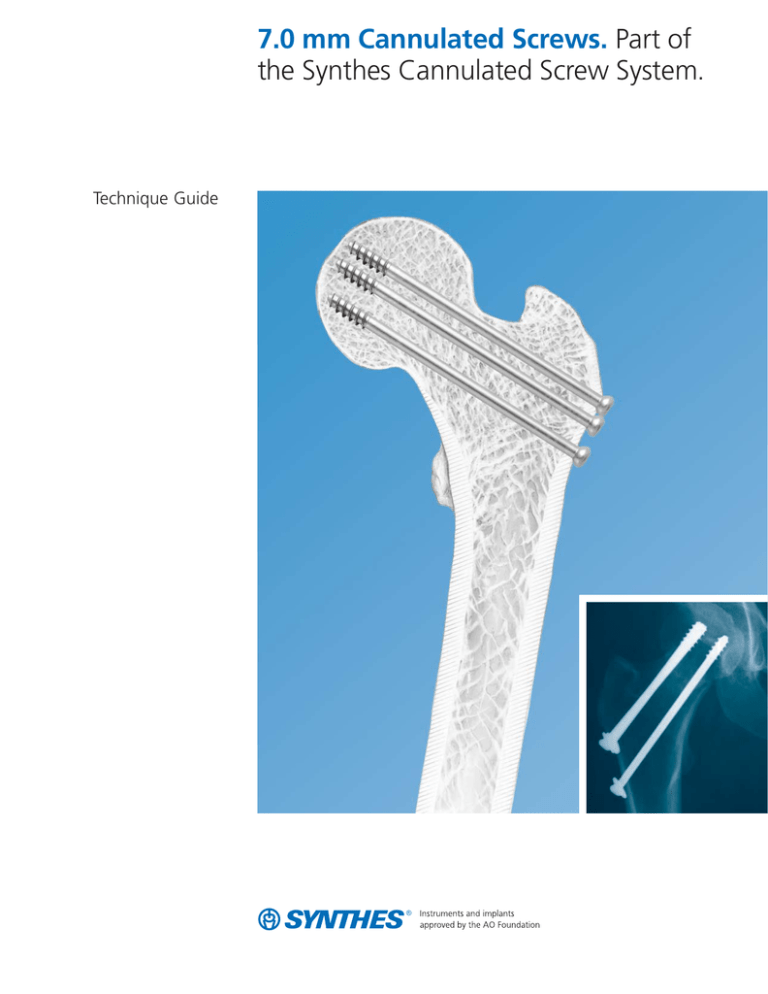

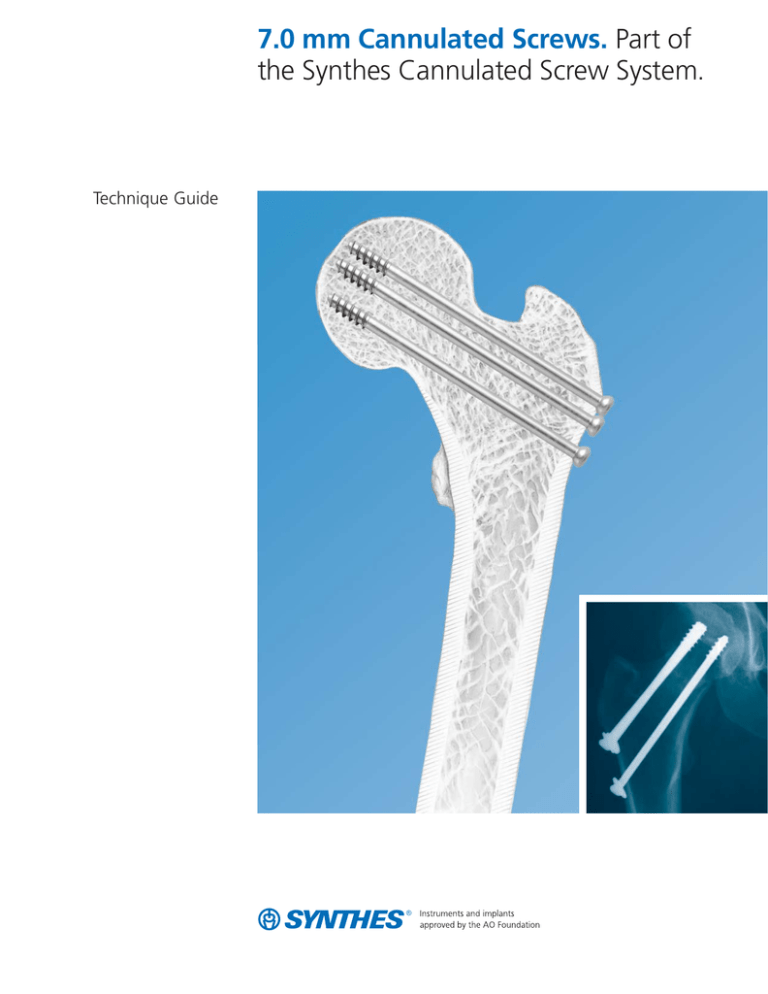

7.0 mm Cannulated Screws. Part of

the Synthes Cannulated Screw System.

Technique Guide

Table of Contents

Introduction

Surgical Technique

Product Information

7.0 mm Cannulated Screws

2

AO Principles

3

Indications

4

Surgical Technique Tips

5

Percutaneous Technique

6

Open Technique

11

Implants

13

Instruments

14

Set List

17

Image intensifier control

Synthes

7.0 mm Cannulated Screws

Features

– Cannulated shaft accepts 2.0 mm diameter

guide wires (threaded and nonthreaded

wires available).

– Hemispherical head ensures optimal annular

contact with washers and Synthes plates when

screws are angled.

– Standard 3.5 mm hexagonal drive is compatible

with screwdrivers in other commonly used

Synthes sets.

– Reverse-cutting flutes assist in screw removal.

– Choice of thread lengths offers best fit of

threads into far bone fragment, for greater

interfragmentary compression.

– Cancellous thread profile uses deep cutting

threads with a large pitch to increase resistance

to pullout. The large pitch also accelerates

screw insertion and removal.

2.0 mm guide wire

8.0 mm diameter head

with 3.5 mm hex drive

Spherical underside

4.5 mm diameter shaft

Reverse-cutting flutes

Cancellous thread design

Thread lengths

16 mm thread

32 mm thread

Fully threaded

Materials

Implant quality

316L stainless steel

2

Synthes 7.0 mm Cannulated Screws

AO Principles

In 1958, the AO formulated four basic principles, which have

become the guidelines for internal fixation.1 These principles,

as applied to cannulated screws, are:

Anatomic reduction

A guide wire marks the prescribed path for the cannulated

screw and secures alignment of the fragments while the

screw is being inserted. The cannulated screw is inserted

over the wire and tightened to further compress the

fragments and hold the reduction.

Stable fixation

Cannulated screws provide interfragmentary compression

and absolute stability across the fracture. The screws are

available in different threads lengths, allowing the surgeon

to optimize purchase in the far fragment for maximum

compression and stability.

Preservation of blood supply

The use of small diameter guide wires allows precise placement of cannulated screws through small incisions. This

technique minimizes disruption of soft tissue and preserves

vascular blood flow for bone healing.

Early, active mobilization

Cannulated screws, combined with AO technique, provide

stable fracture fixation with minimal trauma to vascular

supply. This helps to create an improved environment for

bone healing, accelerating the patient’s return to previous

mobility and function.

1. M.E. Müller, M. Allgöwer, R. Schneider, and H. Willenegger. Manual of

Internal Fixation, 3rd Edition. Berlin: Springer-Verlag. 1991.

Synthes

3

Indications

7.0 mm Cannulated Screws

For fracture fixation of large bones and large bone fragments.

Warning: This device is not approved for screw attachment

or fixation to the posterior elements (pedicles) of the

cervical, thoracic or lumbar spine.

4

Synthes 7.0 mm Cannulated Screws

Surgical Technique Tips

Cleaning cannulations

Instruments

319.27

Cleaning Brush

319.36

2.0 mm Cleaning Stylet

Cleaning the cannulation in each instrument is imperative

for proper function. Instruments should be cleared intraoperatively with the 2.0 mm cleaning stylet to prevent accumulation

of debris in the cannulation and potential binding of the

instruments about the guide wire. Instruments should be

cleaned postoperatively with the stylet and the cleaning brush.

Drilling

Because of their hollow cross section and long length,

cannulated drill bits are more susceptible to breakage

than solid drill bits of the same diameter. Use less axial

force, avoid bending, and advance the drill bit slowly to

minimize the possibility of breakage. Cannulated drill bits

should be inspected after every procedure and replaced if

worn or damaged.

Synthes

5

Percutaneous Technique

1

Insert guide wire

Instruments

319.31

2.0 mm Trocar

319.32

4.5 mm / 2.0 mm Drill Sleeve

319.33

8.0 mm / 4.5 mm Drill Sleeve

319.34

11.0 mm / 8.0 mm Protection Sleeve

Make a stab incision and insert the percutaneous sleeve

assembly (11.0 mm /8.0 mm protection sleeve, 8.0 mm /

4.5 mm and 4.5 mm / 2.0 mm drill sleeves, and 2.0 mm

trocar) through the soft tissue to the bone. Remove the

trocar and insert a 2.0 mm threaded guide wire to the

appropriate depth. Confirm wire placement under image

intensification. Remove all sleeves.

Technique tips:

To prevent slippage, the 4.5 mm / 2.0 mm drill sleeve may be

tapped with a hammer to seat the teeth in the lateral surface.

Run the drill at maximum speed to minimize deflection while

gradually advancing the guide wire.

6

Synthes 7.0 mm Cannulated Screws

2

Insert additional parallel wires (if necessary)

Instruments

319.30

4.5 mm Parallel Drill Guide

319.31

2.0 mm Trocar

319.32

4.5 mm / 2.0 mm Drill Sleeve

Insert one 4.5 mm / 2.0 mm drill sleeve into the outer-most

4.5 mm hole of the parallel drill guide. Place this combination over the previously inserted guide wire and push directly

to the bone.

Insert a second 4.5 mm / 2.0 mm drill sleeve and the 2.0 mm

trocar into any of the other three holes in the parallel drill

guide and press the trocar to the near cortex. Remove the

trocar and insert a guide wire through the 4.5 mm / 2.0 mm

drill sleeve. Insert any additional guide wires following the

same procedure and then replace the drill guide with the

percutaneous sleeve assembly over one of the guide wires.

Technique tip: Avoid placing any bending forces on the first

guide wire, as this will affect parallelism.

Notes:

Any previously inserted guide wire can be used in the outermost hole of the guide for parallel placement of the next

guide wire.

Possible distances between parallel guide wires are 10 mm,

14 mm and 18 mm, measured from the center of the

primary hole of the parallel drill guide to the centers of

the other holes. Plan placement of each guide wire based

on these distances.

Synthes

7

Percutaneous Technique continued

3

Measure for screw length

Instruments

319.21

Cannulated Screw Measuring Device

319.32

4.5 mm / 2.0 mm Drill Sleeve

Remove the two inner drill sleeves. Slide the tapered end of

the cannulated screw measuring device over the guide wire.

This reading determines appropriate screw length. Select a

7.0 mm cannulated screw of this length, with a thread which

engages only the opposite fragment, and set it aside.

Note: Screw length will be 8 mm short of the guide wire tip

(the length of the threaded portion of the wire), preventing

penetration of the far cortex.

8

Synthes 7.0 mm Cannulated Screws

4

Predrill

Instruments

310.69

4.5 mm Cannulated Drill Bit

319.33

8.0 mm / 4.5 mm Drill Sleeve

Place the 8.0 mm / 4.5 mm drill sleeve into the protection

sleeve, and drill with the 4.5 mm cannulated drill bit under

image intensification to the appropriate depth, being careful

not to drill over the guide wire threads and penetrate the far

cortex. Remove the 8.0 mm / 4.5 mm drill sleeve.

Technique tip: Avoid directing the drill bit; let it follow the

guide wire. Take care to remove the drill bit slowly and to

pull back straight while running the drill forward to prevent

guide wire pullout.

Notes:

Depending on bone quality, the surgeon may choose to drill

only the near cortex to prevent inadvertent guide wire pullout.

The calibrations on the cannulated drill bits and the cannulated

tap are read at the surface of the bone and therefore can not

be used when using the percutaneous sleeves. Use image

intensification for confirmation of drilling and tapping depths.

Synthes

9

Percutaneous Technique continued

5

Tap

Instruments

311.69

Cannulated Tap for 7.0 mm Cannulated Screws

319.34

11.0 mm / 8.0 mm Protection Sleeve

Where necessary, tap the near cortex with the cannulated

tap through the protection sleeve. In dense bone, it may be

necessary to tap over the entire nonthreaded length of the

guide wire.

6

Insert screws

Instruments

314.19

Cannulated Hexagonal Screwdriver

319.34

11.0 mm / 8.0 mm Protection Sleeve

Using the cannulated hexagonal screwdriver without the

holding sleeve, insert the previously selected screw (Step 3)

through the protection sleeve. Remove and discard the

guide wire.

Note: In osteopenic bone, use a washer to prevent the screw

head from sinking into bone. Washers cannot be placed

through the percutaneous sleeve. Remove the sleeve before

placing the washer over the guide wire.

10

Synthes 7.0 mm Cannulated Screws

Open Technique

1

Insert guide wire

Instrument

312.71

Parallel Wire Guide

Place a positioning guide wire in the center of the femoral

neck. Place the parallel wire guide over the guide wire through

one of the central diamond-patterned positioning holes.

Notes:

The parallel guide’s position may be adjusted by replacing it

over the guide wire through one of the adjacent positioning

holes of the central diamond pattern.

The parallel guide does not need to lie flush with the bone.

2

Insert additional parallel wires (if necessary)

Instrument

312.71

Parallel Wire Guide

Under image intensification, insert a guide wire to the

desired depth through each of the outer triangle-patterned

placement holes.

Synthes

11

Open Technique continued

3

Remove guide wire

Remove the parallel guide and the positioning guide wire

(inserted in Step 1).

4

Insert screws

Measure, drill, tap and insert each screw before proceeding

to the next, to prevent loss of reduction.

12

Synthes 7.0 mm Cannulated Screws

Implants

7.0 mm Cannulated Screws, 16 mm thread length

– 30 mm–130 mm lengths in 5 mm increments

– 316L stainless steel

7.0 mm Cannulated Screws, 32 mm thread length

– 45 mm–130 mm lengths in 5 mm increments

– 316L stainless steel

Washers, 13.0 mm

– Prevents screw head from sinking into osteopenic bone

Synthes

13

Instruments

292.65

2.0 mm Threaded Guide Wire, 230 mm

310.19◊

2.0 mm Drill Bit, 100 mm, quick coupling

310.69◊

4.5 mm Cannulated Drill Bit, 233 mm,

Jacobs chuck

311.69

Cannulated Tap for 7.0 mm Cannulated

Screws

312.46

4.5 mm/3.2 mm Double Drill Sleeve

312.71

Parallel Wire Guide

◊ Available nonsterile or sterile-packed. Add S to catalog number for sterile product.

14

Synthes 7.0 mm Cannulated Screws

314.11

Holding Sleeve

314.19

Cannulated Hexagonal Screwdriver

319.21

Cannulated Screw Measuring Device

319.27

2.1 mm Cleaning Brush

319.30

4.5 mm Parallel Drill Guide

319.31

2.0 mm Trocar, 118 mm

Synthes

15

Instruments continued

319.32

4.5 mm/2.0 mm Drill Sleeve, 108 mm

319.33

8.0 mm/4.5 mm Drill Sleeve, 99 mm

319.34

11.0 mm/8.0 mm Protection Sleeve, 88 mm

319.36

2.0 mm Cleaning Stylet

319.97

Screw Forceps

16

Synthes 7.0 mm Cannulated Screws

7.0 mm Cannulated Screw Instrument and Implant Set (105.07)

Graphic Case

304.230

7.0 mm Cannulated Screw Instrument and

Implant Set Graphic Case

Instruments

292.65

2.0 mm Threaded Guide Wire, 230 mm, 10 ea.

◊

2.0 mm Drill Bit, 100 mm, quick coupling, 2 ea.

310.19

4.5 mm Cannulated Drill Bit, 233 mm,

310.69◊

Jacobs chuck, 2 ea.

311.69

Cannulated Tap for 7.0 mm Cannulated Screws

312.46

4.5 mm/3.2 mm Double Drill Sleeve

312.71

Parallel Wire Guide

314.11

Holding Sleeve

314.19

Cannulated Hexagonal Screwdriver

319.21

Cannulated Screw Measuring Device

319.27

2.1 mm Cleaning Brush

319.30

4.5 mm Parallel Drill Guide

319.31

2.0 mm Trocar, 118 mm, 2 ea.

319.32

4.5 mm/2.0 mm Drill Sleeve, 108 mm, 2 ea.

319.33

8.0 mm/4.5 mm Drill Sleeve, 99 mm

319.34

11.0 mm/8.0 mm Protection Sleeve, 88 mm

319.36

2.0 mm Cleaning Stylet

319.97

Screw Forceps

Note: For additional information, please refer to package insert.

For detailed cleaning and sterilization instructions, please refer to

http://us.synthes.com/Medical+Community/Cleaning+and+Sterilization.htm

or to the below listed inserts, which will be included in the shipping container:

—Processing Synthes Reusable Medical Devices—Instruments, Instrument Trays

and Graphic Cases—DJ1305

—Processing Non-sterile Synthes Implants—DJ1304

◊ Available nonsterile or sterile-packed. Add S to catalog number for sterile product.

Synthes

17

7.0 mm Cannulated Screw Instrument and Implant Set (105.07) continued

Implants

7.0 mm Cannulated Screws, 16 mm thread length

208.030

208.035

208.040

208.045

208.050

208.055

208.060

208.065

208.070

208.075

208.080

208.085

208.090

208.095

208.100

208.105

208.110

208.115

208.120

208.125

208.130

Length (mm)

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

110

115

120

125

130

Qty.

2

2

2

2

2

2

2

2

4

4

4

4

4

4

4

2

2

2

2

2

2

Note: For additional information, please refer to package insert.

18

Synthes 7.0 mm Cannulated Screws

7.0 mm Cannulated Screws, 32 mm thread length

209.045

209.050

209.055

209.060

209.065

209.070

209.075

209.080

209.085

209.090

209.095

209.100

209.105

209.110

209.115

209.120

209.125

209.130

219.99

Length (mm)

45

50

55

60

65

70

75

80

85

90

95

100

105

110

115

120

125

130

Qty.

2

2

2

2

2

2

2

2

2

2

2

2

2

1

1

1

1

1

Washer, for 4.5 mm Cortex and 6.5 mm

Cancellous Bone Screws, 6 ea.

Also Available

Small Battery Drive with 14.4 V Battery Pack Sets

105.954H

with Hudson Reduction Drive Unit

105.954M

with Modified Trinkle Reduction Drive Unit

105.954T

with Trinkle Reduction Drive Unit

105.957

Power Drive Set

Instruments

292.651

292.652

292.656

310.79

314.22

314.27

304.234

304.235

360.02◊

2.0 mm Threaded Guide Wire, spade point

both ends, 230 mm

2.0 mm Non-Colored Threaded Guide Wire,

spade point, 230 mm

2.0 mm Non-Threaded Guide Wire,

spade point one end, 230 mm, blue

Cannulated Countersink, for 7.0 mm

Cannulated Screws

Cannulated 3.5 mm Hexagonal Screwdriver

Shaft, for 7.0 mm Cannulated Screws

Large Hexagonal Screwdriver, for removal

of 7.0 mm Cannulated Screws

Screw Rack for 7.0 mm Cannulated Screws,

16 mm and 32 mm Threaded

Screw Rack for 7.0 mm Cannulated Screws,

fully threaded

7.0 mm Cannulated Drill Bit, large quick

coupling, 90 mm

Implants

208.135–

208.150

209.135–

209.150

209.420–

209.530

7.0 mm Cannulated Screws

16 mm thread length, 135 mm–150 mm

(5 mm increments)

32 mm thread length, 135 mm–150 mm

(5 mm increments)

fully threaded, 20 mm–130 mm

(5 mm increments)

◊ Available nonsterile or sterile-packed. Add S to catalog number for sterile product.

Synthes

Synthes (USA)

1302 Wrights Lane East

West Chester, PA 19380

Telephone: (610) 719-5000

To order: (800) 523-0322

Fax: (610) 251-9056

© 1997 Synthes, Inc. or its affiliates. All rights reserved.

Synthes (Canada) Ltd.

2566 Meadowpine Boulevard

Mississauga, Ontario L5N 6P9

Telephone: (905) 567-0440

To order: (800) 668-1119

Fax: (905) 567-3185

Synthes is a trademark of Synthes, Inc. or its affiliates.

www.synthes.com

Printed in U.S.A.

9/10

J2425-G