Czech Focus 3/2008

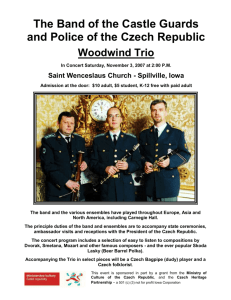

advertisement