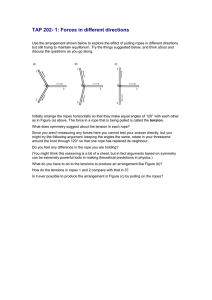

Steel Wire Ropes in Elevators

advertisement