons..............................................................................................................242

4-Selector Switch......................................................................................................243

Device Control ..........................................................................................................244

Hand/Off/Auto Switch ...............................................................................................246

Stage ........................................................................................................................247

Ramp ........................................................................................................................249

Alternator ..................................................................................................................252

Calendar Event Block ...............................................................................................256

Calendar Event Operation........................................................................................257

viii

559 and 1042 Series Operator Interface User Guide

Revision 12

11/08

Contents

Monitoring Displays ............................................................................. 265

Overview...................................................................................................................265

Trend Displays..........................................................................................................266

Bar Graph Displays ..................................................................................................270

Panel Displays..........................................................................................................271

Other Monitoring Displays ........................................................................................275

Maintenance........................................................................................ 277

Overview...................................................................................................................277

Parts .........................................................................................................................277

Messages............................................................................................ 279

Overview...................................................................................................................279

Appendix A - HC900-C70R Redundant Controller Displays................ 289

Overview...................................................................................................................289

Communication Ports Displays ................................................................................290

Alarms/Events/Diags ................................................................................................295

Controller Diagnostics Overview ..............................................................................296

Lead CPU Diagnostics Display ................................................................................299

Reserve CPU Diagnostics Display ...........................................................................299

Communication Ports ...............................................................................................302

Rack Diagnostics Displays .......................................................................................303

Appendix B.......................................................................................... 311

Security Bypass Procedure ......................................................................................311

Index ................................................................................................... 313

Sales and Service ............................................................................... 317

Revision 12

11/08

559 and 1042 Series Operator Interface User Guide

ix

Contents

Tables

Table 1 Specifications ..................................................................................................................................................5

Table 2 Mounting .......................................................................................................................................................15

Table 3 Model 1042 Power supply mounting..............................................................................................................16

Table 4 Wiring.............................................................................................................................................................17

Table 5 Standard key actions......................................................................................................................................23

Table 6 Tasks using standard keys .............................................................................................................................25

Table 7 User-assignable key actions...........................................................................................................................30

Table 8 Display areas defined details .........................................................................................................................33

Table 9 User-assignable displays................................................................................................................................36

Table 10 Top level functions of main menu ...............................................................................................................39

Table 11 Main menu tree............................................................................................................................................40

Table 12 Recipe edit/view details...............................................................................................................................44

Table 13 SPP inputs and current state ........................................................................................................................46

Table 14 Edit program details.....................................................................................................................................49

Table 15 Edit segment details.....................................................................................................................................51

Table 16 Save Program details ...................................................................................................................................52

Table 17 SPP details - Model 1042 ............................................................................................................................54

Table 18 Single SPP details - Model 559 ...................................................................................................................56

Table 19 SPP operate details - Model 559..................................................................................................................58

Table 20 SPP popup menu actions according to state ................................................................................................59

Table 21 View program events details - Model 559...................................................................................................59

Table 22 View program details- Model 559 ...............................................................................................................60

Table 23 Program load details ....................................................................................................................................60

Table 24 Edit segments details ...................................................................................................................................63

Table 25 SPS inputs and current state ........................................................................................................................65

Table 26 Edit schedule details ....................................................................................................................................67

Table 27 Edit segment details.....................................................................................................................................68

Table 28 Edit setpoints details ....................................................................................................................................69

Table 29 Edit segment events details..........................................................................................................................70

Table 30 Edit guarantee hold details...........................................................................................................................71

Table 31 Schedule save details ...................................................................................................................................72

Table 32 Edit guarantee hold limits details.................................................................................................................73

Table 33 Setpoint schedule operation details - Model 1042 .......................................................................................75

Table 34 Setpoint schedule operation details - Model 559.........................................................................................77

Table 35 Scheduler operate popup details - Model 559..............................................................................................79

Table 36 SPS popup menu actions according to state ................................................................................................80

Table 37 Schedule load details ...................................................................................................................................81

Table 38 View schedule events details .......................................................................................................................83

Table 39 View auxiliary data details ..........................................................................................................................84

Table 40 Edit segments details ...................................................................................................................................85

Table 41 Edit Sequence ..............................................................................................................................................89

Table 42 Edit Sequence Steps.....................................................................................................................................90

Table 43 Edit Step Details ..........................................................................................................................................91

Table 44 View Sequence Step Details (Model 1042 Example)..................................................................................92

Table 45 View Sequence Step Outputs (Model 1042 Example).................................................................................93

Table 46 Select State ..................................................................................................................................................94

Table 47 Sequence save details ..................................................................................................................................95

Table 48 Sequencer Operation - Model 1042 .............................................................................................................97

Table 49 Sequencer Operation - Model 559 ...............................................................................................................98

Table 50 Sequencer operate popup details - Model 559.............................................................................................99

Table 51 Schedule load details .................................................................................................................................100

Table 52 Edit Sequence Steps...................................................................................................................................101

Table 53 Edit Step Details ........................................................................................................................................102

x

559 and 1042 Series Operator Interface User Guide

Revision 12

11/08

Contents

Table 54 Loop modes ...............................................................................................................................................103

Table 55 Common loop tasks ...................................................................................................................................105

Table 56 Loop menu visibility..................................................................................................................................106

Table 57 Details of single loop trend........................................................................................................................107

Table 58 Details of Loop Accutune III (listed in order of appearance) ....................................................................108

Table 59 Details of the Tuning Status display ..........................................................................................................110

Table 60 Details of loop Accutune (not listed in order of appearance) ....................................................................112

Table 61 Details of loop tune constants....................................................................................................................113

Table 62 Details of loop control setup......................................................................................................................114

Table 63 Details of carbon loop................................................................................................................................115

Table 64 Details of loop alarm setpoints ..................................................................................................................116

Table 65 Details of loop limits .................................................................................................................................117

Table 66 Details of high output limiting...................................................................................................................118

Table 67 Loop modes ...............................................................................................................................................119

Table 68 Details of loop summary............................................................................................................................120

Table 69 Loop control details ...................................................................................................................................121

Table 70 Details of the Tuning Status display ..........................................................................................................122

Table 71 Multiloop faceplate details ........................................................................................................................124

Table 72 Single loop numeric details .......................................................................................................................125

Table 73 Details of single loop faceplate with loop trend screen .............................................................................126

Table 74 Details of loop tune constants display .......................................................................................................127

Table 75 A/M bias details.........................................................................................................................................128

Table 76 Analog Input Summary details ...................................................................................................................129

Table 77 Analog Output Summary details ................................................................................................................131

Table 78 Digital Input Summary details....................................................................................................................132

Table 79 Digital Output Summary details .................................................................................................................133

Table 80 Variable summary details ..........................................................................................................................134

Table 81 Details of alarm summary..........................................................................................................................138

Table 82 Details of controller diagnostics error status messages .............................................................................143

Table 83 I/O module diagnostics details...................................................................................................................148

Table 84 I/O Module Error Statuses .........................................................................................................................149

Table 85 Bad module details .....................................................................................................................................151

Table 86 Bad Channel details ....................................................................................................................................152

Table 87 I/O module diagnostic details ....................................................................................................................153

Table 88 Serial Port S1/Serial Port S2 (OI) diagnostics and statuses .......................................................................156

Table 89 Network Port diagnostics...........................................................................................................................157

Table 90 Expansion I/O Port diagnostics .................................................................................................................158

Table 91 Controller status details .............................................................................................................................160

Table 92 Set mode details.........................................................................................................................................160

Table 93 Controller modes defined ...........................................................................................................................161

Table 94 Write Database to Flash Memory ...............................................................................................................162

Table 95 Set time and date details .............................................................................................................................163

Table 96 Set security details .....................................................................................................................................163

Table 97 Displays and functions that can be secured ...............................................................................................165

Table 98 Set language details ...................................................................................................................................167

Table 99 Serial Port S1 diagnostic and status information ........................................................................................169

Table 100 Serial Port S1 setup parameters ................................................................................................................170

Table 101 Protocol selection versus setup parameters for the Serial Port S1 ............................................................171

Table 102 Serial Port S2 (OI) details........................................................................................................................172

Table 103 Network port details ................................................................................................................................173

Table 104 View network host details ........................................................................................................................174

Table 105 Host Connection Diagnostics Status Indicators ........................................................................................175

Table 106 View peer connection details....................................................................................................................175

Table 107 View network peer statistics details..........................................................................................................176

Table 108 Peer Connection Status Indicators ............................................................................................................177

Revision 12

11/08

559 and 1042 Series Operator Interface User Guide

xi

Contents

Table 109 Expansion I/O Port details ........................................................................................................................179

Table 110 Modbus Slave Devices display.................................................................................................................180

Table 111 Modbus Slave Details display ..................................................................................................................181

Table 112 File name selection details.......................................................................................................................183

Table 113 Self tests details .......................................................................................................................................184

Table 114 Calibrate AI channel details.....................................................................................................................187

Table 115 Example of AI calibration .......................................................................................................................188

Table 116 Calibrate CJ temp details .........................................................................................................................189

Table 117 Example of CJ calibration ........................................................................................................................190

Table 118 Restore AI factory calibration details ......................................................................................................191

Table 119 Restore CJ factory calibration details ......................................................................................................192

Table 120 Calibrate AO channel details ...................................................................................................................195

Table 121 Example of AO calibration.......................................................................................................................196

Table 122 Restore AO factory calibration details.....................................................................................................197

Table 123 Motor Setup Procedure ............................................................................................................................199

Table 124 Motor Calibration Entry Procedure .........................................................................................................200

Table 125 Calibration Errors .....................................................................................................................................201

Table 126 Auto Calibration Procedure ....................................................................................................................202

Table 127 Semi-Auto Calibration Procedure.............................................................................................................203

Table 128 Hand Calibration Procedure ....................................................................................................................205

Table 129 List disk files details ................................................................................................................................209

Table 130 Load/store profiles details........................................................................................................................211

Table 131 Load/store schedules details ....................................................................................................................213

Table 132 Load/store sequence details .....................................................................................................................214

Table 133 Load/store recipes details ........................................................................................................................216

Table 134 Format disk details...................................................................................................................................218

Table 135 Set mode details.......................................................................................................................................219

Table 136 Controller modes defined ........................................................................................................................219

Table 137 Data storage point factors ........................................................................................................................222

Table 138 Preinitializing ZIP Disk - Model 1042 only ............................................................................................224

Table 139 Storage modes .........................................................................................................................................225

Table 140 View storage status details.......................................................................................................................231

Table 141 Storage controls details............................................................................................................................233

Table 142 View storage setting details .....................................................................................................................236

Table 143 Log off display details .............................................................................................................................239

Table 144 Pushbutton details....................................................................................................................................242

Table 145 Four selector switch details .....................................................................................................................243

Table 146 Device control display details..................................................................................................................244

Table 147 Edit device display details .......................................................................................................................245

Table 148 Hand/Off/Auto switch display details......................................................................................................246

Table 149 Set HOA switch state display details.......................................................................................................246

Table 150 Stage operator display details ..................................................................................................................247

Table 151 Edit stage display details .........................................................................................................................248

Table 152 Ramp operator display details..................................................................................................................249

Table 153 Edit ramp sub-menu display details.........................................................................................................250

Table 154 Edit ramp display details .........................................................................................................................251

Table 155 Alternator operator display details...........................................................................................................253

Table 156 Edit alternator display details ..................................................................................................................254

Table 157 Edit output sequence display details ........................................................................................................255

Table 158 Calendar Event Operator Display details..................................................................................................257

Table 159 Calendar Event Block Menu details .........................................................................................................258

Table 160 SELECT GROUP FOR EDITING menu details ......................................................................................258

Table 161 EDIT EVENT SETPOINTS menu details...............................................................................................259

Table 162 EDIT EVENT SETPOINT display details ..............................................................................................260

Table 163 SET ACTIVE SETPOINT GROUP menu details ...................................................................................261

xii

559 and 1042 Series Operator Interface User Guide

Revision 12

11/08

Contents

Table 164 EDIT SPECIAL DAYS menu details......................................................................................................262

Table 165 EDIT SPECIAL DAY menu details ........................................................................................................263

Table 166 VIEW SPECIAL DAYS EVENT SETUP display details.......................................................................263

Table 167 Example of trend details ..........................................................................................................................267

Table 168 Trend menu..............................................................................................................................................268

Table 169 Sampling rates of trends ..........................................................................................................................269

Table 170 Bar graph display details .........................................................................................................................270

Table 171 4-point panel details.................................................................................................................................272

Table 172 Multi-point panel details..........................................................................................................................273

Table 173 Overview details ......................................................................................................................................274

Table 174 Parts .........................................................................................................................................................277

Table 175 Messages..................................................................................................................................................279

Table 176 Location of Redundant Controller Displays .............................................................................................289

Table 177 Communication Ports Diagnostics and Statuses......................................................................................291

Table 178 Network Ports E1 and E2 display ............................................................................................................293

Table 179 Network Port E1 and Network Port E2 Display details...........................................................................294

Table 180 Details of Controller Diagnostics Overview status messages..................................................................296

Table 181 Details of Lead or Reserve CPU diagnostics error status messages ........................................................299

Table 182 Details of Rack diagnostics error status messages...................................................................................303

Revision 12

11/08

559 and 1042 Series Operator Interface User Guide

xiii

Contents

Figures

Figure 1 559-T12 operator interface.............................................................................................................................1

Figure 2 559-T4 operator interface...............................................................................................................................1

Figure 3 1042 operator interface...................................................................................................................................1

Figure 4 Overview example of HC900 architecture .....................................................................................................4

Figure 5 Cutout dimensions for bracket mounting - Model 559 Type 12.....................................................................9

Figure 6 Mounting in a side enclosure - Model 559 Type 12.....................................................................................10

Figure 7 Panel mounting with brackets - Model 559 Type 12....................................................................................11

Figure 8 Cutout for panel mounting with screws - Model 559 Type 12......................................................................12

Figure 9 Panel mounting with screws - Model 559 Type 12 ......................................................................................13

Figure 10 Model 559 Type 4 operator interface panel cutout.....................................................................................14

Figure 11 Panel mounting dimensions - Model 1042 ..................................................................................................15

Figure 12 Startup display............................................................................................................................................20

Figure 13 View of a 559 operator interface ................................................................................................................21

Figure 14 View of 1042 OI.........................................................................................................................................22

Figure 15 Model 559 Display key label dimensions...................................................................................................32

Figure 16 Model 1042 Display Group key label dimensions .....................................................................................32

Figure 17 Display areas defined .................................................................................................................................33

Figure 18 Display organization ..................................................................................................................................35

Figure 19 Example of saving a program on Model 1042 ...........................................................................................52

Figure 20 SPP operation - Model 1042 ......................................................................................................................54

Figure 21 Single SPP operation - Model 559 .............................................................................................................56

Figure 22 SPP operate popup menu - Model 559 .......................................................................................................58

Figure 23 View program events - Model 559.............................................................................................................59

Figure 24 View program details - Model 559.............................................................................................................60

Figure 25 Example of loading a program from a profile number - Model 1042 ........................................................61

Figure 26 Example of loading a program from a profile list - Model 1042................................................................62

Figure 27 Example of saving a schedule ....................................................................................................................72

Figure 28 Setpoint schedule operation - Model 1042 .................................................................................................75

Figure 29 Setpoint schedule operation - Model 559 ...................................................................................................77

Figure 30 Scheduler operate popup menu - Model 559..............................................................................................79

Figure 31 Example of loading a schedule from schedule number ..............................................................................81

Figure 32 Example of loading a schedule from schedule list .....................................................................................82

Figure 33 View schedule events .................................................................................................................................83

Figure 34 View auxiliary data ....................................................................................................................................84

Figure 35 Edit segments .............................................................................................................................................85

Figure 36 Edit Sequence Steps (Model 1042 Example) .............................................................................................90

Figure 37 Sequencer Operation Display - Model 1042 ..............................................................................................97

Figure 38 Sequencer Operation Display - Model 559 ................................................................................................98

Figure 39 Sequencer operate popup menu - Model 559 .............................................................................................99

Figure 40 Edit Sequence Steps .................................................................................................................................101

Figure 41 IMAN loop mode .....................................................................................................................................103

Figure 42 Single loop trend ......................................................................................................................................107

Figure 43 Multiloop faceplate (Example of 8 Loop faceplate for Model 1042 only)...............................................124

Figure 44 Single loop numeric .................................................................................................................................125

Figure 45 Single loop faceplate with loop trend screen............................................................................................126

Figure 46 A/M bias...................................................................................................................................................128

Figure 47 Alarm group display.................................................................................................................................139

Figure 48 Event summary.........................................................................................................................................141

Figure 49 Controller diagnostics ..............................................................................................................................143

Figure 50 I/O module diagnostics - Model 1042 view .............................................................................................147

Figure 51 I/O module diagnostics - Model 559 view ...............................................................................................147

xiv

559 and 1042 Series Operator Interface User Guide

Revision 12

11/08

Contents

Figure 52 Panel diagnostic log .................................................................................................................................154

Figure 53 Communication ports ................................................................................................................................155

Figure 54 Communications ports display .................................................................................................................168

Figure 55 View host connections (Model 1042 example*) ......................................................................................174

Figure 56 Model 1042 view network host connections ............................................................................................179

Figure 57 Model 559 view network host connections ..............................................................................................179

Figure 58 File name selection...................................................................................................................................183

Figure 59 Self tests ...................................................................................................................................................184

Figure 60 Brightness display ....................................................................................................................................207

Figure 61 Relationship between disk, profile memory, and setpoint programmer ...................................................210

Figure 62 Relationship between disk, schedule memory, and scheduler...................................................................212

Figure 63 Relationship between disk, sequence memory, and sequencer ................................................................214

Figure 64 Required enabled controls for storage......................................................................................................226

Figure 65 Storage control menu with all enablers shown.........................................................................................227

Figure 66 Trend storage: enable conditions..............................................................................................................228

Figure 67 Alarm/event storage: enable conditions ...................................................................................................228

Figure 68 Point log storage: enable conditions.........................................................................................................229

Figure 69 View storage status...................................................................................................................................231

Figure 70 Storage controls........................................................................................................................................233

Figure 71 Initialize storage disk ...............................................................................................................................234

Figure 72 Load storage settings................................................................................................................................235

Figure 73 View storage settings ...............................................................................................................................236

Figure 74 Start new storage settings .........................................................................................................................237

Figure 75 Store storage settings................................................................................................................................238

Figure 76 Pushbutton menu with function keys .......................................................................................................242

Figure 77 Four selector switch display .....................................................................................................................243

Figure 78 Four selector switch popup menu.............................................................................................................243

Figure 79 Device control display..............................................................................................................................244

Figure 80 Edit device display ...................................................................................................................................245

Figure 81 Hand/Off/Auto switch display..................................................................................................................246

Figure 82 Stage operator display ..............................................................................................................................247

Figure 83 Ramp operator display .............................................................................................................................249

Figure 84 Alternator operator displays .....................................................................................................................252

Figure 85 Trend displays ..........................................................................................................................................266

Figure 86 Vertical trend at 2X zoom ........................................................................................................................269

Figure 87 Bar graph displays....................................................................................................................................270

Figure 88 Panel display ............................................................................................................................................271

Figure 89 4-point panel display ................................................................................................................................272

Figure 90 Multi-point panel display .........................................................................................................................273

Figure 91 Panel meter...............................................................................................................................................273

Figure 92 Overview ..................................................................................................................................................274

Figure 93 Help (messages) display...........................................................................................................................275

Figure 94 Main Menu ................................................................................................................................................289

Figure 95 Communication Ports Display...................................................................................................................290

Figure 96 Alarm/Events/Diag Menu..........................................................................................................................295

Figure 97 Controller Diagnostics Overview .............................................................................................................296

Figure 98 Lead or Reserve CPU diagnostics .............................................................................................................299

Figure 99 Rack Diagnostics Display .........................................................................................................................303

Revision 12

11/08

559 and 1042 Series Operator Interface User Guide

xv

Introduction

Overview

What’s in this guide

This guide contains instructions on assembly, installation, wiring, and operation of the 559, and 1042

Series Operator Interface, shown in Figure 1, Figure 2 and Figure 3.

?

F1

ALARM

?

F1

F2

ALARM

F2

F3

F3

F4

ESC

F4

ESC

KB

1

2

3

4

5

1

2

3

4

5

Figure 2 559-T4 operator interface

Figure 1 559-T12 operator interface

Honeywell

F1

7

8

9

4

5

6

1

2

3

.

0

-

F2

F3

F4

?

ALARM

ESC

1

2

3

4

5

6

7

8

Figure 3 1042 operator interface

Revision 12

11/08

559 and 1042 Series Operator Interface User Guide

1

Introduction

CE Conformity (Europe)

Typical readers of this guide

The typical users of this guide are:

•

the technician who installs the OI,

•

the engineer who configures the OI,

•

the operator who views/controls/monitors the process.

What you can do with the OI

The OI lets you perform these tasks:

•

Monitor and control a process.

•

Load/Store/Run Recipes, Profiles, Schedules, Sequences, and Unit Configurations.

•

Display various process data such as trends, alarms, diagnostics, setpoint profiles, and control loops.

•

Store process data to disk.

CE Conformity (Europe)

This product is in conformity with the protection requirements of the following European Council

Directives: 73/23/EEC, the Low Voltage Directive, and 89/336/EEC, the EMC Directive. Conformity of

this product with any other “CE Mark” Directive(s) shall not be assumed.

ATTENTION

The emission limits of EN 50081-2 are designed to provide reasonable protection against

harmful interference when this equipment is operated in an industrial environment. Operation

of this equipment in a residential area may cause harmful interference. This equipment

generates, uses, and can radiate radio frequency energy and may cause interference to radio

and television reception when the equipment is used closer than 30 meters to the antenna(e).

In special cases, when highly susceptible apparatus is used in close proximity, the user may

have to employ additional mitigating measures to further reduce the electromagnetic

emissions of this equipment.

2

559 and 1042 Series Operator Interface User Guide

Revision 12

11/08

Overview of Architecture

Description of Components

The OI is an optional component of a control system that contains:

•

Controller - As the heart of the system, this supports the following features.

−

Control loops

−

Analog and digital I/O

−

Setpoint programming

−

Setpoint scheduler

−

Sequencer

−

Recipe management

−

Start/stop controls

−

Function blocks

−

Fast logic.

•

Hybrid Control Designer - An external PC based configuration tool that is used to graphically

configure the control strategies used by the Controller. It is also used to configure displays and function

keys on the OI. Control strategy configurations are downloaded from Hybrid Control Designer to the

Controller Module through communications or are loaded via the disk drive on the OI.

•

Operator Interface - Provides the operator interface for the Controller Module. It lets the operator

−

Operate the process through various menus and displays,

−

Monitor the process with trends and other graphical displays,

−

View and acknowledge alarms.

See Figure 4.

Revision 12

11/08

559 and 1042 Series Operator Interface User Guide

3

Overview of Architecture

Description of Components

Hybrid Control Designer

• Control Strategy Configuration

• Operator Interface Display Configuration

• Operator Interface Function Key Configuration

• Configuration Upload/Download

• Test and Debug Control Strategies

Controller

• Integrate Loops of Control with

Digital I/O

• Setpoint Programming

• Setpoint Scheduling

• Sequencing

• Alarm Processing

• PID Control, Advanced Control,

and Auto-Tuning/Fuzzy Logic

• Boolean Logic Via Function Blocks

• Advanced Math Computations

Honeywell

F1

F2

7

8

9

4

5

6

1

2

3

0

_

•

?

ALARM

Operator Interface - Example is Model 1042 View

F3

F4

ESC

1

2

3

4

5

6

7

8

• Monitor and Control the Process

• Load/Store/Run Recipes, Profiles, Data Storage Sets,

• Provide organized, visual presentation of information

• Data Storage

Figure 4 Overview example of HC900 architecture

4

559 and 1042 Series Operator Interface User Guide

Revision 12

11/08

Specifications/Mounting/Wiring/Startup

Specifications

Table 1 Specifications

Design

CE Conformity (Europe)

This product is in conformity with the protection requirements of the following

European Council Directives: 73/23/EEC, the Low Voltage Directive, and 89/336/EEC,

the EMC Directive. Conformity of this product with any other “CE Mark” Directive(s)

shall not be assumed. EN61326: Electrical Equipment for Measurement, Control and

Laboratory use. EMC requirements.

Installation Category

(Overvoltage Category)

Category II: Energy-consuming equipment supplied from the fixed installation

(Multiloop Process Controller). Local level appliances, and Industrial Control

Equipment. (EN 61010-1)

Pollution Degree

Pollution Degree 2: Normally non-conductive pollution with occasional conductivity

caused by condensation. (ref. IEC 664-1)

EMC Classification

Group 1, Class A, ISM Equipment

Operator Interface

Components

Model 559

includes a Passive color LCD, 320 x 240 pixels (¼ VGA), full-function front panel keys,

3.5” 1.44 MB diskette for file load and store functions, data storage, and an optional

QWERTY keyboard port.

Model 1042

Includes a TFT Active Matrix Color LCD, 640 x 480 pixels (Std VGA), full-function front

panel keys, standard 3.5” 1.44 MB disk for file load and store functions, data storage,

QWERTY keyboard port, and an optional 100 mb Zip Drive.

The OI software provides a view into the controller, and allows the user to monitor and

control the process through predefined screens.

Power

External 24 Vdc +/- 10% @ 1.0 amp minimum

Enclosure

Material:

Model 559 Type 12:

Structural Foam (Glass filled polycarbonate, UL 94V-1)

Model 559-Type 4:

304 Stainless Steel

Model 1042 Type 4:

Bezel - 20 % glass filled polycarbonate (GE Lexan 3412R)

Chassis - Zinc plated steel with Yellow Chromate coating

Dimensions:

Model 559 Type 12:

Inches: 11.3 wide x 5.7 high x 5.4 deep

Millimeters: 288 wide x 144 high x 136 deep

Model 559-Type 4

Inches: 9.4 wide x 6.25 high x 5.5 deep (3.5" + 2" for Plug and Cabling)

Millimeters: 240 wide x 159 high x 148 deep

Model 1042 Type 4

Inches: 15.8 wide x 9.8 high x 7.2 deep

Millimeters: 400 wide x 248 high x 183 deep

System Interconnection

Revision 12

11/08

Connected to controller through its dedicated RS485 port.

Maximum Distance Between Controller and OI: 601 meters (2000 feet.)

Cable Type: 2 conductor with shield, Belden 9271 or equivalent

Cable termination: 3 position connector at the controller end; screw type terminal strip

required at OI end

559 and 1042 Series Operator Interface User Guide

5

Specifications/Mounting/Wiring/Startup

Specifications

Performance

Average Screen Update Rate: 1.0 seconds

Average Data Entry Response Time: 1.5 seconds

Average Screen Call-up Time: 1.5 seconds

Product Classification

Class I: Fixed, Permanently Connected, Industrial Control Equipment with protective

earthing (grounding). (EN 61010-1)

Mounting

559 Type 12: DIN (288 x 144) compatible panel mounted. May be panel mounted (IP

54, NEMA 12) in indoor non-hazardous locations. This must be panel mounted for a

Type 12 rating.

559 Type 4: Panel mounted indoor only

Model 1042 Type 4: Panel mounted only. Indoor/outdoor.

Display

Model 559

Type: Color (passive LCD), 320 x 240 pixels resolution

Viewing Area: 119 mm wide x 90 mm high (4.7 inches wide x 3.5 inches high)