Product Standards

advertisement

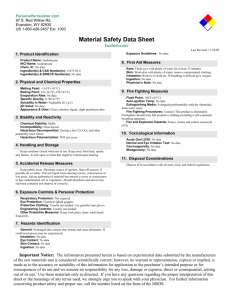

Standards CE MARKING AND THE PERSONAL PROTECTIVE EQUIPMENT DIRECTIVE EUROPEAN STANDARDS (EN’s) The introduction of the CE mark and European Legislation through the introduction of The Personal Protective Equipment Directives (89/686/CEE) and (93/68/CEE) has been a significant and positive development. It has: General Requirements of EN420. ● IDENTIFIED The legislation created a distinct Personal Protective Equipment (PPE) market from the diverse sectors of clothing, safety equipment and footwear. ● EXTENDED PROTECTION It has extended standards into all areas of protective clothing to ensure protection from minor hazards as well as the more serious hazards which were already covered in individual legislation. It has achieved this through introducing three levels of protection – simple, intermediate and complex. ● ENSURED ACCOUNTABILITY The legislation ensures traceability of product to an EC manufacturer or importer who bears the responsibility for ensuring the product is suitable when first placed on the market. EN420 defines the general requirements for most types of protective gloves ● Product, packaging information and marking ● Comfort and efficiency ● Design and construction ● Fitness for the purpose ● Innocuousness ● Storage Sizing Mechanical Hazards EN388 Individual standards advise on the user of pictograms or stating the standard. Some pictograms will also give numeric information indicating performance levels. PICTOGRAM/EN STANDARD The directive also requires a means of identification of the EC based manufacturer, importer or representative who first places the product on the market. The directive and individual standards given further information about the exact nature of this marking appropriate to the type of product. 0-4 0-4 Pass/Fail Antistatic Pass/Fail Chemical and Micro-Organisms EN374 Rating EN374-2 Resistance to penetration by 1-3 micro-organisms. EN374-3 Resistance to chemical hazards 1-6 (permeation) Protection from Cold EN511 Cat II. Intermediate Design – reversible risks. ● Those products which do not fall into either simple or complex design categories. LOGO OR IDENTIFIER For intermediate and complex design products, pictograms or the relevant EN standard indicating the hazard the product protects against are included on the product itself or the immediate packaging. 0-5 Impact Resistance To aid selection of appropriate PPE products, the Personal Protective Directive (89/686/EEC) advises that safety equipment be categorised into three levels of risk protection. These are universally described as simple, intermediate and complex design. Cat III. Complex Design – protection against mortal danger. ● Where the effects of the hazard are serious, cannot be identified by the user and so cause irreversible damage to health. 0-4 b) Blade cut resistance level abcd d) Puncture resistance level All PPE (Personal Protective Equipment) in the European Union is required to carry a CE Mark which indicates that the product fulfils the requirements of the PPE Directive. This includes indicating the level of protection and the test house if appropriate. Cat I. Simple Design – for minimal risks only. ● Where the effects of the hazard are of minimal risk and can be identified without harm to the user. a) Abrasion resistance Level c) Tear resistance level ● HARMONISED It has taken the European ideal forward with the harmonisation of standards to permit free flow of products across the whole of the European market. Rating a) convective cold 0-4 b) contact cold 0-4 c) water permeability 0-1 Thermal Hazards EN407 abcdef Rating Rating a) Burning behaviour level 0-4 b) Contact heat level 0-4 c) Convective heat level d) Radiant heat level 0-4 0-4 e) Small splashes of molten metal 0-4 f ) Large splashes of molten metal 0-4 Note: the higher the score value the better the performance. 0 indicates a fail. X denotes no test. We have reviewed our products and include CE information throughout the catalogue. It should be noted, however, that not all products are covered by the PPE Directive. Many of our product lines are designed as much for product protection, image or purely as replacements to standard clothing than with any protection from a hazard. 104 Standards CLOTHING PROTECTION Protective Clothing for Workers Exposed to Heat EN533 excludes Firefighters and Welders clothing. Protection against Foul Weather Conditions ENV 343 x y This European standard concerns protective clothing against rain, wind and cold at temperatures higher than -5 C. The standard provides for 2 performance parameters: A: min. requirements, fabric combination confirms to EN 533 index 3 + min. the lowest class of min. one of the following properties should be met. ABCDE x: waterproofness (3 levels) y: breathing properties (3 levels) x y If the clothing comes with a thermal lining, a second pictogram will be shown. x: breathing properties (2 levels) y: thermal insulation (2 levels) Protection against Static Electricity EN 1149 This standard concerns protection against the dangers caused by static electricity Protection against HandHeld Chain Saws – EN 381-5 Protection against Cold ENV 342 x y z x Parts 5 of this standard describes the leg guards required for users y of hand-held chain saws, considering the speed of the chain (3 levels = y). In view of the degree of protection of the legs, there are 3 designs (A, B, & C). Design A: The protective area should cover the entire front part of the legs. At the rear a 5cm wide protective strip has to cover the outer side of the left leg and the inner side of the right leg. Design B: On top of the Design A requirements, a 5cm wide protective strip has to cover the inner side of the left leg as well. Design C: Both legs have to be protected all around. This standard determines the requirements for personal protective clothing to be worn at temperatures under -5 C e.g. in cold storage chambers. The following parameters are used: x: resulting thermal insulation measured with underwear of type B (see label) z: breathing properties (3 levels) Hi-Visibility Clothing EN471 x y Specifications for garments that have to attract attention to the person wearing them under conditions of poor visibility, during both daylight and at night. The parameters that should be taken into account are the following: x: surface of fluorescent and retroflecting material (3 levels) y: quality of the retroflecting material (2 levels) Protection against liquid chemicals, spraytight EN465 Type 4 Protection against liquid chemicals, liquidtight EN465 Type 3 Protection against liquid chemicals, limited protection EN467 This standard concerns protection against permeation by dangerous chemical products. Because of the complex requirements for this type of clothing, this pictogram refers to the compulsory reading of the manual which comes with the clothing and where one can find the results of a whole series of tests regarding various properties; moreover, type 3 & 4 clothing must undergo a spraytest in accordance with EN 468 but type 3 also respond to the requirements of the more severe jet test in accordance with EN 463. Protection against Flames EN533 This standard concerns protection against occasional fire by limiting the spreading of flames. y, z y,z: flame spreading index (3 levels) This index is used for clothing after a certain pre-treatment that is indicated with the z index. B (B1-B5):Insulation against convective heat C (C1-C4):Insulation against radiant heat D (D1-D3): Insulation against molten aluminium E (E1-E3): Insulation against molten cast iron In addition, there are also specifications regarding: dimensional stability, regulations with regard to the fixing of protective elements, cutting resistance, and ergonomics. All PPE gloves must adhere to EN 420 General Requirements standards. Other standards relate to other specific types of hazards and risks. The standards create a system for evaluating the performance of the glove according to the designated levels under the Personal Protective Directive. Identification of manufacturer 0110 Glove reference 7 Glove size 12 Pairs Glove quantity The CE mark 1234 Approved body no. CHEMICAL RESISTANCE PERMEATION In compliance with EN374 standard, the breakthrough time is given as a permeation index according to the following table: The breakthrough time (in minutes) of a chemical through the glove is measured in conditions simulating a total immersion of the glove in the chemical at 23˚C Breakthrough time higher than (in minutes) 10 30 60 120 240 480 Permeation index 1 2 3 4 5 6 The gloves scoring the highest index have the best resistance to permeation. Index 0 denotes breakthrough time is less then 10 minutes. 105